Displaying items by tag: Domtar Corporation

At SXSW, Domtar Unveils New, Cutting Edge 'Paper Hotspot'

Say Hello (Again) to Paper - the Original, Wireless, Interactive Communications Platform;

It Offered an Unplugged, Interactive Respite at One of the World's Largest Interactive Festivals

The SXSW Interactive Festival describes itself as "an incubator of cutting-edge technologies and digital creativity," and at the 20th annual show, Domtar Corporation unveiled a wireless venue that made people halt, spurred them to step inside and quickly became one of the most popular features: the Paper Hotspot.

Here's how it worked: In the middle of a tradeshow with flashing lights and loud music to promote new websites, video games and startup ideas, Domtar set up the Paper Hotspot as an oasis. It had comfy couches, a rug, a fireplace and bookshelves filled with books, magazines and sketchpads. People were encouraged to unplug for a moment, to sit down and interact with paper, which some of them did for as long as 30 minutes.

You can see a video of what the Paper Hotspot looked like as well people's interactions with the space here.

"We wanted to be at South by Southwest, because that's where you always see some of the most creative ideas from some of the sharpest minds, and it was interesting to see how people responded to the Paper Hotspot," said Paige Goff, Domtar's Vice President of Sustainable Business & Brand Management. "No matter what people were working on, and no matter how fast they were working, this reinforced the studies that show whether you're an executive or a millennial, people prefer to read on paper and it's faster to read on paper."

The Paper Hotspot comes as part of Domtar's award-winning PAPERbecause campaign (www.paperbecause.com) that showcases the effectiveness and sustainability of paper. The effort has featured a series of satirical videos about the exaggerated pressures to go paperless at the office as well as in our day-to-day lives. The New York Times recently wrote this article about the campaign's latest batch of videos.

"We thought the Paper Hotspot would be a fun, new way to highlight a key message," Goff said. "Even after 2,000 years, paper has a place, even more so in a digital age - it remains a purposeful, personal and environmentally responsible communication medium."

SOURCE DOMTAR CORPORATION

Domtar at the Goldman Sachs Conference

Domtar Corporation (NYSE: UFS) (TSX: UFS) has announced that Mr. Daniel Buron, Senior Vice-President and Chief Financial Officer, will present at the Goldman Sachs Paper, Forest Products and Packaging Conference in Montreal, QC on Thursday, March 14, 2013 at 8:45 a.m. (ET). The presentation will be webcast and can be accessed in the Investors section of the Domtar corporate website at www.domtar.com.

Domtar inaugurates commercial lignin production

Plymouth Mill to produce bio-material with wide range of industrial applications as petro-chemical alternative - the first of its kind in over quarter century

Domtar Corporation has announced that it has successfully installed a commercial-scale lignin separation plant at its Plymouth, North Carolina mill, the first U.S. facility of its type in over 25 years. The production of BioChoiceTM lignin began in February, with a targeted rate of 75 tons a day, destined for a wide range of industrial applications as a bio-based alternative to the use of petroleum and other fossil fuels.

The successful installation of commercial-scale lignin removal capacity at the Plymouth Mill is the culmination of a research and engineering project launched by Domtar in 2010. This project was further boosted when the U.S. Department of Agriculture and the U.S. Department of Energy awarded the company a grant through the Biomass Research and Development Initiative. Domtar's lignin operation sets a new path for the industry and also marks the latest sustainability milestone for a company that has long been recognized as an industry leader in forest certification and environmental stewardship.

"Our vision is to be a global leader in fiber-based innovation," said Bruno Marcoccia, Domtar's director of research and development. "A big part of this is our focus on partnering with best-in class collaborators to develop new products and markets for a wide portfolio of initiatives, like BioChoice."

"The possibilities for making a real difference in terms of offering manufacturers a bio-based alternative to the use of petro-chemicals is truly exciting," said Hasan Jameel, a professor in North Carolina State University's Department of Forest Biomaterials. "This is a big win for sustainability on two counts - Domtar improves the efficiency of its pulp-making process, and at the same time the market gets a reliable, high-quality source of this underused material with so much potential."

