Displaying items by tag: Andritz

ANDRITZ to supply a major expansion of the OCC line to NORPAC, USA

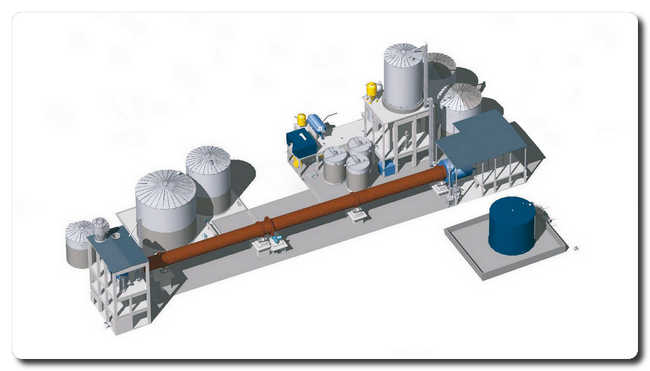

International technology Group ANDRITZ has received an order from North Pacific Paper Company (NORPAC) to supply a major expansion of the OCC line for its mill in Longview, Washington, USA.

Start-up is scheduled for the first quarter of 2022.

ANDRITZ will install a FibreFlow drum pulper, type FFD450EE, as well as various fiber cleaning and reject handling equipment to upgrade the existing OCC line and expand the mill’s production of lightweight recycled packaging papers. The stock preparation system features a capacity of 1,200 bdmt/d and processes a mix of OCC and mixed waste as raw material.

The FibreFlow Drum pulper is a complete pulping system in one unit and ensures best accept quality thanks to the gentle pulping concept and efficient removal of coarse contaminants with minimum fiber loss.

ANDRITZ FibreFlow drum pulper © ANDRITZ

ANDRITZ FibreFlow drum pulper © ANDRITZ

The new drum pulper was ordered in advance, recently arrived at the port of Longview and is currently being moved to the NORPAC mill. "We're excited to reach a big milestone in our work to achieve our vision of opening new markets, providing low-carbon, recycled packaging papers and retaining our talented, innovative workforce," said NORPAC CEO Craig Anneberg. "The new FibreFlow drum is up to the tough job of keeping wastepaper out of landfills and turning it into new, recycled products – that's good for jobs and our environment. I'm also pleased NORPAC can support our local economic recovery in real-time with construction jobs that will make our new facility operational."

North Pacific is an independent paper company delivering a broad range of high-quality papers to customers across the United States and around the world. NORPAC makes high-quality and environmentally conscious copy paper as well as printing and publishing stock.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER ANDRITZ

Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply two semi-chemical fiberlines to Lee & Man Paper, China

International technology Group ANDRITZ has received an order from Lee & Man Paper to supply two semi-chemical fiberlines for its mills in Dongguan, Guangdong Province, and Jiujiang, Jiangxi Province, China.

Start-up of both lines is scheduled for the end of 2022.

The new fiberlines will have a capacity of 1,000 admt/d each and process eucalyptus wood chips to produce semi-chemical pulp, an intermediate grade between kraft pulp and mechanical pulp. Semi-chemical pulp provides excellent fiber properties for corrugated boards, such as fluting paper and other grades produced at the mill.

The highly efficient green liquor pulping technology from ANDRITZ will enable production of excellent pulp quality, high fiber yield as well as optimum interaction with the kraft pulp mill.

ANDRITZ blow line refiner 1CP © ANDRITZ

ANDRITZ blow line refiner 1CP © ANDRITZ

The scope of supply comprises the main equipment for both fiberlines, featuring the following technological highlights:

- ANDRITZ continuous digester specifically designed for the semi-chemical pulping process

- Medium-consistency blow line refiners, type 1CP, to defibrate and homogenize cooked chips at low specific energy

- 5-stage counter-current washing with highly efficient vacuum VT washers and ANDRITZ screw presses to achieve minimum loss in washing and lowest carry-over of detrimental substances

ANDRITZ will also provide the basic engineering as well as supervision of mechanical installation work, commissioning, and start-up.

