Displaying items by tag: DS Smith

“DS SMITH TECNICARTON” GLOBAL SUSTAINABLE PACKAGING COMPANY DS SMITH ANNOUNCE MAX LAMINATION TECHNOLOGY AS CORRUGATED CARDBOARD PACKAGING SOLUTION

DS Smith Tecnicarton, an expert provider of industrial packaging solutions and part of the leading global sustainable packaging company DS Smith, launches MAX lamination technology. The new solution increases the resistance of corrugated cardboard packaging and optimizes stacking potential - extending possibilities for reuse as a fully recyclable solution.

DS Smith Tecnicarton expert designers superimposed up to ten layers of corrugated cardboard to create MAX technology. This includes standardized special folding creases to achieve a larger box format with increased resistance, and the design has evolved out of a six-wave laminated packaging solution comprised of up to ten channels.

DS Smith heavy-duty packaging, the Magnus-IBC Kraft, has a capacity of 1,000 Litres and a resistance of 10,000 KG and the bulk packages have been designed as a sustainable and 100% recyclable alternative to traditional plastic Intermediate Bulk Containers (IBC).

DS Smith production processes and the companies’ unique circular economy design metrics approach has resulted in significant market leading improvements to the technology of large laminate packaging casings.

These include bespoke ergonomic creases that enable packaging to be assembled easily. They are also foldable and have resulted in significant space saving during supply chain cycles as well as successful reuse cycles, and a reduction in CO2 during transportation. For example, in the automotive sector, Tecnipack cardboard has enabled laminated strips to be re-used up to ten times within the supply chain for transportation between Spain and the United States of America (USA).

In addition, the resistance offered by lamination technology has made it possible to replace wooden packaging with lighter, cheaper, and completely recyclable100% cardboard packaging.

DS Smith Tecnicarton has made 100% of its packaging products recyclable or reusable, and DS Smith is committed to fulfilling the objectives of it’s Now & Next Sustainability Strategy ‘Redefining Packaging for a Changing World’.

Ignacio Montfort, Managing Director, DS Smith Iberia:

"We are constantly looking for ways to innovate and find solutions to the environmental challenges of the day. Our company wide 'Now & Next' sustainability strategy and vision is a benchmark for our product innovations and targets. We are confident that these new packaging product innovations will positively impact on the packaging supply chain and environment for future generations, as well as for our present-day clients and their customers as we accelerate the transition to a low-carbon circular economy”.

MAX lamination technology is an innovation created as a result of the opening of a DS Smith facility dedicated to specializing in laminating corrugated cardboard sheets in Arborç (Tarragona) in 2017, and DS Smith Iberia has twenty-six packaging facilities, six recycling facilities, and three paper-making facilities in operation across the Iberian Peninsula.

DS Smith

DS Smith Plc. is a leading global provider of sustainable fibre-based packaging, supported by recycling and papermaking operations. It plays a significant role in the value chain across sectors including e-Commerce, Fast Moving Consumer Goods (FMCG), and industrials. Through its purpose of ‘Redefining Packaging for a Changing World’ and its Now and Next sustainability strategy, DS Smith is committed to leading the transition to the circular economy, while delivering more circular solutions for its customers and wider society. Key targets include replacing problem plastics, taking carbon out of supply chains, and providing innovative recycling solutions. The company has also established a bespoke box-to-box in 14 days model, and circular metrics design capabilities for innovation are integral to operations.

DS Smith headquarters are in London, United Kingdom and the company is a member of the FTSE 100. It holds operations in thirty-four countries and employs more than 30,000 people. DS Smith is a Strategic Partner of the Ellen MacArthur Foundation with a commitment to the circular economy and was originally set up in London in the 1940s as a box-making business by the Smith family.

About DS Smith Tecnicarton, Iberia

DS Smith Tecnicarton specializes in innovative solutions for the industrial packaging sector with a core business focus on creating solutions for single-use and returnable packaging for the transport and logistics of high volume, high weight products, liquid, fluid and bulk products requiring specialist protection.

