Displaying items by tag: pmp group

PMP Group will supply 2nd Intelli-Tissue® 1200 EcoEc tissue machine for Hebei Xuesong Paper Co., Ltd

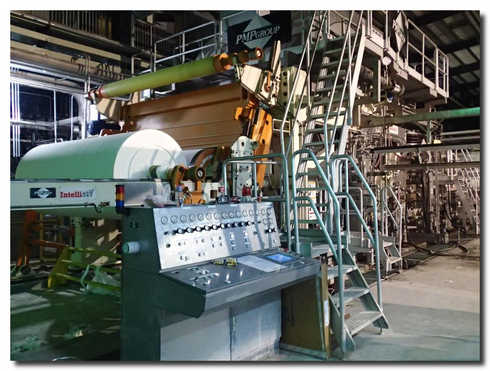

In January, Hebei Xuesong Paper Co., Ltd has signed a contract with PMP Group for 2nd Intelli- Tissue® EcoEc machine. Only 6 months after TM#1 successful start-up, Hebei Xuesong Paper choose PMP Group again as the provider of TM continuing fruitful partnership.

TM#2 (twin line to TM#1) with the brand name of Intelli-Tissue® 1200 EcoEc tissue machine, is characterized by reel trim of 2850 mm, design speed of 1200 m/min and capacity 60 t/d (basis weight 12.5-20 gsm). After TM#2 installation, Hebei Xuesong Paper will have two machines (right and left hand) in the same building based on integrated tissue mill concept.

Hebei Xuesong Paper - a famous tissue-making enterprise in Hebei Province, China - was founded in 1987and produces high-quality tissue products under “Xuesong” brand. PMP Group is a global provider of paper, board and tissue technology and has been serving pulp & paper industry for over 160 years. Efficient cooperation between two companies started from TM#1 project in 2013. First Intelli-Tissue® 1200 EcoEc was brought on stream in April 2014 and thanks to excellent cooperation between Hebei Xuesong Paper and the PMP teams, just 5 days after start-up, the maximum production capacity and tissue quality guarantees were achieved. Recently steam consumption reached an ultra-low level of 1.6- 1.8 t/t, which help to significantly minimize production costs.

TM#2 is actually a twin-sister machine of TM#1 and will also be executed based on philosophy of Optimum Cost Solution including tissue machine full design in Europe (PMPoland), manufacturing of the key components such as a Intelli-JetV® hydraulic headbox and a Intelli-YD™ steel Yankee in Europe (PMPoland), and the remaining manufacturing, tissue machine pre-assembly and tests completed at the Center of Excellence of PMP Group: PMP IB (Changzhou) Machinery & Technology, Changzhou (China). This combination ensures to lower the cost investment for the customer, while maintaining excellent quality of the equipment supplied. PMP will provide a stock approach system, Intelli-Tissue® 1200 EcoEc machine, mechanical drives, electrical drives, a lubrication system, a steam & condensate system and PLC. The PMP team will be responsible for an erection supervision and technological start-up.

The same model of right and left hand machines layout in one building is the most compact solution and the two machines can share a common spare parts base. As a result, both space and costs are saved as well as number of personnel required to run the installations. Finally, the valuable experience of PMP gained from TM#1 project will make TM#2 even more adapted to the customer’s requirements.

Year by year, PMP Group increases its presence in China through implementation of projects for both tissue & paper customers. Last decade in this market, has brought 11 CF tissue machines and 17 capital rebuilds including core technological units such as Intelli-Jet V® headboxes, Intelli-Nip® shoe presses, Intelli-Sizer™ size presses, etc. Combination of advanced technology and rich experience from PMP Group headquarters and convenient local service from PMP IB results in smart integration of assets & competences. This way PMP Intelli-Tissue® 1200 EcoEc tissue machine brings excellent support for its users daily.

Three Forces of PMP Group – The final stage

After a year of intense promotion PMP Group has entered the final stage of its Three Forces of PMP Group – Earth, Wind & Fire campaign. Metaphorical properties of forces of nature have become an inspiration for PMP Group to start a campaign which symbolizes the benefits of the company’s three major, technological lines in the P&P business – Intelli-Technology® (Earth), Intelli-Tissue® (Wind) and Phoenix Concept™ rebuilds (Fire).

After a year of intense promotion PMP Group has entered the final stage of its Three Forces of PMP Group – Earth, Wind & Fire campaign. Metaphorical properties of forces of nature have become an inspiration for PMP Group to start a campaign which symbolizes the benefits of the company’s three major, technological lines in the P&P business – Intelli-Technology® (Earth), Intelli-Tissue® (Wind) and Phoenix Concept™ rebuilds (Fire).

