Displaying items by tag: upm

UPM Tervasaari mill’s rebuilt paper machine 8 starts after renewal

UPM Tervasaari mill’s paper machine 8, producing label release base papers, has been started-up after major renovation. Modifications have been made throughout the paper machine line in order to increase speed and further improve paper quality.

The renewal will increase the capacity of the paper machine by 30,000 tonnes.

"The investment is UPM's way of meeting the increasing demand for label papers. The company wants to secure its market leader position in label papers and support customer growth," says Pentti Putkinen, General Manager of the Tervasaari Mill.

“The new technology enables us to produce even thinner high quality papers. The better efficiency of the paper production and material usage also improves the competitiveness of label papers. This strengthens the position of paper based labelstock in competition with other materials and alternative product decoration techniques in the market”, Antti Heimola, Product Manager of UPM Label Paper explains.

PM 8 was built in 1996. It underwent major renovations in 2006.

The UPM Tervasaari Mill produces approximately 385,000 tonnes of speciality papers annually using three paper machines. UPM signed a preliminary contract in February 2012 and will sell its packaging paper production to the Swedish company Billerud. The transaction includes two packaging paper machines: PM 7 in Tervasaari that produces kraft papers, i.e. envelope, bag and technical papers, and PM 1 in Pietarsaari that produces kraft paper and sack kraft paper. The aim is to finalise the transaction during the second quarter of 2012.

UPM to rebuild Biological effluent treatment plant.

UPM will begin a large construction project at its Pietarsaari pulp mill to rebuild the mill’s effluent treatment plant. The circa EUR 30 million investment will cover the rebuild of all of the main phases of waste water treatment. The work will start immediately and is to be completed at the end of 2013.

”With the rebuild of the effluent treatment plant we will improve the pulp mill’s production efficiency and reduce its environmental impact. The rebuild will also enable further development of the mill in future”, says the mill’s General Manager Kenneth Winberg.

The construction includes a new preliminary clarifier for fibres and an aeration basin, created mainly by excavating rock. The pumping station and compressor house will be completely new constructions.

Continuous improvement in water use

UPM is currently reviewing water management and efficiency in material use at several mills. By 2020, we aim to have reduced waste water volume by 15% in pulp and paper production compared with levels in 2008. Sustainable use of water is one of our core environmental principles.

UPM treats all waste water in primary and secondary effluent treatment plants before it is released into watercourses. The biological treatment stage is an efficient way to remove dissolved organic contaminants and nutrients from waste water. The emission level of waste water is regularly measured and monitored according to valid monitoring plans.

Paper – the gateway to exciting experiences

UPM strongly believes that printed and digital channels complement each other, with paper assuming its natural role within the modern media palette. UPM Paper is bringing together its experts and visionary cooperatives at drupa trade fair in May to showcase exciting examples of combining print and digital channels – providing inspiration and solutions to all those in the media industry.

Print is effective. Need proof?

According to research, print is and remains an extremely powerful advertising medium. So how can you convince advertisers? Participate in UPM’s drupa demo sessions to discover modern ways to engage readers by using print.

Quick Response codes offer real engagement for both brands and readers. By scanning a code with their smart phone readers are able not only to get additional information on their mobile devices, but also able to for instance share contents and make online purchases. For brand owners the ability to collect code data and measure the direct effects of printed channels down to detail demonstrates print marketing effectiveness.

The third dimension

You can find 2D codes across a range of our UPM materials, such as our new Product Catalogue 2012, printed samples and our exhibition invitation. With codes you can pre-register for an appointment on our drupa 2012 stand or check technical specifications of UPM products from our Online Product Catalogue.

Another way to take advantage of the combination of print and digital is to use NFC, (Near Field Communication) tags. At the UPM stand you can test how this works by interacting with our World Design Capital Helsinki posters and stickers. Their tags provide access to the mobile site, m.wdchelsinki2012.fi.

At info sessions on our stand you can hear more about the various examples where print acts as the gateway to exciting experiences.

Future travel catalogues bring pictures alive

Are you ready to explore the possibilities of the future catalogue? We want to spark your imagination with a futuristic example, where a printed travel catalogue can take you to winter wonderland with the magnificent Aurora Borealis. By browsing through tagged pages of a design brochure you are able to experience a whole new kind of printed product that literally brings the pictures alive. This unique cross-media concept has been created in co-operation with UPM, VTT Technical Research Centre of Finland and Finnish Tourist Board.

