Displaying items by tag: James Cropper

Where have all the flowers gone? 18,000 art lovers walk into a room of poppy paper.

The launch exhibition for Manchester’s newly re-opened and revamped Whitworth art gallery caused a stampede of visitors, but few were to know that James Cropper’s paper lies at the heart of Cornelia Parker’s stunning War Room installation.

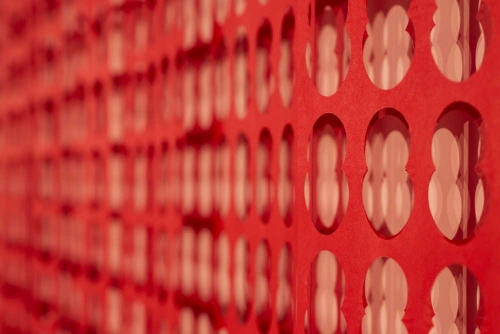

Thousands of punched sheets of James Cropper’s custom-made, red poppy paper now hangs in the most unusual of places - the newly reopened Whitworth art gallery in Manchester. Usually sent for recycling, the vast sheets of paper left with poppy-shaped holes now feature at the heart of internationally renowned artist, Cornelia Parker’s solo exhibition.

A reported 18,000 people passed through the gallery’s doors on its opening weekend, reacting to the international media attention gained by the opening. Many of these visitors took their time to walk into War Room, the immersive installation that sees an entire room bedecked with paper reclaimed from the Aylesford poppy factory. Simply left with the poignant outline of the missing poppy, hung from floor to ceiling and overhead, Parker’s exceptionally well-received, emotionally charged tribute to fallen soldiers asks a literal question: where have all the flowers gone?

The poppy paper is made to exacting standards by James Cropper Paper, especially made to match the colour of the real flower and made to be rub and run resistant to protect clothing. The manufacturer supplies 250km of the paper to the Poppy Factory every year.

The artist likens the intended experience of her installation to that of the op-artists of the 1960s, which saw the likes of Bridget Riley manipulate traditional art techniques to create optical illusions. A ‘walk-in’ piece, visitors are surrounded by with the industrial, rhythmic pattern pressed out of the paper. The breath-taking use of an otherwise wasted material has caused equal pride and intrigue amongst staff at the Cumbrian paper mill.

Phil Wild, CEO of James Cropper, comments: “James Cropper supplies the red poppy paper to the Royal British Legion, and support and respect the fantastic job that they do for past and present veterans and their families. It is really interesting to see thought provoking art and narrative illuminating the effects of war. In re-using the remnants from poppy production to create War Room, Cornelia Parker poignantly reminds us of all the holes in our lives left behind by those who have been lost in conflict.”

Cornelia Parker, famed for her use of found and overlooked materials, presents War Room as part of an exhibition of new commissions and retrospective installations at The Whitworth until Sunday 31 May 2015.

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper is based in the Lake District, England’s first and foremost National Park, with a paper-making heritage that started in 1845. Since its inception the business has been carefully stewarded and nurtured by six generations of the Cropper family.

Today the business is renowned globally for its luxury packaging papers, which accompany many of the world’s most exclusive brands, while the world’s leading artists, galleries and museums use its framing and archival boards alongside its range of conventional artists materials. As well as paper products, James Cropper also manufactures nonwovens from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

Technical Fibre Products (TFP) is a leading nonwoven manufacturer, offering a broad range of high quality, technically advanced nonwovens which can be customised to meet specific application requirements. Established nearly 30 years ago, TFP primarily operates within the automotive, and aerospace composite markets while also providing effective solutions in the defence, energy, consumer electronics, industrial, construction and healthcare markets. Utilising extensive materials knowledge within polymers, particulates & speciality fibres together with high specification lamination, metal fibre coating and converting capabilities, TFP provide a wide range of customised solutions.

To find out more about the innovative production methods, product range, responsible manufacturing principles and history of James Cropper and Technical Fibre Products, please visit www.jamescropper.com and www.tfpglobal.com Making Hearts Melt: Chinese Chocolate Printing Craze Wrapped-Up in ‘Cocoa’

3D printing has delivered spare parts to the International Space Station, concept cars and now delicious, personalised Valentine’s Day gifts. Few things can say ‘I love you’ like an image of your loved one perfectly printed in dark, milk and white chocolate, quite literally having the ability to make each other melt.

Chinese company, Wolfson have conquered the limitations of chocolate’s liquid tendencies to create a printer capable of producing fine images using nothing but the sweet stuff. This year they will be offering beautifully boxed, personalised portraits as gifts under the brand name ‘Euler’s Rose’.

