Displaying items by tag: INNVENTIA

Award to Circular textile paper project

Archana Ashok was awarded the Bo Rydin Foundation for Scientific Research grant for Best Master’s Thesis Project 2017. Her project “Textile paper as a circular material” was carried out within the transdisciplinary TechMark Arena master students’ academy at RISE Bioeconomy division.

Bo Rydin Foundation for Scientific Research annually awards a grant for the year's best master's degree project within SCA's strategic areas; personal hygiene products, tissue paper or forest products.

Archana Ashok, KTH, is rewarded for her project “Textile paper as a circular material” which evaluated circularity of a new paper manufacturing concept where the raw material is largely made up of low value fibres from textile recycling plants. According to the circular economy framework, this is a cascade recycling of fibres from the textile industry to the paper industry, forming thus an industrial symbiosis.

Previously, the textile paper material was produced on a pilot scale at RISE and used as the cover of the Global Outlook report A Cellulose-Based Society, demonstrating thus technical feasibility of producing this circular material. Archana's project took the concept to a new level by investigating whether the textile paper is suitable as a circular packaging material for paper bags. In particular, evaluations of technical performance, environmental and economic aspects of the new material as well as market conditions were combined in a multi-dimensional context of circular economy. The result showed that it could be better to use low value textile fibres as a circular material instead of incinerating it, which is a common practice nowadays.

“Archana's project was unique because it was the first time that we both evaluated and quantified the circularity of a new material by applying circular economy framework. Both research and industry actors will be able to use her results as a guideline and inspiration in evaluating their materials and products,” says Tatjana Karpenja, one of the supervisors at RISE.

“The 6 months journey at RISE was really exciting and fun-filled with the TechMark Arena group having lots of discussions and workshops on circular economy,” says Archana Ashok.

This is the second time in three years this prize goes to a student at TechMark Arena. This transdisciplinary academy brings together master students from various backgrounds in order to work on a common theme. This arrangement encourages a broader approach to a topic and ensures a greater exchange of ideas between students and increased knowledge sharing between different projects. Archana’s supervising team involved Tatjana Karpenja, Marie-Claude Béland, Karin Edström, Hjalmar Granberg and Ida Kulander.

Another project from TechMark Arena 2017 was nominated for the award. Emma Dahlgren at Linköping University with her project “Exploring biodegradable electronics”, aimed at an innovative area, using cellulose substrates for electronics, which would bring both environmental benefits and cost advantages. This research field is an expanding research area currently being explored within RISE.

For more information, please contact Tatjana Karpenja, +46 768767026, This email address is being protected from spambots. You need JavaScript enabled to view it.

For information about the textile paper, see http://www.innventia.com/en/About-us/News1/New-circular-material-with-industrial-symbiosis-in-focus/

Research efforts to ensure more energy-efficient papermaking

The Swedish Energy Agency has recently awarded a grant of MSEK 11 to develop and demonstrate new dewatering processes for papermaking that can eventually be scaled up. Innventia is coordinating the three-year project that is now gathering momentum.

The project aims to develop and demonstrate new, more energy-efficient process solutions on a pilot scale, which it is thought could be implemented industrially within five years. In the case of tissue production and papermaking, energy consumption during the drying stage accounts for a significant portion of total energy needs. Thus, there is immense scope for energy efficiency if dewatering processes, such as wet pressing, and drying can be improved. In the case of thickening, the focus is on using centrifugation. Improved dewatering and drying is expected to be achieved by operating at a significantly higher dewatering temperature, and using a combination of IR-drying, steel belts and conventional drying.

The project includes both fundamental laboratory studies and pilot-scale trials. Industrial case studies will then be used to quantify the energy savings, which can be used as decision-making data for a potential industrial implementation.

“Innventia has developed a number of new fibre-based reinforcing additives that have shown immense potential in terms of improving the efficiency of tissue, paper, and board production. The industrial implementation of these additives give rise to a number of challenges, mainly due to a lack of efficient dewatering processes adapted for the new additives. These additives normally have a high water content, and removing the water can be an extremely tricky process, which is why new process solutions are needed in this area,” says project manager Eva Ålander.

Five companies are participating in the project: Valmet, Sandvik, Ircon Drying Systems, Albany International and Alfa Laval. The research results are expected to have a big impact on future dewatering and drying processes used in tissue production and papermaking. The project content is based on Innventia’s work within the fields of stock design, nanocellulose, tissue, and papermaking. Much of the work will involve Innventia’s FEX pilot paper machine.

