Displaying items by tag: iggesund

Handwritten resistance to smartphone use

How can we persuade schoolchildren and teenagers to loosen their grip on their smartphones and write by hand instead? Bernard Bouvet is chairman of the Union Professionnelle de la Carte Postale, (UPCP), an advocacy organisation for the postcard industry in France. He may not have all the answers but he is at least practising active resistance. In recent years UPCP has put both itself and postcards on the map by creating the writing week Semaine de l’écriture, which aims to teach schoolchildren the value of writing texts by hand. Iggesund Paperboard has supported the campaign since its inception by providing materials for the postcards used in the various writing activities.

“It’s a cultural achievement to promote writing by hand,” says Bernard Bouvet, chairman of the French Union Professionnelle de la Carte Postale (UPCP). “We cannot allow all communication to go via emails and text messages, with the resulting degeneration of the language.”

For the past three school years, UPCP has distributed a postcard on a specific theme – most recently it was love – and organised a competition for the best-composed postcard. A specially composed guide for teachers informs them not only about the competition but also about a range of other school activities that can be done with the postcards. The campaign has been successful – in the first school year 45,000 cards were sent out; this year it was 360,000 and next year the plan is to distribute more than half a million cards. And it is the schools that are driving this strong growth trend.

“Personally I believe it is a cultural achievement to promote writing by hand,” Bouvet explains as he waves an elegant fountain pen. “We cannot allow all communication to go via emails and text messages, with the resulting degeneration of the language.”

The postcard activities and the writing week are of course one method of defending the position of physical postcards in an ever-more digitalised world. The postcard industry in France peaked at the turn of the millennium and since then annual sales have fallen by 20 per cent. However, for the past four years sales have stabilised and are worth about 400 million Euro.

During the second half of the year, the Union Professionnelle de la Carte Postale (UPCP) plans to distribute more than half a million postcards to French schools so pupils can learn the value of writing by hand.

Taking greeting cards and tourist postcards together, the average French person sends seven cards a year. As chairman of the UPCP, Bouvet looks enviously at the UK market, where people each send 54 cards a year.

“But they have a different culture in that respect – it would seem that they even send cards when they get divorced,” he says with a touch of French astonishment at the peculiar habits of the British.

Bouvet began his career as an apprentice typesetter at the age of 14 before becoming a photographer of postcard pictures. He remained loyal to postcards until retiring in February 2015. Despite his retirement, he will continue as the chairman of the UPCP throughout 2016. After that, he wants to continue developing the writing week with new forms of cooperation. In his spare time he intends to teach his 18 grandchildren to put aside their smartphones and write more postcards.

Iggesund

Iggesund Paperboard is part of the Swedish forest industry group Holmen, one of the world’s 100 most sustainable companies listed on the United Nations Global Compact Index. Iggesund’s turnover is just over €500 million and its flagship product Invercote is sold in more than 100 countries. The company has two brand families, Invercote and Incada, both positioned at the high end of their respective segments. Since 2010 Iggesund has invested more than €380 million to increase its energy efficiency and reduce the fossil emissions from its production.

Iggesund and the Holmen Group report all their fossil carbon emissions to the Carbon Disclosure Project. The environmental data form an integral part of an annual report that complies with the Global Reporting Initiative’s highest level of sustainability reporting. Iggesund was founded as an iron mill in 1685, but has been making paperboard for more than 50 years. The two mills, in northern Sweden and northern England employ 1500 people.

Iggesund further reduces carbon emissions

Iggesund Paperboard’s Swedish pulp and paperboard production facility, Iggesund Mill, reduced its fossil carbon dioxide emissions by 86 per cent from 2013 to 2014 from what was already a low level. The reduction is partly due to the investment in a new recovery boiler, which was completed in 2012.

“It always takes time to fine tune a new piece of equipment and we’ve also made some smaller investments to optimise our return from the recovery boiler,” explains Olov Winblad von Walter, Manager of Iggesund Mill. “Now we’re getting close to achieving the potential we expected.”

“It always takes time to fine tune a new piece of equipment and we’ve also made some smaller investments to optimise our return from the recovery boiler,” explains Olov Winblad von Walter, Manager of Iggesund Mill. “Now we’re getting close to achieving the potential we expected.”

