Displaying items by tag: emerson

Emerson Named ‘Industrial IoT Company of the Year’

Award recognises Emerson’s software and technology innovation helping global companies achieve optimal performance

Global technology and software leader Emerson (NYSE: EMR) has been named IoT Breakthrough ‘Industrial IoT Company of the Year’ for the sixth time. The 2024 award recognises Emerson’s advances in sustainability-enabling technologies and software, efforts to accelerate the development and delivery of life-saving drugs, and the company’s industry-leading Boundless Automation™ vision of a next-generation, software-defined industrial automation architecture.

“Emerson’s culture of innovation and extensive automation portfolio are addressing the most urgent challenges of our time: a shrinking experienced industrial workforce, the low-carbon energy transition and the ever-evolving search for new drug treatments,” said Lal Karsanbhai, president and chief executive officer of Emerson. “We are honoured to receive this award that recognises the value Emerson delivers to help customers in so many critical industries achieve their maximum performance.”

Emerson is using its decades of automation expertise to help some of the largest companies in the world meet their sustainability goals. The company’s recent advances in this space include its Ovation™ Green portfolio of renewable power solutions to decarbonise, reduce emissions and seamlessly add more renewable energy to power grids, and Floor to Cloud™ solutions that continuously monitor and visualise critical production data to improve energy efficiencies in factories.

Emerson is using its decades of automation expertise to help some of the largest companies in the world meet their sustainability goals. The company’s recent advances in this space include its Ovation™ Green portfolio of renewable power solutions to decarbonise, reduce emissions and seamlessly add more renewable energy to power grids, and Floor to Cloud™ solutions that continuously monitor and visualise critical production data to improve energy efficiencies in factories.

The award also recognises Emerson’s leadership in developing digital technologies aimed at accelerating drug development. The company recently announced One-Click Technology Transfer™ software that will convert today’s life sciences manufacturing recipe transfer process into a digitalised production platform, helping get new drug therapies to patients faster.

This year, Emerson announced the first of a series of new technology releases that build upon its Boundless Automation vision and serve as the foundation of its next-generation, software-centric automation platform. The new DeltaV™ Edge Environment moves data securely and seamlessly between the intelligent field, the edge and the cloud without losing operational context, enabling greater access to data and faster decision-making.

“Emerson is a consistent winner of our Industrial IoT Company of the Year award because of how effectively it leverages its decades of expertise in digitalisation and automation to help industry leaders transform their operations to address the needs of the future,” said Steve Johansson, managing director at IoT Breakthrough. “We congratulate the Emerson team for taking home our ‘Industrial IoT Company of the Year’ award in the eighth annual IoT Breakthrough Awards programme.”

IoT Breakthrough, which recognises the excellence, creativity and success of Internet of Things (IoT) companies, technologies and products, received more than 4,300 nominations for the 2024 competition. The awards honour the world’s best companies, leaders, technologies and products in a range of IoT categories — from industrial and enterprise, to consumer and connected home. Winners are selected by a panel of senior-level professionals experienced in the IoT space, including journalists, analysts and technology executives.

For more information on Emerson’s automation solutions, please visit Emerson.com.

Emerson’s New Engineering Software Accelerates Plant Modernisation Using Artificial Intelligence

REVAMP simplifies and speeds transition to a modern automation architecture, reducing capital costs by up to 15%

Global technology and software leader Emerson (NYSE: EMR) is helping customers more quickly and efficiently transition legacy technology to modern DeltaV™ automation architecture that modernises and digitises operations. Emerson’s REVAMP advanced software solution uses cloud computing and artificial intelligence (AI) to automate up to 70% of system configuration, reduce errors and manual conversion work, and slash capital costs by up to 15%.

“Modernisation projects too often surprise teams late in the process with cumbersome, unanticipated work and errors from manual conversion,” said Claudio Fayad, vice president of technology for Emerson’s process systems and solutions business. “Emerson’s REVAMP helps project engineering teams modernise their systems more easily, on time and within budget, while also minimising errors and disruptions to production.”

Organisations seeking to modernise control and safety systems often start with decades-old code that must be transitioned to current software. Manually converting and documenting this code is an arduous process that dramatically increases the time and capital requirements for these projects.

REVAMP is a groundbreaking, cloud-based, advanced software solution that manages the transition of legacy applications to optimal control.

REVAMP is a groundbreaking, cloud-based, advanced software solution that manages the transition of legacy applications to optimal control.