DS Smith Now & Next Sustainability ‘Redefining Packaging for a Changing World’ Strategy - https://www.dssmith.com/sustainability/sustainability-strategy

Key targets reached:

- 100% of our packaging is now recyclable or reusable

- 100% of our energy consumption is ISO50001 Certified

- We have already launched one hundred biodiversity projects across Europe & North America

- 100% of our sites in areas of high-water stress now have a water mitigation plan

- All our forests have forest management certification

- 100% of manufacturing sites are FSC certified

- 100% of the papers we use in manufacturing are recycled or chain of custody certified

- We have conducted a group human rights risk assessment and published our Human Rights Policy

Now & Next targets currently ahead of schedule:

- By 2025, remove 1 billion items of problem plastic

- By 2025, optimize fibre for individual supply chains in 100% of new packaging solutions

- By 2030, engage five million people in the circular economy and circular lifestyles

Company website: www.dssmith.com

Fully recyclable Rice Box champions sustainability in sector

DS Smith has partnered with Veetee to create a sector-leading, fully recyclable Rice Box with the aim of removing over 50 tonnes of problem plastic

Delivering sustainable packaging with optimal consumer convenience significantly increases a brand’s chance of standing out on the shelf. Veetee Rice Ltd’s dry rice pack is a sector-leading solution that removes the need to use plastic bags or standard skillets in its packaging, with a box lid that can be removed, used as a measure, and then reseals the pack for ease of storage.

As one of the UK’s largest rice companies, Veetee’s pioneering solution is a fully recyclable fibre-based rice box with a unique portion measure and was created by DS Smith who works closely with their customers to support the removal of problem plastics from supermarket shelves.

The innovative solution reinforces both companies’ position as sector leaders in plastic replacement, as the fully fibre-based box replaces existing plastic bag options currently on the market and aims to remove over 50 tonnes of plastic from the UK market.

FTSE 100 sustainable packaging company DS Smith worked closely with Veetee and its design brief to create a product that is not only friendlier on the environment but makes it simple for customers to measure portions using a replaceable box lid. The concept of incorporating the portion measure is unique to the sector, solving a consumer problem and helping the brand to stand out from its competitors.

Dave Ellerington, Head of Design & Innovation and Business Development at DS Smith Packaging UK & Ireland said: “It’s been excellent to work with Veetee who share our goal of reducing the use of harmful plastics and giving consumers truly sustainable options. We were able to use our unique circular design principles and metrics in the development of this design to ensure the final product is convenient for customers as well as being sustainable.

“Our work with Veetee has once again been able to show how packaging is vital for brands who are looking to become more circular and reduce their environmental impact”.

James Brett, Marketing Director for Veetee Group said: “Working with DS Smith to create our industry-leading rice box has allowed us to achieve our goal of selling our product that is a premium, sustainable solution and disruptive on the shelf. We’re also proud to be providing an enhanced customer experience through the box’s unique portion measure, meaning the packaging helps our brand stand out from the crowd”.

The pack has been developed to be filled on Veetee’s fully automated packing lines and within its existing footprint to maximise and improve supply chain efficiency. Following design, development, and manufacturing in the UK, the rice box was first launched in the US in May 2021 before being sold in major UK supermarkets.

CASE STUDY

Market-first rice box champions sustainability in sector

DS Smith has partnered with Veetee to remove over 50 tonnes of problem plastic with innovative fully recyclable fibre-based rice box

Veetee Rice Ltd – one of the largest rice companies in the UK, supplying rice to major supermarkets and exporting internationally to over 50 countries – has partnered with DS Smith to create packaging that optimises consumer convenience and helps it stand out on supermarket aisles, whilst designing-out unnecessary plastics.

Veetee sought to introduce several new features to their packaging design including developing a premium dry rice pack for supermarkets, replacing plastic bags with a carton board pack and ensuring the carton was leak-proof and stable when being filled on Veetee’s automated packing lines.

In collaboration with Veetee, DS Smith’s technical and operational experts went through a series of design developments. The final product successfully designed-out the need for plastic bags and created a lid that doubled up as a portion measure, which is unique in the sector.

The concept of incorporating the portion measure solves a consumer problem and helps Veetee to stand out from its competitors. The new packaging design – which is a fully recyclable fibre-based box –aims to remove more than 50 tonnes of plastic from the UK market and demonstrates DS Smith’s continued expertise in replacing problem plastic.

Dave Ellerington, Head of Design & Innovation and Business Development at DS Smith Packaging UK & Ireland said: “Reducing the volume unnecessary plastics in circulation and giving consumers truly sustainable options are two goals that we share with Veetee. We used our unique circular design principles in the development of this solution, to ensure the final product would maintain and optimise materials whilst being fully recyclable.