Comprehensive offering with the latest, innovative paper products

UPM continues to offer a broad range of papers for various end-uses: magazines, newspapers, books, catalogues, office papers, envelopes, labels, packaging and many more. At UPM, we are continuously developing new solutions to produce hi-tech papers for our customers from renewable natural resource using our state-of-the-art production facilities.

At drupa trade fair in May you can familiarise yourself with our latest, innovative paper products such as UPM Eco product family, recycled fibre based office papers and UPM SwanBarrier which has a unique combination of functionalities which no paper has ever had.

Significant savings with UPM Eco X H

UPM Eco X H, an uncoated soft-calendered paper, is a new option within our product portfolio. It is available in 40 gsm (36 gsm and 38 gsm upon request). With UPM Eco X H it is possible to gain significant cost advantages as it enables excellent results with lower weight. It offers considerable savings in in paper consumption, transportation, postage and handling.

Using UPM Eco X H also gives an environmental edge because it contains recycled fibre and has low carbon footprint. UPM Eco X H has been awarded the EU Eco-label and is available as PEFC or FSC certified.

UPM Eco X H is particularly suitable for retail flyers, catalogues and special offer advertising material.

A true paper renaissance in office papers

UPM Office Recycled premium is a high white paper made from 100 % recycled fibres which makes it an environmental and sustainable choice for office documents. Here you will find one of the highest quality recycled papers in the market. It is suitable for laser printers, inkjet printers, copiers as well as fax machines using laser and inkjet printing methods. The new grade has a uniform sheet formation and good bulk. In addition, this product is supplied with both the EU Ecolabel and FSC certification.

UPM Office Recycled plus - 100 % recycled paper with Blue Angel

UPM Office Recycled plus offers a valuable complement to the wide range of UPM Office papers. It is a superb white paper made from 100 % recycled fibres. A functional and an environmental choice for office documents. UPM Office Recycled plus is Blue Angel accredited and has EU Ecolabel certification. In addition, this grade is equipped with FSC forest certification. It is suitable for laser printers, inkjet printers, copiers and fax machines.

Both grades offer following benefits

• 100% post-consumer waste deinked pulp fibres

• excellent whiteness & cleanliness

• uniform sheet formation

• good bulk to roughness ratio

• excellent printability including inkjet

UPM SwanBarrier papers – a new biodegradable barrier paper range

UPM is to launch a new recyclable and biodegradable barrier paper range – UPM SwanBarrier and UPM SwanBarrier light. These exceptional oneside coated barrier papers are made online. They have water vapour barrier and/or medium grease resistance. The main end uses are bread bags for hard crust bread, or biscuit and greasy food wrappings.

UPM SwanBarrier and UPM SwanBarrier light have a unique combination of functionalities which no paper has ever had. They are produced from renewable wood fibre with no plastics or fluorochemicals, so they are completely recyclable or biodegradable. And done online – no transportation needed between producer and converter.

UPM SwanBarrier is available in 65 and 60 gsm and UPM SwanBarrier light in 45 and 55 gsm. The papers are produced at UPM Jämsä River mills in Finland.

Stay tuned for UPM drupa news by following us at www.upmpaper.com and www.twitter.com/UPM_Papers.

UPM to outsource part of its IT services to HCL

UPM and HCL Technologies Limited (HCL) have signed a five year outsourcing frame agreement of IT infrastructure services.

As part of this agreement, HCL will provide data center, end user support, network services and professional IT services to UPM. HCL will also set up a data center in Finland and strengthen its existing Espoo Delivery Center to provide the services.

Approximately 250 UPM employees globally are within the scope of the planned outsourcing. Transferring UPM employees are expected to move to HCL upon closing, which is expected to take place at the end of August 2012, subject to signing of local transfer agreements and customary closing conditions.

“The agreement enables UPM IT to offer unified and cost effective IT infra services to UPM businesses“, says the CIO of UPM, Turkka Keskinen. “With this engagement we aim to increase scalability and flexibility as well as ensure access to world class competences and best practices”, he continues. “In the future, UPM IT focuses on strategy and governance, business-IT development, application management as well as demand and service management.”

“HCL has proven experience in delivering complex, end-to-end outsourcing engagements to globally dispersed organizations. We are pleased that this expertise has today positioned us as UPM’s partner of choice for IT services. We stay committed to creating transformational value for UPM in this engagement and look forward to a long and mutually rewarding relationship”, says Anant Gupta, President, HCL Technologies ISD.

“Through this engagement we will aim to optimize and transform UPM’s IT infrastructure to ensure enhanced and cost-efficient IT operations,” added Venu Gopal Lambu, AVP & Head of Continental Europe, HCL Technologies ISD.