Emerson’s REVAMP advanced software combines an extensive knowledge base from similar modernisation projects with Emerson’s experience library to develop continuously updating AI models. Each modernised control system feeds back into the REVAMP software, creating learning algorithms that perpetually get smarter and faster at converting legacy code.

The applied AI in REVAMP informs project teams of the engineering requirements before migration projects even begin, making planning easy. The AI engine analyses native files from the existing distributed control systems, safety instrumented systems or programmable logic controller back-ups while using a global library of thousands of successful projects to sort, select and automate engineering tasks. The modernisation project is automatically fully documented, and significant portions can be generated in the DeltaV control system, enabling the latest capabilities and using modern standards.

Emerson project teams around the world have access to the most recent functionalities and libraries of this secure, cloud-native tool. And with embedded machine learning, the libraries grow and improve as projects become more efficient over time.

Learn more at Emerson.com/revamp.

About Emerson

Emerson (NYSE: EMR) is a global technology and software company providing innovative solutions for the world’s essential industries. Through its leading automation portfolio, including its majority stake in AspenTech, Emerson helps hybrid, process and discrete manufacturers optimise operations, protect personnel, reduce emissions and achieve their sustainability goals. For more information, visit Emerson.com.

Emerson Presents Software and Solutions To Help Manufacturers Achieve Sustainability and Business Performance Goals

European events outline how advanced automation software drives digital transformation of operations

Emerson is hosting a series of Innovation Days to provide process industry and manufacturing companies with valuable insights into how advanced automation software solutions can help maximise environmental sustainability and business performance. The free of charge events, being held across Europe throughout 2022, will demonstrate how the latest industrial software and systems can drive the digital transformation of operations, leading to increased operational efficiency, uptime, safety and profitability.

The Innovation Days feature a broad range of presentations from industry experts addressing the use of advanced diagnostics to monitor the health and performance of instrumentation and control technology, simple ways of transforming data into actionable insights, analysing the efficiency of machines, the use of cloud-based SCADA to monitor remote assets, improving reliability and safety through corrosion and erosion monitoring, and leveraging machine learning technology to optimise plant control and increase production.

Emerson’s in-person Innovation Days will showcase how advanced software solutions can help achieve increased sustainability and business performance.

Emerson’s in-person Innovation Days will showcase how advanced software solutions can help achieve increased sustainability and business performance.

“Through our extensive portfolio of innovative software solutions, Emerson is able to generate business value by implementing data management, monitoring and control architectures that provide actionable insights, leading to wide-ranging operational improvements,” said John Nita, president of Emerson’s Automation Solutions business in Europe. “The Innovation Days will demonstrate how harnessing software-based technology and digitally transforming operations can help organisations achieve their business and sustainability targets.”

The Innovation Days will feature interactive hands-on demonstrations that show how to improve visibility to key operational data and prioritise the most critical information for improved operations. Delegates will be able to explore pervasive sensing technologies in a 3D virtual plant tour. There will also be opportunities for them to share their experiences, network with their peers and discuss their specific application challenges. The Innovation Days are aimed at management, project and operations personnel, engineers, and maintenance specialists. The events will be held in more than 20 different countries and presented in the local language.

There will be Innovation Days held in the UK and Ireland from June 7th to 23rd. For further details, a complete calendar of events and pre-registration, visit Emerson.com/InnovationDay.

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial and residential markets. Our Automation Solutions business helps process, hybrid and discrete manufacturers maximise production, protect personnel and the environment while optimising their energy and operating costs. Our Commercial & Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency and create sustainable infrastructure. For more information visit Emerson.com.

Radar technology overcomes the toughest level measurement challenges

The severe operating conditions commonly encountered in pulp mills can prove challenging for level measurement instrumentation. Ingemar Serneby, of Emerson Automation Solutions, explains how the latest non-contacting radar transmitters meet these challenges and provide an accurate and reliable solution.

The various stages of the pulp production process involve a broad range of applications in which accurate and reliable level measurements are essential. These measurements play a crucial role in reducing chemical use, product variability and energy costs; optimising production and storage efficiency; and increasing plant and worker safety. However, the severe operating conditions commonly encountered in pulp mills can prove challenging for most level measurement technologies. Common measurement challenges include turbulence, foaming surfaces, corrosive chemicals, condensation, viscous materials, density and pressure variability, high temperatures, dust generation, and media with a low dielectric constant. It is therefore essential for companies to select instrumentation that can best overcome these challenges to provide the high degree of level measurement certainty they require.