“Our work with Veetee has once again highlighted why packaging cannot be overlooked by brands looking to reduce their environmental impact. It’s really satisfying knowing that our solution will remove over 50 tonnes of problem plastic from circulation, avoiding further waste being sent to landfill or ending up in our environment.”

James Brett, Marketing Director for Veetee Group said: “Working with DS Smith to create our market-first rice box has allowed us to achieve our goal of selling a product that is not only premium, but disruptive and sustainable. We’re proud to be providing an enhanced customer experience as the only brand to include a portion measure within the packaging’s design.”

The rice box has been developed to be filled on Veetee’s fully automated packing lines and within its existing footprint to maximise and improve supply chain efficiency. The one-piece design enables a high-quality print to be used on the inside and outside of the carton, creating an enhanced customer opening experience. The complex double-skinned construction creates a collar for the lid, whereas most other carton packs are single skinned.

The pack is entirely designed, developed and manufactured in the UK at DS Smith’s Neath site.

For more information on DS Smith, please visit: https://www.dssmith.com/packaging

For more information on Veetee Rice, please visit: https://www.veetee.com/

About DS Smith:

DS Smith is a leading provider of sustainable fibre-based packaging worldwide, which is supported by recycling and papermaking operations. It plays a central role in the value chain across sectors including e-commerce, fast moving consumer goods and industrials. Through its purpose of ‘Redefining Packaging for a Changing World’ and its Now and Next sustainability strategy, DS Smith is committed to leading the transition to the circular economy, while delivering more circular solutions for its customers and wider society – replacing problem plastics, taking carbon out of supply chains and providing innovative recycling solutions. Its bespoke box-to-box in 14 days model, design capabilities and innovation strategy sit at the heart of this response. Headquartered in London and a member of the FTSE 100, DS Smith operates in 34 countries employing around 30,000 people and is a Strategic Partner of the Ellen MacArthur Foundation. Its history can be traced back to the box-making businesses started in the 1940s by the Smith family.

DS Smith removes over 313m pieces of problem plastic in two years

Sustainable packaging firm leads plastic replacement fight

DS Smith has just announced that it has designed out over 313 million pieces of problem plastics in the last two years alone1 as part of its ambitious plastic replacement programme.

The significant figure equates to more than three million units per week, as customers and consumers demonstrate demand for fibre-based packaging as an alternative to hard-to-recycle plastics.

To meet this demand, DS Smith designers have worked with customers to create 1,000s of new innovations to replace plastic. Solutions have been created to remove everyday plastic items including ready-meal trays, plastic fruit and vegetable punnets and plastic six pack rings that pollute the planet. This all comes at a time when campaign groups are highlighting the amount of plastic that ends up as waste, making it more important than ever to remove them at the design phase.

Samantha Upham, Sustainability Business Partner – Sales, Marketing & Innovation commented: “With our help, customers are accelerating their ambitions to remove problem plastics from their products. By using our Circular Design Metrics, we can easily show not just where plastic can be replaced, but how circular their packaging is right now and where we can make improvements together.

“All 700 of our designers have been trained in our Circular Design Principles, which means we can design out problem plastics at inception stage and find alternative fibre-based solutions which deliver the required attributes.”

Over the next year, DS Smith will continue to drive adoption of fibre-based alternatives amongst customers in response to consumer demand for plastic alternatives. In a recent survey commissioned by DS Smith, 4 in 10 consumers (41 per cent)2a wanted packaging made from alternative renewable sources, whilst in a separate survey, 52 per cent of Brits said they would purchase products that contain less plastic to help improve recycling rates in the UK.2b

As part of DS Smith’s Now & Next sustainability targets, the company has an ambition to take one billion pieces of problem plastics off supermarket shelves, replacing them with corrugated alternatives. DS Smith’s plastic replacement work and wider sustainability progress can be found in its latest sustainability report which can be found here.

- Over a 2-year period from May 2020 to April 2022

- Market research conducted by OnePoll:

- Consumer research: 2,000 UK adults who have shopped online in the past six months. Conducted between 17th June and 23rd June 2022

- Consumer research: 2,000 UK adults who have shopped online in the past six months. Conducted between 17th June and 23rd June 2022

About DS Smith:

DS Smith is a leading provider of sustainable fibre-based packaging worldwide, which is supported by recycling and papermaking operations. It plays a central role in the value chain across sectors including e-commerce, fast moving consumer goods and industrials.