Mr. Edmond Lee, CEO Lee & Man Paper, says: “We decided to focus on our own fresh fiber production as an alternative to imported kraft and recycled fiber pulp as raw materials. With the new fiberlines, we will become more self-sufficient in pulp imports and less vulnerable to market fluctuations. ANDRITZ’s operating experience with similar installations in recent years, especially the first and only installation of this kind in China, was the main driver for our decision.”

Established in 1994, Lee & Man Paper manufactures linerboards of various grades and corrugating medium of different specifications used for several industrial packaging purposes. The group owns five paper mills and one pulp factory in China as well as several production bases in Vietnam, Malaysia and other countries.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply key pulp production equipment for Nine Dragons Paper mills in China

International technology Group ANDRITZ has been awarded orders from Nine Dragons Paper, China, to supply equipment and key process technologies for five of their mills.

Start-ups are scheduled for 2022 and 2023.

ANDRITZ white liquor plant © ANDRITZ

ANDRITZ white liquor plant © ANDRITZ

The scope of supply on EPS basis includes the following equipment:

- A white liquor plant with a capacity of 10,500 m3/d, including a recausticizing plant and an ANDRITZ LimeKiln. The recausticizing plant delivery includes a green liquor cooler, a LimeSlake slaker-classifier, three causticizer tank agitators, a drum filter for dregs handling, a LimeWhite filter for white liquor filtration to achieve high white liquor quality, and a LimeDry filter for efficient lime mud filtration to ensure high lime mud dryness and consequently a low heat consumption in the kiln. The ANDRITZ LimeKiln, with a capacity of 950 t/d burnt lime, will be equipped with a high-efficiency LimeCool sector cooler.

- A recausticizing plant with a capacity of 5,800 m3/d.

- Two ash re-crystallization (ARC) systems with ash handling capacities of 400 t/d and 200 t/d respectively, to treat the ash from the electrostatic precipitator by decreasing the chloride and potassium content while recovering sodium and sulphate.

- A recausticizing plant with a capacity of 5,800 m3/d.

- An ash re-crystallization (ARC) system with an ash handling capacity of 200 t/d to treat the ash from the electrostatic precipitator by decreasing the chloride and potassium content while recovering sodium and sulphate.

- Three recausticizing plants with a capacity of 2,500 m3/d each.

These orders once again confirm the excellent business relationship between ANDRITZ and Nine Dragons Paper.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,950 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ successfully starts up a new HERB recovery boiler at Kuantum Papers Limited, India

International technology Group ANDRITZ has successfully started up a new 500 t/d HERB chemical recovery boiler at Kuantum Papers Limited in Saila Khurd, Hoshiapur district in the state of Punjab, India.

The boiler is designed to handle a mixture of hardwood and agro-based black liquor and enables environmentally friendly and more energy-efficient operation compared to a conventional boiler with direct contact evaporator. Thus, the mill’s pulp production as well as the power-to-heat-ratio are substantially increased. The boiler also features a unique vertical air system to minimize air emissions.

The scope of supply also comprised:

- Engineering for the entire system except civil work and electrical and automation equipment

- Complete pressure parts

- Auxiliaries such as start-up oil burners, black liquor burners, smelt spouts

- Safety-related system (SRS)

First black liquor firing at Kuantum Papers Limited “Photo: ANDRITZ”.Pavan Khaitan, Managing Director, Kuantum Papers Limited, says: “We are very satisfied with the successful start-up of the ANDRITZ boiler. The entire team at ANDRITZ has worked tirelessly with us for successful commissioning of the HERB recovery boiler along with the set of evaporators.”

First black liquor firing at Kuantum Papers Limited “Photo: ANDRITZ”.Pavan Khaitan, Managing Director, Kuantum Papers Limited, says: “We are very satisfied with the successful start-up of the ANDRITZ boiler. The entire team at ANDRITZ has worked tirelessly with us for successful commissioning of the HERB recovery boiler along with the set of evaporators.”