Measurement technologies

Various technologies can be employed to monitor and measure the level of fluids and solids. The most basic method is the manual process of viewing the medium through a sight glass. Other traditional techniques include electro-mechanical devices such as floats and displacer switches, capacitance point level switches, ultrasonic technology, differential pressure sensors, laser-based devices and load cells. In pulp mills, however, these methods are increasingly being replaced by modern electronic technologies such as vibrating fork level switches, guided wave radar (GWR) transmitters, non-contacting radar transmitters and acoustic scanners. These advanced devices provide enhanced functionality and increased diagnostics capability, leading to improved measurement accuracy and repeatability, reduced maintenance requirements and lifecycle costs, and greater reliability.

Södra Cell mill, in Värö, Sweden, solved two demanding level measurement challenges by installing advanced non-contacting radar transmitters from Emerson.

Södra Cell mill, in Värö, Sweden, solved two demanding level measurement challenges by installing advanced non-contacting radar transmitters from Emerson.

Non-contacting radar

Non-contacting radar technology provides a top-down, direct measurement of the distance to the surface, which is highly accurate and reliable and can be used with liquids, sludges, slurries and some solids. With built-in diagnostics, a lack of moving parts, and straightforward installation and commissioning, non-contact radar transmitters provide both ease-of-use and low maintenance requirements.

To perform continuous level measurements, non-contacting radar transmitters use one of two main modulation techniques – either pulse or frequency modulated continuous wave (FMCW). In pulse systems, thousands of short radar pulses are emitted from an antenna positioned at the tank top directly towards the material below. These pulses are reflected back to the transmitter from the material’s surface. The transmitter measures the time delay between the transmitted and received echo signal, and an onboard microprocessor calculates the distance to the material’s surface, and consequently the level measurement.

Transmitters using FMCW technology transmit a radar signal with increasing frequency over time to create a signal sweep. The signal echo reflected from the surface is picked up by the antenna. Because the frequency of the transmitted signal constantly varies, the echo frequency always differs slightly from the transmitted signal at any given moment. The difference between these frequencies is directly proportional to the distance from the transmitter to the surface, thereby enabling the level to be measured.

Radar transmitters based on FMCW technology have more than 30 times higher sensitivity than devices using pulsed technology, which maximises their signal strength and enables them to deliver greater measurement accuracy and reliability. As a result, they are regarded as the most stable measurement technique available, and are becoming widely adopted throughout the manufacturing and process industries.

A Rosemount 5408 Non-Contacting Radar Level Transmitter installed on the lime silo.However, FMCW technology has traditionally used more electrical energy than pulse and has thus been deployed only within four-wire radar transmitters. Installing four-wire devices can involve implementing additional cable infrastructure, which is costly and time-consuming, thus limiting the applications in which FMCW transmitters have been used. However, the improved energy efficiency of the latest FMCW devices allows power and communication to be provided by two wires, which eliminates the need for extra infrastructure, enables quick installation and reduces costs.

A Rosemount 5408 Non-Contacting Radar Level Transmitter installed on the lime silo.However, FMCW technology has traditionally used more electrical energy than pulse and has thus been deployed only within four-wire radar transmitters. Installing four-wire devices can involve implementing additional cable infrastructure, which is costly and time-consuming, thus limiting the applications in which FMCW transmitters have been used. However, the improved energy efficiency of the latest FMCW devices allows power and communication to be provided by two wires, which eliminates the need for extra infrastructure, enables quick installation and reduces costs.

Although level measurement technology selection is very much application-dependent, non-contacting radar transmitters provide a broad range of important benefits that enable them to meet many of the toughest challenges presented during pulp production.

Turbulence and foaming

In mixing and blending applications in pulp mills, surface turbulence and foaming liquids are among the most common challenges that level measurement instrumentation needs to overcome. Heavy turbulence or a large amount of foam can affect the signal strength of non-contacting radar transmitters. However, recent advancements in this technology include dedicated software algorithms that counteract the effects of turbulence and surface foaming. Alternatively, devices can operate in bypass chambers or stilling wells to negate these problems.

Corrosive media and condensation

The chemicals commonly used in pulp mills present another challenge for level measurement instrumentation, and devices must be designed to cope with this type of aggressive media. The latest non-contacting radar devices overcome this challenge by incorporating an all-PTFE process seal antenna, engineered specifically to maximise resistance to corrosive chemicals and high condensation levels.