‘A Cellulose-Based Society’ generates three new research projects

The ‘Cellulose Fibre materials’, ‘Cellulose for the Future’ and ‘Paper mill for textile recycling in the circular economy framework’ research projects have recently been launched as a direct result of Innventia’s ‘A Cellulose-Based Society’ project. The preliminary studies from these projects will result in, among other things, proposals for our next research programme, which starts in January 2018.

Back in spring, Innventia launched its third Global Outlook Report ‘A Cellulose-Based Society’, which surveyed people’s attitudes to materials that we all use in our everyday lives and described trends and driving forces that are pushing us towards a more sustainable future. The three projects are the results of the needs inventory and research campaign that were organised within the framework of ‘A Cellulose-Based Society’.

The three projects in brief:

Elisabeth Sjöholm, project manager, what is ‘Cellulose Fibre materials (CelFi)’ about?

Elisabeth Sjöholm, project manager, what is ‘Cellulose Fibre materials (CelFi)’ about?

It focuses on scaling up All-cellulose composites (ACC) – a hot-pressed, high-density cellulose material. An increased understanding of the properties of ACC material and the scope for upscaling also provides us with important knowledge for continued development of other types of hot-pressed cellulose-based materials, such as hybrid laminate consisting of a core containing cellulose and a metal skin. Potential applications include modern materials for buildings and cities.

Katarina Ohlsson, project manager, what is ‘Cellulose for the Future (CelFu)’ about?

Katarina Ohlsson, project manager, what is ‘Cellulose for the Future (CelFu)’ about?

One of the challenges of research into cellulose is that the amount of new materials is often limited. This project will facilitate, in various ways, the creation of technology and a knowledge platform for research and upscaling for separation of fibres and wood components within the 1-10 kg range. The focus will also be on establishing cooperation and partnerships with academic research groups.

Tatjana Karpenja, project manager, what is ‘Paper mill for textile recycling in the circular economy framework (Circular Fibres)’ about?

Tatjana Karpenja, project manager, what is ‘Paper mill for textile recycling in the circular economy framework (Circular Fibres)’ about?

The project is evaluating the techno-economic and sustainability performance of a new concept for paper production. The work focuses on new paper materials where a significant proportion of the fibre raw material consists of low-grade fibres from textile recycling plants. During pilot testing at Innventia, we previously proved that it is technically possible to manufacture paper with attractive material properties from just such raw materials. Based on the framework for a circular economy, this involves so-called ‘cascade recycling’ of fibres from the textile industry to the paper industry. You can experience the new paper in the cover of the ‘A Cellulose-Based Society’ report, which is Innventia’s demonstrator of potential applications for this exciting new material.

Swedes most positive about new products from forest resources

In an international comparison, Swedes stand out as the most positive about a more cellulose-based society, a transition that is necessary for a sustainable future. From an international perspective, however, this development appears to provoke strongly polarized reactions. The view of the forest and its role in our society touches us, and awakens strong feelings around the world. This is revealed in the report Innventia is presenting today. In the report, 2,500 consumers from five countries have had their say on how best to arrive at a more sustainable and circular society.

In the report "A Cellulose-Based Society", Innventia focuses on the conditions for a vital social transformation - from a fossil-based and linear society to a biobased and circular society. In cooperation with Kairos Future, 2,500 consumers from Sweden, the United States, China, Germany and Brazil were asked about their thoughts and attitudes to sustainability, the environment, materials and impact.

Overall, there is a huge desire among consumers to shop in an environmentally responsible way. And it is through their consumption and lifestyle choices that people see the best opportunity for directly impacting on the development. Another view that unites all countries is that "creating more effective material recycling systems" is highlighted as by far the best measure for making the world more sustainable; this is in competition with eleven other measures such as "Tax CO2 emissions harder", "Invest in new energy sources", "Ban environmentally harmful substances in products" or "Tax travel and transportation harder".

"At Innventia, we are working for a biobased, circular economy based on materials from the forest," explains Birgitta Sundblad, President of Innventia. "Cellulose has a number of applications, from paper and packaging to modern materials in our buildings and cities. When the natural building block of cellulose is used in the service of people, things start to get really interesting: cosmetics, food, clothing and medicines are just some of the opportunities we see. This is what we call A Cellulose-Based Society."

A future in which the forest becomes a more important resource in the manufacture of materials and products seems to be strongly polarizing. The view of the forest and its role in our communities touches us, and awakens strong feelings, and the differences between countries are huge. In Sweden, a large majority are positive about such a development. Even in the USA, positive reactions are in the majority, but in Germany, Brazil and China about half of those surveyed are more critical and concerned about what a move towards a more cellulose-based society would mean.