A wide range of potential applications for BioChoice lignin exists, including fuels, resins and thermoplastics.

Dryden's Jim Blight earns Mill Manager of the Year recognition from Industry Association

Domtar Corporation has announced that Jim Blight, General Manager of the Domtar mill in Dryden, Ontario, was named Mill Manager of the Year at the annual PaperWeek Canada industry conference in Montreal. The award is given out by the Pulp and Paper Technical Association of Canada, or PAPTAC, to recognize outstanding leadership and performance results in the Canadian pulp and paper industry.

Domtar Corporation has announced that Jim Blight, General Manager of the Domtar mill in Dryden, Ontario, was named Mill Manager of the Year at the annual PaperWeek Canada industry conference in Montreal. The award is given out by the Pulp and Paper Technical Association of Canada, or PAPTAC, to recognize outstanding leadership and performance results in the Canadian pulp and paper industry.

Jim has worked at the Dryden Mill since 1998, and has been in the General Manager role since 2007.

"Taking quantum leaps in production capacity, cost structure, quality and safety performance is always the result of the hard work of many, but it takes a leader to bring out the best in people that allows these positive, sustainable results to happen," noted Martin Lorrion, Domtar's Vice-President of Manufacturing. "We're rightfully proud of him and what he's been able to accomplish with a strong team in Dryden."

"I need to share this professional honour with my colleagues here at the mill," added Jim Blight. "We've had to make some difficult but necessary changes over the recent years to reposition ourselves for the changing global markets - we're now a safer, more competitive operation thanks to many people making a sustained, collective effort over a long period of time."

SOURCE: DOMTAR CORPORATION

Domtar releases new wave of comical videos, highlighting paper's enduring value in everyday life

To update its award-winning PAPERbecause campaign (www.paperbecause.com), Domtar Corporation has announced a new series of videos that take a humorous approach to highlight the irreplaceable value of paper.

The 30-second spots mark the third wave of videos in the campaign that showcases the effectiveness and sustainability of paper. While the initial videos featured satirical office settings and exaggerated pressures to go paperless, the four new videos bring that comedy to everyday situations, ranging from a bridal shower to a business lunch.

For example:

- A husband disappoints his wife on their anniversary by choosing to send an e-card instead of a paper card with a handwritten note.

- A woman at a bridal shower receives a hideous vase, but she's relieved once she locates the receipt, showing how paper can make any gift the perfect gift.

- A man using his home computer can't get his new router to work because there are no paper instructions, and he cannot log on to download the PDF.

- A waiter at a restaurant butchers his customers' orders by not writing them down.

The videos will debut in March on the websites of The New York Times, National Geographic and other news outlets. They will also be featured on PAPERbecause.com, Domtar.com, YouTube (www.youtube.com/paperbecause) and Facebook, www.facebook.com/domtarpaper.

"The PAPERbecause campaign has always promoted the responsible use of paper and the need to balance print vs. pixels, and we wanted to illustrate several instances of when paper is the most effective way to communicate on a logical and emotional level," said Paige Goff, Domtar's Vice-President of Sustainable Business and Brand Management. "Our previous office videos reminded people how Domtar has long been a leader in sustainable paper production, but with the new videos, we wanted to focus on everyday life."

Since PAPERbecause debuted in 2010, it has won many awards from the public, the print industry and marketers.

"We've been very pleased with the recognition PAPERbecause has received, and we think it speaks to a bigger point," Goff said. "Even after 2,000 years, there are times when no substitute for paper will suffice."

SOURCE DOMTAR CORPORATION

Domtar Enhances Recyclebank Green Schools Program

Domtar Corporation has announced it is furthering its partnership with Recyclebank® by supporting the Recyclebank Green Schools Program, which awards schools grant money for unique student projects that will make a positive environmental impact on their communities. Domtar will make more students' green projects a reality by contributing additional donation dollars, as well as awarding a year's supply of EarthChoice® Office Paper to the school with the most innovative project. Domtar is committed to providing more sustainable paper options; its EarthChoice Office Paper meets the global forest management standards of the Forest Stewardship Council™ (FSC®) and is certified by the Rainforest Alliance.