UPM launches a new service for all-in-one colour and workflow management

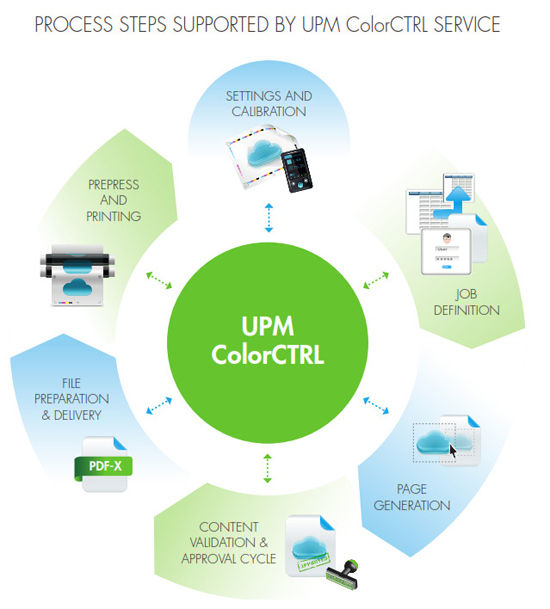

UPM will introduce a new service UPM ColorCTRL at drupa in May. The new workflow management application is developed to support users in reaching the best possible print result on UPM Papers – each time. It is created in co-operation with market leading supply chain partners including the expertise of UPM’s technical field team, the best-in-class workflow system by Dalim Software and award-winning ColorServer technology by GMG in one application.

As a Biofore Company UPM strives for continues development and innovative solutions with added value. “UPM’s services are tailored to improve our customers’ business processes and to help them to reach their business targets – from efficiency and also environmental point of view. UPM ColorCTRL is an excellent example of this,” says Thomas Ehrnrooth, Vice President of Marketing and Communications.

UPM ColorCTRL is a web based pdf workflow management application. It is the first full turnkey solution in the market which covers the whole process from the creation of the print ready pdf page to the final colour accurate print product. It is enabled through the use of optimised paper profiles by GMG.

UPM ColorCTRL is a cost effective and easy to use cloud based solution. With a service based fee the user will get an access to an online tool, which enables them to control workflows between different collaborators.

The service comes with consultancy and has everything in one package including pdf approval collaboration, version control, pre-flight checking, collaborative softproofing and colour optimisation. No investment or maintenance cost in local servers, hardware or software is needed.

“UPM ColorCTRL is an online service which allows easy collaboration with all partners in the value chain - from brand owner to advertising agency, publisher and printing house,” explains Gerd Carl, Project Manager for UPM ColorCTRL, and continues: “UPM ColorCTRL cuts down the time to market for quality print products and gives users savings in time, materials and investment costs.”

DALIM SOFTWARE provides its ES workflow technology for the UPM ColorCTRL workflow online platform and the GMG ColorServer engine secures the optimal print ready pdf quality. Proof to print match is obtained using the optimized GMG ColorProof software within the package. Colour accuracy of the final print product will be achieved by always up-to-date UPM paper profiles, service setup and consultancy.

UPM is piloting the new service with selected customers during the spring and will introduce UPM ColorCTRL at the UPM stand in drupa.

Turn the page with UPM at drupa 2012

It’s time to turn the page and write the next chapter in the story of paper. UPM will do it at drupa 2012.

It’s time to turn the page and write the next chapter in the story of paper. UPM will do it at drupa 2012.

The acquisition of Myllykoski has made UPM the undisputed leader in publication papers. We can now serve our customers even better than before with a best in class offering - products, services, reliable and accessible supplies and sustainable operations. Along with the acquisition UPM has put even stronger focus on publication papers by allocating more dedicated resources to both the magazine and newspaper publisher segments.

At drupa you can familiarise yourself with UPM's wide range of papers for every end use and printing method. New solutions, like UPM SwanBarrier, for the packaging industry, wide DIGI paper offering or low basis weights products, such UPM Eco product family, are just some of the interesting product examples and innovations presented by UPM at drupa 2012.

UPM believes in co-operation throughout the value chain. By joining the expertise of UPM Paper and visionary cooperatives we’ve created inspiring features and solutions for modern print media. Come and see how codes, tags and augmented reality truly add new dimensions to print. You’ll also discover how they help to measure printed media effectivity. Check out our demo sessions and take a peek into the future of paper.

UPM is known for the know-how and expertise of its technical sales team. At drupa we will launch a new service for web based pdf workflow and colour management. It has been developed to produce colour accurate print products on UPM paper quicker and easier than ever. Come and hear more about UPM ColorCTRL and other UPM services at our stand.

