Displaying items by tag: INNVENTIA

Advanced lightweight material from forestry

Promising research findings with carbon fibre from lignin are presented in a new doctoral thesis by Ida Norberg

On 20 April, Ida Norberg defended her doctoral thesis “Carbon fibres from kraft lignin” at Innventia in Stockholm.

Her thesis shows that lignin, a substance that is found in wood but is removed during kraft pulp production, has great potential for use as a raw material for manufacturing carbon fibre. Carbon fibre is strong and light, with many applications. Today, demand is mainly limited by the high cost of production, with the petroleum-based raw material and fibre spinning accounting for around 50 percent of the cost. Thanks to LignoBoost technology*, the pulp mill can extract extremely pure lignin which could be used for carbon fibre, thus increasing access to a raw material for carbon fibre. According to studies reported on in Ida’s thesis, the cost of production could also be lowered by using lignin.

Her thesis shows that lignin, a substance that is found in wood but is removed during kraft pulp production, has great potential for use as a raw material for manufacturing carbon fibre. Carbon fibre is strong and light, with many applications. Today, demand is mainly limited by the high cost of production, with the petroleum-based raw material and fibre spinning accounting for around 50 percent of the cost. Thanks to LignoBoost technology*, the pulp mill can extract extremely pure lignin which could be used for carbon fibre, thus increasing access to a raw material for carbon fibre. According to studies reported on in Ida’s thesis, the cost of production could also be lowered by using lignin.

Ida carried out much of her doctoral work within the framework of the LigniCarb research project, with the aim of examining and demonstrating the possibilities of making carbon fibre from kraft lignin. One of the outcomes of this work was a brand new research environment at Innventia, where carbon fibre is now prepared on a laboratory scale.

“When I started this work six years ago, there was nothing except for a literature study by Elisabeth Sjöholm at Innventia,” explains Ida. “At that time, there were only three of us working on this project: Göran Gellerstedt from the Royal Institute of Technology, Elisabeth Sjöholm and me. Now there are lots of us involved, and there’s a great deal of interest from industry. It’s been exciting going from having nothing at all to now having lab equipment where we can actually produce carbon fibre. Hopefully, this work can lead to the full potential being realised and investment in larger scale, more advanced equipment.”

“There’s a lot to be gained from better equipment, such as the possibility of spinning a large number of fibres at the same time,” adds Elisabeth Sjöholm, who was Ida’s supervisor and is the project manager for LigniCarb. “But despite only having simple equipment, we can still show that kraft lignin has great potential as a raw material for carbon fibre. Building up knowledge is also extremely important in order to obtain expertise within what is a new area for us.”

In her studies, Ida has compared lignin from hardwood (birch and eucalyptus) and softwood (a mixture of spruce and pine). One important conclusion is that the differences in the lignin are reflected in the carbon fibre process. Softwood lignin has proven to be harder to liquefy and spin, but once lignin fibres have been produced they are easier to use later on in the process. The opposite is true with hardwood. A major breakthrough came when the team succeeded in spinning fibres from softwood lignin. This had previously been thought impossible, but is of particular interest to the forest industry in the northern hemisphere, such as the Nordic region and North America.

“This thesis is extremely interesting, and can be seen as another step towards the biorefineries of the future, where every component part of the wood is used based on its own unique properties, becoming raw materials for many different applications,” says Peter Axegård, Director of Business Area Biorefining at Innventia.

SustainComp Final Open Conference

Why you should mark this event in your calenderer for 2012!

The final conference for the SustainComp project financed by the EU will take place in Stockholm on June 14-15. This conference, which is open to all, will report on results achieved throughout the project.

“We will be outlining what we have accomplished and show a number of demonstrators prepared in this project. SustainComp is a combination of scientific project and materials and process development. This mix is reflected in the programme for the conference, which will include fundamental issues for discussion, as well as material concepts,” says Project Coordinator Mikael Ankerfors.

The conference begins following the final session of Paper Chemistry conference and continues in parallel with the final session of Paper physics.

Registration before May 14, 2012.

Conference venue

June 14 at Clarion Sign Hotel, Norra Bantorget Stockholm, Sweden, between 13.00–17.00.