Up till now the viewers had the opportunity to see adverts, movies and articles in regard to Wind (Intelli-Tissue®) and Fire (Phoenix Concept™). Now the time has come to present the final element – Earth (Intelli-Technology® - Platform Concept for Papermakers). This specific line is characterized by low media consumption (ECO) and high runnability – thus the green color and the connection to Mother Nature. In this specific area paper producers are offered complete paper machines for special papers (like MG), as well as highly advanced paper and board units. Product portfolio covers all key technological sections of PM: Intelli-Jet V® hydraulic headbox, dewatering unit – Intelli-Top® former, Intelli-Nip® Shoe Press, Intelli-TriNip™ press, Intelli-Sizer™ metering size press (film press), Intelli-MicroCrepe™ and an Intelli-Reel®. PMP Intelli-Technology® Platform, as a compact and flexible solution for paper & packaging producers, reflects all benefits that are associated with one of the most powerful Forces of Nature – Earth.

Entering the final stage of the Three Forces of PMP Group campaign however, does not mean its end. By fulfilling the last phase of the project the company has taken the idea to the next level and despite maintaining the general concept, developed it to meet wider expectations. New releases are planned to be implemented since the beginning of 2016 and will include all three mentioned before Forces. More information to come.

PMP Group’s next Intelli-Tissue® EcoEc 1200 put on stream

It is our pleasure to announce that on October 22nd 2014 PMP Group – a global provider of paper technology – has successfully started up another Intelli-Tissue® 1200 EcoEc machine in China. This time the project was executed for Henan Hulijia Industrial CO., LTD.

Hulijia Group within the last ten years has grown into one of the companies with the most competitive vitality and development potential in the tissue industry in the Henan Province, providing professional nursing products.

The Intelli-Tissue® 1200 EcoEc machine for Henan Hulijia of double-press configuration, of design speed 1200 mpm and a reel trim of 2.85 m produces virgin fiber-based tissue (50 t/d). It is equipped with a modern single-layer hydraulic Intelli-Jet V® headbox, a 4-roll Crescent Intelli-Former®, double nip Intelli-Press®, 12ft ribbed, steel Yankee Dryer Intelli-YD™, exchaust Air Cap and an Intelli-Reel®. Except for premium quality of the final product, the TM is characterized by ultra-low media consumption figures (steam consumption is at a level of 1.7 T/T). Despite its compact size, the Intelli-Tissue® 1200 EcoEc machine can easily replace 10 locally made machines.

PMP’s scope of supply covers i.a. approach flow system, entire tissue machine - including auxiliary systems like lubrication, steam & condensate, mechanical drive,electrical drive and tissue machine controls. The line was designed in Europe and manufactured both in China and Poland. PMP Group is implementing this way Optimum Cost Solution strategy and takes the advantage of the favorable location of its Center of Excellence – PMP IB (Changzhou) Machinery & Technology Co. Ltd.

PMP Group to supply an Intelli-Jet V® hydraulic headbox to Sun Paper, China

In January 2014, PMP Group – a global provider of paper and tissue technology, signed a contract with Sun Paper, China, for the delivery of an Intelli-Jet V® hydraulic headbox. PMP’s unit will be delivered to the Yanzhou mill (Shandong Province) which is the largest single pulp and paper site in China. The main goal of the project is to change the existing production profile from 1-layer to 3-layer paper products.

In January 2014, PMP Group – a global provider of paper and tissue technology, signed a contract with Sun Paper, China, for the delivery of an Intelli-Jet V® hydraulic headbox. PMP’s unit will be delivered to the Yanzhou mill (Shandong Province) which is the largest single pulp and paper site in China. The main goal of the project is to change the existing production profile from 1-layer to 3-layer paper products.

Sun Paper company is more than 30 years old and over the past decade it has managed to create a brand characterized by high quality and modern technology. Currently their total production is reaching 4 million tons. The company’s annual turnover is estimated in the amount of 30 billion RMB, however, this number is set to be increased in the upcoming 5-10 years, to 100 billion RMB. Sun paper is known for having a significant position on the Chinese market as a paper supplier, nonetheless, the company has noticed a huge potential of premium tissue products and decided to expand its market potential.

PMP Group’s scope of delivery includes a4‑channel hydraulic headbox – (Intelli-Jet V®) of 3880 mm pondside, machine controls, assembly and start-up supervision. The unit will be installed on PM#16, which produces film base paper (140-250 gsm) and has an operating speed of 600 mpm. Hydraulic headbox will include consistency profiling system, which assures excellent basis weight control, resulting with uniform paper web structure and better CD basis weight profile. Start-up is scheduled for the second half of 2014.

PMP Intelli-Jet V® hydraulic headbox is one of PMP Group’s most advanced products and is the key element in both Intelli-Technology® and Intelli-Tissue® platform. Only since the year 2000, PMP Group has sold over 100 headboxes worldwide, whereas 67 of those units are located in Asia.