The company, founded by graduates of the University of Cambridge, returned to the UK in search of the ideal packaging for their innovative product, deciding on James Cropper’s Cocoa papers for the in-box wrapping – a paper itself produced by recycling the cocoa shells discarded during chocolate’s production.

Developed in collaboration with international cocoa trade supplier, Barry Callebaut and launched in 2013, Cocoa is part of James Cropper’s wide range of papers developed with sustainability-conscious customers front of mind. The ‘Cocoa Shell’ colour variant of the naturally pigmented stock for the chocolate photograph’s protective wrapper contrasts with the deep red tone of the outer box made of Colorplan Scarlet from G . F Smith.

The precarious science of printing with chocolate involves bringing the three shades of confectionery to temperatures between 34c and 38c, after which point they will become too runny to form an accurate image. Such devotion to honing this craft has been applauded by James Cropper.

Chris Brown, Commercial Director, said: “It took James Cropper’s development team numerous trials to master the ability to incorporate cocoa shell powder into a paper that was ready for printing, food contact and it’s numerous other uses, but the perseverance paid off. We’re delighted that similarly tenacious and innovative entrepreneurs in China have found such a good use for the papers, and hope those who give and receive these gifts find a lifetime of happiness together.”

The luxurious gift box with gold foil print says ‘Euler’s Rose’ – a name drawn from a fable concerning two lovers, re-united over such a chocolate gift – and the great physicist, Albert Einstein’s famous quote: “Gravitation cannot be held responsible for people falling in love.”

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper is based in the Lake District, England’s first and foremost National Park, with a paper-making heritage that started in 1845. Since its inception the business has been carefully stewarded and nurtured by six generations of the Cropper family.

Today the business is renowned globally for its luxury packaging papers, which accompany many of the world’s most exclusive brands, while the world’s leading artists, galleries and museums use its framing and archival boards alongside its range of conventional artists materials. As well as paper products, James Cropper also manufactures nonwovens from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

Technical Fibre Products (TFP) is a leading nonwoven manufacturer, offering a broad range of high quality, technically advanced nonwovens which can be customised to meet specific application requirements. Established nearly 30 years ago, TFP primarily operates within the automotive, and aerospace composite markets while also providing effective solutions in the defence, energy, consumer electronics, industrial, construction and healthcare markets. Utilising extensive materials knowledge within polymers, particulates & speciality fibres together with high specification lamination, metal fibre coating and converting capabilities, TFP provide a wide range of customised solutions.

To find out more about the innovative production methods, product range, responsible manufacturing principles and history of James Cropper and Technical Fibre Products, please visit www.jamescropper.com and www.tfpglobal.com

Julie Tomlinson

E: This email address is being protected from spambots. You need JavaScript enabled to view it.

T: +44 1539 818413

A Cut Above: Bar made from paper brings standalone style to fashion launch

A stylish bar, fit for a lavish cocktail party before being recycled, has been produced by British design studio, Flow Creation using luxury papers from British manufacturer, James Cropper

170 year-old paper innovators, James Cropper and heritage clothing brand, Thomas Pink joined forces to commission a stunning paper bar and set of paper drinking accessories, designed to stand as a centrepiece in the hallowed halls of London’s Institute of Contemporary Arts (ICA) during the London Collections fashion event.

170 year-old paper innovators, James Cropper and heritage clothing brand, Thomas Pink joined forces to commission a stunning paper bar and set of paper drinking accessories, designed to stand as a centrepiece in the hallowed halls of London’s Institute of Contemporary Arts (ICA) during the London Collections fashion event.

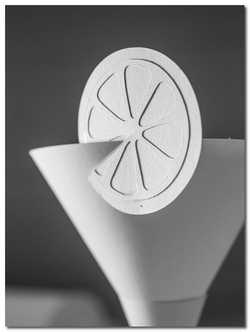

Developed and built by Sam Robins of design studio, Flow Creation, the free-standing bar, made from two different weights of James Cropper’s White Kendal Manilla stock came complete with paper glasses, lamps and fine architectural detail to complement the historic setting. Constructed to stand at the heart of Thomas Pink’s, London-inspired Autumn/Winter 2015 collection launch on Saturday 10 January 2015, the collaboration called on the designer to evoke the crisp freshness of a new, white shirt while testing the qualities of the versatile paper stock.

