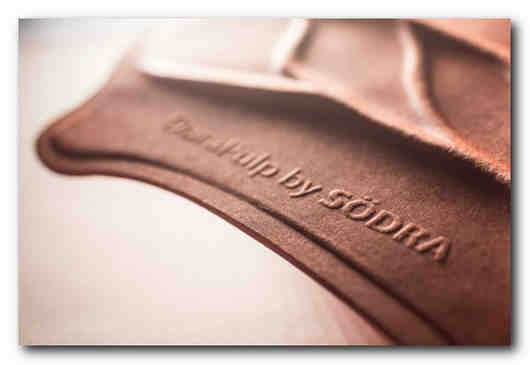

Södra is now taking further steps to commercialise the composite material DuraPulp. A project to construct a dry-process machine has commenced, financed through a grant of EUR 2.1 million from the EU's LIFE funding programme.

The material in DuraPulp has properties that require special handling during the moulding process. The current method is wet-moulding, but to meet customer requests, Södra is now investing in a machine that can dry-mould the material.

"To be specific, this is a more efficient production process because it uses less water and less energy. The wet-mould method we are using today takes about two minutes, while dry-moulding takes two seconds. This technology will enable us to demonstrate products for high-volume markets, such as electronics and consumer packaging," says Urban Blomster, a business developer at Södra.

The first stage of the project was to procure external resources for the construction of the machine, with former partner, SWT Development in Varberg, Sweden, being selected for the assignment.

The machine is scheduled to be operational by the end of 2016.

For further questions, please contact:

Urban Blomster, business developer at Södra

Tel: +46 (0)706-837 785