June 15 at Innventia, Drottning Kristinas väg 61, Stockholm, Sweden, between 9.00–14.00.

Double win for Innventia

Innventia’s Marco Lucisano was awarded the Best Presentation Award at Paper Physics 2011 in Graz, Austria. The same person does not usually win more than once, but this was the second time Marco had been voted the winner in this category by participants at the conference.

Innventia’s Marco Lucisano was awarded the Best Presentation Award at Paper Physics 2011 in Graz, Austria. The same person does not usually win more than once, but this was the second time Marco had been voted the winner in this category by participants at the conference.

“This award is particularly important to me, because it relates to conveying knowledge,” he said. “Our goal must always be to get our message across, and this is essential if what we do is to be of any use.”

The award was presented at the conference dinner on 7 September, together with the prestigious Van den Akker Prize for Paper Physics. This accolade also went to Innventia, being awarded to Petri Mäkelä for work carried out at Innventia. Petri now works for Tetra Pak.

Equipped for future refining

In recent years, research has shown that refining is highly significant in terms of the strength properties of paper. Here at Innventia, we have a wide range of refining equipment for everything from laboratory-scale trials to full-scale trials.

In Innventia’s research projects, PFI mills – which can refine at the minimum 30 g – are often used for initial trials to evaluate factors such as a fibre’s strength potential. The pilot facility also includes full-size refiners for pilot trials. The intermediate stage now includes Innventia’s Voith refiner (1.7-2.1 kg pulp) for refining under more industrial-like conditions, but with smaller quantities. This can be used when refining large quantities of pulp is undesirable, but where researchers still want to carry out trials under industrial-like conditions. Chemical Pulp is an Innventia research cluster in which the Voith mill is used to evaluate more industrial-like refining.

Marie Bäckström, head of the Fibre Engineering group at Innventia, believes that the Voith refiner has a definite place:

“At the Voith refiner, we can look at different refining fillings and different fibre raw materials. The equipment is highly flexible, and besides traditional applications can also be used for refining mechanical pulp and carrying out studies using deionised water.”

Innventia has also constructed a refining loop next to the FEX pilot facility, which offers a whole range of different testing opportunities using industrial refiners. The effect of different fillings, pulps and pulps mixtures, flow conditions, chemical environment are just some of the process conditions that can be studied.

“We’ve worked long and hard with refining here at Innventia,” continues Marie. “For example, we’ve developed a new concept for LC-refining of mechanical pulp that has now been implemented at a large Swedish mill. With our ultramodern stock preparation system, we hope to be able to help our customers to create additional future concepts.”

New materials by mimicking nature

Last week, Innventia’s Jasna Stevanic Srndovic submitted her thesis on interactions between polymers in the cell wall of spruce wood fibres. The new knowledge in this area contributes to making existing paper industry processes more efficient and to develop new materials from biopolymers. The driving force behind her work is to find means to make better use of the earth’s resources in a sustainable way.

Last week, Innventia’s Jasna Stevanic Srndovic submitted her thesis on interactions between polymers in the cell wall of spruce wood fibres. The new knowledge in this area contributes to making existing paper industry processes more efficient and to develop new materials from biopolymers. The driving force behind her work is to find means to make better use of the earth’s resources in a sustainable way.

The threat of global warming and limited fossil resources calls for ways to better use our resources. One way could be to streamline industry processes, such as in the paper industry, by reducing energy consumption in the production of thermomechanical pulp (TMP). This can be done by applying various chemical and / or enzymatic pretreatments of wood. Jasna’s thesis presents results that provide a better understanding of polymer interactions within the primary cell wall of spruce wood fibres and its implications for the energy demand in the refining process. She demonstrates how applying a low degree of sulphonation pre-treatment to spruce wood chips caused a weakening of these molecular interactions, as well as an increased softening and swelling of the material, thereby reducing the energy consumption within the refining process.

Another way to better protect the environment is to use renewable resources to a greater extent. Large quantities of polymers, such as cellulose, hemicelluloses and lignin, recovered from residual materials from the paper industry and agriculture, can be used to produce new renewable packaging materials. In her work, Jasna has investigated the ultrastructure of the secondary cell wall of spruce wood fibres, and has tried to imitate the structures found in wood fibres by preparing biocomposites and evaluating these as packaging materials.