Following deliveries of 315gsm and 180gsm papers to his Blackpool studio, Robins combined manual hand-working and paper cut techniques with computerised design and cutting processes to develop the bar and drinking paraphernalia. As well as working with Thomas Pink’s commercial team and both event and lighting designers for his cues, he looked to the ICA itself for inspiration, noting detail from the Corinthian columns and ornate cornicing.

Sam says:“Initially I was shocked by the size of the venue; it’s a really grand, imposing space. The bar has grown to 8.5 metres long as a result. Thomas Pink really let me develop the design and specifications with little intervention, simply asking that it did the job of allowing models to interact with it as an alternative to your usual catwalk fashion show. The paper has stood up to every test I have thrown at it, with heavier stock taking the burden of structural support and the lighter weight allowing for decorative elements. Many of the props are really quite large, but can stand without additional support.”

As well as creating lemon slices, martini glasses and even a paper-framed, 3D artwork of the Thomas Pink logo, ‘cheeky fox’, Robins has incorporated LEDs and RGB lighting tape into hidden parts of the bar to ensure it responds to thematic changes during the show. The only structural concession required of the paper, to give models confidence in using the bar naturally, was an MDF sub-structure for surface strength and ballast. To close the event, gathered VIPs of the fashion industry and press were handed pink pens and invited to leave messages on the clean, white surface.

As well as creating lemon slices, martini glasses and even a paper-framed, 3D artwork of the Thomas Pink logo, ‘cheeky fox’, Robins has incorporated LEDs and RGB lighting tape into hidden parts of the bar to ensure it responds to thematic changes during the show. The only structural concession required of the paper, to give models confidence in using the bar naturally, was an MDF sub-structure for surface strength and ballast. To close the event, gathered VIPs of the fashion industry and press were handed pink pens and invited to leave messages on the clean, white surface.

Chris Brown, Commercial Director of James Cropper, said: “Our customers come to us for a product that is perfectly matched to their needs, and in this case our White Kendal Manilla was ideal for laser cutting as well as the purity of its colour. Kendal Manilla has become established as a benchmark in quality in the art, craft and stationery markets and has proved perfect for the intricate construction of this fun, visually stunning project.”

The paper bar will be recycled following the press launch alongside the PINK Drink/James Cropper branded paper drinks cups used to serve cocktails at the event. The Kendal Manilla stock contains up to 40% reclaimed fibres from single-use drinks cups. The reclaimed pulp originates from James Cropper’s own, pioneering recycling plant, which sees the formerly unrecyclable waste material given a new lease of life.

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper is based in the Lake District, England’s first and foremost National Park, with a paper-making heritage that started in 1845. Since its inception the business has been carefully stewarded and nurtured by six generations of the Cropper family.

Today the business is renowned globally for its luxury packaging papers, which accompany many of the world’s most exclusive brands, while the world’s leading artists, galleries and museums use its framing and archival boards alongside its range of conventional artists materials. As well as paper products, James Cropper also manufactures nonwovens from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

Technical Fibre Products (TFP) is a leading nonwoven manufacturer, offering a broad range of high quality, technically advanced nonwovens which can be customised to meet specific application requirements. Established nearly 30 years ago, TFP primarily operates within the automotive, and aerospace composite markets while also providing effective solutions in the defence, energy, consumer electronics, industrial, construction and healthcare markets. Utilising extensive materials knowledge within polymers, particulates & speciality fibres together with high specification lamination, metal fibre coating and converting capabilities, TFP provide a wide range of customised solutions.

To find out more about the innovative production methods, product range, responsible manufacturing principles and history of James Cropper and Technical Fibre Products, please visit www.jamescropper.com and www.tfpglobal.com

'Lost' British Paper Brand Relaunched by James Cropper Paper

Croxley Heritage Re-launched in 2015

Prestigious British paper brand returns with a mission to reignite the romance in quality stationery.

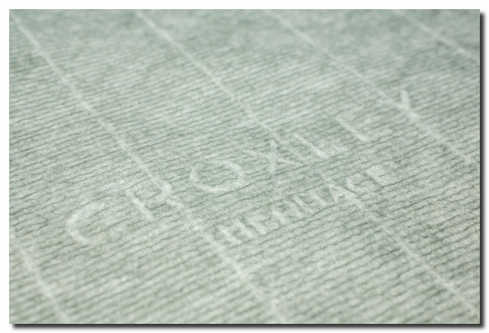

One of the great British stationery brands Croxley Heritage is to be reintroduced to the desks of discerning business and private paper buyers via a relaunch at Paperworld, Frankfurt between Saturday 31 January – Tuesday 3 February 2015. Inspired by the original brands of John Dickinson & Co. Ltd of London, established in 1804, the stationery line will be reactivated by luxury paper manufacturer, James Cropper.