UPM is exhibiting in PrintCity hall 6 as part of the joint PrintCity Alliance and is also sharing expertise in PrintCity’s Hot Topic clusters. UPM is presenting technical innovations improving runnability, printability and the latest value added solutions in newspaper printing. New UPM Seminars and Workshops for printing industry players will be introduced at the PrintCity area. Alliance members have also produced new value added printed materials.

UPM sees a bright future for paper as part of the modern media palette. Come and meet us at our stand in hall 6 and see how paper works as the gateway to exiting experiences.

Stay tuned for UPM drupa news by following us at www.upmpaper.com and www.twitter.com/UPM_Papers.

Turn the page with UPM Paper - the gateway to exciting experiences.

UPM continues to invest in efficient energy generation

UPM continues to invest in efficient energy generation and builds a new combined heat and power plant at the UPM Schongau mill in Germany. The target is to significantly reduce energy costs as well as to secure the energy supply. The total investment is EUR 85 million.

The new power plant will generate process heat as well as electricity for the mill. It will also provide sustainable and energy efficient district heating for roughly 750 households and public institutions such as local school and hospital in Schongau. The renewed energy supply at the mill will be based on the highly efficient combined heat and power technology utilising gas as a fuel.

“The new gas power plant will improve the security and self-sufficiency of energy supply to our mill,” explains Winfried Schaur, General Manager, UPM Schongau. “The renewal of the energy generation ensures efficient production and will safeguard the competiveness of the mill. Furthermore, it guarantees a sustainable paper production loop based on innovative and low-emission technologies.”

The start-up is planned by the end of 2014. The gas power plant will replace the old plant facility which has operated more than 40 years.

UPM aims to achieve improved energy efficiency and energy savings in all its businesses. The company favours a wide range of low-emission energy sources. During the past decade UPM has invested over EUR 1 billion on carbon neutral power and heat generation at its mill sites.

(UPM-Kymmene)

UPM sells its RFID business to SMARTRAC

UPM has reached an agreement with SMARTRAC N.V. today whereby UPM sells its RFID business to SMARTRAC. UPM will become an indirect shareholder of SMARTRAC with a 10.6 percent economic interest through the company OEP Technologie B.V. The closing of the deal is expected to take place during the first quarter of 2012. The transaction is still subject to regulatory approvals.

SMARTRAC is registered in the Netherlands, and is one of the global market leaders in high-quality RFID inlays for electronic passports and contactless credit cards as well as for RFID transponders for public transport applications.

“UPM has been developing and investing in its RFID inlay business for a number of years. The business unit has evolved from a small venture to a sizeable business and is now recognised as the market leader in its field. Combining the business unit with a company with the industry’s widest RFID business portfolio, we give it new leverage to continue to develop successfully. We see significant value increase potential in this new combination. Therefore we are pleased to become an indirect shareholder of SMARTRAC,” says Jussi Vanhanen, President, Engineered Materials, UPM.

“Becoming part of the leading player in the RFID industry opens up totally new possibilities for us. I am convinced that this new setup will be a strong player in the growing RFID market place, ready to offer support and solutions to customers around the world,” says Marcus Vaenerberg, Senior Vice President, UPM RFID.

“UPM RFID is a true pioneer in the global RFID tags and inlay business. We are delighted to add such an experienced and capable crew to our global team. The transaction will provide us with a strong product offering for NFC and UHF RFID tags and inlays and will furnish us with favourable additional manufacturing capacities in strategically important markets. The combination of SMARTRAC and UPM RFID will significantly accelerate our momentum as a developer and supplier of passive RFID tags and inlays for all relevant application fields of today and tomorrow”, said Dr. Christian Fischer, CEO of SMARTRAC.

UPM to establish competence centre for eucalyptus research in Uruguay

UPM will strengthen its research on eucalyptus fibre and build a competence centre at the Fray Bentos pulp mill in Uruguay. The new centre including expansion of the existing laboratory facilities will be operational during the first half of 2012.

The new competence centre will focus on the research of eucalyptus species and their impact on end product properties. The Fray Bentos competence centre will evaluate the aspects of the eucalyptus species growing in Uruguay with the aim to accelerate the process of selecting the best trees to be planted in the future.

“At the Fray Bentos mill site we can combine our expertise in the pulp process with the plantation forestry operations know-how in an innovative way. The new competence centre will also enable us to strengthen the cooperation with our customers in product development,” says Sami Saarela, Vice President for UPM’s pulp production.

The Fray Bentos competence centre will operate as part of UPM’s global R&D Network. The competence centre will increase research activities and training of the Uruguayan engineers in the development of eucalyptus fibers.