Displaying items by tag: voith

Voith strengthens its position in the Russian energy market and establishes a joint venture with RusHydro

Voith Hydro and RusHydro, one of the largest supplier of hydropower in the world, signed a contract establishing the inception of the joint venture VolgaHydro LLC in Moscow. Each company holds a share of 50 percent of the joint venture. RusHydro will exercise the industrial leadership, Voith Hydro will be responsible for the operational management. Voith Hydro will appoint the Chief Executive Officer (CEO) and RusHydro will announce who will become the Chief Financial Officer (CFO). Any decision over VolgaHydro will be made by RusHydro and Voith Hydro commonly. The headquarters of VolgaHydro will be the city of Balakovo in the Russian Federation.

“Having founded this joint venture, Voith strengthens its position in the significant Russian hydropower market sustainably”, says Dr. Roland Münch, Chief Executive Officer of Voith Hydro. VolgaHydro will closely keep in touch with its customers providing excellent know-how and the entire range of expertise.

With a technical potential of 424 GW power, the hydromarket in Russia has a bright outlook. By now, only 46 GW of hydropower has been installed. Besides the possibility to build new hydropower plants, the joint venture focuses on extensive modernizations of old hydropower stations. For instance, Voith and RusHydro have already started to renew the plants Miatlinskaya and Saratovskaya. Voith also modernized the technical equipment of the hydropower plant Uglich for RusHydro as a customer. Voith supplied a complete machine set for the plant and, furthermore, equipped Uglich with electrical and mechanical equipment and automation systems.

Voith’s commitment in Russia goes back to the year of 1899. In that year, the company delivered the first full-fledged paper machine to the city of Sokol. Today, Voith conducts its business at six locations in the Russian Federation. Generally, the Russian market has high potential in the field of energy, oil, gas, raw materials, logistics and automotive. Voith considers these markets as its key sphere of activity.

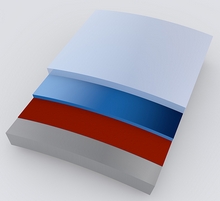

NanoPro – new roll cover for calenders

At the beginning of 2013, Voith launched the NanoPro roll cover for calenders onto the market, which offers a very noticeable reduction of vibrations. This new cover is available for supercalenders, soft calenders and multi-nip calenders.

At the beginning of 2013, Voith launched the NanoPro roll cover for calenders onto the market, which offers a very noticeable reduction of vibrations. This new cover is available for supercalenders, soft calenders and multi-nip calenders.

NanoPro provides a reliable and consistent performance as it has unique attributes in areas where vibrations would normally restrict the performance of roll covers. In comparison with other conventional roll covers, it manages to further reduce vibrations, even under difficult conditions. The annual operating and maintenance costs are thus lowered. Moreover, the profile of NanoPro remains uniform due to its high level of wear and abrasion resistance.

NanoPro provides a reliable and consistent performance as it has unique attributes in areas where vibrations would normally restrict the performance of roll covers. In comparison with other conventional roll covers, it manages to further reduce vibrations, even under difficult conditions. The annual operating and maintenance costs are thus lowered. Moreover, the profile of NanoPro remains uniform due to its high level of wear and abrasion resistance.

The multi-layer fiber-reinforced roll cover guarantees a uniform distribution of nanoparticles. Customized components and the manufacturing process ensure that the NanoPro layers can withstand severe impact damages. NanoPro also distributes a high compressive stresses evenly over the entire nip. Thus the customer can count on the best possible sheet characteristics for gloss and smoothness and ultimate running behavior.

Voith develops pulp drying machine with energy-saving dryer section

Voith now offers complete pulp drying machines, from headbox to the cross cutter and bale packing and thus is further expanding its technological leadership. What is new and unique is the vertical arrangement of the rolls in the dryer section. This valuable innovation is patented by Voith, saves energy and leads to a much higher evaporation.

Voith now offers complete pulp drying machines, from headbox to the cross cutter and bale packing and thus is further expanding its technological leadership. What is new and unique is the vertical arrangement of the rolls in the dryer section. This valuable innovation is patented by Voith, saves energy and leads to a much higher evaporation.

- Voith now offers complete pulp drying machines

- A patented vertical dryer section guarantees more effective and more resource-conserving production

- Customers can use the only complete pilot machine worldwide for their own tests at Voith

The goals of ensuring higher productivity and lower resource consumption were achieved. The installed former ensures that the web enters the dryer section with a much higher dry content. Since mechanical dewatering is less expensive than thermal dewatering, the customer is thus offered a clear advantage.