Inventor of continuous mechanised paper production techniques, John Dickinson (1782-1869) established mills across the world at the height of his powers as a leading, Victorian industrialist. However, it was his mill at Croxley Green, Hertfordshire on the banks of the Grand Union canal that gave some of the famous Dickinson brands - including Croxley – their names, with paper running off the production line there for 150 years until 1980.

Having been recently acquired by James Cropper – based in Cumbria at the heart of England’s Lake District – 2015 sees Croxley Heritage re-launched to carry the values and traditions of one of the world’s oldest and most sought after paper products, with the brand’s custodians encouraging buyers to rediscover the romance of beautifully made, traditional stationery.

Chris Brown, Commercial Director of James Cropper, said: “Croxley Heritage is a name synonymous with the best traditions of British paper manufacturing, born of a pioneering paper maker, John Dickinson. Like Dickinson, James Cropper - great-great-great grandfather of our Chairman Mark Cropper – believed in the production of only the highest quality papers. It is fitting that we have the opportunity to take this brand back onto the market in the best of their founding traditions.”

The paper fibre used to make the contemporary versions of Croxley Heritage will be comprised of 90% post-consumer waste and 10% reclaimed cup fibre from James Cropper’s own reclaimed fibre facility, opened last year following a £5million investment. The production process uses Hydro Power from a newly commissioned hydro plant on the river Kent (developed with Ellergreen Energy); ensuring Croxley Heritage is as clean to produce as it appears in its final form. Croxley Heritage is a watermarked paper range in a neutral colour palette – white, cream, silver, wedgwood – available in a selection of wove, laid and linen finishes.

Phil Wild, CEO of James Cropper, said: “Business users looking for a paper to reflect their credentials will find the Croxley Heritage range perfect for letterheads, business cards and other uses, but we also recognise that sustainable sourcing is also a reputational issue for all of our customers. The production process has been carefully designed to ensure the environmental impact of every sheet of paper is dramatically reduced by using state-of-the-art recycling technologies and sustainable energy procurement.”

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper is based in the Lake District, England’s first and foremost National Park, with a paper-making heritage that started in 1845. Since its inception the business has been carefully stewarded and nurtured by six generations of the Cropper family.

Today the business is renowned globally for its luxury packaging papers, which accompany many of the world’s most exclusive brands, while the world’s leading artists, galleries and museums use its framing and archival boards alongside its range of conventional artists materials. As well as paper products, James Cropper also manufactures nonwovens from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

Technical Fibre Products (TFP) is a leading nonwoven manufacturer, offering a broad range of high quality, technically advanced nonwovens into the composites market, which can be customised to meet specific application requirements. Established nearly 30 years ago, TFP primarily operates within the automotive, and aerospace composite markets while also providing effective solutions in the defence, energy, consumer electronics, industrial, construction and healthcare markets. Utilising extensive materials knowledge within polymers, particulates & speciality fibres together with high specification lamination, metal fibre coating and converting capabilities, TFP provide a wide range of customised solutions.

To find out more about the innovative production methods, product range, responsible manufacturing principles and history of James Cropper and Technical Fibre Products, please visit www.jamescropper.com and www.tfpglobal.com

Looks like suede and feels just like suede: James Cropper’s leather-effect papers

Responding to the demands of the luxury market, British paper innovators create a packaging solution that may more accurately mimic the texture of premium, napped leathers than any other produced.

Putting their technological capabilities to the test, product developers at James Cropper Paper have succeeded in closely reproducing the soft, yet durable qualities of suede leathers in a paper-based form. Following the merge of the company’s production and converting functions earlier this year, the launch of Carvetian Suede heralds a new era of innovation, with luxury brands set to benefit from the close links between the mill and co-located facility.

Taking its name from Iron Age settlers in the North of England, the Carvetii, Carvetian Suede has been produced to better mimic one of both ancient and modern civilisation’s most widely used and versatile materials. Initially available to buyers in four colours drawn from a natural palette - Crystal, Calico, Sandstone and Pebble – the product will formally launch at Luxepack Monaco 2014 between Mon 27 – Wed 29 October 2014 at the Grimaldi Forum, Monaco.