Through its purpose of ‘Redefining Packaging for a Changing World’ and its Now and Next sustainability strategy, DS Smith is committed to leading the transition to the circular economy, while delivering more circular solutions for its customers and wider society – replacing problem plastics, taking carbon out of supply chains and providing innovative recycling solutions. Its bespoke box-to-box in 14 days model, design capabilities and innovation strategy sit at the heart of this response.

Headquartered in London and a member of the FTSE 100, DS Smith operates in 34 countries employing around 30,000 people and is a Strategic Partner of the Ellen MacArthur Foundation. Its history can be traced back to the box-making businesses started in the 1940s by the Smith family.

DS Smith Targets 30% Reduction of Carbon Emissions by 2030 in Partnership with World Kinect Energy Services

Energy management partnership to drive sustainability goals at packaging provider

DS Smith, the FTSE 100 leading provider of sustainable packaging, has just announced a new partnership with World Kinect Energy Services to manage energy consumption for its Recycling, Paper and Packaging sites across 26 European countries.

World Kinect Energy Services will support the DS Smith’s long-term goal to reduce carbon emissions by 30% by 2030, in line with the reaffirmation of that target in the company’s newly launched Now and Next Sustainability Strategy. With a large focus on the company’s 14 European paper mills, the partnership will provide DS Smith with tactical solutions to energy purchasing and usage, increasing efficiencies and reducing waste in production.

Adding value to DS Smith’s existing energy portfolio, World Kinect Energy Services will support the company to mitigate risks and maximise its energy data through price risk management services including market intelligence, regulatory reporting, and cost and consumption reporting. The partnership will continue to ensure a competitive strategy for total energy costs across all its European markets.

Terry Cogan, vice president, World Kinect Energy ServicesGerald Maunz, Procurement Director for Energy at DS Smith commented: “

Terry Cogan, vice president, World Kinect Energy ServicesGerald Maunz, Procurement Director for Energy at DS Smith commented: “

“As a global business with sustainability as the foundation of our overall business strategy, being able to manage energy consumption efficiently across all our sites is fundamental. We were impressed with the professionalism, price risk management skills and reporting capabilities that the energy experts and portfolio management team at World Kinect Energy Services demonstrated.”

Gerald Maunz, Procurement Director for Energy at DS Smith Terry Cogan, Vice President at World Kinect Energy Services added: “All our customers have differing requirements, whether it’s specific financial or reporting processes, or sustainability and carbon reduction targets and it is our priority to ensure those needs are met. We are looking forward to working with the team at DS Smith over the next three years to help them maximise their energy data and exploit it to manage and minimize risks in what is a complex and volatile market.”

Gerald Maunz, Procurement Director for Energy at DS Smith Terry Cogan, Vice President at World Kinect Energy Services added: “All our customers have differing requirements, whether it’s specific financial or reporting processes, or sustainability and carbon reduction targets and it is our priority to ensure those needs are met. We are looking forward to working with the team at DS Smith over the next three years to help them maximise their energy data and exploit it to manage and minimize risks in what is a complex and volatile market.”

In the past year, DS Smith has hit a number of sustainability milestones including an 11% reduction in emissions in 2019 compared to 2015 on a like-for-like basis. The partnership with World Kinect Energy Services will drive this momentum, ensuring significant progress is made against key sustainability targets.

About DS Smith:

DS Smith is a leading provider of corrugated packaging, supported by recycling and papermaking operations. Headquartered in London and a member of the FTSE 100, DS Smith focuses on creating innovative sustainable packaging solutions in 34 countries employing around 30,000 people. Using the combined expertise of its divisions – Packaging, Recycling and Paper – DS Smith works with customers to deliver solutions that reduce complexity and deliver results throughout the supply chain. Its history can be traced back to the box-making businesses started in the 1940s by the Smith family.

About World Kinect Energy Services

World Kinect Energy Services is a trusted global leader in energy management, fuel supply, and sustainability. It helps clients buy better and buy smarter energy through the delivery of trusted energy advice and solutions, sustainability services and data management.

Its four core solutions include:

- Energy Management

- Sustainability

- Brokerage

- Supply & Trade

With more than 5,000 industry experts and dedicated account managers based in North America, Europe, and Asia, it manages over 200 TWh of power and gas.