This is the first of six HERB recovery boilers currently being installed in India by ANDRITZ, thus showing the strong market share ANDRITZ holds on the Indian pulp and paper market.

Kuantum Papers is active in the production and marketing of wood-free writing and printing paper, thereby providing an alternative to wood-based paper while conserving precious resources and protecting the environment.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 27,200 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ successfully starts up complete LC pulping system at Papeleira Coreboard, Portugal

International technology Group ANDRITZ has successfully started up a complete continuous low-consistency (LC) pulping system at Papeleira Coreboard, Portugal.

The new ANDRITZ LC pulping system installed features several design upgrades:

- FibreSolve FSR pulper with advanced rotor design for efficient slushing at lowest fiber loss and highest availability

- Advanced ANDRITZ TrashTrap for reliable separation and removal of heavy and light rejects early in the process

- State-of-the-art ragger which allows – in combination with the new pulper rotor design – superior forming, handling and removal of pulper rags.

The scope of supply also comprised a detrashing pump, FibreGuard detrasher, FibreWash Drum, cleaners and a RejectCompactor for further treatment of rejects. ANDRITZ provided the basic engineering as well as the supervision of erection on site and start-up via remote support.

Complete LC pulping system supplied by ANDRITZ at Papeleira Coreboard © ANDRITZ

Complete LC pulping system supplied by ANDRITZ at Papeleira Coreboard © ANDRITZ

Manuel Delgado, Plant Manager, Papeleira Coreboard says: „I´m very proud of our operators who managed the successful start-up despite the challenging circumstances caused by the pandemic. The ANDRITZ team provided excellent remote support from Austria.”

Papeleira Coreboard processes LOCC (Local Old Corrugated Containers) with a line capacity of 300 bdmt/d and a reject content of up to 10% to produce different types of coreboard. The company is part of the Arteche Paper Holding and manufactures paper, pulp and cardboard focusing on 100% recycled paper and cardboard as raw material for its production.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ successfully starts up tissue production line delivered to Berli Jucker Cellox, Thailand

International technology Group ANDRITZ has successfully started up the tissue production line delivered to Berli Jucker Cellox Ltd. for their mill in Prachinburi, Thailand.

The PrimeLineCOMPACT tissue machine has a design speed of 1,900 m/min and a paper width of 2.8 m. A PrimePress XT Evo shoe press installed there dewaters the web gently, but still achieves a far higher post-press dryness than conventional presses. The 16 ft. PrimeDry Steel Yankee is made entirely of steel, having an evaporation rate that is 10-15% higher than that of cast iron models, which results in 8-10% better machine performance. This combination – the latest shoe press technology and a steel Yankee – leads to a high drying capacity and achieves remarkable cost savings and operational flexibility as well as improved product quality. The entire line is equipped with an ANDRITZ PrimeControl automation package, providing an optimized production process.

ANDRITZ successfully starts up a PrimeLineCOMPACT tissue production line at Berli Jucker Cellox, Thailand. “Photo: ANDRITZ”.

ANDRITZ successfully starts up a PrimeLineCOMPACT tissue production line at Berli Jucker Cellox, Thailand. “Photo: ANDRITZ”.

In addition, ANDRITZ supplied the stock preparation system with two lines in order to process both short-fiber and long-fiber pulp, with the option of adding recycled fiber. The lines also have an approach flow system and a dissolved air flotation (DAF) unit for fiber recovery. The water system installed is designed to minimize water consumption, thus ensuring highest efficiency and sustainable operation.

The line was started up successfully under very challenging conditions due to the Covid pandemic.

A key part of this success is thanks to Metris – the ANDRITZ digitalization platform – which ensures maximum mill performance at Berli Jucker Cellox, Prachinburi. In these challenging times with their travel restrictions, Metris effectively reduced personal contact by making use of remote functionalities. Remote assistance by ANDRITZ specialists enabled a straightforward commissioning-to-start-up phase and, in addition, ensures constant optimization of production processes, operator troubleshooting and decision support.