The mill’s environmental improvements are not limited to carbon dioxide. Emissions of sulphur have also been cut by 82 per cent, nitrogen oxides by 19 per cent and particulates by 90 per cent – all compared with 2011, which was the last year the old recovery boiler was operating. A conscious decision on operating strategy and investments in process stages that previously used fossil fuel oil have also contributed to the radical reductions in air-borne emissions.

Iggesund Mill is not the only component of the Holmen Group to succeed with its environmental work. Between 2013 and 2014 carbon dioxide emissions per tonne of manufactured paperboard and paper products within the Group were cut from 123 kilos to 67 kilos. This is almost 50 per cent and demonstrates clearly that the Group has taken yet another step to reduce the climate impact of its own operations.

In recent years the Holmen Group has received a number of awards for its sustainability work. In 2014 Iggesund was given the Bio Strategy of the Year award by the industry organisation PPI. The Holmen Group was also included on the Carbon Disclosure Project’s list of the 187 global companies that are leaders in the battle to tame the climate threat.

“We’re very satisfied with this year’s outcome and I believe we’ve thereby strengthened our position as a leader in sustainability efforts,” comments Lars Strömberg, Director of Sustainable and Environmental Affairs at Holmen.

In 2013 Iggesund also commissioned a biomass CHP plant at the company’s Workington Mill in the UK. By switching its energy source from fossil fuel to biomass in a single step, the mill eliminated almost all the fossil carbon emissions from its production process. At Iggesund Mill in Sweden, bioenergy supplied 99.1 per cent of the energy used in the production process during 2014. Today the emissions from all paperboard production within the Holmen Group are within a few tenths of one per cent of being fully fossil free.

“Our strategy of investing in fossil-free technology at the mills in Sweden and the UK have been decisive steps in our sustainability work,” Strömberg emphasises. “The fact that we’ve been rewarded with top positions in various rankings and indexes proves that active work with energy and climate issues gives us a credibility that also strengthens our brands.”

Iggesund

Iggesund Paperboard is part of the Swedish forest industry group Holmen, one of the world’s 100 most sustainable companies listed on the United Nations Global Compact Index. Iggesund’s turnover is just over €500 million and its flagship product Invercote is sold in more than 100 countries. The company has two brand families, Invercote and Incada, both positioned at the high end of their respective segments. Since 2010 Iggesund has invested more than €380 million to increase its energy efficiency and reduce the fossil emissions from its production.

Iggesund and the Holmen Group report all their fossil carbon emissions to the Carbon Disclosure Project. The environmental data form an integral part of an annual report that complies with the Global Reporting Initiative’s highest level of sustainability reporting. Iggesund was founded as an iron mill in 1685, but has been making paperboard for more than 50 years. The two mills, in northern Sweden and northern England employ 1500 people.

Further information:

Staffan Sjöberg

Public Relations Manager

This email address is being protected from spambots. You need JavaScript enabled to view it.

Iggesund Paperboard

SE-825 80 Sweden

Tel: +4665028256

Mobile: +46703064800

www.iggesund.com

Invercote G from Iggesund

Upgraded for better digital printing

“We’re seeing almost an explosion of digitally printed folding cartons. For a company like ours which offers stiff paperboard of the highest quality this is a terrific development,” comments Fredrik Lisinski, who is responsible for developing Iggesund Paperboard’s sales to the digital print market.

Strong brands led by Coca Cola have shown that the intelligent personalisation or regionalisation of packaging and labels can drive sales. Presses designed for higher grammages as well as new finishing equipment are opening up new possibilities. At the same time, larger sheet formats are paving the way for better economies of scale for digital printing.

“In addition, new applications are appearing that were previously unimaginable,” Lisinski adds. “Fifteen – or even ten – years ago, who could have thought that a print run of five calendars featuring photos of someone’s grandchildren or three copies of a photo book could form the financial backbone of a printing firm.”

Invercote, which is Iggesund’s flagship product, has paved the way for digital printing on thicker paper materials since the technology was introduced in 1993. Today’s Invercote G is certified for a variety of digital print technologies and is recognised as the market leader by digital printers when they need a thicker or stiffer material than usual.