Coating, viscosity and dirty antennas

Pulp applications can involve fluids that coat or stick to some level measurement instruments, but non-contacting radar transmitters are unaffected by coating and viscosity since they do not come into contact with the process media. However, a device’s antenna can become dirty and this can affect its performance. The latest radar transmitters can detect a dirty antenna via signal quality metric diagnostics. This enables preventative maintenance to be scheduled, thereby avoiding process upsets or shutdowns, reducing costs, and increasing reliability, safety and efficiency.

Density, temperature and pressure

In the reactor vessels used in pulp mills, the density of liquids can change as part of the reaction, while extreme temperatures and variable pressures are commonplace. All these factors can affect the performance of level measurement technologies. Non-contacting radar transmitters are a suitable solution in these applications as they do not need to compensate for density changes, and their measurement accuracy is not affected by high temperatures or pressure changes.

Solids measurement

Measuring the level of solids and powders – in lime silos, for instance – presents various challenges, the most fundamental of which is the uneven nature of the material surface. The peaks and troughs of uneven surfaces deflect energy away from a radar signal and can generate false signal reflections that affect measurement accuracy. By using a signal processing algorithm that merges surface peaks, the latest radar transmitters based on FMCW technology are able to overcome this challenge and provide a high degree of accuracy, even with rapid changes in level.

Dust generation

The considerable amount of dust generated in pulp production can affect the performance of level measurement technology. Non-contacting radar transmitters usually handle dust well, but a heavy layer can clog the antenna and block the signal. The latest devices overcome this issue with an integrated air purging system that cleans the antenna, thereby preventing signal loss and maintaining measurement accuracy.

Dielectric constant

When measuring media with a low dielectric constant – such as the lime powder used in pulp production – much of the radiated energy from pulse radar transmitters is lost, leaving very little energy to be reflected back. However, the superior sensitivity of non-contacting radar transmitters based on FMCW technology maximises their signal strength and enables them to accurately and reliably measure low dielectric media.

Södra Cell mill, Värö, Sweden

Typical examples of how advanced non-contacting radar technology is helping pulp producers to meet their toughest level measurement challenges can be seen at the Södra Cell mill, in Värö, Sweden. The mill is one of the world’s most modern pulp production facilities, producing around 700,000 tons of high-quality, chlorine-free softwood pulp and 1.6 TWh of energy annually. The company was facing two demanding level measurement challenges, which it solved by installing advanced non-contacting radar transmitters from Emerson.

The first challenging application required the level measurement of very fine lime powder stored in silos that are 27 metres high. As the powder piles up inside the silos, the material tends to form in towers beneath the inlet, producing an uneven surface. In addition, the powder covers everything with a fine layer that is prone to build-up, making it difficult to measure the level with any degree of accuracy. Other challenging factors include the long distance to be measured and the powder’s low dielectric constant.

Södra had tried using mechanical devices, ultrasonic technology and radars, but their performance was affected by clogging. With the majority of non-contacting radar devices, the signals are very low, which makes them unreliable. However, the company found a solution by installing Rosemount™ 5408 Non-Contacting Radar Level Transmitters with parabolic antennas.

The Rosemount 5408 uses FMCW technology, and its increased sensitivity allows it to successfully measure lime powder, despite its low dielectric constant. The parabolic antenna’s built-in air purging adapter prevents the lime powder from building up. To ensure accurate measurement, the Rosemount 5408 uses special software algorithms specifically designed to handle the characteristics of solids.

Since being installed, the Rosemount 5408 has proved to be extremely reliable, despite the dusty conditions. This has resulted in less maintenance being required and a reduction in downtime, leading to improved productivity.

Södra also needed to find a better way of measuring the level in mixing tanks containing a mixture of lye and soap. The media is aggressive and contaminating, with a dense, thick layer of foam forming on its surface, making it a very demanding environment for level measurement technology. The company had tried using a number of different technologies to accurately and reliably measure the level in these 18-metre tanks. However, mechanical devices experienced problems caused by build-up, while the nozzle of GWR transmitters proved to be too narrow, causing measurement errors whenever the probe came close to the nozzle.

Due to the problem with build-up, Södra required a measurement solution that was resistant to the media, and therefore installed Rosemount 5408 Non-Contacting Radar Level Transmitters with PTFE process seal antennas. The superior sensitivity and advanced software functions of the Rosemount 5408 enable it to accurately measure through foam, even when the surface is turbulent. The transmitter’s signal quality measurement functionality is able to detect abnormal process conditions such as antenna coating, while its PTFE process seal prevents the media from building up on the transmitter, thereby maintaining an accurate and reliable measurement.

