Ianadmin

ITC Limited chooses Pasaban to upgrade one of its sheeting machines

The lifetime of your machines concerns us. PASABAN UPGRADES EXTEND THE LIFETIME OF YOUR MACHINES.

In this case, the machine is a 1992 KDD 1900 paper and cardboard sheeter owned by ITC Limited (India).  Because of it being a highly automated sheeter and of a certain age, it presented various problems such as obsolete drives and controls, frequent stops for maintenance work, poor performance and an unsatisfactory final product.

Because of it being a highly automated sheeter and of a certain age, it presented various problems such as obsolete drives and controls, frequent stops for maintenance work, poor performance and an unsatisfactory final product.

In pursuit of the most appropriate solution and with the aim of improving performance and solving these inefficiencies, Pasaban provided ITC with the Upgrades service. After a thorough analysis of the possibilities for updating the machine, a solution was proposed and it was completed in just three weeks.

During the first two weeks, technicians completed the relevant mechanical and electrical work, replacing the damaged electrical parts of the original installation. They also installed new motors, photocells, detectors and other auxiliary elements.

The “Pasaban drives software” system was also included, for verifying the new digital regulators and for using the online service through the TeamViewer software and an Internet connection supplied by the customer.

Once these works were finished, the technical team continued with the set up of the machine, carrying out the relevant tests until the machine was in optimal operating condition.

All these improvements guarantee that the machine will operate without any problems for a longer period of time, also improving the quality of the final product by minimising the outages arising from maintenance problems.

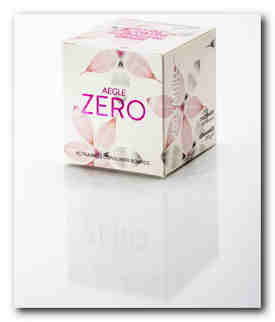

AEGLE Zero. The natural choice.

AEGLE Zero, a new uncoated folding boxboard with an uncoated reverse, has been added to the range of packaging materials offered by Kotkamills from their BM2 cartonboard machine in Kotka, Finland.

AEGLE Zero is a special uncoated packaging grade, suitable for food and non-food end-uses, where a natural look is as important as excellent printability and conversion properties. The grade is made from the same strong, virgin Nordic fibre that AEGLE Pro and AEGLE White are made from and offers the same opportunity for creative design. Printability, CD stiffness and value are all offered by this special new grade.

AEGLE Zero is a special uncoated packaging grade, suitable for food and non-food end-uses, where a natural look is as important as excellent printability and conversion properties. The grade is made from the same strong, virgin Nordic fibre that AEGLE Pro and AEGLE White are made from and offers the same opportunity for creative design. Printability, CD stiffness and value are all offered by this special new grade.

“The tactile and natural looking surface of AEGLE Zero provides the opportunity for creative packaging design where values of pure, organic quality are implicit in the final product choice. It offers a real opportunity for packaging differentiation and is suitable for a range of printing processes and finishing techniques, like hot and cold foiling. A natural choice from Kotkamills AEGLE range of folding boxboards,” says David Ingham, Sales Director Consumer Boards at Kotkamills.

AEGLE Zero is produced in the range of 305 to 615 micron and is available to order now.

Kotkamills Group in brief

Kotkamills is a responsible partner that delivers renewable products and performance to its customers' processes via product innovations created from wood, a renewable raw material. The key brands of the company include Absorbex® and Imprex®, both innovative laminating paper products for the laminate, plywood and construction industries. Moreover, Kotkamills offers ecological, technically sound and visually attractive wood products for demanding joinery and construction. In summer 2016, Kotkamills started up a new board machine producing AEGLE(TM) Folding Boxboard and ISLA(TM) Food Service Boards, including the capability to add barriers on-machine. All Consumer Boards material solutions are fully recyclable and repulpable.

Kotkamills has two production sites in Finland, located in Kotka and Imatra. The majority shareholder of Kotkamills is MB Funds, a Finnish private equity firm.