Domtar Corporation has announced it is furthering its partnership with Recyclebank® by supporting the Recyclebank Green Schools Program, which awards schools grant money for unique student projects that will make a positive environmental impact on their communities. Domtar will make more students' green projects a reality by contributing additional donation dollars, as well as awarding a year's supply of EarthChoice® Office Paper to the school with the most innovative project. Domtar is committed to providing more sustainable paper options; its EarthChoice Office Paper meets the global forest management standards of the Forest Stewardship Council™ (FSC®) and is certified by the Rainforest Alliance.

Recyclebank is the company that rewards people for taking everyday green actions with discounts and deals from locally-based businesses and national brands. Each year, the Recyclebank Green Schools Program awards environmental project grants to schools in Recyclebank communities. Together, these schools, their students and their communities work to encourage residents to donate points that Recyclebank transfers into real dollars for schools—thereby turning a community's green actions into funds for a local school. Since 2007, Recyclebank has granted close to $400,000 to more than 125 schools. This year, Domtar will award an additional $500 to every school that reaches 50 percent of its donation goal.

"At Domtar, we are passionate about supporting educational projects, like the Recyclebank Green Schools Program, as it is an important part of our company's commitment to the sustainable development of our communities," said Paige Goff, Vice-President of Sustainable Business and Brand Management at Domtar. "By partnering with Recyclebank, we are able to guide more students and consumers to make sustainable choices, which ultimately help to reduce their overall environmental impact."

Since 2011, Domtar has been working with Recyclebank to increase awareness of the benefits of responsible paper production, use and recycling. Past projects for Recyclebank members, sponsored by Domtar, have included educational gaming modules about responsible forestry, seasonal Web content about paper usage and recycling and a rewards offer for EarthChoice Office Paper.

"Since we began the Green Schools Program, it has been inspiring to see the creative and thoughtful approaches from schools across the country in the spirit of solving today's pressing environmental challenges," said Karen Bray, vice president of marketing, community solutions at Recyclebank. "We admireDomtar's ongoing commitment to sustainability, and together we look forward to empowering more of tomorrow's environmental leaders to put their ideas into action and make an impact on our planet."

SOURCE DOMTAR CORPORATION

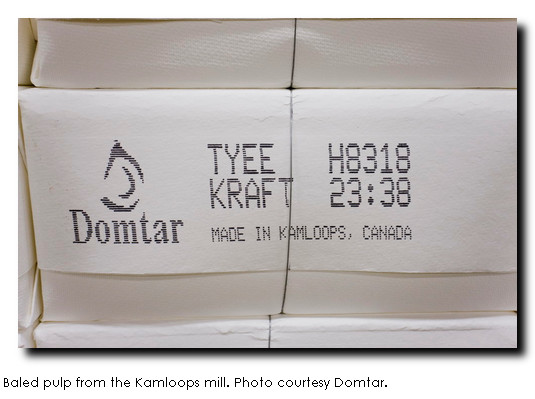

Domtar closes one line at Kamloops

Domtar will permanently shut down one pulp machine at its Kamloops, B.C., facility, putting 125 employees out of work and curtailing Domtar's annual pulp production by approximately 120,000 air-dried metric tons of sawdust softwood pulp.

The pulp machine, known at the mill as the "A-Line", is expected to be closed by the end of March 2013.

“Prevailing economic conditions in the global pulp markets and the deteriorated competitiveness of this small pulp manufacturing line, coupled with unforeseen boiler repair costs, have forced us to rationalize this pulp production capacity. We will focus our energy and resources on optimizing the larger, more competitive, 'B' pulp manufacturing line which will continue to operate," said Mike Edwards, senior vice-president, pulp and paper manufacturing.

Domtar spokesperson Bonnie Skene told the Kamloops Daily News that problems with a key boiler for the A-line were discovered during the fall maintenance shutdown, and were a contributing factor in the closure.

