Valmet has launched a new Valmet High Solids Measurement (Valmet HS) that enables stable and accurate measurements for industrial wastewater treatment, pulp and paper production and a wide range of other industrial processes. Valmet HS measures for over 30% solids or 1-70% moisture.

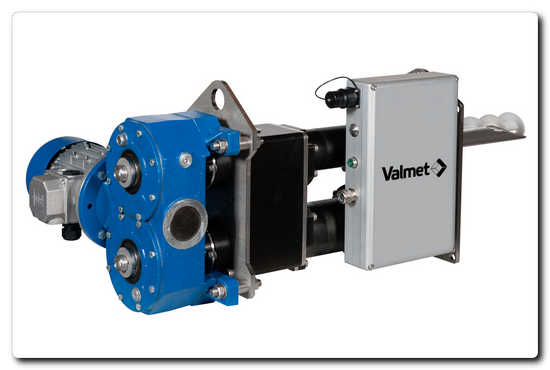

Originally designed for municipal waste water plants, Valmet HS is based on microwave technology and features a patented sensor structure. It extracts a continuous sample flow from a downfall or drop leg section in the process and returns it back to the process after the solids content has been measured.

"We see high potential for this solution especially in the pulp and paper industry where an accurate high solids measurement provides many benefits, such as improved high consistency control, cost savings and higher quality," says Jarmo Havana, Product Manager, Automation, Valmet.

Cost and fuel savings lead to better sustainability

The new measurement brings numerous benefits to its users. It helps to minimize transport costs of sludge in waste water applications and reduce supplementary fuel use where sludge fuels a boiler, thus improving the sustainability of industrial processes. Additionally, Valmet HS makes it possible to optimize total solids levels and follow up, in real time, the performance of dewatering or drying processes.

Already in use after a high-consistency roll press, Valmet HS provides accurate pulp consistency control to refining and consequently more stable-quality pulp to the paper machine. Benefits include lower press energy consumption, reduced fiber crushing and the prevention of too high consistency causing damage to process equipment.

Other proven applications of Valmet HS include wastewater sludge solids measurement after dewatering in pulp and paper applications, measuring sawdust moisture before pelleting in the wood processing industry and sludge moisture monitoring before incineration.

"The solution has been so successful that new applications are coming up all the time. Ongoing development work in various industries includes the measurement of moisture with starch, sugar and gypsum as well control of a thermal drying processes," adds Havana