Pisit Samatha, Associate Director of Manufacturing at Berli Jucker Cellox, with the first TM5 paper on reel. “Photo: ANDRITZ”.

Pisit Samatha, Associate Director of Manufacturing at Berli Jucker Cellox, with the first TM5 paper on reel. “Photo: ANDRITZ”.

“I can remember when we first started talking about commissioning during the pandemic and, to be honest, we both felt some uncertainty given the challenging circumstances,” explains Tine Kocbek, ANDRITZ Project Manager for Tissue. Apinan Laocharoensuk, Managing Director of Berli Jucker Cellox Ltd., adds: “It took a lot of courage from both sides and also mutual trust to agree on such an arrangement. We really appreciated the excellent teamwork by the ANDRITZ colleagues from Europe and China. Today, we can confirm, it was the right decision!“

This order once again underlines ANDRITZ’s strong market position as one of the leading suppliers of machines and systems to the Asian tissue industry as well as highlighting the company’s expertise in challenging situations.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 27,200 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

World record production with ANDRITZ HC refiner at Jiangsu Bohui Paper Industry, China

In close cooperation with its customer Jiangsu Bohui Paper Industry, international technology group ANDRITZ recently achieved a milestone in high-consistency (HC) refining by processing a peak capacity of 1,300 admt/d of local hardwood chips per day and achieving sustainable production of 1,150 admt/d at the mill in Dafeng, China.

ANDRITZ supplied two separate fiberlines with capacities of 1,500 admt/d and 750 admt/d, respectively, featuring the well-proven P-RC APMP (Pre-Conditioning Refiner Chemical Alkaline Peroxide Mechanical Pulp) technology for the new chemi-thermo-mechanical pulping system. With a total capacity of 2,250 admt/d, this system is the largest worldwide.

The world’s largest HC refiner – the ANDRITZ TX68 Photo Andritz

The world’s largest HC refiner – the ANDRITZ TX68 Photo Andritz

The world record was achieved with the ANDRITZ TX68, the world’s largest HC refiner, as part of the second P-RC APMP system despite a defined single-line capacity of 750 admt/d. The TX68 refiner with an advanced feeding system is the centerpiece of the process and the latest innovation by ANDRITZ in HC refining.

Chen Bo, Pulp Production Manager at Jiangsu Bohui Paper Industry, comments: “Aiming at more flexibility for our folding boxboard production, we adapted the system in close cooperation with the ANDRITZ experts and were finally able to achieve this impressive milestone. We are especially proud that we succeeded in obtaining the necessary system configurations despite several challenges due to the Covid-19 situation. ANDRITZ China provided excellent on-site support in parallel with ANDRITZ’s key experts in Europe using remote solutions.”

Jiangsu Bohui Paper Industry Co., Ltd. is a subsidiary of Shandong Bohui Paper Industrial Co., Ltd., a listed company established in 1994 focusing on the production of ivory board, culture paper, linerboard, paper for gypsum plasterboard, and market pulp for the papermaking industry.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. The global product and service portfolio is rounded off with plants for power generation, recycling, the production of nonwovens and panelboard, as well as automation and digital solutions offered under the brand name of Metris. The publicly listed group today has around 27,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power production, flue gas cleaning plants, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

ANDRITZ to supply evaporation plant to ITC Paperboards and Specialty Papers Division in India

International technology Group ANDRITZ has received an order from ITC Paperboards and Specialty Papers Division (ITC-PSPD) to supply a new evaporation plant for its Bhadrachalam unit located in Telangana, India.

ANDRITZ will supply a new 7-effect evaporation plant on EPC basis with a capacity of 390 t/h that will concentrate kraft black liquor to a final dry solids content of 75%. The plant will be the largest in India and have the capability to improve the quality of condensate from the existing mill so that it can be re-used effectively in the mill and also to reduce water consumption.