Steam consumption in the dryer section is reduced compared to conventional sections. Due to more efficient evaporation, the temperature of the web in the dryer section has also been reduced. Another benefit of the higher evaporation rate is the reduced size of the dryer and therefore of the building. High energy and cost savings are thus achieved.

Steam consumption in the dryer section is reduced compared to conventional sections. Due to more efficient evaporation, the temperature of the web in the dryer section has also been reduced. Another benefit of the higher evaporation rate is the reduced size of the dryer and therefore of the building. High energy and cost savings are thus achieved.

The case of the Brazilian pulp manufacturer Lwarcel Celulose in Lençóis Paulista demonstrates a further series of advantages with the vertical arrangement of the dryer section. Altogether, the vertical arrangement is substantially more space-saving. Lwarcel installed the vertical dryer section directly after its existing conventional dryer section – and with a running drying machine. In addition, the pulp manufacturer confirms that the vertical dryer section has an extremely practical side-effect when there is a web break: the broke web doesn’t build up between the rolls, but instead simply falls through the vertical arrangement. Cleaning takes only minutes rather than hours.

The pilot machine in São Paulo illustrates the entire pulp drying process and offers Voith customers the chance to conduct their own test runs. In the area of pulp drying technology Voith offers many years of experience. Since 1998, NipcoFlex presses have been installed in pulp drying machines. The quality of the products is reflected in a high market share for the shoe presses for these machines. But in the future, Voith will no longer provide just individual components but rather the entire production line.

Improved polymer matrix leads to reliable tissue production

To ensure especially long-lasting and efficient operation, Voith has now launched its newly developed MajorSoft and MegaSoft rubber roll covers for tissue production.The distinctive feature of these roll covers is their improved multilayer structure. Due to various improvements in production, the bonding force between the individual cover layers is four times as strong as with conventional rubber roll covers.

Tests over several years show that MajorSoft is very long-lasting and durable and at the same time it improves production efficiency. MegaSoft has an innovative functional layer that consists of a special rubber polymer matrix characterized through better wear resistance and mechanical strength. Grooves and open surfaces of up to 35% are now possible. Re-hardening is reduced, the void volume is increased and there are less material deformations.

Tests over several years show that MajorSoft is very long-lasting and durable and at the same time it improves production efficiency. MegaSoft has an innovative functional layer that consists of a special rubber polymer matrix characterized through better wear resistance and mechanical strength. Grooves and open surfaces of up to 35% are now possible. Re-hardening is reduced, the void volume is increased and there are less material deformations.

In test runs a tissue machine achieved a production speed increase of 25 m/min, dry content was 1.2% higher and total production increased by 1.3%, all thanks to MegaSoft. The tissue manufacturer can save nearly 180,000 euros annually by using MegaSoft.

MegaSoft or MajorSoft – the cover that is best suited for the respective tissue machine is determined on site by experts from Voith. The decision mainly depends on the condition of the nip and the profile of the Yankee cylinder.

Voith Secures Major Orders for Hydro Power Plant Modernizations in Brazil and China

Heidenheim. Another success for Voith’s hydro power business in important growth markets: at the turn of the year, the company has received several major orders for the modernization of hydro power stations in Brazil as well as in China. The combined contract value of the projects is about €185 million.

Heidenheim. Another success for Voith’s hydro power business in important growth markets: at the turn of the year, the company has received several major orders for the modernization of hydro power stations in Brazil as well as in China. The combined contract value of the projects is about €185 million.

"Our success with these orders shows that the trend towards modernization in major hydro power markets is further continuing," said Dr. Roland Münch, CEO and President of Voith Hydro Holding in Heidenheim. "As an additional important mainstay, the growing modernization business complements the existing activities regarding new constructions. Thanks to our comprehensive competency and long-term experience we are able to benefit from both developments."

For the three major projects in Brazil, Voith is modernizing the power plants Salto Santiago and Passo Fundo on behalf of Tractebel Energia S.A., as well as Chavantes hydro power station for the operator Duke Energy. In the 1,420-MW power station Salto Santiago, the four turbines and generators, the electro-mechanical equipment, as well as the automation technology are completely refurbished and renewed. At the 226-MW hydro power plant Passo Fundo, Voith modernizes the two generating units, the automation systems as well as the governors for the turbines. The Chavantes project covers the renewal of three generating units, including turbines and generators, and the associated electro-mechanical systems in the 414-MW-plant.