ANDRITZ and PulpEye enter into cooperation agreement

International technology Group ANDRITZ and PulpEye have entered into a cooperation agreement to promote, market, and sell PulpEye analyzer technology exclusively in ANDRITZ PULP & PAPER package offerings.

This ANDRITZ and PulpEye cooperation will enable customers to benefit from improved online chip and fiber datalytics in order to optimize the right process parameters in fiberlines and pulping processes, for instance by improving yield and optimizing chemical consumption. Furthermore, ANDRITZ and PulpEye can also provide customers with a remote online platform for operations support through IoT solutions.

PulpEye sampling and analyzing cabinet

PulpEye sampling and analyzing cabinet

PulpEye is an innovative measurement technology company focusing globally on online pulp quality analysis applications for the pulp and paper industry. The PulpEye equipment is used to control the quality of any kind of pulp – sulfate and sulfite pulps, both short and long fiber, bleached and unbleached, TMP, CTMP and BCTMP as well as NSSC, OCC, and de-inked pulps. Recent product launches include modules measuring vessel cells and fiber wall thickness, as well as a fast consistency calibration module.

ANDRITZ PULP & PAPER is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as the treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboard (MDF), as well as recycling plants are also part of this business area.

ABB’s pulp & paper Network Platform 800 scanner wins Red Dot design award

ABB’s recently introduced Network Platform 800 scanner has been recognized with the prestigious Red Dot award in the groundbreaking design category. This completely new scanner’s structure provides customers with a stable, solid foundation for precision measurements of product quality and consistency during the process of making pulp or paper. The scanner detects the slightest imperfections in the paper web to ensure that on-spec product is made for and delivered to end customers. ABB worked with Irish product design firm Dolmen to design the scanner to be durable, accurate, and perform flawlessly in rough mill environments.

“We are delighted to be honored with this prestigious design award,” said Jim Fisher, Global Product Group Manager for Pulp and Paper, “This underscores ABB’s ongoing commitment to continuously improving our customers’ experience and delivering products that help to be more successful.”

- Red Dot design award recognizes the most innovative product designs from around the world

- Network Platform 800 scanner awarded with Red Dot for high design quality

- Completely new scanner design provides pulp and paper customers with solid, stable foundation for precision measurements of product quality and consistency

Manufacturers and designers from around the globe are invited each year to enter their products in the competition. The jury of around 40 independent designers, design professors and specialist journalists test, discuss and assess each individual product. The year’s competition included more than 5,500 entries from 54 countries. The Network Platform 800 received the “Red Dot for high design quality”.

Network Platform 800 is a right-sized scanner for today’s small-to-mid size paper machines.

Network Platform 800 is a right-sized scanner for today’s small-to-mid size paper machines.

The Network Platform 800 is a high-performance scanner correctly-sized for today’s small-to-mid size paper machines of up to 6.2 meters (244 inches) sheet width. When combined with ABB’s leading-edge paper sensors and controls, Network Platform 800 is a critical component of the ABB quality control (QCS) system for improving paper quality, optimizing paper machine stability and improving process efficiency. Its combination of powerful processing and real-time data acquisition provides precise sensor and frame coordination, fast signal processing and world-class measurement accuracy.

Professor Dr. Peter Zec, founder and CEO of the Red Dot Award, stated “The Red Dot winners are pursuing the right design strategy. They have recognized that good design and economic success go hand in hand. The award by the critical Red Dot jury documents their high design quality and is indicative of their successful design policy.”