The rapid development of digital presses and increasingly widespread interest in using digital print on packaging led Iggesund to take the next step with Invercote.

“The upgraded Invercote G that we’re rolling out into the market this spring will give us a complete portfolio of products for digital applications,” Lisinski explains.

“Invercote Creato is the best choice for all two-sided printed materials such as covers and various types of cards, but also for packaging with equal demands on both sides of the paperboard. The upgraded Invercote G will give customers who want a clear difference between the paperboard’s two sides but who still want to be able to print on both sides using their digital presses precisely what they’re looking for.”

The secret lies in the new coating on the reverse side of the upgraded Invercote G.

Iggesund’s engineers were asked to create a reverse side with improved printing properties – in both offset and digital – but without compromising on the natural feel that has been the product’s hallmark for many years. The market’s reactions to the upgrade have far exceeded expectations.

With this new product Iggesund wants to give the entire digital print industry a tool with which to smash all the barriers that have hindered digitally printed folding cartons from achieving its full potential.

“We don’t want our customers to have to choose between good printability in digital applications and first-class packaging characteristics in terms of designability and material stiffness and strength,” Lisinski says. “With Invercote we want to give them both. Our status as the market leader proves we’re on the right path. With this upgraded product I’m convinced that the entire digital packaging print market will take another leap forward.”

Over the past year Iggesund has made major efforts to increase the availability of Invercote in the most common formats for digital presses.

“We’ve followed the market and worked with the leading press manufacturers. The result is a product portfolio that is perfectly suited to people who do digital printing on higher grammages,” Fredrik Lisinski concludes.

Valmet receives order from Holmen for softwood line rebuild at Iggesund mill

Valmet will deliver equipment and services for a rebuild of the soft wood pulp line at Holmen's Iggesund mill in Sweden. The rebuild will improve production stability, cut variable costs and increase pulp production capacity by 15 percent equally to 50,000 tonnes. The works will be implemented in two stages during 2015 and 2016.

Valmet will deliver equipment and services for a rebuild of the soft wood pulp line at Holmen's Iggesund mill in Sweden. The rebuild will improve production stability, cut variable costs and increase pulp production capacity by 15 percent equally to 50,000 tonnes. The works will be implemented in two stages during 2015 and 2016.

The order is included in Valmet's first quarter 2015 orders received.The value of the order will not be disclosed.

"We have a good experience since we have had Valmet presses in our mill for many years. This rebuild will eliminate bottle necks in the process and increase pulp capacity. We will also cut variable costs which will strengthen our competitiveness", says Olov Winblad von Walter, Mill Director, Iggesund.

"This rebuild is the first step towards a press based bleach plant. The high outlet consistency makes the process easier to control and the volume of effluent will be less than for washers with lower discharge consistencies. Also water and chemical consumption will be minimized. We are looking forward to a good co-operation in this project", says Mikael Gustafsson, Sales Manager, Valmet.

Technical information about Valmet's delivery

The scope of the Valmet delivery includes main machinery, basic engineering and erection. In the first stage, two pressure diffusers will be rebuilt, one in the cooking plant and one in the brown stock washing, where also a new TwinRoll press, will be installed. In the second stage, the oxygen delignification stage will be extended into a two-stage OxyTrac system, which will make it possible to still reach lower kappa numbers in case of a further production increase. In the bleach plant two new TwinRoll presses will be installed.

About Holmen and Iggesund mill

Holmen is a forest industry group that manufactures printing paper, paperboard and sawn timber and runs forestry and energy production operations.

Holmen's Iggesund mill is one of the most advanced, fully integrated pulp and paperboard mills in the world. The product family is called Invercote and is used for the highest quality graphics products and packaging. Exclusive packaging for perfume, chocolate, wine, spirits, cigarettes and CD covers are examples of applications. The mill has a production capacity of 340,000 tonnes per year and has 800 employees.

For further information, please contact:

Mikael Gustafsson, Sales Manager, Pulp and Energy Business Line, Valmet, Tel. +46 70 653 3809

Valmet Corporation is a leading global developer and supplier of services and technologies for the pulp, paper and energy industries. Our 10,500 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Valmet's objective is to become the global champion in serving its customers.

Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Read more www.valmet.com , www.twitter.com/valmetglobal

Iggesund’s challenge to designers: Improve the packaging in your local shops!

Iggesund Paperboard is working via the American crowdsourcing company Crowdspring to challenge the world’s designers to improve existing consumer packaging.

“Every day we all see examples of packaging that could be improved by a better choice of materials or a better design,” explains Staffan Sjöberg, who is in charge of the project at Iggesund Paperboard. “Now we’re giving designers all over the world the chance to contribute their ideas on how to replace packaging made of glass, plastic or metal with solutions that use paperboard.”

Iggesund is challenging designers to make everyday consumer packaging more sustainable by replacing plastic, glass and metal with paperboard. As one example, a decade ago almost all sandwich packaging was made of plastic – now paperboard packaging is increasingly common for sustainability reasons.

He stresses that Iggesund is not looking for inexpensive ideas which can be put into commercial use. Instead, the aim is to get a picture of how global designers as a collective group believe they can steer packaging development in a more sustainable direction.

“We will not claim any commercial rights to the ideas that come in,” Sjöberg says. “We’re just interested in getting a snapshot of how designers believe they can improve the packaging they see in the shops they visit on a daily basis. We want to publish the ideas and maybe reproduce some of them in physical form but we are not interested in exploiting them commercially.”

For Crowdspring the collaboration with Iggesund Paperboard is an unusual project. Normally the online marketplace’s services are used when someone wants either a number of inexpensive design proposals or a wide range of ideas.

“This is an unusual reason for initiating a project with us,” comments Mike Samson, who is coordinating the project with Iggesund. “But we believe its combination of sustainability and innovative thinking will attract many of the thousands of designers listed in our database.”

Iggesund Paperboard is part of the Swedish forest industry group Holmen, one of the world’s 100 most sustainable industrial companies according to the UN Global Compact Index. Iggesund’s annual turnover is close to SEK 5bn (EUR 525m) and its flagship product Invercote is sold in over 100 countries.

The company has two product families, Invercote and Incada, which are both among the quality leaders in their segment. Since 2010 Iggesund has invested SEK 3.3bn (EUR 346m) to increase the energy efficiency and reduce the fossil carbon emissions from its paperboard mills. The investments have made both mills almost self-sufficient in electricity.

Iggesund and the Holmen Group report their fossil carbon emissions to the international Carbon Disclosure Project and are on the project’s A List, which singles out almost 200 companies world wide for their work against climate change. The two companies’ environmental data are integrated into their annual reports, which are produced in accordance with the Global Reporting Initiative’s highest level of sustainability accounting.

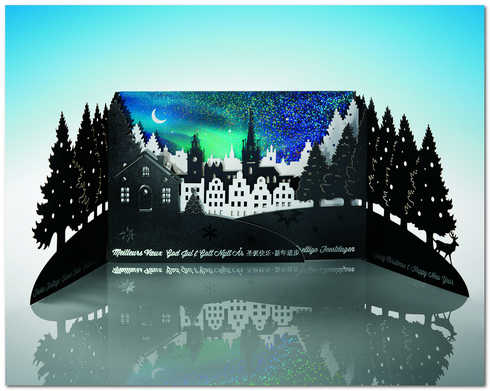

A shimmering winter’s night on Iggesund’s Christmas card

Iggesund Paperboard’s 2014 Christmas card takes its recipients on a journey from a forest setting to the city of Stockholm profiled against a sky gleaming with the northern lights. Iggesund has a tradition of using its Christmas card as an ambassador for paperboard as a material and to display various printing techniques. This year’s edition was designed by Papersmyths of Bristol, England, who also managed the production as a whole.

Iggesund continues its tradition of sophisticated Christmas cards featuring an exciting design. This year’s card combines a forest theme with typical Stockholm buildings silhouetted against a shimmering Scandinavian winter’s night, and was designed by Papersmyths in Bristol, England.

The card is in the form of an altarpiece whose laser-cut doors form the outline of a forest. They open to reveal a city skyline in several layers, whose relationship to each other depends on how wide the doors are opened.