Find out more about our services here www.world-kinect.com

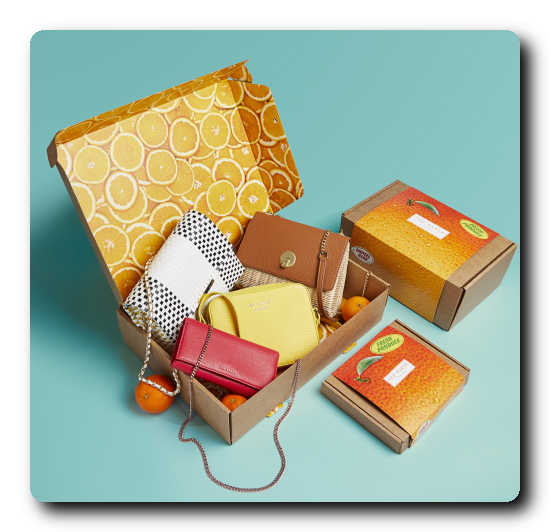

Ted Baker achieves seasonal sustainability with DS Smith

Fashion retailer enhances sustainability credentials with reusable e-commerce box

Ted Baker set out to improve the sustainability of its e-commerce packaging, while retaining its trademark ‘wow’ factor for customers. For an innovative solution, Ted turned to leading packaging strategist, DS Smith.

Responding to a changing market

With an increasing awareness on issues relating to improved environmental performance, Ted Baker wanted to take the lead in redesigning their packaging to better respond to their customers’ needs.

As part of this revamp, packaging production was on shored – moving it from the Far East back to the UK - a decision which contributed to the reduction of company’s carbon footprint, while allowing the brand the flexibility to update the packaging design to reflect seasonal campaigns, and the reactivity to deal with increased peaks in trade.

In need of packaging robust enough to withstand multiple journeys through a complex supply chain, the new e-commerce packaging focused on the reuse and recycle principles of the circular economy. Working with DS Smith, the company developed a completely recyclable box with the aim of reusing 20% of its boxes annually – a target that has already been exceeded with an average reuse rate of 27%. To accompany the new box, an innovative reusable and resealable sleeve was designed, using the brand’s bold and exciting designs.

Rob Carle, UK Head of Sales, e-commerce at DS Smith, said “The sleeve protects the parcel during transit and means that customers can return items in the same box by simply reversing the sleeve and securing it back around the box. It arrives back in the Distribution Centre with no labels on it, and so can be used again for other customer orders, doing potentially upwards of three journeys through the courier network.”

Georgina Jarvis, Print Production Manager at Ted Baker, said “Finding a solution to the environmental considerations of packaging returns has been an ongoing challenge. By working with DS Smith, we were able to make the concept a reality.”

Testing the concept

Protecting the product and the condition of the box is a vital role of the sleeve. For this reason, the packaging design and its eight size variations were tested in DS Smith’s state-of-the-art DISCS laboratory to simulate the rigours of the e-commerce supply chain journey. A significant amount of time was spent testing the packaging for efficiency on Ted Baker’s packing line to ensure that pack time was not affected.

The unboxing experience

Focusing on sustainability, it was important for Ted Baker to have a partner able to respond quickly to any design and print requests. Alongside improving the sustainability of the packaging, the inside of the box and the new sleeve provide a blank canvas for colourful and impactful lithographic designs to enhance the customer unboxing experience. The decorative print on the interior of the box is hidden from view on arrival to the customer and gives an added ‘wow factor’ during the unboxing experience.

Georgina explains, “Developing a collaborative relationship with DS Smith and finding the perfect solution to our e-commerce packaging has been a fulfilling experience.”

Rob adds, “Ted Baker are really pushing the boundaries of packaging design with new print techniques, and it’s exciting for DS Smith to be supporting them on this constantly evolving brief each season.”

Ted Baker and DS Smith are continuing to develop new seasonal print designs to entice and engage customers, while striving to increase the continued use of the boxes and maintain momentum on improving sustainability metrics for the company.

For more information on DS Smith and its digital print capabilities, please visit: https://www.dssmith.com/packaging

For more information on Ted Baker and its global sustainability strategy, please visit: http://www.tedbakerplc.com/teds-responsibilities/sustainability-and-the-environment

The Modern Man takes a greener approach

Provider of premium grooming products adapts its packaging to reflect sustainable values and customer expectations

The Modern Man has been sending luxury male grooming products to customers around the world since 2009 and as an e-commerce business, robust and impactful packaging has always been crucial. The company began collaborating with DS Smith in 2014 and, as a result, developed an eye-catching e-commerce pack, which guaranteed its high-end products arrived in perfect condition, no matter the destination.