“Nature’s unique material structures have many excellent qualities,” explains Jasna. “For example, they can withstand variations in climatic conditions. By attempting to imitate these synthetically, it may be possible to develop new bio-based materials with adapted qualities. I’ve produced hemicellulose films with improved mechanical properties by strengthening these with nanocellulose.”

“Increased knowledge regarding the interactions between the wood polymers is very important in order to be able to separate these in a better way, for use in new materials and other applications,” says Lennart Salmén, head of the Fibre and Material Science group at Innventia.

“Working towards a more sustainable society is the driving force behind my work and I hope the results will find an application in the industry”, concludes Jasna.

Jasna Stevanic Srndovic work is largely financed by Formas Wood Wisdom NET and the Wallenberg Wood Science Centre.

New tool for measuring packaging performance

“Performance within packaging logistics is all about doing the right things, doing things right, and positioning your products and services in relation to your competitors’ products and services,” says Innventia’s Chris Dominic, who will be defending his thesis on the subject this week. His work highlights the demands and requirements placed on packaging by various players, and offers tools for developing more efficient systems.

“The aim of my thesis is to reinforce knowledge about packaging and its integral role with actors throughout the supply and demand chain,” he continues. “The aim is to be able to improve packaging logistics performance from a holistic perspective, thereby avoiding the risk of suboptimisation at any stage. It’s not just you who needs to be satisfied – so does your customer, and your customer’s customer.”

Chris has created a model for improving knowledge about packaging logistics. This model includes the Packaging Scorecard tool, which measures the performance of packaging logistics and shows which deficiencies exist at various levels within the supply chain. The tool has been further developed, and is already available online under the name of Packaperforma.

“I started working with packaging because it’s an interesting area for demonstrating in a concrete manner how logistics works,” explains Chris, who trained as a logistician. “But to my surprise, I discovered that there weren’t any tools for measuring performance in this field!”

The tool that Chris has now developed structures the requirements placed on packaging by various actors. The user inputs data about his own packages. By comparing this with data for the “best in class” packaging, the tool suggests effective packaging development where deficiencies are identified. It therefore answers questions such as “Where do I stand in comparison with my competitors, and what should I do to improve my packaging?”

In order to be able to say something about packaging logistics performance, it is important to understand the supply chains within packaging logistics. In his research, Chris interviewed almost a hundred companies within various value chains and conducted case studies.

“We talk rather carelessly about value chains. It’s actually a case of companies, or more accurately people within companies, who should have these contacts and knowledge about packaging. For the manufacturer, the question of how to design packaging is a central aspect, whereas the distributor sees things differently. At some point here the packaging makes the transition from hardware to become a service.”

Is the tool fully developed now? No – Chris already has his next goal in sight.

“I want to investigate how aspects such as sustainability can be applied to the packaging logistics models. Then we come to questions such as fossil fuels, water consumption and energy efficiency, but these go hand in hand with existing ways of thinking. The aim is therefore to investigate how effective logistics can contribute towards a more sustainable world.”

An impressive aim, and one that is worthy of a newly qualified Doctor in Packaging Logistics.

Chris Dominic will defend his thesis on 13 April at 13:15 in the STFI room.

Birgitta Sundblad appointed President of Innventia

Birgitta Sundblad has been appointed the new President of Innventia AB, a research and innovation company. She will take up her position on 1 July 2011, when the current President, Professor Gunnar Svedberg, is retiring.

At present, Birgitta Sundblad is the Global Director of AFH (Away from Home) Tissue Product Development and Innovation at SCA, where she has had various appointments for a little more than 12 years. Throughout her career, Birgitta has worked with research and development, in which she has had several leading positions in the chemical and forest industries.

“Birgitta Sundblad’s experience in research and development work, with its emphasis on the customer and consumer, will strengthen the development of Innventia in being a world-leading innovation partner,” states Director Mats Nordlander, Chairman of the Innventia Board.

Birgitta Sundblad comments, “I feel both proud and honoured to be given this challenge. I believe that my experience as manager of interdisciplinary teams will be a very good foundation for building a strong, well structured company, together with everyone at Innventia, not only to meet the challenges of today but also of the future.”

