Displaying items by tag: voith

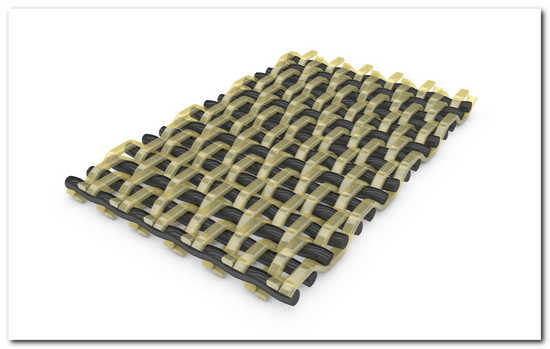

Magma and MagmaHigh: New Dryer Fabrics from Voith for the High-temperature Range

Voith has enhanced its CleanWeave product range with the new Magma and MagmaHigh dryer fabrics. Magma dryer fabrics are made from hydrolysis-resistant PPS which ensures performance in the hottest dryer positions.

- Heat-resistant material for high-temperature ranges

- Clean machine run due to proven weave pattern

- Predictable servicing schedule for cost-efficient operation

Extreme temperatures in some paper machines put dryer fabrics under severe stress and call for special material properties. Hydrolysis-resistant PPS reduces the stress on the fabric, allows service intervals to be properly planned and thus prevents unscheduled machine downtimes. Moreover, both Magma and MagmaHigh use the weave pattern that has already proven effective in the CleanWeave product range. The weave structure features industry low internal void volume, which significantly reduces dirt within the fabric. Due to its relatively low number of yarn crossover points, this compact weave pattern makes surface cleaning easier and ensures constant air permeability. This guarantees that the fabric maintains its air permeability for optimum drying and web running properties over its entire service life.

The superior reliability of Magma and MagmaHigh dryer fabrics makes planning easier and ultimately leads to more efficient and economic paper machine operation. As well as the dryer fabrics, Voith offers excellent service support and associated consultancy services.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 20,000 employees and earns €4.3 billion in sales. It has locations in over 60 countries and is one of the large family-owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.

CMPC Riograndense chooses Voith for Pulp Dryer Rebuild

Voith has been chosen by CMPC Riograndense to carry out a rebuild of its PDM1 pulp dryer in Guaíba, a city located in the Brazilian state of Rio Grande do Sul.

Voith has been chosen by CMPC Riograndense to carry out a rebuild of its PDM1 pulp dryer in Guaíba, a city located in the Brazilian state of Rio Grande do Sul.

The rebuild project aims to improve the machine's stability and performance, as well as to make it easier to carry out maintenance services on the machine's drive systems. Upon scheduled completion in the second half of 2016, the PDM1 will increase its capacity to produce up to 1,320 metric tons per day at a speed of 165 meters per minute.

The project will be carried out under the PLP (Process Line Package) concept, whereby Voith takes full responsibility for procuring and managing the supply of all the necessary equipment and services to operate the machine. This includes new controls for the machine's individual drive systems, a steam box with automatic profile control, a threading system, the lubrication and steam and condensate systems, electrical drives, basic and detail engineering and electromechanical assembly, along with all the necessary training and commissioning services.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 20,000 employees and earns €4.3 billion in sales. It has locations in over 60 countries and is one of the large family-owned companies in Europe.*

* Excluding the discontinued Group Division Voith industrial Services.