Since integrating the Rosemount 5408 into the distributed control system at the mill, Södra has been delighted with the positive results. These include significantly reduced maintenance and downtime, and an increase in productivity.

To learn more about Emerson’s Rosemount 5408 Non-Contacting Radar Level Transmitter, visit www.Emerson.com/rosemount5408

Emerson’s New Magnetic Flow Meter Transmitter Simplifies Installation, Maintenance and Operation

Emerson has introduced the Rosemount 8712EM Wall Mount Magnetic Flow Meter Transmitter with additional protocols, powerful diagnostic capabilities and usability features to help users in the pulp and paper, metals and mining, and other industries gain quick and easy insight into their processes.

Rosemount 8712EM wall mount transmitter provides easy navigation in the field and additional protocols for increased measurement confidence

Rosemount 8712EM Wall Mount Magnetic Flow Meter Transmitter.The meter’s local operator interface was designed using Human Centered Design concepts, making it easier and faster for technicians to navigate in the field. According to Scott Dudek, product manager for Rosemount magnetic flow meters, “The Rosemount 8712EM melds usability pioneered by Emerson’s Human Centered Design Group with the quality, capabilities, and reliability that customers have come to trust from Emerson.”

Rosemount 8712EM Wall Mount Magnetic Flow Meter Transmitter.The meter’s local operator interface was designed using Human Centered Design concepts, making it easier and faster for technicians to navigate in the field. According to Scott Dudek, product manager for Rosemount magnetic flow meters, “The Rosemount 8712EM melds usability pioneered by Emerson’s Human Centered Design Group with the quality, capabilities, and reliability that customers have come to trust from Emerson.”

The Rosemount 8712EM’s diagnostic suite includes high process noise detection and ground fault detection. The electrode coating diagnostic offers two set points to alert when coating is present and when it is affecting flow measurement, enabling preventative maintenance. Smart Meter Verification continuously monitors the health and performance of the meter for ultimate measurement confidence.

Universal transmitter capability allows the 8712EM to operate with any existing magnetic flow meter sensor and allows backwards compatibility with all Rosemount magnetic sensors. This feature not only makes the transmitter easier to integrate with older units, but it also enables the use of the 8712EM’s advanced diagnostic features.

The Rosemount 8712EM supports HART 7 for 32-character-long tag capability for reduced start-up time, as well as options for intrinsically safe HART outputs and Modbus RS-485.

For more information, visit www.Emerson.com/magneticflowmeter

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial, and residential markets. Our Emerson Automation Solutions business helps process, hybrid, and discrete manufacturers maximise production, protect personnel and the environment while optimising their energy and operating costs. Our Emerson Commercial and Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency, and create sustainable infrastructure. For more information visit www.Emerson.com

The industry’s first SIL 3 certified single controller for water and steam enables plants to protect valuable assets and improve worker safety

The industry’s first sil 3 certified single controller for water and steam enables plants to protect valuable assets and improve worker safety

Emerson’s Mobrey™ Hydratect™ 2462 provides proven, reliable detection of water or steam. It can now be used within an SIS loop to further reduce risk of dangerous failure.

Emerson’s water and steam detection system is the world’s first single controller solution to be certified to IEC 61508 for safety instrumented functions up to SIL 3. The Mobrey™ Hydratect™ 2462 Water and Steam Detection System is used in a wide variety of applications where the detection of water or steam is vital for safe and efficient plant operation, such as boilers, steam drums and steam line drain pots. This helps to protect valuable plant assets, prevent downtime, save costs and improve worker safety.

The Mobrey™ Hydratect™ 2462 Water and Steam Detection System is certified to IEC 61508 for safety instrumented functions up to SIL 3.

The Mobrey™ Hydratect™ 2462 Water and Steam Detection System is certified to IEC 61508 for safety instrumented functions up to SIL 3.

The functional safety assessment performed by Exida enhances Hydratect’s reputation for reliability and durability. Exida, world leaders in functional safety certification, have assessed Hydratect and determined that it meets the requirements of SIL 3. The Hydratect system is ideal for the most demanding applications within power generation, refineries, chemical, steel, pulp and paper plants. It can operate in process conditions of up to 300 bar and 560°C. Failure of equipment in such applications can have serious consequences – the Hydratect offers the benefit of SIL 3 approval guaranteeing its reliability.

Hydratect is a modern replacement for conventional float switches, and consists of a compact twin-channel electronic unit, connected to a pair of electrodes. Each channel gives independent indications of the presence of water or steam that are more reliable than those obtained with electro-mechanical devices, which have the possibility of failing in an unsafe condition. By installing the electrodes in vessels or steam lines and measuring the resistance, the presence of water can be detected, allowing appropriate safety measures to be taken.