The original e-commerce pack had a real “wow” factor when opened as the inner liner of the box was printed with a striking design. While The Modern Man was delighted with the packaging, over time, it became more concerned about whether the packaging aligned with its green credentials.

Matt Crowson, founder of The Modern Man, explains: “We were increasingly distributing a number of vegan and sustainable grooming products and it seemed incongruous for us to be using additional resources to print on the inside of the box. While telling our brand story has always been crucial, our approach to this narrative changed. Recyclable packaging, made with recycled materials, and resulting in minimal waste became a top priority. We got in touch with DS Smith and together began work on a new design.

“Once again, it was essential that the packaging solution secured and protected the products – many of our items are bottles and if they break in transit, our brand and sales will naturally suffer. Over the last few years, our customers’ average order value has grown and we have moved towards even higher-end products, so it’s crucial that the packaging looks good and reflects the quality of the products we sell. Finally, from an operational point of view, we wanted the boxes to be quick and easy to assemble for our teams in the warehouse.”

DS Smith’s expert design team worked closely with The Modern Man to create a more sustainable e-commerce pack, made from recycled materials. It took the printing out of the inside and incorporated a recyclable, corrugated pad which secures the product without any need for void fill or packing materials. There is hardly any empty space so the company is not paying to ship air and the product is protected and safe. The box is self-locking, easy to assemble and tamper proof. The addition of an easy opening strip also ensures there is a seamless opening process for customers when receiving their package.

Rob Carle, UK head of e-commerce sales, DS Smith comments: “Many of The Modern Man’s products are being shipped across the world. Therefore, Matt and the team needed to have 100 per cent confidence that its packaging could withstand the rigours of the supply chain. We were able to provide this peace of mind as the design was tested on our unique DISCS™ equipment.”

Named after the types of testing (Drop, Impact, Shock, Crush, Shake), DISCS™ is an industry leading process, which assesses whether packaging can survive the average e-commerce supply chain. Each piece of equipment replicates a part of the product journey and therefore provides real world testing.

Matt Crowson adds: “The final piece of the puzzle for us is that DS Smith also takes away our waste cardboard and recycles it. This closed loop model means that old packaging is being turned into strong, high quality, recycled papers by DS Smith rather than going to landfill. We feel that this greener approach is vital for our brand integrity – it matters to us and it matters to our customers.”

Speaking about his experience of working with DS Smith, Matt concludes: “Over the last five years, we have enjoyed a truly collaborative relationship with DS Smith, which has grown over time to include our two newer brands Calissa.com and salonwholesale.com. DS Smith are easy to work with and flexible. It has been such an encouragement that a large, international packaging company has been willing to work with us, a relatively small e-commerce start-up. We have a genuine, personal connection with the DS Smith team and share a deep passion for working sustainably and stewarding the earth’s resources effectively.”

For more information on DS Smith, please visit https://www.dssmith.com/packaging

For more information on The Modern Man, please visit https://www.themodernman.co.uk/

Three cheers for Laithwaites’ award-winning advent calendars

DS Smith UK partners with Laithwaites to bring indulgent, on-trend wine and beer advent calendars to consumers this festive season.

To maximise sales around the Christmas period and continue to innovate its offer, Laithwaites – the UK’s number one destination for buying wine online – approached DS Smith UK’s packaging division to design advent calendars for its wine and new craft beer ranges.

Wine Advent Calender

Wine Advent Calender

The design, which won the Corrugated: Online Retail and Consumer Goods accolade at the 2017 UK Packaging Awards, needed to be robust enough to meet the demands of the e-commerce supply chain yet stand out in the competitive advent calendar marketplace. Laithwaites required a model that was easy to assemble and pack on site, presented the drinks in a way that reflected a more traditional advent calendar, and incorporated simple-to-follow instructions for the consumer. The print also had to be the highest quality to bring the pack to life and capture a real festive feel.

DS Smith embraced this challenging brief and worked closely with Laithwaites to create an innovative design that was attractive to look at, but could also protect the glass bottles in transit and support the 9kg and 13kg weight of the packs. DS Smith were able to achieve this by using its industry-leading technology DISCS™ – which replicates each part of the product journey for testing (Drop, Impact, Shock, Crush, Shake) to ensure the packaging was up to the rigours of the real-world supply chain.