In Sanmenxia hydro power plant in China, Voith is modernizing two 50-MW turbines as well as other components and automation elements. In order to reduce erosion due to strong abrasion by the sands of the Yellow River, Voith had already initiated a research project in cooperation with the customer while having optimized a further turbine in the plant some time ago. This experience will be supportive for the current project and does not only ensure improved resistance to erosion but also an efficiency increase of about four percentage points, resulting in an annual plus of just under eight million kilowatt hours per unit.

China and Brazil are among the largest hydro power markets in the world. Apart from working on new infrastructure projects, both countries are increasingly focusing on the modernization and refurbishment of hydro power plants that have been running for decades now. This is development that has already started to take place in North America and Europe accordingly.

The Importance of Hydro Power

Hydro power is the largest, oldest and also most reliable form of renewable energy generation. Worldwide it makes an indispensable contribution to stable power supplies and hence to economic and social development - in industrial countries and also in rapidly growing regions. At the same time, hydro power significantly contributes to climate-protecting energy generation. Voith has been a leading supplier of this technology since the early beginning of hydro power utilization, and continuously develops and improves this technology.

Voith Holds Its Own in a Difficult Environment

The Voith Group has finished the fiscal year 2012 (ending September 30) satisfactorily in a challenging market environment. The globally active family-owned company increased its Group sales by 2 percent to EUR 5.7 billion compared to the record value of the previous year. With EUR 5.7 billion, orders received were behind the excellent value of last year amounting to EUR 6.4 billion (-10 percent), which, among other things, was due to an extraordinarily high volume of major orders from the hydro power market. At EUR 6.1 billion per September 30, 2012, orders on hand were slightly above the previous record level (2011: EUR 6.0 billion).

The Voith Group has finished the fiscal year 2012 (ending September 30) satisfactorily in a challenging market environment. The globally active family-owned company increased its Group sales by 2 percent to EUR 5.7 billion compared to the record value of the previous year. With EUR 5.7 billion, orders received were behind the excellent value of last year amounting to EUR 6.4 billion (-10 percent), which, among other things, was due to an extraordinarily high volume of major orders from the hydro power market. At EUR 6.1 billion per September 30, 2012, orders on hand were slightly above the previous record level (2011: EUR 6.0 billion).

All key figures are positive, although on a lower level than in the past year. Despite the declining sales for graphic paper machines in the Group Division Voith Paper, Voith was able to generate one of the best operational results in the history of the Group. The operational result before non-recurring result was EUR 341 million (-18 percent), the net income amounted to EUR 114 million (-43 percent).

Stable thanks to broad portfolio

"The year 2011/2012 has presented Voith with massive challenges. We have worked intensively on our profitability and our future growth, and laid crucial foundations to ensure that Voith can continue to grow profitably," said Dr. Hubert Lienhard, President and CEO of the Corporate Management Board of Voith GmbH at the company's Balance Sheet Press Conference. According to Dr. Hermann Jung, Chief Financial Officer of Voith, one of the key reasons for the stable business development despite this challenging market environment is the Group's broad portfolio. "We can offset declining sales in individual markets. Because we serve five core industries that follow different cycles: energy, oil & gas, paper, raw materials, transport & automotive. This portfolio has allowed us to grow during the economic crisis in 2009. We were also able to cushion the noticeable slump in the market for graphic paper machines," stated Jung.

All Group Divisions make a positive contribution to sales and earnings

Voith Hydro, one of the world's leading complete suppliers for hydro power plant equipment, was able to increase its sales by 7 percent to EUR 1.3 billion and to raise its operational result by 11 percent to EUR 100 million. As predicted, orders received remained below the previous year, which was marked by major hydro power projects, yet still reached a good value with EUR 1.3 billion (-25 percent).

Sales at Voith Industrial Services, a leading supplier of technical services for key industries such as automotive, energy, the chemical and petrochemical sector, as well as machine construction and aerospace, rose by 9 percent to EUR 1.1 billion. A major contributor to this result was the good business in the automotive industry. The operational result increased to EUR 41 million (+1 percent).

At Voith Paper, the pioneer of the paper industry, sales declined by 5 percent to EUR 1.7 billion due to adverse market conditions. Especially new business was severely affected by the structural slump in demand for graphic paper machines: Orders received dropped by 13 percent to EUR 1.7 billion. Voith has promptly introduced a restructuring program. The negative impact resulting from these measures has already been fully absorbed in the 2012 end-of-year accounts. The operational result of Voith Paper decreased by 41 percent to EUR 84 million.

Voith Turbo, specialist for drive technology, increased its sales by 2 percent to EUR 1.6 billion. Orders received amounted to EUR 1.5 billion - a three-percent drop compared to the previous year. With EUR 151 million, the operational result of Voith Turbo continues to be on a high level, albeit below the value of the previous year (-8 percent).