About the Red Dot Design Award:

In order to appraise the diversity in the field of design in a professional manner, the Red Dot Design Award breaks down into the three disciplines of Red Dot Award: Product Design, Red Dot Award: Communication Design and Red Dot Award: Design Concept. The Red Dot Award is organized by Design Zentrum Nordrhein Westfalen and is one of the world’s largest design competitions. In 1955, a jury convened for the first time to assess the best designs of the day. In the 1990s, Red Dot CEO Professor Dr. Peter Zec developed the name and brand of the award. Ever since, the sought-after Red Dot award has been the revered international seal of outstanding design quality. More information is available at www.red-dot.org

About ABB

ABB (ABBN: SIX Swiss Ex) is a pioneering technology leader in electrification products, robotics and motion, industrial automation and power grids, serving customers in utilities, industry and transport & infrastructure globally. Continuing more than a 125-year history of innovation, ABB today is writing the future of industrial digitalization and driving the Energy and Fourth Industrial Revolutions. ABB operates in more than 100 countries with about 132,000 employees. www.abb.com

More Efficiency in stock preparation: InfiltraDiscfilter with new HiCon 2.0 technology from Voith

In the BlueLine stock preparation product portfolio, the InfiltraDiscfilter with new HiCon 2.0 technology from Voith satisfies two of the key customer requirements for modern paper manufacturing, enabling efficient and resource-conserving production, an increase in fiber yield and water consumption may be reduced. The improved efficiency in the stock preparation offers a potential capacity increase of up to 20 percent at the disc filter and savings in pump energy of maximum 50 percent.

- Prevents vat thickening

- Minimizes maintenance and operating costs

- Up to 20 percent capacity increase and 50 percent less pump energy

Conventional disc filters not only necessitate a high level of monitoring and maintenance; especially in the event of process fluctuations they can cause malfunctions that result in costly machine downtimes. These kinds of problems are triggered above all by uncontrolled highs in stock consistency in the disc filter. If such highs go undetected this often results in a thickening in the vat, especially in high freeness ranges. In these circumstances the disc filter clothing is exposed to high mechanical stresses and can readily become damaged. In the worst-case scenario the entire filter is damaged. To prevent such difficulties, the stock flow is diluted upstream of the disc filter, which is associated with a considerable increase in pump energy and loss of drainage capacity.

The InfiltraDiscfilter with new HiCon 2.0 technology from Voith is used in the BlueLine stock preparation unit at Schoellershammer PM 6.

The InfiltraDiscfilter with new HiCon 2.0 technology from Voith is used in the BlueLine stock preparation unit at Schoellershammer PM 6.

For its HiCon 2.0 technology Voith is also relying on the proven bagless system but has added two new decisive innovations: Firstly, the HiCon disc filters are fitted with a solid system which safely guides the discs. As a result the new disc filters are much more robust and have even longer service lives. In addition, the flow pattern in the vat is reversed, by feeding each individual disc with the flow of stock separately from the others. The patented innovative technology from Voith's BlueLine range prevents the occurrence of critical areas in which the pulp thickens. This allows production to be run with a stock consistency that is up to two percent. Disc filters with HiCon technology can optionally be integrated into existing machines during an upgrade.

With the launch of its BaglessPlus technology in 2012, Voith had already eliminated a large number of vulnerabilities in conventional filters and had thus set a new benchmark for disc filters. On the one hand because the bagless filters reduced maintenance and operating costs, and on the other because they can better withstand critical situations and therefore reduce the number of costly shutdowns.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

For 150 years, Voith’s technologies have been inspiring customers, business partners and employees around the world. Founded in 1867, Voith today has around 19,000 employees, sales of €4.3 billion and locations in more than 60 countries worldwide and is thus one of the largest family-owned companies in Europe. Being a technology leader, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive.

Valmet to supply an Advantage NTT tissue production line to Sofidel S.p.A in Spain

Valmet will supply a complete tissue production line to Sofidel's Ibertissue mill in Buñuel, Navarra, in Spain. The delivery includes an Advantage NTT 200 tissue production line, stock preparation equipment and automation system. Start-up of the new line is scheduled for third quarter 2018.

The order was included in Valmet's first quarter 2017 orders received. The value of the order is not disclosed.

The up-coming new line in Spain will be Sofidel's fourth Valmet Advantage NTT tissue line in Sofidel's machine fleet. Previously the company has bought one NTT machine to their Delitissue mill in Poland and two NTT machines to their new site, Circleville in Ohio, USA. All in all, this is the 15th tissue machine supplied by Valmet to Sofidel.