Rob Carle, Head of E-commerce sales at DS Smith UK, said: “Laithwaites is always pushing the boundaries of what is possible with online shopping and is keen to give its customers a sense of theatre in the home – something our packaging can deliver. Our DISCS™ technology provided invaluable insights, which enabled us to create a pack proven to best protect the fragile cargo and deliver a beautifully-designed premium product to consumers. We’re absolutely delighted that the design was recognised at the UK Packaging Awards.”

Beer Advent Calendar

Beer Advent Calendar

Andy Hawker from Laithwaites commented: “The final design is just what we hoped for and the award win is just the cherry on top! We knew DS Smith were the right people to design a pack that would both protect the bottles and appeal to our customers. We expect this year’s sales to exceed 2016 and that wine and beer lovers across the country will be having a very merry advent season thanks to these innovative new products!”

The Laithwaites Advent gift pack won the Corrugated: Online Retail and Consumer Goods Award at the UK Packaging Awards, which took place on 22 November 2017.

About DS Smith

DS Smith operates in over 36 countries and employs around 26,000 people. Using the combined expertise of our four divisions – Packaging, Recycling, Paper and Plastics – we work with customers to deliver solutions that reduce complexity and deliver results throughout the Supply Cycle. For more information, visit www.dssmith.com.

DS Smith is the UK’s leading supplier of corrugated packaging. Our comprehensive product range includes retail ready packaging, transit cases, consumer units, packs printed for gift and POS applications, and heavy duty packaging for industry. DS Smith’s national network of manufacturing plants service thousands of customers, from multinationals to local businesses.

Using PackRight®, our unique way of working, our highly-skilled people work closely with customers to specify packaging that achieves real results. Typically our customers achieve sales growth, or reductions in cost, waste and carbon at every stage of the Supply Cycle. For more information, visit

Acquisition of EcoPack and EcoPaper, Romania

DS Smith Plc (the Group) is pleased to announce it has entered into an agreement to acquire EcoPack and EcoPaper, (collectively “the Business”) for an enterprise value of circa €208 million.

DS Smith Plc (the Group) is pleased to announce it has entered into an agreement to acquire EcoPack and EcoPaper, (collectively “the Business”) for an enterprise value of circa €208 million.

The Business is a leading integrated packaging and paper group in Romania; family owned for many years. It will significantly enhance our capacity to serve customers in this high growth region as well as supporting our wider substantial Eastern European presence. The Business includes both high quality packaging assets as well as a new paper machine, built in 2017, that specialises in high quality, light-weight paper, which is particularly well-suited to supporting our performance packaging solutions.

The Business has grown strongly over many years and is primarily focused on serving the local FMCG market. It is very complementary to our customer and asset base providing an excellent opportunity for further growth as well as significant cost synergies.

The acquisition consideration and repayment of debt, together totalling €208 million, will be satisfied from existing cash and debt facilities, and from €35 million of DS Smith shares to be issued to the vendor. The acquisition is expected to be earnings enhancing immediately, is consistent with the Group’s medium term financial targets and equates to a post synergy multiple of c. 5 – 6x EBITDA. Completion is expected within our third fiscal quarter, following Romanian Competition Authority approval and the satisfaction of other customary closing conditions.

Flexible collaboration between DS Smith and The Works

DS Smith’s UK e-commerce division has partnered with The Works Stores Ltd to create a corrugated storage solution for its new warehouse facility.

A staple on the UK high street, The Works specialises in books, toys, gifts, stationery and arts & crafts, all at discounted prices. Reaching customers of all ages both in store and online, the company has steadily grown and now sells over one million products every week, and serves over 22.5 million customers annually.

As a result of this expansion, The Works moved to a new storage and distribution facility in February 2017 to accommodate its extensive product base. With 18,000 SKUs to sort and store, the leading entertainment retailer required a flexible storage solution that would provide the best possible operational efficiency.

As a result of this expansion, The Works moved to a new storage and distribution facility in February 2017 to accommodate its extensive product base. With 18,000 SKUs to sort and store, the leading entertainment retailer required a flexible storage solution that would provide the best possible operational efficiency.

Working in partnership with The Works, DS Smith’s specialist e-commerce team designed a corrugated pick bin that allowed flexibility, strength, ease of assembly and durability. The made-to-measure pick bin also enables The Works to use every space within the warehouse, to guarantee high product visibility so the picking team can work efficiently, and to minimise any damage during the storing process.