“In their turn, the building facades are profiled against a night sky with northern lights,” explained Iain Smyth of Papersmyths. “The shimmering effect is created with a clear holographic twinkling foil, with the moon and stars reversed out. The forest and city silhouettes are finely laser cut and decorated with spot UV ink stars, with Christmas greetings in silver foil blocking to create a really exciting scene.

“I wanted to convey the feeling of both the forest, which is the starting point for Iggesund’s products, and the Scandinavian winter night.”

The card consists of five parts, which were assembled into one unit. The complex assembly was done with the help of a team of undergraduate students in Bristol but the task placed high demands on the participants.

“They needed a combination of deft fingers and good humour to succeed,” Smyth added.

To give the card even more of a Christmas touch, a special envelope was created to underline the idea that this is almost a Christmas present. The envelope has an elegant closure which makes the most of Iggesund paperboard's tensile strength.

The card was printed by Taylor Brothers in Bristol and the laser cutting done by Lasercraft of Huntington, England.

Iggesund Investing €60 Million in increased capacity and quality

The board of the Holmen Group, which includes Iggesund Paperboard, decided on Wednesday to give the green light for investments totalling EUR 60 million in Iggesund’s mills at Iggesund, Sweden and Workington, England.

At Iggesund the investments will eliminate bottlenecks in pulp production so it can be increased from the current 370,000 tonnes to 420,000 tonnes. The target for the board mill is to increase the capacity by 10 per cent without investments.

“After we brought the new recovery boiler on line and developed our purification systems for both air and water, the mill now has unused potential, in both the pulp and board mill, which we can activate,” comments Olov Winblad von Walter, Director of Iggesund Mill. “This is exciting because we are taking yet another step towards being one of the world’s leaders in mill technology with the lowest environmental impact. This move also further reinforces our competitiveness in the form of lower variable costs.”

The investment in Workington will increase the mill’s paperboard production capacity from the current 200,000 tonnes to 220,000 tonnes. This investment will also make the mill a leader in folding box board technology thanks to a rebuild of the paperboard machine’s press section which will increase product quality. The rebuild will be completed by June 2016.

The investment in Workington will increase the mill’s paperboard production capacity from the current 200,000 tonnes to 220,000 tonnes. This investment will also make the mill a leader in folding box board technology thanks to a rebuild of the paperboard machine’s press section which will increase product quality. The rebuild will be completed by June 2016.

“We are experiencing strong demand for our improved Incada, not least because European converters regard it as the paperboard with the best runnability for applications involving mass-market consumer products,” comments Ulf Löfgren, Managing Director of Iggesund’s mill at Workington. “In that situation of course it is positive that we can increase our capacity so more people can benefit from Incada’s advantages.”

“We see no difficulty in increasing Incada’s presence in Europe,” adds Arvid Sundblad, Vice President Sales and Marketing at Iggesund. “Our market share has been limited by our capacity. The planned capacity increase combined with Incada’s recognised quality and our service gives us a excellent position.”

Over a five-year period Iggesund Paperboard has invested strongly in strengthening its competitiveness via lower energy costs, whilst simultaneously minimising its use of fossil fuels. A total of EUR 361 million has been used for this purpose in both Workington and Iggesund. The investments announced now are more focused on increasing production.

“We have reduced our environmental impact and also taken control of our energy costs,” Sundblad concludes. “We are well equipped to face tougher competition in the paperboard market but above all with regard to other types of packaging material. Our strategy is organic growth and for Workington, this is the first step in that direction. The announced investments will give us an excellent market position in terms of both product quality and capacity.”

Iggesund awarded for reducing environmental impact

Iggesund has embarked on a substantial initiative to reduce its environmental impact, which is now being recognized the world over. In October, the Pulp & Paper Industry (PPI) presented Iggesund with its “Bio Strategy of the Year” award based on an extensive investment program to reduce fossil carbon emissions.

“For several decades Iggesund has been systematically working to free itself from dependence on fossil fuel; switching the source of energy required to power our mills to bioenergy and, at the same time, increasing our energy efficiency,” says Arvid Sundblad, Vice President of Sales and Marketing for Iggesund. “We are satisfied with what we have achieved and pleased at the signs of recognition from the outside world.”