"What we have seen from the performance of the Advantage NTT lines started up so far, we are more convinced than ever that this is the technology for the future. It will give us the flexibility we need to get a competitive advantage in the market," says Luigi Lazzareschi, CEO of Sofidel

Valmet Advantage NTT tissue machine

Valmet Advantage NTT tissue machine

"We are of course excited that Sofidel once again decided to go for the Advantage NTT technology to support their path toward future tissue making. It is a perfect match for Sofidel's ambition to produce high quality tissue products with low energy consumption supporting their goal to reduce greenhouse gas emissions," says Jan Erikson, Vice President, Sales, Tissue Mills business unit, Valmet.

Technical information of the delivery

The new tissue machine will have a design speed of 1,800 m/min in textured mode and 2,000 m/min in plain mode. The production line is optimized to save energy and fiber as well as add possibilities for product differentiation and increased capacity of premium quality products.

Valmet's scope of supply comprises a complete tissue production line including an Advantage NTT tissue machine, with an OptiFlo headbox and a cast alloy Yankee cylinder. It will also be featured with the Advantage tissue technology including, an AirCap hood with Air system, WetDust system and a SoftReel B reel. Valmet will also deliver detailed mill engineering, stock preparation equipment as well as an automation package including DCS (distributed control) and QCS (quality control) systems.

About the customer Sofidel S.p.A

The Sofidel Group is one of the leading manufacturer of paper for hygienic and domestic use worldwide. Established in 1966, the Group has subsidiaries in 13 countries - Italy, Spain, the UK, France, Belgium, Germany, Sweden, Poland, Hungary, Greece, Romania, Turkey and the USA - with more than 5,500 employees, a consolidated turnover of 1,842 million Euros (2016) and a production capacity of over one million tonnes per year. Sofidel is a member of UN Global Compact and the international WWF Climate Savers programme.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

ZELLCHEMING-Expo 2017: Exhibition forum entirely dedicated to the topic “Industry 4.0” and further highlights

The countdown is running: At ZELLCHEMING-Expo, from 4 – 6 July 2017 visitors get an exclusive and up-to-date insight into future challenges and new approaches along the process chain of the pulp and paper production. Especially at the exhibition forum participants will not only be informed but also inspired by the main topic “Industry 4.0” for new development opportunities in their companies. With the keynote speech under the heading “Good sides, bad sides – Why the paper industry also has to reinvent itself,” web journalist and TV presenter Richard Gutjahr sensitized for the future topic on the first exhibition day:

“Not even one in two represents of the paper industry believes that the digitalization, the “Internet of Things” and the “Industry 4.0” will have a profound effect on the own business. But the lessons of history tell us that especially those who feel the safest will be hardest hit by the change. The lecture will show why the step from the analog to the hyper interlinked digital age will be bigger than the invention of the book printing and why no industry will remain untouched by this change.”

Practical knowledge-transfer

Other sources of information provide the workshop “Industry 4.0“ of the ZELLCHEMING technical committee pulp and paper testing (TEST), the workshop “Technologies from TODAY for the products of TOMORROW” of the Papiertechnischen Stiftung as well as the lecture series “The VDI and its effects on the paper industry” of the ZELLCHEMING technical committee microbiology. This year, the already established Cellulose Symposium will present again the latest discoveries in the field of polysaccharide research.

Learn from the best: Presentation of revolutionary and long-lasting ideas

The exhibitor lecture series “Best Practice – Learn from the best“ under professional supervision of the association ZELLCHEMING e.V. as well as the lecture series of the publisher Deutscher Fachverlag with presentations from exhibitors of the market place, will also offer particular insights into practice.

Amongst others, participants experience from the company Creapaper GmbH how sustainable, revolutionary and easily grass can be used in paper production and which potential reveals thereof. Also the topic “Cloud-based analysis of the control accuracy” provides practical information. The company Siemens AG reports concerning this matter about saving potentials in the pulp and paper production.