Peter Jowitt, Interim Head of Distribution at The Works, commented: “One of the biggest challenges we’ve faced is finding the most efficient and reliable solution for our storage warehouse, particularly as our range of products is so varied and growing all the time. For our new facility, we needed a product which had in-built flexibility and could adapt according to the size of both the products and storage space available.”

Sara Blount, Sales Manager, e-commerce at DS Smith UK, said: “Having collaborated with The Works stores for a number of years, we have a strong understanding of the business, its e-commerce pack and pick operation layout and most importantly for this project, its operational limitations. Using this insight, we were able to evaluate the space available and take on board the needs of the packaging operatives and the business as a whole to find a flexible, best-fit solution for a business with unpresented UK growth, and we’ve designed, produced and delivered that.”

About DS Smith

DS Smith operates in over 36 countries and employs around 26,000 people. Using the combined expertise of our four divisions – Packaging, Recycling, Paper and Plastics – we work with customers to deliver solutions that reduce complexity and deliver results throughout the Supply Cycle. For more information, visit www.dssmith.com.

DS Smith is the UK’s leading supplier of corrugated packaging. Our comprehensive product range includes retail ready packaging, transit cases, consumer units, packs printed for gift and POS applications, and heavy duty packaging for industry. DS Smith’s national network of manufacturing plants service thousands of customers, from multinationals to local businesses.

Using PackRight®, our unique way of working, our highly-skilled people work closely with customers to specify packaging that achieves real results. Typically our customers achieve sales growth, or reductions in cost, waste and carbon at every stage of the Supply Cycle. For more information, visit www.dssmithpackaging.co.uk.

DS Smith supports classroom design programme to help children with asthma

DS Smith develops prototypes for students as part of “Designing Our Tomorrow” classroom initiative.

In partnership with the University of Cambridge, DS Smith has developed a number of prototypes from designs by secondary school students. The goal was to design a type of packaging which would contain everything a young child with asthma would need, whether they’re at home, at school or elsewhere; and one which would help reduce anxiety of children with asthma by using child-friendly design themes.

The programme, called Designing Our Tomorrow (DOT), was founded by researchers at the University of Cambridge, and brings real-world problems into classroom design and technology sessions in secondary schools, encouraging the next generation of UK designers and engineers.

Themes included a monkey character where the inhaler and spacer become a banana that the child can ‘feed’ the monkey with and then copy themselves. Other themes include a pack shaped like a cat where the inhalers become mice that are stored in a smaller box shaped like a wedge of cheese; and a folding pack that can hang on a door for easy access at home but can be quickly zipped up and put in a bag to take out.

Five of the best designs were presented by the secondary school students at the British Paediatric Respiratory Society conference in Cambridge in June. Some of the designs were made into prototypes by DS Smith and will be piloted with the NHS in London through the Health London Partnership.

Ian Hosking of Cambridge’s Department of Engineering, who co-leads the Designing Our Tomorrow (DOT) programme, in collaboration with the Faculty of Education said: “Students were tasked with not merely designing packaging but an experience. In other words, we wanted to make it fun and re-frame what education can be – projects like these start to form a broader evidence base of what’s possible. In addition, by working with industry, it takes the project beyond a competition to something that can make a difference to patients and help prevent avoidable asthma deaths in children.”

Russell Turner, Head of Ideation & Solutions of DS Smith’s UK Packaging Division said: “We have loved working alongside these Cambridgeshire school children to develop innovative prototypes that have the potential to radically transform the experience of children with asthma. We hope that working with us has helped them realise that ideas become more powerful when they become a reality, and shown them how exciting design and engineering can be as a career.”

About DS Smith

DS Smith operates in over 36 countries and employs around 26,000 people. Using the combined expertise of our four divisions – Packaging, Recycling, Paper and Plastics – we work with customers to deliver solutions that reduce complexity and deliver results throughout the Supply Cycle. For more information, visit www.dssmith.com.

DS Smith is the UK’s leading supplier of corrugated packaging. Our comprehensive product range includes retail ready packaging, transit cases, consumer units, packs printed for gift and POS applications, and heavy duty packaging for industry. DS Smith’s national network of manufacturing plants service thousands of customers, from multinationals to local businesses.

Using PackRight®, our unique way of working, our highly-skilled people work closely with customers to specify packaging that achieves real results. Typically, our customers achieve sales growth, or reductions in cost, waste and carbon at every stage of the Supply Cycle. For more information, visit www.dssmithpackaging.co.uk.