The delicate feel of Carvetian Suede was trialled in May 2013, when a dog sculpture was created using the product for the Gerald and James exhibition in New York, an event that showcased the product alongside James Cropper’s commitment to supporting the best in contemporary design. The dog, resplendent in its stylish suede coat, was a keen demonstration of the creative potential offered by the paper. Carvetian Suede is now available to international buyers and presents itself as an opportunity for packaging designers around the world.

Chris Brown, Commercial Director of James Cropper, said: “Papers that recreate the textures and behaviours of other materials sometimes fall short due to the quality of the base paper and the expertise involved in their creation. With Carvetian Suede, James Cropper uses a high quality foundation in our papers and hundreds of hours of expert-led product development to ensure the product is flawless and fit for purpose. The inclusion of a high percentage of recycled fibres, a characteristic of the vast majority of James Cropper papers, means commercial buyers also buy into our commitment to sustainable production.”

Each run of Carvetian Suede, in any of the available colours, is manufactured with a minimum of 40% recycled, post-consumer fibres. The product is intended to provide not only luxury brands with a lavish packaging solution, but also encourage those compiling business documents, brochures and creative advertising materials with a show stopping finish.

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper is based in the Lake District, England’s first and foremost National Park, with a paper-making heritage that started in 1845. Since its inception the business has been carefully stewarded and nurtured by six generations of the Cropper family.

Today the business is renowned globally for its luxury packaging papers, which accompany many of the world’s most exclusive brands, while the world’s leading artists, galleries and museums use its framing and archival boards alongside its range of conventional artists materials. As well as paper products, James Cropper also manufactures nonwovens from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

Technical Fibre Products (TFP) is a leading nonwoven manufacturer, offering a broad range of high quality, technically advanced nonwovens which can be customised to meet specific application requirements. Established nearly 30 years ago, TFP primarily operates within the automotive, and aerospace composite markets while also providing effective solutions in the defence, energy, consumer electronics, industrial, construction and healthcare markets. Utilising extensive materials knowledge within polymers, particulates & speciality fibres together with high specification lamination, metal fibre coating and converting capabilities, TFP provide a wide range of customised solutions.

To find out more about the innovative production methods, product range, responsible manufacturing principles and history of James Cropper and Technical Fibre Products, please visit www.jamescropper.com and www.tfpglobal.com

For further information

Julie Tomlinson

E: This email address is being protected from spambots. You need JavaScript enabled to view it.

T: +44 1539 818413

James Cropper Sponsors Third Edition of Frieze Masters Art Fair

British paper innovators and suppliers of archival and display papers to the world’s leading art galleries and artists joins international collectors to celebrate the work of past masters.

Since 2012, Frieze Masters has brought art lovers and selected international galleries together to reflect on and collect the work of many of history’s most revered artists. James Cropper has been proud to sponsor the annual event and will support this year’s edition, taking place in Regents Park, London, between Wed 15 – Sun 19 October 2014.

Focusing on art made prior to 2000, the fair assembles over 120 leading galleries, representing work from ancient to modern art. Previous editions have seen galleries from as far as Brazil, Canada, France, Germany, Italy, Russia and Spain take up temporary residence at the London event.

Representatives from many of the world’s leading arts institutions visit Frieze Masters to view the vast range of sculptures, paintings and drawings on show and listen to professional talks from many of the most respected artists and arts professionals. Among those reflecting on historical works in a contemporary context at this year’s fair are Wim Pijbes, Director of the lauded Rijksmuseum in Amsterdam and celebrated British ceramicist and writer, Edmund de Waal.

Mark Cropper, Chairman of James Cropper PLC and sixth generation member of the Cropper family, said: “James Cropper has a long history of providing specialist papers to artists and arts institutions and is proud to extend this association with the classical and contemporary arts by sponsoring Frieze Masters for the third year. We will look forward to welcoming our guests to the fair, giving them the opportunity to enjoy the remarkable breadth of art on display.”

James Cropper paper is the world’s only manufacturer to have a Mountboard factory located alongside the paper mill itself, enabling the company to provide bespoke solutions for the storage, display and archive of precious works of art to internationally-renowned galleries. The same factory assists photographers and artists to display their work on durable digital board products, including the recently launched Khora Digital, a creative box presentation that can be directly printed, instantly assembled and hung.

James Cropper PLC maintains constant links with the creative industries, not only within its paper division, incorporating converting capabilities, but also Technical Fibre Products, a specialist supplier into to the composites market for non-wovens for aerospace, automotive and construction

Contact

Julie Tomlinson

This email address is being protected from spambots. You need JavaScript enabled to view it.