Significant increase in investments, intensive R&D activities

In fiscal 2012, Voith's investment in the sustainability of the company continued unabated. The Group increased its investment volume significantly by nearly one third above the level of the previous year, spending EUR 272 million (+29 percent), which corresponds to an investment quota of 4.8 percent of the overall Group sales. The company also increased its R&D expenditure to EUR 267 million (+3 percent), thus reaching an R&D quota of 4.7 percent.

In the business year just ended, Voith also invested heavily in the training of young people: At the company headquarters in Heidenheim Voith is building a new training center for about EUR 16 million. At the Voith location in Kunshan, China, work has begun for a training center based on the German dual training principle, in which Voith is investing approximately EUR 7 million. "We are aware that the future of Voith as technological leader largely depends on highly skilled experts, the creativity of its engineers and the readiness and the ability to invest boldly in new products and activities also in the future," said Lienhard at the Balance Sheet Press Conference.

Outlook 2013: growth expected to be restrained

In view of the ongoing difficult framework conditions, such as the Euro debt crisis, an uncertain capital market environment and subdued economic prospects on all major markets and industries, Voith anticipates that developments in 2013 will continue to be restrained. "Dealing with the changes in some of our core markets will continue to be high on our agenda also in 2013, and we cannot see any dynamic growth in 2012/2013, but we expect altogether stable business developments for the Voith Group," stated Lienhard. Based on the assumption that growth for the global economy will be moderate, the Voith CEO foresees that orders received will be at a high level, with sales and results developing at a measured pace, while the net income will improve.

Jens Pohl Appointed as Head of Voith Engineering Services

Effective from January 1, 2013, Voith Engineering Services will see a new business executive: Jens Pohl will be taking over the lead of Voith Engineering Services in the Group Division Voith Industrial Services.

The 45-year-old mechanical engineer comes from the engineering services provider MBtech. There he served as member of management for sales, marketing and purchasing and was also responsible for the worldwide subsidiaries. Pohl started his career in 1994 at the former Mercedes-Benz AG, now Daimler AG, where he performed various operative and strategic international management tasks in the passenger car division, at the group headquarters, and in its affiliates.

The 45-year-old mechanical engineer comes from the engineering services provider MBtech. There he served as member of management for sales, marketing and purchasing and was also responsible for the worldwide subsidiaries. Pohl started his career in 1994 at the former Mercedes-Benz AG, now Daimler AG, where he performed various operative and strategic international management tasks in the passenger car division, at the group headquarters, and in its affiliates.

Jens Pohl brings along comprehensive international expertise in the automotive industry and a wide-ranging knowledge of the aerospace and other high-tech branches. At Voith, he will be responsible for the Engineering Services in the sectors Aerospace, Road and Rail. In this function he will succeed Thomas Mauthe who will be leaving Voith at the end of the year.

Voith Breaks Ground for the New Voith Training Center in Kunshan/China

Shanghai/Kunshan. With a ceremonial first cut of the spade, Voith cele-brated the official construction start of its new Voith Training Center in Kunshan in the South-Chinese province of Jiangsu today. The company is investing about Euro 7.3 million in the new Training Center, which will be opened in 2014. The ceremony was attended by Dr. Hubert Lienhard, President & CEO of the Corporate Management Board of Voith GmbH, as well as leading representatives from local government and administration.

The new building is the largest training facility of Voith outside Germany. With the new Training Center, Voith intends to meet its growing demand for qualified personnel in China. Against the background of the current Five-Year-Plan of the Chinese government, in which subjects such as re-newable energies, protection of resources and mobility are high on the agenda, the Voith Group sees great opportunities for its core markets en-ergy, raw materials, as well as transport & automotive and paper. Voith has more than 20 subsidiaries and employs approximately 3,000 people in China. In the course of planned further expansions, the number of Voith employees in China will have increased to about 5,000 by 2016.

"Voith is a company that has always set standards in vocational education and training. We are pleased that we can now bring our experience gained in this field to Kunshan, in order to train Chinese Voithians here. Wherever possible, we would like to introduce our Dual Education principle in all countries, in which we are actively represented as a company. We already do that today, for example in Brazil, where Voith has been taking an active part in the market for almost 50 years. With our new Training Center in Kunshan we underline the importance of the Chinese market," said Dr. Hubert Lienhard in his speech.

