A newsprint manufacturer has seen that retrofitting new steam profiler actuators is a cost-effective way to extend the life of the profiler, ensure reliability and reduce maintenance costs.

By Mark Williamson, Journalist Engineer

During the latter part of 1990s the market for steam profilers was at its peak, but many of those original investments are now starting to show their age. Some actuators are failing at an accelerated rate and the cost of maintenance is getting high. Tasowheel, a profiler actuator manufacturer based in Tampere, Finland, now offers a solution for those ageing profilers to bring their performance and reliability up to a high standard. Most importantly for papermakers, a retrofit actuator solution extends the service life of older profilers and reduces the cost of maintenance. Prolonging equipment life and reducing costs is welcomed by papermakers nowadays. Moreover, the retrofit with new, improved actuators can be done at a considerably lower cost than a complete rebuild of older actuators. Tasowheel has the expertise to do this since they have been manufacturing OEM actuators for profiler suppliers for over thirtyyears. Now, they offer an independent solution for existing profilers.

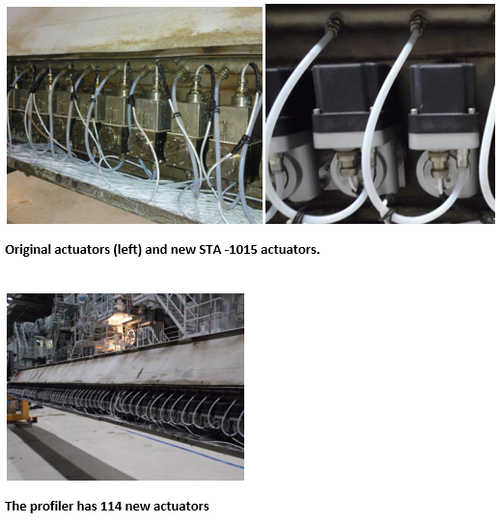

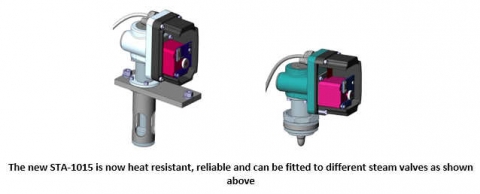

A major European newsprint manufacturer has seen the benefits of the solution. Their steambox, installed in 1999, was showing its age and many of the actuators were failing regularly in the high temperature environment. Their replacement was a maintenance burden every six months when the profiler was taken out and overhauled. Tasowheel proposed a solution in which the old and now obsolete actuators would be replaced in-situ with new bolt-on actuators that were designed to perform reliably even with high temperatures. Isolation of the control card from the heat and heat resistance of its components and motor coil cables and bearings were the key design improvements of the new STA-1015 actuator. STA-1015 can replace old model electromechanical steambox actuators types (EMA15, EMA1000 and STC900).The customer noted that the new actuators fitted perfectly with the same connections and even the same gaskets as the old ones. To evaluate the reliability, a test actuator was provided which was fitted for an extended period, ensuring that there were no control, compatibility or reliability issues. There were no problems during the test period.

Overhauls: from six months to two years

The mill placed an order for 114 new actuators. From placement of the order to the delivery mill staff were kept well informed of progress which was particularly important considering the tight delivery schedule defined by a papermachine extended shutdown opportunity. The actuators were installed in September, 2014 by three mill staff over two day shifts. No night shifts were needed.

The customer reports that the replacement cost was considerably less than alternative solutions since no original-design replacement actuator was available. Overhaul of the entire old actuator set was possible but would have required considerable downtime, manpower and lost production. The cost of the OEM service components were at least 20% more expensive than the Tasowheel solution.

With the reliablity problem solved, the mill staff hope to extend the steam profiler overhaul cycle to two years from the previous six months. This means lower maintenance costs and a longer lifetime with better reliability for the profiler.