T: +44 1539 818413

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper is based in the Lake District, England’s first and foremost National Park, with a paper-making heritage that started in 1845. Since its inception the business has been carefully stewarded and nurtured by six generations of the Cropper family.

Today the business is renowned globally for its luxury packaging papers, which accompany many of the world’s most exclusive brands, while the world’s leading artists, galleries and museums use its framing and archival boards alongside its range of conventional artists materials. As well as paper products, James Cropper also manufactures nonwovens from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

Technical Fibre Products (TFP) is a leading nonwoven manufacturer, offering a broad range of high quality, technically advanced nonwovens into the composites market, which can be customised to meet specific application requirements. Established nearly 30 years ago, TFP primarily operates within the automotive, and aerospace composite markets while also providing effective solutions in the defence, energy, consumer electronics, industrial, construction and healthcare markets. Utilising extensive materials knowledge within polymers, particulates & speciality fibres together with high specification lamination, metal fibre coating and converting capabilities, TFP provide a wide range of customised solutions.

To find out more about the innovative production methods, product range, responsible manufacturing principles and history of James Cropper and Technical Fibre Products, please visit www.jamescropper.com and www.tfpglobal.com

About Frieze Masters

Frieze Masters is an art fair founded in 2012 to give a unique contemporary perspective on art of all ages. Frieze’s first fair for historical art, Frieze Masters coincides with, and is within walking distance of Frieze London. Frieze was founded by Matthew Slotover and Amanda Sharp with the launch of frieze magazine in 1991 this was followed by the opening of Frieze London in 2003, which is now one of the world’s leading contemporary art fairs.

Completing the Loop: Recycled Coffee Cups Re-Enter the Consumer Market

Disposed-of paper cups return to consumer hands as James Cropper launches ‘Coffee’, a range of high-specification papers using fibres extracted from previously unrecyclable paper cups.

Single-use disposable coffee cups finally became recyclable in July 2013, when James Cropper unveiled a purpose-built Reclaimed Fibre Facility, the first commercial processing plant able to separate valuable pulp fibres from the polythene lining of billions of cups thrown away each year. The British manufacturer now returns those fibres to the supply chain in Coffee, a range of papers that demonstrate the highest standards in sustainable, luxury paper production.

Launching at Packaging Innovations 2014 (Tue 30 September - Wed 1 October), Coffee is comprised of 50% reclaimed fibres (RCF) that were once ‘single use’ coffee cups, offering luxury brands, including food and drink producers, the opportunity to repurpose a high quality paper source previously lost to landfill. The range has been initially produced in a range of six colours inspired by the skills of Baristas and the alchemy of coffee making - Latte, Cappuccino, Caramel, Hazelnut, Mocha and Espresso.

James Cropper has been announced as coffee cup sponsor of the Packaging Innovations 2014 event at the Business Design Centre, London. Integral thermal sleeves on the event cups have been made with RCF, effectively reintroducing recycled coffee cups to their original use for the very first time. The messaging on the event cups encourages drinkers to ‘Be In The Loop’ by taking their cups to the James Cropper Stand, E57, and posting used cups into a collection device to start the recycling process all over again.

Chris Brown, Commercial Director said: “Disposable coffee cups were a problem for our industry and now we’ve turned them into an opportunity. Technology has moved on so that we can create new products using high-levels of reclaimed materials, which are indiscernible in their quality from papers that are made wholly from virgin fibres. Packaging manufacturers and suppliers are under increasing consumer pressure to prove they are responsible with natural resources, and the Coffee range is just one of the ways in which our investment in new recycling processes makes it easier for them to respond to those demands, without compromising their products and brand values.”

Opened by Her Majesty The Queen, James Cropper’s Reclaimed Fibre Facility based in Cumbria, UK is the result of a £5million investment and has been recognised by the paper industry as a landmark development in the progression of sustainable paper production. The Luxepack In Green Award was presented to James Cropper in October 2013 in recognition of this contribution. In the year since opening, thousands of coffee cups and other food and drink packaging materials have been recycled to create new paper products, but Coffee sees the percentage of RCF pulp increase to 50% for the very first time.

Earlier this year, James Cropper PLC became one of 14 international companies to formally join the Paper Recovery and Recycling Group (PCRRG), drawing together paper and paper cup manufacturers with high street coffee retailers, to conduct in-market trials of recycling processes and end products, with emphasis on the UK market.

James Cropper PLC maintains significant investment in new technologies not only within its paper division, incorporating converting capabilities, but also Technical Fibre Products, a specialist supplier into to the composites market for non-wovens for aerospace, automotive and construction.