By detecting low water level in steam drums, Hydratect helps to prevent boiler tubes overheating, which could lead to an explosion, while detecting high water level prevents the generation of wet steam which could cause costly turbine blade erosion. Using Hydratect to detect water in steam line drain pots, as part of a turbine water induction prevention system (TWIP), helps prevent damage to turbine blades, cylinders and the housing.

The electronics unit provides a local indication of steam, water and fault states, and features configurable fault and trip outputs. Component failure, cable faults, ground faults and electrode problems are continuously self-monitored. Additional reliability is provided by triple redundancy of critical components, which ensures that failures result in a safe condition. An individual power supply to each channel further enhances reliability.

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial, and residential markets. Our Emerson Automation Solutions business helps process, hybrid, and discrete manufacturers maximise production, protect personnel and the environment while optimising their energy and operating costs. Our Emerson Commercial and Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency, and create sustainable infrastructure. For more information visit www.Emerson.com.

Emerson launches holistic asset monitoring platform to improve reliability and plant availability

New platform allows users to easily monitor asset health from inside or outside the plant

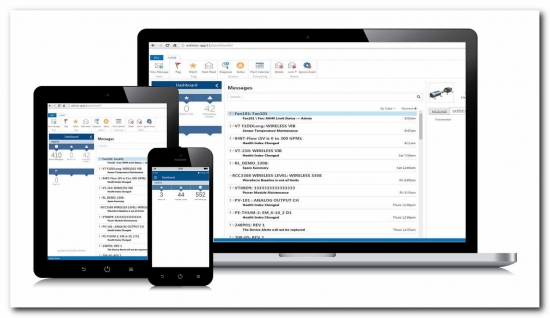

Emerson introduces the AMS ARES™ Platform, designed to prioritise and deliver asset and device health data, enabling maintenance decisions that increase operational and asset availability. Anywhere and anytime, users can securely access and share key data, with asset health summaries available on traditional desktop PCs, laptops, smartphones, and tablets−inside or outside the plant.

The introduction of the AMS ARES Platform represents an evolution toward a new, modern portfolio of AMS technologies and services, focused on providing digital intelligence and tools to help customers operate their plants and assets more effectively. Part of Emerson’s Plantweb™ digital ecosystem, the AMS ARES Platform gathers data from multiple sensing technologies, and provides a holistic view of the current health status of plant assets.

Persona-based access to information ensures the right personnel have instant access to clear health overviews of assets that are relevant to their plant responsibility. A streamlined dashboard and embedded tools for assigning prioritisation based on criticality allow users to determine quickly the urgency of an issue, facilitating faster workflows to increase plant performance.

“Plant personnel need to know the health of their assets in relevant time to when they need it,” said Duncan Schleiss, vice president of business development, Emerson Automation Solutions. “Emerson is committed to delivering solutions that provide information to those that can fix problems before they become production issues. By providing a secure, flexible and easy to deploy platform that communicates with many types of assets, asset health is published and available to all with minimal effort and in relevant time.”

The AMS ARES Platform marks a measurable shift away from managing data and toward delivering actionable insight. More asset visibility doesn’t have to mean slogging through more data. The AMS ARES Platform delivers information based on responsibility so that each person sees only pertinent data.

Designed as a platform to evolve with process industry evolutions, the AMS ARES Platform takes advantage of the OPC UA open architecture. Giving users the potential for HMI and historian connectivity and access to business intelligence and reporting tools, the AMS ARES Platform can make asset health truly part of the business dashboard.

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial, and residential markets. Our Emerson Automation Solutions business helps process, hybrid, and discrete manufacturers maximise production, protect personnel and the environment while optimising their energy and operating costs. Our Emerson Commercial and Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency, and create sustainable infrastructure. For more information visit Emerson.com.

Contact information

This email address is being protected from spambots. You need JavaScript enabled to view it.

Emerson introduces a new non-intrusive temperature solution that delivers accurate and repeatable process temperature measurement

EMERSON INTRODUCES A NEW NON-INTRUSIVE TEMPERATURE SOLUTION THAT DELIVERS ACCURATE AND REPEATABLE PROCESS TEMPERATURE MEASUREMENT WHILE SIMPLIFYING DESIGN, INSTALLATION AND MAINTENANCE

Rosemount™ X-well™ Technology is a complete point solution for accurately measuring process temperature without the need for a thermowell or process penetration

Emerson Process Management introduces Rosemount X-well Technology, a surface sensing temperature measurement solution that eliminates the need for thermowell process penetration when measuring process temperatures in pipe applications. This solution provides an accurate and repeatable internal process temperature measurement, while eliminating possible leak points and simplifying specification, installation and maintenance.