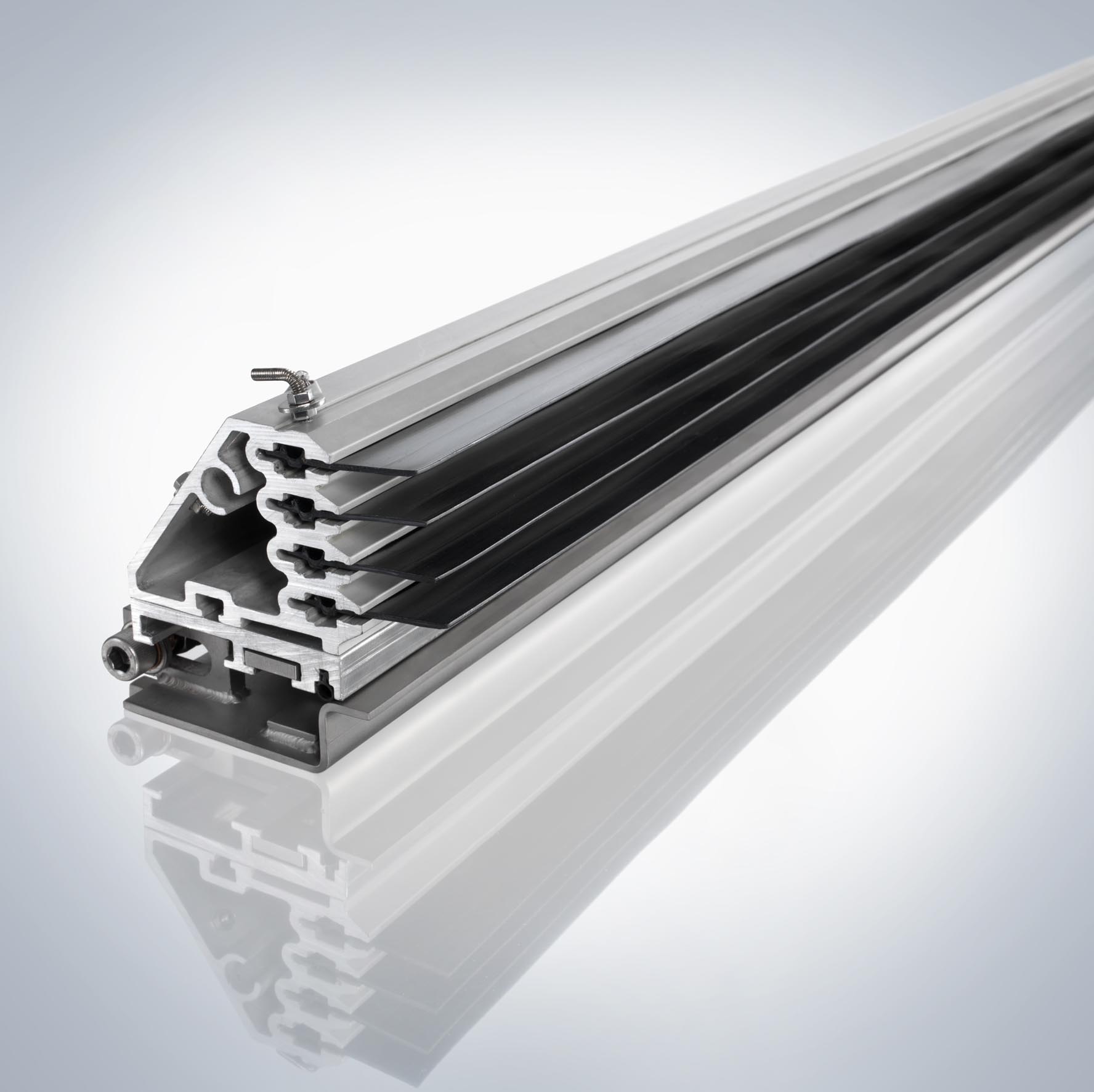

New sealing technology from Voith: upgrade for ProRelease+

Voith’s new MultiSeal Plus sealing technology improves processes in the dryer section of paper machines. Thanks to a shorter high-vacuum zone, the fabric deflection is significantly reduced and fabric wear is decreased. In addition, the adjustable SkySeal Plus sealing strips consistently optimize fabric runs and extend maintenance intervals. The entire sealing technology upgrades the web stabilization system ProRelease+ and results in better performance and an increase in machine speed.