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper is based in the Lake District, England’s first and foremost National Park, with a paper-making heritage that started in 1845. Since its inception the business has been carefully stewarded and nurtured by six generations of the Cropper family.

Today the business is renowned globally for its luxury packaging papers, which accompany many of the world’s most exclusive brands, while the world’s leading artists, galleries and museums use its framing and archival boards alongside its range of conventional artists materials. As well as paper products, James Cropper also manufactures nonwovens from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

Technical Fibre Products (TFP) is a leading nonwoven manufacturer, offering a broad range of high quality, technically advanced nonwovens into the composites market, which can be customised to meet specific application requirements. Established nearly 30 years ago, TFP primarily operates within the automotive, and aerospace composite markets while also providing effective solutions in the defence, energy, consumer electronics, industrial, construction and healthcare markets. Utilising extensive materials knowledge within polymers, particulates & speciality fibres together with high specification lamination, metal fibre coating and converting capabilities, TFP provide a wide range of customised solutions.

To find out more about the innovative production methods, product range, responsible manufacturing principles and history of James Cropper and Technical Fibre Products, please visit www.jamescropper.com and www.tfpglobal.com

Customer Experience Enhanced as James Cropper Simplifies Paper Division

James Cropper is merging its two paper divisions, Speciality Paper and Converting, into one business to simplify and optimise customer service.

James Cropper is the new, simplified name for the speciality paper and converting business of James Cropper PLC, operating from the company’s traditional manufacturing and administration base in Burneside, Cumbria. Led by Commercial Director, Chris Brown, the move sees the sales and marketing teams merged into one, allowing more cross selling of the products and capabilities of those divisions.

The combined division grew sales by 7% to £71.5m in the year to March 2014, with operating profit of £2.5m, a 20% increase on the year before.

The merger of the two divisions coincides with a complete rebrand, stressing the company’s heritage and its commitment to innovation and customer service. The combination of the two allows the specialist paper product portfolio to combine the specialist colours, embossings, and surface enhancements with mount-boards, high-quality inkjet papers, display board and luxury packaging.

Chris Brown says: “By combining the converting and paper businesses under one brand, we invite our existing and future customers to task us with completing the most challenging production requests, from sales to delivery, on just one manufacturing site. Our mill has an unrivalled reputation for colour and scientific research into new paper finishes. The ambition is to offer customers a seamless service.”

James Cropper PLC also incorporates Technical Fibre Products (TFP), suppliers of nonwoven, speciality fibre products to industries including aerospace, automotive and electronics markets. TFP remains a standalone business as it operates in very different market niches.

Remembrance Poppy Production Makes a Symbolic Start at James Cropper

Preparing for the 2014 Poppy Appeal, while poignantly commemorating the lives lost during World War One, the production of the red paper for 40 million Remembrance Poppies is set in motion by a veteran.

Every year 250 kilometres of red paper is produced at James Cropper in Cumbria, destined for the Poppy Factory in Kent where it is turned into millions of Remembrance Poppies. This year holds special significance as the 100th anniversary of the start of the First World War and to mark the occasion Mr David Horsman, a former weapons engineer and ships diver in The Royal Navy,symbolically kick-started the paper production process.

Invited by the paper making firm to tip the all-important red dye into a new batch of poppy paper, Mr Horsman, from Kendal, saw the concentrated red colourant gradually turn the swirling container of paper pulp deep crimson, helping to celebrate and raise-awareness of The Royal British Legion’s Poppy Appeal. After serving on vessels including HMS Liverpool between 1979 and 1987, Mr Horsman called on the help of the Royal British Legion for financial assistance. Now a successful businessman, he gives thanks for the support offered to him by giving his time as a Poppy Appeal Organiser.

Although poppies are manufactured nearly every day of the year at facilities in Aylesford, Kent and Richmond, Greater London to meet overwhelming public demand, James Cropper contacted charity representatives earlier in the year to arrange the symbolic start of production celebration and invite their special guest. There was an opportunity for reflection once the dye had worked its magic and the mill swung into action to turn the pulp into paper.

Phil Wild, Chief Executive of James Cropper, said: “Although we are involved each year in the production of papers for Remembrance Poppies, we don’t take it for granted what the poppy means to so many families and the country as a whole. Everyone at both James Cropper Paper and Technical Fibre Products are proud to be able to arrange this special gesture of remembrance and support for the Poppy Appeal and are grateful to Mr Horsfield for his service, fundraising contributions and time to mark the occasion with us.”