"The industry is facing a significant communicative challenge," says Birgitta. "Consumers want to understand the significance of the bioeconomy and do the right thing, but those of us who develop and produce new biobased solutions need to get better at both explaining how they affect the planet and communicating the sustainability aspects."

"The consumer survey clearly shows that we are aware that our lifestyle is affecting the planet. But we are unsure about what exactly we should do about it. The survey and trends show overall that the really successful brands and organisations will be those with the ability to actually demonstrate ground-breaking ideas and concepts in reality for consumers. The attitude to what is possible and desirable will then change. We call this the Demonstration Economy and understanding this is the key to social transformation," says Marco Lucisano, Innventia.

For more information, contact Marco Lucisano, +46 (0)768-767 285, This email address is being protected from spambots. You need JavaScript enabled to view it.

A brief summary of the report can be downloaded at: www.acellulosebasedsociety.com

The report in figures

- 62% of Swedes say they are positive about development towards a more cellulose-based society. 31% say they are upset, angry or worried.

- A clear majority in all countries believe that consumers themselves have the greatest responsibility for the environment through their consumption and lifestyle choices.

- People in Brazil are most concerned about environmental issues (76%). Sweden is least concerned about this on an international comparison (26%)

- Swedish consumers are in third place on the question of buying environmentally friendly alternatives. At the top come China (48%), Brazil (46%), Sweden (21%).

- Consumers in Brazil have the worst consciences (41%) when they don't shop in an environmentally-friendly way (China 34%, USA 17%, Sweden 14%, Germany 4%).

- 51% of Swedes say that the material played a role in their latest purchase (China, with 80%, followed by Brazil, with 74%, rank even higher).

- The material that consumers in all countries say they want to avoid most is plastic. Most valued are natural materials such as wood and wool.

About the report

The Global Outlook 2016 report contains an international survey, a global analysis and future scenarios. The survey was distributed digitally at the start of 2016 to 2,500 people between the ages of 16 and 88 in five countries (500 respondents per country in Sweden, Germany, the United States, Brazil and China).

About Innventia

Innventia is a world-leading research institute that works with innovations based on forest raw materials. Our business concept is to generate and refine research findings and ideas based on forest raw materials for the benefit of customers throughout the value chain. We call this approach boosting business with science. Read more about us at www.innventia.com

About Kairos Future

Kairos Future is an international consulting and research company that helps businesses and organisations to understand and shape their futures. We provide our customers with the big picture using trend and business intelligence analyses, innovation and strategy. Read more about us at www.kairosfuture.com

How do we want to make the world more sustainable?

How do consumers want to get a more sustainable world? What sacrifices, measures and opportunities do we see, today and in the long term? How do we feel about a transformation in which raw materials from the forest are used to manufacture new products? A new report from Innventia investigates the actual conditions for a more circular and biobased society. 2,500 consumers from five countries have had their say on how we can best make the world more sustainable.

Innventia's latest report, Innventia Global Outlook: A Cellulose-Based Society, investigates the conditions for a transition to a circular and biobased society. What global changes, future opportunities and constraints do we have to deal with? How do the views of consumers differ in different parts of the world? How do we best accept responsibility for the development we see before us? This is Innventia's third report in a series of forward-looking reports that have gained a lot of international attention.

Innventia's latest report, Innventia Global Outlook: A Cellulose-Based Society, investigates the conditions for a transition to a circular and biobased society. What global changes, future opportunities and constraints do we have to deal with? How do the views of consumers differ in different parts of the world? How do we best accept responsibility for the development we see before us? This is Innventia's third report in a series of forward-looking reports that have gained a lot of international attention.

Together with Kairos Future, Innventia has completed a consumer study in Sweden, Germany, the United States, Brazil and China. 2,500 consumers were asked about sustainability, the environment, lifestyles and impact. The report reveals several surprising results regarding where consumers really are, in thought and deed, prior to a switch to a more circular and sustainable society.

The key insights from the report will be presented on 24 May, when representatives of Innventia and Kairos Future will be on hand.

Time: 16:30-18:00, 24 May 2016

Venue: International Wood Biorefining Week, Stockholmsmässan, Mässvägen 1, Älvsjö

To register and for more information, contact Marco Lucisano:

+46 (0)768-7 67 285, This email address is being protected from spambots. You need JavaScript enabled to view it..