- Reduced fabric wear thanks to minimized deflection

- Faster production speeds through an optimized vacuum zone

- Greater durability of sealing strips and easier servicing

The MultiSeal Plus is the carrier system for the SkySeal sealing strips. A key innovation is the horizontal adjustability of the new strips, which can be re-adjusted by up to 12 millimeter depending on the amount of wear. As a result, the correct distance between fabric and sealing system is guaranteed at all times. The SkySeal is available in two models with different hardness levels, which makes it easier to accommodate the characteristics and requirements of the respective paper machine. As a result the sealing strips suffer less abrasion.

The MultiSeal Plus carrier systems can be adjusted to provide an optimum seal of the release zones in the ProRelease+ sealing systems. Thanks to the new technology, the high-vacuum zone can be shortened overall. This results in an increase in runnability and reduced energy costs. The entire upgrade for ProRelease+ should be suitable for all fast-running paper machines.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 20,000 employees and earns €4.3 billion in sales. It has locations in over 60 countries and is one of the large family-owned companies in Europe.*

* Excluding the discontinued Group Division Voith industrial Services.

At Tissue World New Orleans, Voith offers solutions to increase efficiency, productivity and quality

With Papermaking 4.0, Voith is introducing its networked solutions to increase the efficiency, productivity and quality of the entire paper production process supply chain. In addition, Voith will be showcasing NipcoFlex T, a shoe press developed to reduce energy con-sumption and raw material in tissue production. At Tissue World, which is taking place in New Orleans from March 15 to 17, trade visitors will find Voith at stand E 240.

- Papermaking 4.0 increases productivity and quality

- NipcoFlex T lowers production costs

- Find Voith at exhibition stand E 240

![]() Systems like OnCare and OnEfficiency are solutions that stem from the new Papermaking 4.0 concept. OnCare facilitates the maintenance management of paper machines, from planning, servicing and documenta-tion through cost control to spare parts management. The permanent monitoring of the entire paper machine allows optimization potentials to be identified and preventive maintenance measures to be planned and implemented. Preventive maintenance reduces unscheduled downtimes and the paper machine’s availability will increase. Unlike conventional software solutions, OnCare represents a complete maintenance concept, with the distinctive feature being that data are already embedded in the software system. Likewise, it is possible to integrate OnCare in existing systems.

Systems like OnCare and OnEfficiency are solutions that stem from the new Papermaking 4.0 concept. OnCare facilitates the maintenance management of paper machines, from planning, servicing and documenta-tion through cost control to spare parts management. The permanent monitoring of the entire paper machine allows optimization potentials to be identified and preventive maintenance measures to be planned and implemented. Preventive maintenance reduces unscheduled downtimes and the paper machine’s availability will increase. Unlike conventional software solutions, OnCare represents a complete maintenance concept, with the distinctive feature being that data are already embedded in the software system. Likewise, it is possible to integrate OnCare in existing systems.

In addition, Voith also developed OnEfficiency to maximize the paper ma-chine’s potential. OnEfficiency Forming gets right to the process at the heart of papermaking: sheet formation. This is measured and analyzed with a package of sensors so that dewatering, retention and flocculation can be stabilized and at the same time coordinated. As a result of the sta-ble process, raw materials and chemicals can be saved and energy usage reduced. Voith is a specialist in the entire paper manufacturing process and ensures that its customers benefit from a dependable documentation of practical experience in papermaking process management.

The increase in machine efficiency and improvement of paper quality are also at the core of the NipcoFlex T. At various paper mills, the innovative shoe press from Voith has already demonstrated that it can increase productivity and reduce costs. NipcoFlex T offers the benefits of up to 5% higher dry content, representing up to 20% thermal energy savings or up to 20% higher production, while maintaining the same or better paper quality. The production parameters of the press can be monitored online and re-adjusted if necessary.

Alfredo Sarli, Sales Manager at Voith Paper Air Systems, will be providing further insights into the latest work on tissue papers in his presentation “Energy Optimization of the Yankee Dryer Hood” to be held at 9:10 am on March 16, 2016 at the conference running alongside Tissue World.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 20,000 employees and earns €4.3 billion in sales. It has locations in over 60 countries and is one of the large family-owned companies in Europe.*

* Excluding the discontinued Group Division Voith industrial Services.