Exhibition: Keyplayer and newcomers show know-how

At the exhibition of ZELLCHEMING-Expo 2017, visitors also feel the pulse of the market. Here, 150 companies present their latest products and services. Well-known keyplayers like ABB Automation, Andritz, Siemens, Pöyry, Valmet and Voith Paper, also a lot of small medium-sized companies are represented. Furthermore, various first-time exhibitors present themselves to a high-class audience at the “Newcomer Pavilion“ and show there know-how.

Better connected through participation at the frame program

The already established evening events enable visitors to expand their network focused in the industry beyond the exhibition and to continue conversations in a relaxed atmosphere. On the first day of the event, the “After Fair” takes place in the foyer of hall 4.1. For the second time, the “Summer Evening” of the association ZELLCHEMING e.V. invites to “Depot 1899”, a traditional restaurant in the former tram railway station in Frankfurt a. M.

For the first time in 2017, the ZELLCHEMING-Cup takes place. It is a table football tournament which takes place during the exhibition. This makes it child's play for the visitors to become familiar with the exhibitors and to win attractive prices.

The entire lecture program and further information can be found at www.zellcheming-expo.com/forum

The free registration for visitors, the current exhibitor list, further information as well as details about the framework program of ZELLCHEMING-Expo are available at www.zellcheming-expo.com

About ZELLCHEMING e. V.

The Association of Chemical Pulp and Paper Chemists and Engineers is an association which has dedicated itself fully to the various issues and topics surrounding chemical pulp production and paper making. We see ourselves as a technical-scientific professional association for the chemical pulp paper industry as well as its suppliers. Anybody who is involved with chemical pulp production and paper making in Europe will find that we offer a comprehensive range of information as well as strong representation of interests for the concerns and issues affecting our high-tech sector. We provide our members with an international network for the exchange of information and technical contacts in which topics discussed range from research and development concerning paper making through to ecology and the future of the chemical pulp industry and paper industry.

HexaSolutions invests in eCon synchro knife sheeter from BW Papersystems to double yearly output

French paper converter will also highly improve cut and stack quality

HexaSolutions, a paper and board converter based in Château-Thierry, Champagne province, in the heart of France, refer to themselves as firefighters. Firefighters for their customers: offset printers. No matter if they urgently need a specific paper grammage or a certain sheet size or if they want to use their existing rolls but in a smaller width, HexaSolutions is dedicated to serving their customers, offering customized solutions in superior quality.

For providing such around-the-clock services, the company heavily relies on its equipment. Having started their business 5 years ago, HexaSolutions sees a permanent growth especially in their folio sheeting business. With the rising demand for high quality stacks, with grammages ranging from 100 g/m2 in paper up to 400 g/m2 in board, their existing sheeting equipment no longer meets the high requirements in cut quality.

By investing now, in a new eCon synchro knife folio sheeter from BW Papersystems’ brand MarquipWardUnited, HexaSolutions will be able to provide their customers with press ready stacks with superior cut and stack quality and the quick delivery they need.

"The cut quality and the wide spectrum of production capacities of the eCon sheeter were really the key factors of this investment," said Christophe Kopp, Managing Director of HexaSolutions. "As a converter, we should provide the best stack quality and the best delivery time for our customers based around Paris, so we were convinced to make the right choice with BW Papersystems equipment." His new eCon folio sheeter has a 1650 mm working width, is equipped with 4 unwinds and features the industry leading MarquipWardUnited knife technology with a maximum knife load of 1000 g/m² for flexibly converting a wide range of products. This new sheeter ideally supports HexaSolutions’ mission to be their customers’ firefighters.