ABOUT THE REPORT

The report, A Cellulose-Based Society, comprises an international survey, a global analysis and future scenarios. The survey was distributed digitally at the start of 2016 to 2,500 people between the ages of 16 and 88 in five countries (500 respondents per country in Sweden, Germany, the United States, Brazil and China).

ABOUT INNVENTIA

Innventia is a world-leading research institute that works with innovations based on forest raw materials. Our business concept is to generate and refine research findings and ideas based on forest raw materials for the benefit of customers throughout the value chain. We call this approach Boosting Business with Science. Read more about us at www.innventia.se

ABOUT KAIROS FUTURE

Kairos Future is an international consulting and research company that helps businesses and organisations to understand and shape their futures. We provide our customers with the big picture using trend and business intelligence analyses. The company was founded in 1993. It has its head office in Stockholm and has representatives and partners around the globe. Read more about us at www.kairosfuture.com

New biobased packaging, sustainable textiles and second generation biorefineries

Innventia is involved in three new European projects aiming for innovative solutions for a future bioeconomy. PULPACKTION will develop packaging solutions for specific food and electronic packaging applications. The objective for NeoCel is to processes enabling the sustainable production of textile fibres and the BIOSKOH project will showcase how a number of Innovation Stepping Stones can realise a breakthrough in techno-economic viability of lignocellulosic biorefineries. The three projects are all partially financed by BBI JU, a partnership between EU and the Bio-based Industries Consortium.

Today, products with medium and high barrier requirements such as specific food and electronic packaging applications are packed in polymer fossil based solutions. The new PULPACKTION project will develop 100% bio-based integral packaging solutions with similar properties to existing fossil-based solutions. This will be achieved by using wet-moulding production of wood pulp mixed with other bio-based compounds in order to tailor the properties of the final material. To fulfil the fully bio-based approach, new barriers of optimised biopolymers will be implemented onto the wet moulded substrate. PULPACKTION involves 13 partners and is coordinated by Rottneros Packaging. Innventia will be responsible for the activities regarding consumer insight and play an active role in the development, production and evaluation of new fibre formulations. Furthermore, Innventia will participate in investigating the performance of developed fibre formulations in pilot scale trials as well as sustainability evaluations of produced materials and concepts.

For information, contact This email address is being protected from spambots. You need JavaScript enabled to view it.

The driving force for the NeoCel project is the growing need for textiles produced from sustainable resources using environmentally friendly processes. The main objective is to develop innovative and techno-economically feasible alkaline processes which could be integrated with pulp mills. This will enable the sustainable production of higher quality eco-innovative textile fibres from reactive high-cellulose pulps. A consortium of 15 partners representing the whole chain from cellulose raw material to cellulose garments has been formed. Innventia with well renowned skills in pulping technology, chemical recovery/regeneration, advanced fibre characterisation and techno-economic evaluation plays an active part in most work packages. The consortium, coordinated by SP Technical Research Institute of Sweden, expects that a successful project will enable creation of 75,000 new jobs and a turn-over increase of Euro 9.5 billion for European forest products, textile and clothing industries within 15 years.

For information, contact This email address is being protected from spambots. You need JavaScript enabled to view it.

The BIOSKOH project will pave the way for a European bioeconomy by showcasing how a number of innovation stepping stones, such as yield, biomass cost, brownfield and industrial symbiosis, can realise a breakthrough in techno-economic viability of lignocellulosic biorefineries. The overall aim is to realise the largest second generation biorefinery in Europe and the first step is a flagship plant that will produce 55 kton of cellulosic ethanol per year for EU bio-fuel mandates. This will be built on a brownfield industrial site in the eastern part of the Slovak Republic. The BIOSKOH consortium is coordinated by Energochemica and involves 11 partners from 7 European countries. Partners include the full value chain starting from land owners and feedstock producers. Innventia is involved in lignin valorisation which is an important part in building the commercial concept.

For information, contact This email address is being protected from spambots. You need JavaScript enabled to view it.

New organisation at Innventia

On 4 April, 2016, Innventia launched a new organisation. The mobilisation is being undertaken so that we are better equipped for the opportunities and challenges that we will be encountering in the bioeconomy of the future.

The operation is being organised in two new business areas, Biorefinery & Biobased Materials under the direction of Catharina Ottestam and Papermaking & Packaging, under Marco Lucisano. At the same time a function is being established with specific responsibility for bioeconomic strategy through Peter Axegård.