Training and education have, by tradition, always had high priority at Voith. The company has been one of the key pacemakers in vocational training and education for more than 100 years. Only a few weeks ago, Voith also started with the construction of a new Training Center at the company's headquarters in Heidenheim. This project represents an investment of Euro 16 million. The fact that Voith is establishing two dedicated training centers in two key markets not only proves the local commitment of Voith in these markets, but also demonstrates the sustainability and long-term orientation of the company.

Official Start of Construction Work on New Voith Training Center

Heidenheim. With a symbolic first cut of the spade, Voith has marked the official start of the construction work of its new Training Center in Heidenheim. Together with the four best Voith apprentices who had also received awards from the Chamber of Commerce and Industry, Dr. Hubert Lienhard, Chairman of the Management Board of Voith GmbH welcomed representatives from politics and business for a celebration at the Ploucquet Areal. Among the guests were Thomas Reinhardt, Chief Administrator of the District of Heidenheim, Bernhard Ilg, Mayor of the city of Heidenheim, Helmut Althammer, President of the East Württemberg's Chamber of Commerce and Industry and Eberhard Faecke, the architect of the new Training Center.

"Only when we build can we develop further, and only where we build are things moved on," said Dr. Lienhard in his speech. "The new building is yet another milestone in the 100-year tradition of apprenticeship schemes at Voith. Time and again has our company provided a fresh impetus to all issues of vocational training for young people." Job training and education are rated highly at Voith. At Heidenheim alone, the company currently trains about 180 young people in 13 different occupations. Worldwide, more than 1,200 apprentices and students are presently honing their career perspectives at Voith.

"Only when we build can we develop further, and only where we build are things moved on," said Dr. Lienhard in his speech. "The new building is yet another milestone in the 100-year tradition of apprenticeship schemes at Voith. Time and again has our company provided a fresh impetus to all issues of vocational training for young people." Job training and education are rated highly at Voith. At Heidenheim alone, the company currently trains about 180 young people in 13 different occupations. Worldwide, more than 1,200 apprentices and students are presently honing their career perspectives at Voith.

With a total investment of Euro 16 million for the new Training Center, Voith shows its commitment to the Heidenheim headquarters. The new building is to be opened in late 2013. The new Training Center, designed by the Leinfeld architect Eberhard Faecke, concentrates on transparency, functionality and inspiration. Due to the new location in the immediate vicinity of the company's head office, vocational training and further education are now also "optically" in focus. "With this groundbreaking ceremony, we are starting the construction work for a piece of the future of Voith right at our traditional headquarters. In doing so, we are laying the perfect foundation for the training of future apprentices," stated Dr. Lienhard.

Following the speech of the Voith CEO, Mayor Bernhard Ilg welcomed the guests and praised the concerted and decisive undertaking. "Heidenheim is currently in the public eye, because the town is developing at rapid speed. Never before have we seen so many investors in housing, trade and industry." Ilg expects that the Training Center will also have a positive impact on the town center, which is being further enhanced by projects such as the new library, a health center, a day nursery and a supermarket.

Negotiation Partners Settle for Reconciliation of Interests

In conclusion of their discussions about the restructuring measures at Voith Paper, the chief negotiators of Voith Paper and the relevant Workers' Council Committees have settled for a reconciliation of interests on September 11, 2012.

In May 2012, Voith Paper had announced restructuring measures due to a structurally induced ongoing decline in sales in the field of graphic paper machines.

According to the reconciliation of interests both sides have agreed upon that about 50 jobs less than the initially intended figure will be cut at Voith Paper in Germany and Austria. This is a total of 670 rather than the initial 710. This means that 317 job cuts will affect the location Heidenheim. At the location Ravensburg, 218 jobs will be cut, while Krefeld cuts down on 66 jobs and St. Poelten in Austria on 69 jobs.

Regarding the implementation of these adaptive measures, the negotiation partners have agreed on the following key points:

- It is still the declared goal to introduce all measures in the most socially acceptable way and, wherever possible, avoid forced redundancies. If forced redundancies really are inevitable, they will, at the earliest, come into effect at the end of 2013. This does not affect the existing operational rules in Heidenheim and Krefeld.

- The existing Centers of Competency including Automation at all German Voith Paper locations and in St. Poelten/Austria will remain there until the end of 2015.

- Voith will establish a training corporation at the location Ravensburg. Employees will be offered severance payments, combined with the option of changing into this training corporation.

- The location Ravensburg will continue to operate maintenance and manufacturing services on a small scale.

- The R & D facilities in Ravensburg and Krefeld will remain at their locations.

This concluding settlement paves the way for the reorganization of Voith Paper as of October 1, 2012. The company will provide further information on the results of the reorganization in the next few weeks.