But HexaSolutions does not only want to improve its product quality with the addition of a new synchro knife sheeter from BW Papersystems, they also expect to double their production output from 5,000 tons to 10,000 tons per year. Their ambitious goal: HexaSolutions wants to become the Number 1 paper and board converter for Paris, the capital city of France, and its suburbs. "Our eCon sheeter will be the most modern sheeter installed in a paper converting plant in France, and so with this new investment our target is to establish ourselves as a premium folio sheet supplier," concludes Kopp.

HexaSolutions’ decision for an eCon sheeter from BW Papersystems and MarquipWardUnited continues its global success story. Since its launch in September 2014, the eCon has been sold more than 40 times. The sheeter in France marks the 7th installation in Europe, with more installations to come in the next months.

ABOUT BW PAPERSYSTEMS

BW Papersystems incorporates nine of the strongest brands in the industry: BW Bielomatik, Curioni, JAG SYNCHRO, Kugler-Womako, MarquipWardUnited, SHM, VortX, WillPemcoBielomatik and Wrapmatic. Market leading technology is available for folio-size, cut-size and digital-size sheeting and packaging of paper, board and other materials, plus stationery, passport production, RFID processing, Book-on-Demand finishing and specialized paper converting applications. For the corrugating industry, we offer full corrugators, rotary die cutters, flexo folder gluers and starch mixing systems. www.bwpapersystems.com

ABOUT BARRY-WEHMILLER

Barry-Wehmiller is a diversified global supplier of engineering consulting and manufacturing technology for the packaging, corrugating, sheeting and paper converting industries. By blending people-centric leadership with disciplined operational strategies and purpose-driven growth, Barry-Wehmiller has become a $2-plus billion organization with 11,000-plus team members united by a common belief: to use the power of business to build a better world. CEO Bob Chapman shares the story of the company’s transformation in his new book, Everybody Matters: The Extraordinary Power of Caring for Your People Like Family To learn more, go to www.barrywehmiller.com

Pöyry and Betulium sign co-operation agreement to unlock full value chain benefits for clients in bio-based businesses

Pöyry and Betulium have signed a Letter of Intent (LOI) for co-operation that will enable both companies to serve their clients better in bio-based businesses. Pöyry and Betulium share common objectives in bioindustry: together they have the know-how and experience which can be used especially in the field of nanocellulose for composites, plastics and similar materials as well as for wood-based nanocellulose and material testing in both the forest and chemical industries.

Betulium Oy is a Finnish clean-tech company established in 2013. Betulium provides renewable, biodegradable, and high-performance water-based cellulose materials to replace or supplement synthetic organic polymers in a vast number of industrial applications. Betulium runs a pilot plant producing material on an industrial scale in Espoo, Finland. Nanocellulose can be used in the manufacture of paper, feeds, foods, cosmetics and pharmaceuticals.

Betulium Oy is a Finnish clean-tech company established in 2013. Betulium provides renewable, biodegradable, and high-performance water-based cellulose materials to replace or supplement synthetic organic polymers in a vast number of industrial applications. Betulium runs a pilot plant producing material on an industrial scale in Espoo, Finland. Nanocellulose can be used in the manufacture of paper, feeds, foods, cosmetics and pharmaceuticals.

Pöyry has a proven track record in process engineering excellence in the chemicals and biorefining sectors and knows the complex bioindustry value chain, megatrends, drivers and business partners. Pöyry's highly-skilled experts can help clients to identify value added opportunities and commercialise bioproducts with engineering solutions that maximise profitability, sustainability and health, safety and environmental (HSE) aspects.

"Our services in bio-based solutions cover the whole project life cycle from identifying opportunities through market studies and developing the business idea to the design and start-up of industrial scale production plants. This co-operation initiative will benefit both parties but especially our clients who can make use of the whole value chain advantages reached from one source, enabling smoother and more efficient R&D operations," says Nicholas Oksanen, Executive Vice President of Pöyry's Industry Business Group.