Based on Innventia's well renowned competence in cellulose science, the Biorefinery & Biobased Materials business area links together all the skills required for producing substances that can be put together into functional materials and chemicals. This can involve new markets and new applications which will contribute to a growing bioeconomy.

Within the Papermaking & Packaging business area we have now linked together the value chain from material, via production technology to application and use. It also fits well with the growing need for demonstration to enable up-scaling and industrial implementation.

"The new organisation will give us better opportunities to meet the challenges of the industry. It also harmonises with the strategies for a stronger Swedish institute sector through RISE Research Institutes of Sweden," says Birgitta Sundblad, President of Innventia.

For more information, please contact:

Birgitta Sundblad, telephone +46 (0)768-767325, This email address is being protected from spambots. You need JavaScript enabled to view it.

Prize for Innventia's Ali Naderi for nanocellulose research

Ali Naderi at Innventia has been awarded this year's Kompetensutvecklingspris (Skills Prize) from the Gunnar Sundblad Research Foundation. The prize of SEK 500,000 is for development of methods for studies of nanocellulose-based materials.

Ali Naderi is a senior researcher within the Paper Chemistry and Nanocellulose group at Innventia. Nanocelluloses are exceptionally strong materials, putting them in the same class as Kevlar. However, in contrast to Kevlar and other materials based on fossil raw materials, nanocelluloses are produced from abundant renewable materials such as wood. The research and development into various nanocellulose-based applications took off in earnest five years ago when Innventia started the world's first pilot facility for production of nanofibrillated cellulose (NFC), a form of nanocellulose produced through the delamination of cellulose fibres. The use of NFC for the production of electrically conductive paper materials, barrier materials in packaging or as reinforcement in paper, cardboard and composite materials is now being studied.

This prize makes it possible for Ali Naderi to spend five months at Stony Brook University in New York. Along with Professor Benjamin S. Hsiao, an authority in employing X-ray scattering for the characterising of materials, develop methodologies for the study of NFC-based systems. It is envisaged that the methodologies will lead to a better understanding of the modes of interaction of NFC with varying materials.

"It's really exciting! I have been given the opportunity to learn an analysis method that may be of huge value to Innventia's research activities," says Ali Naderi.

"Advanced analysis is important in order to get the full potential of nanocellulose. This allows the new CNF-based materials to seriously compete by their unique properties, says Anna Wiberg, Research Manager in Paper Chemistry and Nanocellulose at Innventia.

The prize will be awarded by His Majesty King Carl XVI Gustaf of Sweden on 12 April during Skogsnäringsveckan (Forestry Week) in Stockholm. For more information, visit www.forestindustries.se/.

For more information, please contact:

Ali Naderi, telephone +46 (0)768-767321, This email address is being protected from spambots. You need JavaScript enabled to view it.

Anna Wiberg, telephone +46 (0)768-767361, This email address is being protected from spambots. You need JavaScript enabled to view it.

About the prize

The Gunnar Sundblad Research Foundation's Skills Prize has been awarded annually since 2007. The prize aims to promote the development of the Swedish pulp and paper industry towards new and improved products and services that can meet today's increasingly tough competition. The prize enables a researcher from the Swedish research and innovation system to work at a foreign research environment in order to develop, make contacts and bring home new knowledge. The Gunnar Sundblad Research Foundation Board is appointed by the Swedish Forest Industries Federation Board.

Improved thermographic process analysis and characterisation of fines and fillers

Kari Hyll at Innventia defended the doctoral thesis: "Image-based quantitative infrared analysis and microparticle characterisation for pulp and paper applications" on 12 February. The project involves how to improve thermographic process analysis and characterisation of fines and fillers.

Using image-based measurement methods we are able to both analyse a greater proportion of the paper web on the machine and obtain morphological information about the particles in the stock. When it comes to measurements of the paper web, there are many benefits of using infrared thermography, which gives a temperature image of the web. However, to obtain accurate measurement values using this technology, a material property known as emittance must be known.

In the doctoral thesis work, Kari Hyll measured the emittance of fibre-based samples and investigated how it is affected by various factors that are relevant at a mill, e.g. moisture and temperature. One application was implemented where accurate temperature measurement values are essential, namely calculation of thermal energy during deformation of paper. When it comes to measuring the particles in a stock, fibre analysers have not been able to detect many fines and filler particles due to a limited image resolution.

"I have evaluated new instruments with better resolution and shown that they enable us to obtain new information about fines and filler. I have also devised and evaluated a method for differentiating between fines and filler in a mixture, something that no current instrument can do," says Kari.