Birgitta, 53 years old and a Master of Science in Chemical Engineering since 1981, has divided her professional life between SCA and Eka Chemicals (Akzo Nobel). During these years, she has mainly worked with research and development matters, but she has also worked in the fields of production, sales and marketing. She was on the Board of EIRMA (European Industrial Research Management Association) from 2007 to 2010 and was consequently the first woman to be a Vice Chairperson of the EIRMA Board.

8th International Paper and Coating Chemistry Symposium, Stockholm, June 10-14, 2012

FIRST CIRCULAR AND CALL FOR PAPERS

The 8th International Paper and Coating Chemistry Symposium will be arranged in Stockholm, June 10-14, 2012. Previous symposiums have been held in Stockholm 1988, 1992, 2000 and 2006, in Ottawa 1996 and in Montreal 2003 and 2009. The 2012 symposium will be organised by Innventia and KTH.

Scope of the Symposium

The 8th International Paper and Coating Chemistry Symposium will cover the latest developments in the fields of paper chemistry, coating chemistry and nanotechnology for the paper industry. The scope of the symposium will be to discuss the performance of chemical additives in papermaking and coating operations. Both fundamental and more applied contributions are welcome.

Tentative topics are listed below. There will be at least one invited overview lecture for most of the topics. Some of these may have a more futuristic character, which in a sense can add to the flavour of the symposium.

Coating chemistry

- Green coatings

- New printing techniques/inkjet

- Paper-liquid interactions

- Barriers/nanobarriers

- Interactive surfaces

- Antibacterial surfaces/Bioactive surfaces

- Colloid chemistry

Paper chemistry

- Nature of joint strength

- Green chemicals/sustainability

- The application of nanotechnology in paper applications

- Non-wood paper chemistry

- New materials in paper and board products

- Wet- and dry strength

- Fibre engineering

- Retention formation

- Sizing and hydrophobation

- Colloid chemistry

- Dewatering

- Wet-end chemistry

Oral paper and poster submissions

Prospective authors are kindly invited to submit an abstract either for an oral presentation or a poster presentation. Regarding oral presentations, authors can either chose to submit a 1 page abstract or an extended abstract (2-3 pages) for evaluation. Required length for a poster abstract is 1 page.

Please notice that abstracts will only be accepted by electronic submission. In order to submit, please use this link www.paperconferences2012.com/submissions) and follow the instructions.

Authors will be notified of acceptance of papers/posters around December 15, 2011. If the oral paper is accepted, an extended abstract is required and must be submitted before March 1, 2012.

The extended abstracts will be printed in a “Book of abstracts” and distributed at the Symposium. The length of the presentation of the contributed papers will be around 20 minutes.

Information about the The 8th International Paper and Coating Chemistry Symposium

Please visit the conferences website www.paperconferences2012.com, where more details about the programme will be made available.

For more information sign up for our newsletter or contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

Hairy fibres important for paper strength

"Invention to measure crill can enhance quality and save energy"

Crill are particles that are too small to be visible under an ordinary microscope but that are of great importance for fibre bonding in paper. A method for measuring crill, which was developed thirty years ago, is now being made available for industrial use.

“It’s only during the past three years, while working in one of our research projects, that we realized how important crill really is. The content of crill was found to be the variable that showed the strongest covariation with strength,” says Lars Wallbäcks at Innventia, a research company in Sweden.

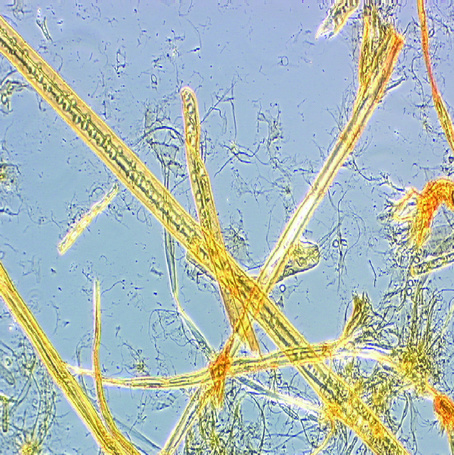

Micrograph (1.2 x 1.2 mm). Crill are the thin black threads on and around the fibres.