Emerson Process Management introduces Rosemount X-well Technology, a surface sensing temperature measurement solution that eliminates the need for thermowell process penetration when measuring process temperatures in pipe applications. This solution provides an accurate and repeatable internal process temperature measurement, while eliminating possible leak points and simplifying specification, installation and maintenance.

Rosemount X-well Technology is available in the Rosemount 648 Wireless Temperature Transmitter and Rosemount 0085 Pipe Clamp Sensor Assembly. These components work together to calculate process temperature via the transmitter’s thermal conductivity algorithm. Rosemount X‐well Technology works by measuring the pipe surface temperature and ambient temperature, and combining this information with an understanding of the thermal conductivity properties of the installation and process piping.

A major advantage of Rosemount X-well Technology is accurate process temperature measurement without requiring any intrusions or penetrations into the process, allowing for quicker and easier installation along with simplified long-term maintenance. Users do not have to design, size or maintain thermowells. Wake Frequency Calculations are eliminated, as well as time spent determining material compatibility, the right insertion length and the necessary profile.

With Rosemount X-well Technology, users can also add temperature measurement points without having to shut down a process. X-well Technology can be installed with a standard pipe clamp procedure and ordinary hand tools, and does not require a skilled contractor.

“Rosemount X-well Technology is the best of both worlds as it provides an accurate process temperature similar to a thermowell while maintaining the benefits of a non-intrusive surface measurement,” said Jason Rud, senior principal design engineer at Emerson Process Management. “Current surface temperature sensing technology only provides a surface measurement that can be easily influenced by ambient temperature, while Rosemount X‐well Technology corrects for external conditions to infer the process temperature.”

Applications that can benefit from Rosemount X-well Technology include pipelines, high velocity flows, slurries, heavy particulate fluids, wellheads, clean-in-place processes, high viscosity fluids and harsh processes in the oil & gas, chemical, refining, food and beverage, metals and mining and pulp and paper industries.

To learn more about the Rosemount X-well Technology, please visit www.EmersonProcess.com/Rosemount-Xwell.

About Emerson Process Management

Emerson Process Management (www.EmersonProcess.com), an Emerson business, is a leader in helping businesses automate their production, processing and distribution in the chemical, oil and gas, refining, pulp and paper, power, water and wastewater treatment, mining and metals, food and beverage, life sciences and other industries. The company combines superior products and technology with industry-specific engineering, consulting, project management and maintenance services. Its brands include Bettis™, DeltaV™, Fisher™, Micro Motion™, Ovation™ and Rosemount™.

About Emerson

Emerson (NYSE: EMR), based in St. Louis, Missouri (USA), is a global leader in bringing technology and engineering together to provide innovative solutions for customers in industrial, commercial, and consumer markets around the world. The company is comprised of five business segments: Process Management, Industrial Automation, Network Power, Climate Technologies, and Commercial & Residential Solutions. Sales in fiscal 2015 were $22.3 billion. For more information, visit www.Emerson.com.

Contact information

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.EmersonProcess.com/Rosemount-Xwell

Caption:

Rosemount X-well technology provides an accurate, repeatable process temperature measurement while eliminating possible leak points and simplifying specification, installation and maintenance.

Emerson combines key maintenance tasks in a single tool for improved savings and efficiency

CSI 2140 Machinery Health Analyzer adds an interface to laser shaft alignment fixtures, making technicians’ field time more productive

Emerson Process Management has enhanced its portable CSI 2140 Machinery Health Analyzer with a wireless interface to popular laser shaft alignment tools. This advance reduces two burdens − equipment and time − for operators performing vibration analysis and corrective tasks in the field.

The CSI 2140 Machinery Health Analyzer adds an interface to laser shaft alignment fixtures, making technicians’ field time more productive

The CSI 2140 already offers four-channel plus phase data collection to save time and effort, advanced vibration analysis that embeds expertise in the tool, and multi-plane balancing to correct imbalance in industrial fans. By adding a wireless link to laser fixtures, Emerson further streamlines the work process. Using the CSI 2140, personnel can perform route-based vibration data collection; analyse the root cause; and align the machine − all in one trip. At the same time, they can identify and solve machinery faults to prevent any unplanned downtime.