The conclusion presented by Kari in their thesis is that thermographic applications requiring more exact measurement values can now be employed, fines and fillers can be measured with better resolution and a potential method for distinguishing between fines and fillers has been developed.

Kari's supervisors are Lars Mattsson, Production Engineering, KTH Royal Institute of Technology, and Hannes Vomhoff, Research Manager at Innventia.

"Evaluation and implementation of new measuring methods is a central element of Innventia's research activities, and consequently we will derive great benefit from Kari's results. For example, they will facilitate quantitative analysis of process variations with the aid of thermography. In the future we plan to link the analysis directly to the quality control system on a board machine," says Hannes Vomhoff.

The work has primarily been carried out at Innventia, in collaboration with KTH Production Engineering, which is the department that Kari has been associated with.

For more information, please contact:

Hannes Vomhoff, Innventia, +46 (0) 8 676 74 88, This email address is being protected from spambots. You need JavaScript enabled to view it.

LignoCity – a new centre for new green technologies

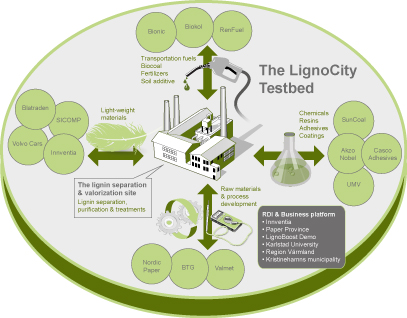

Innventia, Nordic Paper and Paper Province have started a collaboration to develop the future forest-based bioeconomy. The first step is to establish an open test bed called LignoCity. Here, companies can develop and scale up technology that refines lignin to new climate-friendly fuels, chemicals and materials.

LignoCity – a new centre for new green technologies

As the world heads towards a bio-based economy, lignin – a by-product of pulp production – is increasingly seen as a raw material with great potential. Lignin could be a green alternative for producing fuels and energy as well as chemicals and lightweight materials. Great efforts are being made to develop processes and to refine different lignin qualities for different applications.

Thanks to a broad newly established collaboration initiated by Innventia, Nordic Paper and Paper Province, several of these initiatives can now be realised. With financial support mainly from VINNOVA, Innventia’s demonstration plant in Bäckhammar will be further developed and made into an open test bed for companies who want to evaluate and validate new refining concepts in the lignin area. The plant is currently the only one in the world that can produce tailor-made lignin qualities in sufficient quantities for upscaling. The purpose of LignoCity is to create a centre where ideas are brought together and opportunities for commercial development are identified and supported. Lignin from kraft pulp production and other sources, for example from ethanol and sugar production, can be processed at the plant. The project involves 18 industrial and public players, including Karlstad University, the municipality of Kristinehamn and Casco Adhesives AB.

“With LignoCity, we are bringing together business models, technological development and infrastructure for research, development and innovation. In the long term, we also hope to be able to extract other components from the black liquor and tackle other process streams,” says Per Tomani, manager for the LignoCity project and the Lignin & Carbon Fibres focus area manager at Innventia.

“It is extremely valuable for the region’s businesses to have access to this type of open test facility, so that we can continue the development of a forest-based bioeconomy,” says Maria Hollander, CEO of Paper Province.

Kristinehamn is aiming high when it comes to innovations concerning new green fuels. Our goal is to profile ourselves as a municipality with a viable and creative business, where we carry on our technical traditions by creating future innovation. Efforts like LignoCity can help creating jobs and we are proud that the municipality contributes to this, says Carina Welin, Information manager.

Innventia established the demonstration plant in 2006 in order to demonstrate the LignoBoost process. This technology, which today is owned by Valmet and installed at pulp mills in the United States and Finland, was developed in collaboration between Innventia and Chalmers. Thanks to LignoBoost, it is possible to obtain a lignin that is so clean it can be used as a raw material for carbon fibre. Innventia runs a number of research projects in this area, and has built up an infrastructure for testing and demonstration in collaboration with the research institute Swerea SICOMP.

In addition to Innventia, Nordic Paper and Paper Province, the following organisations are involved in LignoCity: Akzo Nobel Bygglim AB, Region Värmland, Biokol Sverige AB, LignoBoost Demo AB, Blatraden AB, BTG Instruments AB, Bionic Group of Companies, Ren Fuel K2B AB, SunCoal Industries GmbH, Swerea, UMV Coating Systems AB, Valmet Power AB and Volvo Cars. More companies are welcome to join the venture.