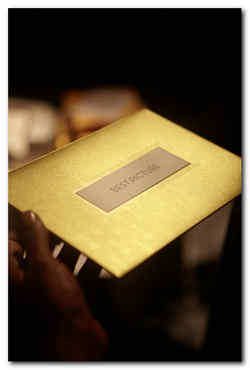

Voith and the Oscars® – a Short Story about the Night’s Glamorous Envelopes

Los Angeles. “And the Oscar goes to…“ – these magic words will once again make 24 movie stars very happy at the 88th presentation of the Academy Awards®. The famous stage at the Dolby Theater® will also feature a little piece of Voith, when the world’s entertainment industry is looking excitedly at the golden envelopes. Because the paper for the envelopes, which currently contain the presumably 24 best kept secrets of the film industry, originates from a paper machine made by Voith.

Gmund Treasury – this is the name of the award-worthy paper used for the Oscar® envelopes. Gmund Papier (Gmund Paper) produces the glamorous paper on its paper machine PM 407 from Voith. In 1979, the first high-quality papers made on PM 407 rolled off the production line at the Gmund paper makers. Voith originally built the machine for a Swiss paper manufacturer. After a rebuild, it was brought to Gmund at Lake Tegernsee, where it continues to make its special contribution to the Oscar® ceremony for the fifth time.

Gmund Treasury – this is the name of the award-worthy paper used for the Oscar® envelopes. Gmund Papier (Gmund Paper) produces the glamorous paper on its paper machine PM 407 from Voith. In 1979, the first high-quality papers made on PM 407 rolled off the production line at the Gmund paper makers. Voith originally built the machine for a Swiss paper manufacturer. After a rebuild, it was brought to Gmund at Lake Tegernsee, where it continues to make its special contribution to the Oscar® ceremony for the fifth time.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 20,000 employees and earns €4.3 billion in sales. It has locations in over 60 countries and is one of the large family-owned companies in Europe.*

* Excluding the discontinued Group Division Voith industrial Services.

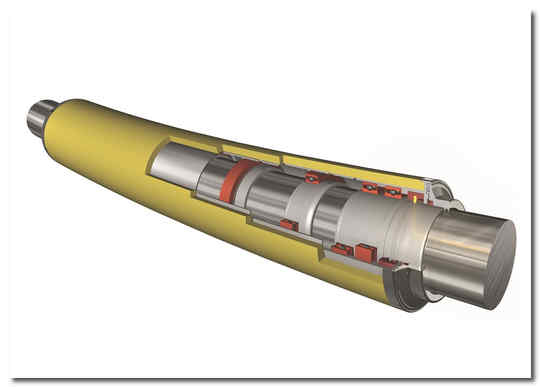

Innovative spreader roll technology from Voith: EvoStretch and SolarStretch

With the EvoStretch spreader roll, Voith has launched a new model at the start of the year that offers significantly longer service intervals than standard spreader rolls. The newly developed EvoStretch high-performance bearings feature one or two ceramic balls as well as the usual steel balls, giving each bearing a special self-repairing effect. The ceramic balls remove contaminants, smooth the contact surfaces and thus have an integrated polishing function. This ’self-healing effect’, proven in close cooperation with a well-known ball bearing manufacturer, clearly slows bearing wear and substantially reduces servicing costs.

The StretchUp Service from Voith is the roll service tailored to spreader rolls. As part of the StretchUp Service, it is now possible to upgrade spreader rolls of all manufacturers to use the EvoStretch bearings. Handling the roll service through Voith’s central service center in Laakirchen, Austria ensures short transport paths and delivery times and thus also saves costs.

Voith has now also successfully developed a further spreader roll component to increase service life: The market leader in high-performance roll covers made from polyurethane now also offers SolarStretch polyurethane sleeves for spreader rolls. SolarStretch features abrasion resistance that is twice as effective as standard rubber sleeves and can also be supplied in a variety of surface designs.