Strategic investment in a turbine-equipped recovery boiler have made the mill in Iggesund, Sweden fossil-fuel free to roughly 95% and nearly self-sufficient with respect to electricity; and in a biomass boiler at its mill in Workington, England, completely fossil-fuel free and a net supplier of green energy to the national electricity grid. The annual reduction in fossil carbon emissions from both mills is equivalent to taking more than 85,000 cars off the road.

But the story hardly ends there. Also in October, the Holmen Group, which includes Iggesund Paperboard, was elevated to the “A List” of the CDP Climate Performance Leadership Index 2014. The CDP (Carbon Disclosure Project) is an international not-for-profit organization that has the world’s only global system for measuring, reporting on, handling and sharing important environmental information.

But the story hardly ends there. Also in October, the Holmen Group, which includes Iggesund Paperboard, was elevated to the “A List” of the CDP Climate Performance Leadership Index 2014. The CDP (Carbon Disclosure Project) is an international not-for-profit organization that has the world’s only global system for measuring, reporting on, handling and sharing important environmental information.

Placement on the A List means that the Holmen Group is now one of 187 globally active companies that are regarded as being the most advanced for the actions they have taken to reduce carbon dioxide emissions and to manage the business risks associated with climate change.

“Our high placement in this evaluation proves that active energy and climate efforts plus clear communication about them reinforce both our brand and our credibility in the sustainability area,” says Lars Strömberg, Director of Sustainable and Environmental Affairs at Holmen.

Just over a year ago, the Holmen Group was added to the United Nations Global Compact Index, which lists the world’s 100 most sustainable companies. This year’s evaluation results have just been announced and Holmen remains on that list.

“In this context it is important to note that we are a heavy process industry competing with companies like banks and insurance companies, whose biggest environmental problem is the ozone emissions from their office laser printer. Yet our environmental work can easily hold its own against them,” Sundblad emphasises. He adds that this recognition of the group’s environmental efforts is part of everything that Iggesund supplies to its customers.

“Our service has many aspects, ranging from delivery service to knowledge transfer – and we include them all under the concept of Care by Iggesund. This includes having an environmental programme that reinforces our customers’ businesses.”

Care by Iggesund includes everything from customised delivery solutions to knowledge transfer, a sample service, technical support in local markets and transparent sustainability work.

22 000 unique covers of Inspire

When Iggesund Paperboard planned the first digitally printed cover for its inspirational magazine Inspire, the ambition level was high. The whole issue was devoted to the possibilities of digital print, and one of the goals was to produce 22,000 unique covers in a way never done before.

Each and every one of the 22,000 covers of Iggesund Paperboard’s inspirational magazine Inspire is unique, with variable printing of colour fields, varnish patterns and time codes.

Just adding a recipient’s name or a serial number was a bit too easy. More interesting was to start from Inspire’s tradition of using graphics on its cover. The Inspire editorial team created a 16-minute-long film where each frame was then used as a cover.

“It might seem like a roundabout procedure but it was far simpler than creating 22,000 individual print files using layout software,” Thomas Idebäck, Motion Graphic Designer, says.

The variation in the printed covers lies partly in the colour fields but also in the spot varnish. The colour field variations by themselves make each cover unique but the varnish patterns also vary. Each cover is also marked with the time code of the particular film frame on which it is based.

Digaloo digital printers in Stockholm were sent the 1.4 TB of raw data that had to be processed into pages. As the work progressed, the amount of data being processed grew to between 3.5 and 4 TB. Fortunately the printers had invested in a new press and a RIP (Raster Image Processor) IN-100 to increase their processing capacity.

“This print run is totally unique. I’ve talked with colleagues in my international network of digital printers and no one has heard of anything similar,” says Jannes Dahlgren, CEO of Digaloo. The company took 27 hours of active printing time to complete the project.

