Displaying items by tag: Cristini SpA

Cristini Diagnostic Systems will be present at the MIAC Show in Lucca

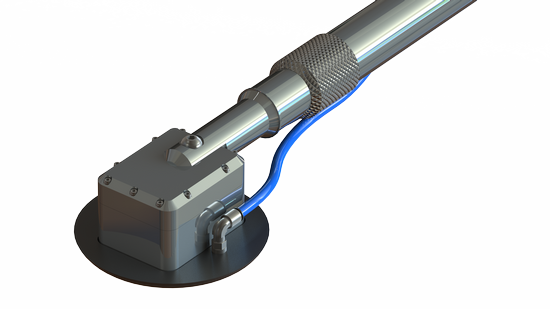

SmartScan™ LM, a new compact microwave sensor for measuring the humidity in the sheet will be presented.

SmartScan™ LM is a sensor based on ultra-short microwaves, for the accurate measurement of humidity in the sheet on low weights and humidity, typical of post-size positions.

SmartScan™ LM complete the SmartScan™ family targeted for the press section already on the market, a success installed in numerous machines across Europe and North America.

SmartScan™ sensors are engineered to overcome the typical limits of the NIR (Near Infrared) technologies. This new generation of sensors is characterized by the most compact construction on the market, with single side measurement. These characteristics and the absence of reflectors and/or sensors on the reverse side of the sheet, allows a wider freedom in installation solutions than all the sensors currently on the market.

Cristini Diagnostic Systems will be present at stand 110.

Cristini Paper Machine Clothing & Diagnostic Systems

Cristini is proud to showcase its Diagnostic systems line at MIAC 2015 in Lucca (Oct 14th-17th), featuring its EasyScan™ family of traversing beams. EasyScan 100, 300 & 500 are different versions available either for the transportation of portable felt scanners or equipped with DCS integrated sensors for the measurement of felt moisture & permeability. The beams are guaranteed maintenance free, with an extremely compact design to fit virtually any position on a paper machine.

Cristini continues to be one of the world’s most innovative clothing producers, offering endless and pin seam press fabrics as well as forming fabrics designed for all paper machines. In MIAC will be presented also EnerMaster™, a new Forming Fabric designed especially for packaging grades to increase forming quality, while reducing energy costs. The new line of Spiral Dryer fabrics for all grades MaxSpiral™, Maximum stability for Maximum life will be also presented at the show. Come visit us at Booth 106.