The “traditional” European Paper Making Industry has been declining and restructuring in Europe over recent years. Nonetheless there are opportunities which do appear in this industrial sector, thanks mainly to the development of new applications and product innovations. This is particularly apparent in the fields of tissue making, packaging and with specialty papers. SYNTHRON, a subsidiary of PROTEX INTERNATIONAL has a 40 year history in the paper making industry: SYNTHRON – considers that innovation is a priority – and allocates 5% of its turnover for R&D in order to develop new applications and novel chemistries for paper making and to anticipate the future requirements of this particular market.

The “traditional” European Paper Making Industry has been declining and restructuring in Europe over recent years. Nonetheless there are opportunities which do appear in this industrial sector, thanks mainly to the development of new applications and product innovations. This is particularly apparent in the fields of tissue making, packaging and with specialty papers. SYNTHRON, a subsidiary of PROTEX INTERNATIONAL has a 40 year history in the paper making industry: SYNTHRON – considers that innovation is a priority – and allocates 5% of its turnover for R&D in order to develop new applications and novel chemistries for paper making and to anticipate the future requirements of this particular market.

For Robert MOOR, CEO of SYNTHRON: “we have to anticipate the future requirements of paper making which is presently in transformation. To remain focused in the chemistry of this sector, our Center of Studies and Discoveries develops products and searches to innovate constantly”.

SYNTHRON has refined and specializes its product range by launching a new auxiliary: SYNTHRO®STAB HE which is used in tissue making manufacturing process to remove bad odours. The tissue making sector produces paper for public and domestic sanitary use also products like disposable handkerchiefs, baby’s diapers, temporary medical sheeting used for examinations, domestic kitchen roll, tablecloths and towels…), this market segment is growing.

The tissue making process can involve either virgin pulp fibres of cellulose or contain some recycled cellulose fibres. One of the main problems encountered by the producers of this type of paper is the presence of bad odours, often caused by residues of hexanal (or hexanaldehyde C6H120). SYNTHRO®-STAB HE, functions by interfering with the chemical reaction which releases the smell by blocking and the deactivating the catalysts of the reaction. SYNTHRO®-STAB HE meets the requirements of the Food and Drug Administration (FDA).

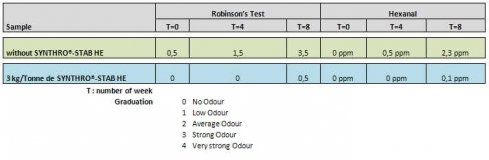

Robinson’s test proves the efficacy of SYNTHRO ®-STAB HE:

After 8 weeks, the background concentration of the treated product is 0,1 ppm versus 2,3 ppm this clearly demonstrates the effectiveness of SYNTHRO®-STAB HE as the bad odour has been eliminated from the tissue.

Generally paper tissue usage increases with rise of living standards, and for the Consumer it’s important to improve the quality of the tissue and to offer an effective solution to eradicate bad odours from the product.

The SYNTHRO®-STAB HE manufactured at industrial site of Auzouer-en-Touraine in Indre et Loire and in Saint-Avold in Moselle (France).