Tom Nelson, CSI 2140 senior technology manager at Emerson, defined the addition of alignment as, “the last piece of the puzzle to deliver a single, superior tool for diagnosing and correcting faults in rotating equipment.”

The shaft alignment option for the CSI 2140 uses the familiar, intuitive Emerson interface to guide technicians through a three-step process that quickly achieves precision alignment. The laser fixtures employ a unique Sweep technology to measure misalignment easily, even in tight clearance applications. An advanced option monitors the corrective machine moves in vertical and horizontal directions simultaneously. All data collected with the CSI 2140 can be uploaded wirelessly to a single database using the AMS Suite: Machinery Health™ Manager software. This enables the maintenance team to collect data, analyse problems, and document results in parallel.

For more information on the CSI 2140 Machinery Health Analyzer, please visit www.EmersonProcess.com/ResolveProblems

Emerson's new butterfly valve combines cost savings with high-performance in meeting a wide variety of process application needs

Fisher® 8590 high-performance butterfly valve features a highly optioned, single design platform that reduces engineering, installation, operational and maintenance costs

Emerson Process Management introduces the Fisher® 8590 high-performance butterfly valve that brings a selection of disk seals, actuator designs and material combinations to meet plant-wide throttling and on-off requirements.

Ben Fletcher, product manager at Emerson, explained the design intent behind the 8590 butterfly valve. “Our goal was to give application engineers the ability to combine a single valve platform with a selection of proven technologies to control a diverse range of CL600 process demands.”

“As an example, several dynamic disk seals are available in the 8590 design to meet temperature conditions that range from low-to-moderate up to 538°C (1000° F). Severe service and cryogenic applications can be met as well with the appropriate metal-polymeric or rugged stainless steel seal construction,” Fletcher added. “Since one valve design meets several needs, overall valve engineering, purchasing, installation, operation and maintenance costs are reduced.”

'Fisher 8590 high-performance butterfly valve brings a selection of disk seals, actuator designs and material combinations to meet plant-wide throttling and on-off requirements'

Utilising a lugged body design across the CL600 size range of NPS3 – NPS24, the 8590 can incorporate a splined shaft that accepts either a spring-and-diaphragm or pneumatic piston actuator. It is also available with either a square or keyed shaft that combines with handlevers, handwheels or pneumatic piston actuators.

The pressure-assisted design of the 8590 disk seals provides tight shutoff and permits the use of smaller, less expensive actuators in meeting full ASME B16.34 shutoff capabilities.

The 8590 offers true bidirectional shutoff, which means that torque necessary to open and close the valve remains constant regardless of the differential pressure across the disk. Slam-shut conditions are not created as the disk nears its seat, which extends seal life and avoids actuator and piping damage.

Besides shutoff given by the choice of elastomer and metal disk seals, the optional ENVIRO-SEAL® packing system combines with the valve’s micro-smooth shaft surface to keep emissions below 100 parts per million (PPM). Yet another extreme 8590 capability involves sour liquids and gases, with trim and bolting materials available to comply with NACE MR0175-2002, NACE MR0175-2002-2003, MR0103, and MR0175/ISO 15156.

With a CL600 rating per ASME B16.34, the valve’s face-to-face dimensions meet EN558, API609, MSS-SP68, and ASME B16.10 standards. The valve body self-centres on the line flange bolts as a fast, accurate means of centring the valve in the pipeline.

For more information visit www.EmersonProcess.com/Fisher

About Emerson Process Management

Emerson Process Management (www.EmersonProcess.com), an Emerson business, is a leader in helping businesses automate their production, processing and distribution in the chemical, oil and gas, refining, pulp and paper, power, water and wastewater treatment, mining and metals, food and beverage, life sciences and other industries. The company combines superior products and technology with industry-specific engineering, consulting, project management and maintenance services. Its brands include PlantWeb™, Syncade™, DeltaV™, Fisher®, Bettis™, Micro Motion®, Rosemount®, Daniel™, Ovation™ and AMS Suite.

About Emerson

Emerson, based in St. Louis, Missouri (USA), is a global leader in bringing technology and engineering together to provide innovative solutions for customers in industrial, commercial, and consumer markets around the world. The company is comprised of five business segments: Process Management, Industrial Automation, Network Power, Climate Technologies, and Commercial & Residential Solutions. Sales in fiscal 2014 were $24.5 billion. For more information, visit www.Emerson.com

Contact information

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.EmersonProcess.com/Fisher