From Carnaby Street to global recognition

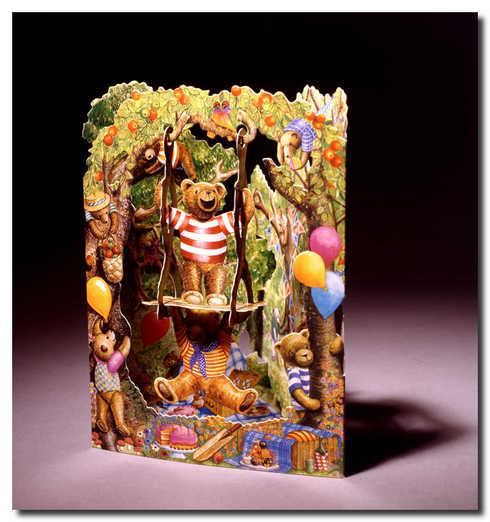

It all began with a small design studio on a little road off Carnaby Street. SANTORO was Lucio and Meera Santoro’s small-scale venture into innovative graphic design. Today their work is found around the world and they have won some 50 international awards for their designs, greeting cards and 3D books.

The company’s first big success came with its Swing Cards, a series of movable 3D greeting cards which are sent flat but which unfold themselves immediately they are removed from the envelope. Over the years the collection has gradually expanded and now consists of more than 90 different cards, which are sold world-wide, with over 15 million recipients to date.

“If I’d realised how much work is involved in every card I never would have started this,” commented Lucio Santoro in the company’s showroom at the current headquarters at Rotunda Point in Wimbledon. “This must be the highest level of construction using paper materials.”

“But at the same time, the demanding construction work has also protected us from copies and plagiarists. There are many other products which are far easier to copy.”

It was while working on the original Swing Cards collection during the first half of the 1990s that the studio first encountered the paperboard called Invercote made by Iggesund Paperboard. Since then all the studio’s advanced collections have been made using Invercote.

“Invercote maintains a very high and consistent quality,” Lucio Santoro said. “For our purposes, though, a few of its unusual features are the most important. Its very high tear resistance enables us to create finer details while at the same time the construction is more durable.

“Another important property is dimensional stability. Few people realise that when you are working in three dimensions you not only have to ensure perfect registration between the printing inks but also with the printed image on the reverse. Dimensional stability is crucial for this.”

Over time SANTORO has built up a portfolio of designs, which the studio now licenses to other users, an activity that currently brings in almost half the company’s revenues. Designs by Santoro are now printed on everything from bags and gift articles to housewares, notebooks, ceramics, apparel and footwear to name just a few. Lucio and Meera have also produced three 3D non-fiction books: Journey to the Moon, Wild Oceans and Predators.

Sophisticated greeting cards are still an important part of SANTORO’s business. Last year the company launched its Pirouettes collection, which has good prospects of emulating the popularity of the Swing Cards.

“We believe strongly in Pirouettes – you have to when it takes about two years to develop a collection,” Lucio said. “Sales have gone well so far but it will be a few years before we can see how the collection measures up to Swing Cards’ twenty years of popularity.”

About 30 people work at SANTORO’s design studio in London, with a further 60 employees around the world.

Caption: “Invercote’s tear resistance and dimensional stability are incredibly important to us as a company making sophisticated moveable constructions from paper material,” said Lucio Santoro, who together with Meera Santoro founded SANTORO in 1985. © Iggesund

Iggesund

Iggesund Paperboard is part of the Swedish forest industry group Holmen, one of the world’s 100 most sustainable companies listed on the United Nations Global Compact Index. Iggesund’s turnover is just over €500 million and its flagship product Invercote is sold in more than 100 countries. The company has two brand families, Invercote and Incada, both positioned at the high end of their respective segments. Since 2010 Iggesund has invested more than €380 million to increase its energy efficiency and reduce the fossil emissions from its production.

Iggesund and the Holmen Group report all their fossil carbon emissions to the Carbon Disclosure Project. The environmental data form an integral part of an annual report that complies with the Global Reporting Initiative’s highest level of sustainability reporting. Iggesund was founded as an iron mill in 1685, but has been making paperboard for more than 50 years. The two mills, in northern Sweden and northern England employ 1500 people.

Further information:

Staffan Sjöberg

Public Relations Manager

This email address is being protected from spambots. You need JavaScript enabled to view it.

Iggesund Paperboard

SE-825 80 Sweden

Tel: +4665028256

Mobile: +46703064800

www.iggesund.com