Since 1978, James Cropper has produced the red paper for Remembrance Poppies. A British company overseen by the sixth generation of the Cropper family as Chairman, they are renowned for bespoke papers and laboratory technicians have taken colour samples from real poppy petals to ensure the paper is the closest possible colour match to the real thing.

Marcus Hawthorn, Area Manager for Cumbria at The Royal British Legion, said: “It’s a pleasure to witness the start of the poppy journey at James Cropper. The red paper will be transformed into millions of poppies, which enables the Legion to continue providing practical help and support to the whole Armed Forces community. In this poignant year which marks the centenary of the First World War we encourage the nation to reflect on the sacrifices made by all Service men and women who fought for the freedom we enjoy today.”

From Cumbria, the paper makes the 300 mile trip to the South East, where Poppy Factories produce more than 40 million Remembrance Poppies, 500,000 poppies of other types, 5 million Remembrance petals, 100,000 wreaths and sprays, 750,000 Remembrance Crosses and other Remembrance items.

Dave Watson, Chief Operations Officer of James Cropper, joined the guest of honour at the event and commented: “We are very proud of our longstanding involvement in the production of the paper poppy, and it must be said that there is more to this iconic emblem than at first meets the eye – the paper colour does not run in the rain or rub off onto clothing, it retains its vibrant colour and holds its shape. The diverse technical chemistry required to achieve this ensures the paper poppy is worn with confidence the world over as a symbol of respect and remembrance.”

For more information about the Poppy Appeal visit http://www.britishlegion.org.uk

Compostable Alternative to Plastic and Metal: Södra and James Cropper present DuraPulp

Swedish forestry giant and Britain’s leading paper and technical fibre innovators join forces to establish strong, durable and degradable DuraPulp in the international marketplace.

A paper product that can carry the weight of an adult and be composted within 100 days has emerged from Sweden to compete as a lightweight, sustainable alternative to plastic. DuraPulp is the subject of a new partnership between Södra and 169 year old paper and technical fibres manufacturer James Cropper PLC,which was announced today.

The potential of DuraPulp has brought the two, global leaders in pulp and technical fibre innovation together to develop applications for the bio-composite material and stimulate interest amongst other pioneering, environmentally-minded manufacturers to integrate it into packaging and product design. James Cropper PLC. and Södra’s agreement is exclusive to premium markets, aiming to further establish DuraPulp in sectors such as luxury fashion, cosmetics, automotive and interior design sectors in a broad, international campaign.

The blend of carefully selected wood fibres and renewable, non-fossil based biopolymer can be heat pressed to take on any rigid form, or used as a sheet where there is a requirement for high tearing and bend tolerance or air permeability. Unlike other composite products, DuraPulp is believed to be the only one available where the primary content is pulp fibre and draw on 100% renewable resources, while remaining completely biodegradable.

Patrick Willink, Chief Technology Officer of James Cropper, said: “Sustainability has to be at the heart of manufacturing for the future, both for cost-effective production and the responsible protection of the environment for future generations. This is an ethos we know we share with Södra as both companies work hard to provide products that have a low carbon impact, going so far as to each generate our own electricity.

“This partnership is driven not only by the desire to help DuraPulp take on the global burden of non-degradable plastics, which are still widely used, but also to apply our key strengths of an unrivalled colour palette and international marketing expertise to a game-changing product.”

Initially borne of research by Swedish scientific research institute, Innventia, Södra has explored the adaptability of DuraPulp in a series of design-led commissions, including a paper-thin, waterproof chair, moulded packaging to cradle delicate objects in transit and an electric desk lamp. Its biodegradability has been embraced as a feature, being made into a seed pod from which plants will grow after the fibre has perished, proving that DuraPulp exists not only as the fibre of product packaging, but of the product itself.

James Cropper PLC includes not only its specialist paper and converting company, a bespoke paper and packaging supplier to the biggest names in the luxury goods market, but also sister company, Technical Fibre Products (TFP). TPF provides customised non-woven solutions for use in areas such as fire protection and aviation and it is this breadth of experience and capability that is expected to push DuraPulp into exciting, unchartered territories.

Patrick Willink goes on to say: “James Cropper and TFP’s extensive technical abilities, clearly demonstrated by our track record in product development, and global market reach, will mean that we will be able to speed up the commercialisation of DuraPulp. Together we will be exploring new markets across the world to further establish how this unique product can provide a credible alternative to fossil-based materials.”