Increased abrasion resistance significantly extends service intervals and thus ensures continuous availability of the spreader rolls.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 20,000 employees and earns €4.3 billion in sales. It has locations in over 60 countries and is one of the large family-owned companies in Europe.*

* Excluding the discontinued Group Division Voith industrial Services.

Suzano Papel e Celulose contracts with Voith to deliver two tissue paper machines

![]() Suzano Papel e Celulose has contracted with Voith to deliver two tissue machines. The machines will be installed at the company's Imperatriz and Mucuri locations. The machine located in Imperatriz is scheduled for start-up in June 2017, whereas the one located in Mucuri is expected to go on-line in September 2017.

Suzano Papel e Celulose has contracted with Voith to deliver two tissue machines. The machines will be installed at the company's Imperatriz and Mucuri locations. The machine located in Imperatriz is scheduled for start-up in June 2017, whereas the one located in Mucuri is expected to go on-line in September 2017.

Voith will be responsible for supplying the complete tissue lines, which will be equipped with NipcoFlex T shoe presses and the EcoChange system to allow a reliable reel spool change. Within the Process Line Package Voith provides the machines and also the supply of all the auxiliary equipment and services. Once completed each machine will have a manufacturing capacity of nearly 220 metric tons of paper daily, at a speed of 2,000 meters per minute.

"The customer's choice of Voith for this project is extremely important, since it underscores both companies' long-term partnership. There is currently a strategic expansion at Suzano. This is the company's first project in the tissue segment,” said Flávio Silva, President for Voith Paper South America.

Suzano Papel e Celulose is a forestry-based company and one of the largest producers of pulp and paper in Latin America. Its annual production capacity amounts to 4.7 million metric tons of paper and pulp.

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets for energy, oil & gas, paper, raw materials, transport & automotive. Founded in 1867, Voith employs more than 20,000 people, generates €4.3 billion in sales, operates in over 60 countries around the world and is one of the biggest family owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.

Voith to supply complete Sack Kraft Production Line in Russia

Voith has received an order from Segezha Pulp and Paper Mill (Segezha PPM) to supply a complete process line for sack paper. The Segezha Group aims to use the new line to further expand its position as a global market leader for sack paper.

Voith will supply the complete turnkey production line to the customer at its Segezha facility in the Russian republic of Karelia. Segezha PPM will produce sack papers from unbleached sulfate pulp on the new PM 11, which has a wire width of 4,950 mm and design speed of 800 m/min. The machine’s annual capacity is 110,000 metric tons, which will allow Segezha PPM to increase its production output at this site by 40 percent. During signing of the contract, Segezha Group President Sergey Pomelov said that "following the startup of the PM 11, the Segezha Group intends to move up the ranks to become the world's second largest producer of sack papers. We are confident that we can achieve this goal in collaboration with Voith.” The company currently ranks fourth on the international market and second on the European market.

Nikolay Naumov, General Manager of Segezha PPM, who was extremely satisfied with the discussions ahead of the contract signing, added: “I hope that the cooperation between Segezha PPM and Voith during implementation of the project will be just as impressive and exemplary.”

Voith’s scope of supply includes the complete production line with stock preparation, a MasterJet headbox, a single NipcoFlex press, a MasterReel reeler, a VariFlex winder and the entire process know-how. Voith will also supply the complete automation, electrical installations and initial clothing package for the production line.

Segezha PPM was founded in 1939 and currently has an annual production capacity of 280,000 metric tons of pulp and 265,000 metric tons of sack paper. The company is a market leader for sack paper and has been part of the Paper and Packaging Division of the Segezha Group JSF Systema since 2014.

Further information is available on the Voith website at www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets for energy, oil & gas, paper, raw materials, transport & automotive. Founded in 1867, Voith employs more than 20,000 people, generates €4.3 billion in sales, operates in over 60 countries around the world and is one of the biggest family owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.