Did you know? Pöyry has been delivering bioindustry solutions for 60 years.

http://www.poyry.com/services/smart-solutions/bioindustry

About Poyry

Pöyry is an international consulting and engineering company that delivers smart solutions across power generation, transmission & distribution, forest industry, chemicals & biorefining, mining & metals, transportation and water. Pöyry's net sales in 2016 were EUR 530 million. The company's shares are quoted on Nasdaq Helsinki (POY1V). Approximately, Poyry has 5500 experts. 40 countries. 130 offices.

Valmet launches new Industrial Internet offering and starts partnership with Tieto

Valmet takes its Industrial Internet services to the next level by launching a new offering and opening four Performance Centers for energy, pulp, paper and board and tissue customers. At the same time, Valmet has signed a partnership agreement with Tieto, which is the first step in building a leading Industrial Internet ecosystem bringing the key players together.

"Valmet is the leading process technology, automation and services provider for pulp, paper and energy industries globally. The technologies we provide to our customers are equipped with advanced sensors and measurement devices that gather important data from machines and processes. Furthermore, Valmet's automation systems that many of our customers have provide a solid data source. Combining the data from these sources with data from customers' other mill and plant systems creates an enormous amount of data. The core benefit to our customers is that our experts know which data to analyze and how to utilize it. This know-how is built into our Industrial Internet applications and services," says Jari Almi, Director, Industrial Internet, Valmet.

"Valmet is the leading process technology, automation and services provider for pulp, paper and energy industries globally. The technologies we provide to our customers are equipped with advanced sensors and measurement devices that gather important data from machines and processes. Furthermore, Valmet's automation systems that many of our customers have provide a solid data source. Combining the data from these sources with data from customers' other mill and plant systems creates an enormous amount of data. The core benefit to our customers is that our experts know which data to analyze and how to utilize it. This know-how is built into our Industrial Internet applications and services," says Jari Almi, Director, Industrial Internet, Valmet.

Industrial Internet offering for reliability and performance

Valmet's Industrial internet applications and services are built to improve the reliability and performance of customers' processes. The Industrial Internet enabled reliability services consist of online monitoring, predictive diagnostics and data analysis to improve mill and plant efficiency, to help to plan right-timed maintenance and to prevent unplanned shutdowns. Valmet's Industrial Internet enabled performance services concentrate on integrating data from different systems together with production data to optimize mill and plant level operations. They also include both individual process and the whole machine fleet optimization services.

Four Performance Centers to provide Industrial Internet services

Valmet has established four Performance Centers that are the customer's channel to all Valmet Industrial Internet applications and services. Customers can contact the Performance Centers and get real-time support from Valmet experts and the customer's processes can also be monitored remotely. Moreover, the Performance Centers offer data discovery and big data analysis services based on agreed targets. Performance Centers have been established for pulp, energy, paper, board and tissue industry customers and the Valmet experts work in them both physically and virtually where ever they are through a remote connection.

Solution ecosystem with leading industry players

To provide comprehensive Industrial Internet offering to its customers, Valmet is building an Industrial Internet solution ecosystem that brings leading industry players together. The purpose of the ecosystem is to create new value-adding applications and services to pulp, paper and energy industries. This will offer superior performance for Valmet's customers, compared to each actor operating independently. The now signed partnership with Tieto is a significant step in building the ecosystem.

"This partnership with Tieto is an important step towards creating a strong Industrial Internet ecosystem and comprehensive services for our customers. Through this cooperation and the companies' complementary offerings, production process and business data can be integrated and optimized for the customers' benefit," says Jari Almi.

"We are pleased to be part of new data-driven ecosystems and to deepen our partnership with Valmet to innovate new services and solutions around supply chain and processes optimization. The collaboration starts around Enterprise Resource Planning and Manufacturing Execution Systems, and we are looking forward co-creating new opportunities around industrial internet and data to our customers," says Satu Kiiskinen, Executive Vice President, Tieto.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Tieto aims to capture the significant opportunities of the data-driven world and turn them into lifelong value for people, business and society. We aim to be customers' first choice for business renewal by combining our software and services capabilities with a strong drive for co-innovation and ecosystems. www.tieto.com