The mill’s B-line has an annual capacity of approximately 350,000 air-dried metric tons of softwood kraft pulp and employ approximately 300 people.

Domtar announces closing of sale of Ottawa/Gatineau hydro assets

Domtar Corporation has confirmed the November 20 closing of its previously announced Definitive Purchase and Sale Agreement ("the agreement") signed by its Canadian subsidiary, Domtar Inc., for the sale of its hydro assets inOttawa, Ontario and Gatineau, Québec. The purchaser is Chaudière Hydro L.P. ("Chaudière Hydro"), the newly-created affiliate of Energy Ottawa Inc.

Domtar Corporation has confirmed the November 20 closing of its previously announced Definitive Purchase and Sale Agreement ("the agreement") signed by its Canadian subsidiary, Domtar Inc., for the sale of its hydro assets inOttawa, Ontario and Gatineau, Québec. The purchaser is Chaudière Hydro L.P. ("Chaudière Hydro"), the newly-created affiliate of Energy Ottawa Inc.

The approximately $46 million transaction, after closing adjustments, includes Domtar's three power stations (21 MW of installed capacity), Domtar's water rights in the area, as well as the company's equity stake in the Chaudière Water Power Inc. (CWPI) ring dam consortium. With the closing of the agreement, the 12 workers currently operating the three power stations become employees of Chaudière Hydro.

SOURCE DOMTAR CORPORATION

Domtar officially launches "The Forest Academy" website

Domtar Corporation has announced the launching of an interactive, educational site The Forest Academy. The tool, introduced a few months ago, has reached a milestone of 25,000 visitors. The Forest Academy builds on Domtar's original youth education website "Tree World" that had been developed in the 1990s. It provides elementary school students with fun, informative games about trees and forest ecology,

"We're thrilled that teachers and parents are finding the new site to be a useful and engaging learning tool," notes Pascal Bossé, Domtar Vice-President Communications and Investor Relations. "We put a lot of effort into creating the site's top quality educational content, but the flash programming of the games is what makes it fun for adults and kids to learn, and what makes The Forest Academy so unique."

In addition to the games, teachers will find a faculty manual with a wealth of information about trees and forest ecology. For more information, please visit http://www.theforestacademy.com.

SOURCE DOMTAR CORPORATION

Domtar Joins International Call to "Follow The Frog"

Domtar will be joining businesses and individuals around the globe to participate in the Rainforest Alliance's second annual Follow the Frog Week that kicks off today, September 17, and runs through September 23.

Domtar will be joining businesses and individuals around the globe to participate in the Rainforest Alliance's second annual Follow the Frog Week that kicks off today, September 17, and runs through September 23.

Follow the Frog Week is an international social media campaign that encourages shoppers to help create a healthier planet by choosing products that feature the Rainforest Alliance Certified™ green frog seal. This trustmark, found on coffee, tea, chocolate, fruit, furniture and paper, is recognized by consumers globally as a symbol of sustainability. Products featuring the seal come from farms and forests that meet a rigorous set of criteria that protect wildlife, soils and waterways and the well-being of workers, families and communities.

"We strive to be the preferred supplier of environmentally sound forest products to our customers, while leaving the smallest environmental footprint and helping them reduce theirs," notes Lewis Fix, Vice-President of Sustainable Business and Brand Management. "And, we're happy to participate in this campaign to promote Rainforest Alliance Certified™ products."

Domtar has worked together with the Rainforest Alliance for many years on responsible paper production and fiber sourcing. In 2005, Domtar and the Rainforest Alliance signed a collaborative agreement when the EarthChoice product line was launched, later renewing the agreement in 2009. Rainforest Alliance applauds the forest management practices that support the Domtar EarthChoice® product family. All Forest Stewardship Council ™ (FSC®) certified Domtar EarthChoice products proudly bear the Rainforest Alliance Certified™ seal.

For more information on Follow the Frog Week please visit: www.rainforest-alliance.org/followthefrog

For more information on Domtar's sustainability commitment and strategy, please visit: http://www.domtar.com/en/sustainability/index.asp

SOURCE DOMTAR CORPORATION