Voith Paper Upgrades North American Roll Cover Plants with Investments in New Equipment and Technology

![]() Voith Paper, a long-time leader in roll covers and mechanical roll service for paper machines, has recently made significant investments in its North American roll cover facilities to support the manufacture of new products and ensure roll cover consistency and timely delivery.

Voith Paper, a long-time leader in roll covers and mechanical roll service for paper machines, has recently made significant investments in its North American roll cover facilities to support the manufacture of new products and ensure roll cover consistency and timely delivery.

Voith Paper has recently made significant investments in its North American roll cover facilities.

"We're continuously seeking to elevate the quality of our products and their performance on our customers' machines," said John Fox, President of Voith Paper North America. "To this end, we've introduced new technologies, upgraded equipment and made process improvement in all five of our North American roll cover plants."

Voith Paper's specific plant investments include:

- WebNet bonding technology incorporated into the polyurethane manufacturing process

- Technology installation and upgrades for polyurethane casting in cover manufacturing plants

- Installation of advanced work cells in all mechanical roll service plants

"By keeping our facilities on the leading edge in terms of technology and efficiency, we are able to improve value add and delivery time for our customers," Fox said.

Voith's Neenah roll covers plant continues to be the one-stop roll service center for the Midwest, providing rubber, poly, resin calender, resin press, ceramic/thermal spray cover manufacturing, as well as mechanical roll service. This facility offers a freight advantage to regional customers thanks to its breadth and depth of offerings.

In addition to Neenah, Voith Paper has roll cover plants in Springfield, Ore., West Monroe, La., Austell, Ga., and Hawkesbury, Ontario.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

Contacts

Voith Paper

Terri Robinson, 001-252-265-4405

Successful startup: Voith retrofits Braviken PM 53 to produce new paper grades

Voith has upgraded and successfully commissioned the paper machine PM 53 at Holmen Paper in Braviken, Sweden. The PM 53 can now produce various paper grades ranging from newsprint to sophisticated SC papers, including the recently developed Holmen UNIQ SC paper. This paper grade in the basis weight range 43 – 50 g/m2 is suitable for magazines, catalogs and advertising supplements.

Voith has upgraded and successfully commissioned the paper machine PM 53 at Holmen Paper in Braviken, Sweden. The PM 53 can now produce various paper grades ranging from newsprint to sophisticated SC papers, including the recently developed Holmen UNIQ SC paper. This paper grade in the basis weight range 43 – 50 g/m2 is suitable for magazines, catalogs and advertising supplements.

As part of the three-week upgrade, Voith replaced the former EcoSoft calenders with a Janus MK 2 calender. The special design of this calender, featuring a 45° incline of the roll stack, meant that the existing Nipco rolls could be reused while achieving a 40 percent higher line load. The MasterReel reel winder was relocated for reasons of space and fitted with a LunaReel rubber roll cover, a minor adjustment that was necessary to be able to produce the higher-quality paper grades.

The special machine concept of the Janus MK 2 calenders allowed the upgrade to be carried out quickly and efficiently. There was no need for major structural work in the building, as the new calender could be placed on the existing paper machine foundations thanks to the 45° incline of the roll stack, putting it on the same level as the paper machine. The inclined stack configuration also provides furtherbenefits like reduced susceptibility to vibrations, shorter roll change times and very good access.

Holmen Paper was happy with the cooperation with Voith and the paper quality as Production Manager Jenny Melander confirms: “The paper was already of a very good quality directly after startup.” The rebuild allows Holmen Paper to enhance its flexibility, because the PM 53 can switch the calender between single, double or multi-nip operating modes at any time without interrupting production, enabling it to produce paper qualities ranging from matt to glossy and from low to high density.

Holmen Paper is part of the Swedish Holmen Group and a major manufacturer of graphic papers. At mills in Braviken and Hallsta in Sweden and Madrid, Spain, it produces high-quality papers for newspapers, magazines, catalogs, advertising supplements and books.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing re-source-saving products to reduce the use of energy, water, and fibers. Fur-thermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw mate-rials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.