ANDRITZ evaporation plant. “Photo: ANDRITZ”

ANDRITZ evaporation plant. “Photo: ANDRITZ”

ANDRITZ’s lamella technology in the evaporators ensures the desired steam economy at all times, reduces energy consumption by circulation pumps, as well as providing higher black liquor concentration and stability, thus leading to increased and stabilized power production in the recovery boiler. The technology also delivers optimized vapor condensate quality that contributes towards a reduction in the mill’s operating costs. In addition, fewer and shorter washing cycles will enhance overall availability.

This investment is part of ITC-PSPD’s recovery plant modernization project to further strengthen its market position in the paperboard and specialty paper segment.

ITC-PSPD is one of the largest manufacturers of packaging and graphic boards in Southern Asia. The company’s Bhadrachalam unit produces value-added folding boxboard.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. The global product and service portfolio is rounded off with plants for power generation, recycling, the production of nonwovens and panelboard, as well as automation and digital solutions offered under the brand name of Metris. The publicly listed group today has around 27,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power production, flue gas cleaning plants, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

ANDRITZ to supply non-condensable gases (NCG) incineration system for Bracell’s new pulp mill in Brazil

International technology Group ANDRITZ has received an order from Bracell to supply the non-condensable gases (NCG) incineration system on EPCC basis for Bracell’s pulp mill Project “STAR” in Lençóis Paulista, in the state of São Paulo, Brazil.

The incineration system supplied by ANDRITZ enables safe and environmentally friendly treatment of all types of diluted or concentrated malodorous and toxic gases, thus meeting the strictest environmental and social requirements. The gases are eliminated by quench-type incinerators with flue gas scrubbers.

The incineration system supplied by ANDRITZ enables safe and environmentally friendly treatment of all types of diluted or concentrated malodorous and toxic gases, thus meeting the strictest environmental and social requirements. The gases are eliminated by quench-type incinerators with flue gas scrubbers.

The NCG incineration system is based on ANDRITZ’s self-developed A-Recovery+ concept, which focuses on use of the side streams in the recovery cycle. This order confirms the good relationship between Bracell and ANDRITZ, which is one of the main suppliers of Bracell’s new pulp mill currently being built in Lençóis Paulista.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. The global product and service portfolio is rounded off with plants for power generation, recycling, the production of nonwovens and panelboard, as well as automation and digital solutions offered under the brand name of Metris. The publicly listed group today has around 27,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power production, flue gas cleaning plants, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

ANDRITZ to supply stock preparation equipment for sack paper production to Segezha Pulp and Paper Mill, Russia

International technology Group ANDRITZ has received an order from Segezha Pulp and Paper Mill, a member of the Segezha Group (part of PJSC Sistema), to supply stock preparation equipment for its mill in Segezha, Republic of Karelia, Russia. Start-up is scheduled for the beginning of 2021.

The new system will feature a capacity of 350 bdmt/d and process bleached market pulp bales to produce a new final product – white high-porosity sack paper. The scope of supply comprises the bale feeding line with a manual dewiring station, an ANDRITZ FibreSolve FSV pulper for efficient slushing, a ModuScreen CP protection screen, as well as the complete control and electrification system.

The new system will feature a capacity of 350 bdmt/d and process bleached market pulp bales to produce a new final product – white high-porosity sack paper. The scope of supply comprises the bale feeding line with a manual dewiring station, an ANDRITZ FibreSolve FSV pulper for efficient slushing, a ModuScreen CP protection screen, as well as the complete control and electrification system.

With start-up of the new line, the Segezha Group will be the first producer of high-porosity sack paper in Russia. The entire production volume will be supplied to the company’s own converting facilities.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. The global product and service portfolio is rounded off with plants for power generation, recycling, the production of nonwovens and panelboard, as well as automation and digital solutions offered under the brand name of Metris. The publicly listed group today has around 27,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power production, flue gas cleaning plants, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.