When measuring crill, you measure how "hairy" the fibres are. The more crill found on and around the fibres, the better binding ability they have, which in turn results in a stronger paper. In order to improve paper strength, it is therefore very useful to be able to measure the amount of crill in a pulp. With the aid of a crill sensor, it is possible to determine the amount refining required for optimizing the amount of crill in the pulp. This is also important from an economic point of view, since fibre refining is a very energy intensive process in paper production.

With the support of Forska & Väx (Research & Growth), a VINNOVA Programme, Innventia and Eurocon Analyzer, a measurement technology company, are developing a crill sensor for on-line application in pulp and paper mills. The aim is to make it possible to produce improved paper and pulp quality at lower energy costs.

The basic method for measuring crill was developed in the early 1980s by Thorulf Pettersson at Innventia. However, at that time, no importance was given to the small threads that surround the fibres. The crill sensor has been used in laboratory and pilot environments over the years, but it is only in the last three years, during the Advanced Fibre Management Project, that there has been a realization of how important crill is, when it comes to paper strength properties.

The crill measurement technique has been significantly improved since it was first invented. Jointly with Eurocon, it is now being further developed, since it is being integrated with their analysis platform, called PulpEye. Unlike sensors based on conventional image analyses, the crill sensor makes measurements of crill rapidly and frequently, which means that it is very suitable for online measurements in paper production.

“It's great that this invention can be utilized on a larger scale and that pulp and paper producers can now use this measurement technique to improve their processes and products,” says Thorulf Pettersson at Innventia.

EU approves Swedish support to LignoBoost demonstration plant

European Commission has authorised a Swedish grant of SEK 90 million to development of a LignoBoost demonstration plant at a Swedish pulp mill. LignoBoost will enable the mill to replace the fossil fuel in the lime kiln with lignin, reducing oil dependence and carbon emissions. The Commission estimates that the investment would also generate important external benefits, contributing in particular to knowledge spill-overs and environmental protection.

“ It is with great pleasure that we can notice that the EU understands the importance of an industrial demonstration plant that can demonstrate a crucial piece of the vision to transform modern kraft pulp mills into biorefineries. The fact that the financial support from the Swedish Energy Agency has been approved by the EU is a good driving force for the LignoBoost process to become a reality. The Commission decision will hopefully, eventually, relieve the pulp mills of their dependence on fossil oil and give them a new product to use as a high-grade biofuel or bio-based raw material for chemicals and materials,” says Per Tomani, Innventia.

The LignoBoost process is based on a research collaboration between Innventia and Chalmers, who developed a process for extracting high quality lignin from sulphate pulp mills. Research work on the process and the use of lignin as fuel has been run for years by Innventia under predominantly the Swedish Energy Agency, Södra Cell, Stora Enso, Metso, Nordic Paper and Fortum Värme. The process provides opportunities for increased capacity at lower cost than expansion of a limited recovery boiler. Profitability improved further if the lignin can be used as a substitute for fossil fuel oil, for example, pulp mill lime kilns or as raw material for production of even more valuable products such as carbon fibre. In May 2008, Innventia sold LignoBoost to the international technology company Metso and thereby increased the potential for further commercialisation and realisation of industrial plants.

In July 2010, the Swedish Energy Agency granted support to a demonstration plant at Södra Cell pulp mill in Mörrum. The European Commission has now ruled that the project complies with EU guidelines on state aid for research, development and innovation.

Joaquín Almunia, Vice-President of the Commission in charge of competition policy, declared:

“The project will pave the way to transform a pulp mill into a real bio-refinery without unduly distorting competition. Fossil fuel will be replaced by a novel source of renewable energy, contributing to Europe's 2020 objectives concerning R&D, climate change and energy.”

For more information on LignoBoost:

Per Tomani, Innventia AB

tel. +46 8 676 7281, This email address is being protected from spambots. You need JavaScript enabled to view it.

INNVENTIA AB is a world leader in research and development relating to pulp, paper, graphic media, packaging and biorefining. Our unique ability to translate research into innovative products and processes generates enhanced value for our industry partners. We call our approach boosting business with science. Innventia employs 270 people, based in Stockholm, Bäckhammar, Trondheim and London.