Displaying items by tag: Metso Group

Metso strengthens global service network by opening center next to Suzano's new mega pulp mill in Brazil

Metso will expand its global service network by opening a new service center to serve Suzano Papel e Celulose S.A.'s 1.5-million-tonne greenfield pulp mill in Maranhão, northeastern Brazil. The service center will supply roll grinding and other maintenance services, and will have a storage for selected spare parts and consumables. The center will be located in Imperatriz, close to the Maranhão mill, and will be operational in late 2013. The groundbreaking ceremony for the new service center was held in Imperatriz on April 25, 2013.

The groundbreaking ceremony of the new service center to be built in Imperatriz was held on April 25, 2013. Pictured are (left to right) Adriano Canela, Project Manager, Suzano Papel e Celulose, Sebastião Madeira, Mayor of City of Imperatriz, Elio Krummenauer, Director, Services, South America, Metso, Volnei Remor Hilbert, Industrial Manager of Suzano Maranhão mill, Celso Tacla, Area President, South America, Pulp, Paper and Power, Metso, and Jukka Tiitinen, President, Services business line, Pulp, Paper and Power, Metso.

"This investment is in line with Metso's strategy for services growth. Local support to customers and long-term partnerships bring value both to our customers and Metso," says Jukka Tiitinen, President, Services business line, Pulp, Paper and Power, Metso.

In addition, Metso and Suzano Papel e Celulose S.A. have agreed that Metso will establish mill maintenance for the entire Maranhão mill. With the agreement Metso will take responsibility for the establishment of the mill's maintenance management system and support Suzano in establishing materials management operations. The value of the agreement will not be disclosed.

"We have decided to contract Metso to bring equipment manufacturer's process knowledge and maintenance expertise in establishing maintenance for the Maranhão mill. We expect to have efficient maintenance plans and organization in order to contribute to a reliable start-up and quick learning curve, from the first days of operation," says José Alexandre, Industrial Director, Suzano Papel e Celulose.

All main technology for the Maranhão pulp mill is being supplied by Metso. Metso's scope of supply covers wood handling, cooking plant and fiberline, pulp drying and baling, evaporation, power boiler, recovery boiler, causticizing and lime kiln, and an integrated automation solution for all process areas. The mill is scheduled to start up in the second half of 2013.

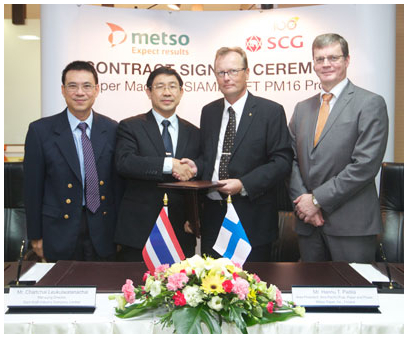

Metso to supply containerboard line for Siam Kraft Industry in Thailand

The new OptiConcept M production line will provide high productivity at low operating cost

Metso will supply an OptiConcept M containerboard production line with an extended scope of supply implementation for the Ban Pong mill of Siam Kraft Industry Co., Ltd. in SCG Paper in Ratchaburi, Thailand. The start-up of the machine is scheduled for 2014. The value of the order will not be disclosed.

The novel OptiConcept M production line represents a new way to design, build and operate a paper machine. It is designed for high productivity at low operating cost. The innovative industrial design and engineering of the OptiConcept M production line facilitate assembly of the line. In its design, usability and safety are also at a new level.

The order is included in Metso’s Pulp, Paper and Power first quarter 2013 orders received.

Technical information

Metso’s delivery will comprise a complete OptiConcept M boardmaking line from headbox to reel including an approach flow system, steam and condensate systems, surface size preparation and supply systems, a winder and machine clothing. The automation solution includes MD/CD and machine controls, profilers for the headbox and condition monitoring sensors for the critical machine sections.

In addition, Metso’s extended scope of supply will include complete mill engineering, and mechanical installation and supervision services related to commissioning, testing and start-up of the machine.

The 7.25-m-wide (wire) PM 16 will utilize a new sizing method providing better strength properties. The production capacity of PM 16 is approximately 300,000 tonnes of recycled fluting in the basis weight range of 90-150 g/m2. The design speed is 1,300 m/min.

Siam Kraft Industry Co., Ltd. in SCG Paper produces and markets industrial and packaging paper in Thailand and internationally. It offers corrugating medium, linerboard, coreboard, industrial sack kraft, bag papers, plaster linerboard, duplex board as well as converted and finished products. The company was founded in 1984 and is based in Bangkok, Thailand. Siam Kraft Industry Co., Ltd. operates as a subsidiary of SCG Paper.

Metso: Get inspired by tissue

Tissue paper can be attractive for many reasons depending on your needs and who you are. In an “emergency” situation you don’t even want to think about being without it. No way! An iPad may be good for many reasons or uses but it can never replace a roll of tissue paper.

But last week, attending the Tissue World exhibition in Barcelona, Spain I realized that tissue paper can be most valuable for other reasons.

I happened to meet there a guy who is collecting tissue hankies. In his collection, he has handkerchiefs from all over the world and from most companies, and some of the samples are really old. Last time he counted them there were more than 12.000 different packages of various brands. The collection is so amazing that the organizers of Tissue World sponsored his booth.

Creative use of tissue

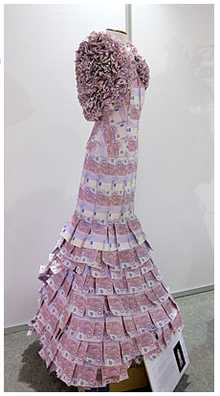

In the opposite part of the exhibition hall I found another exhibitor who has developed a new creative way of utilizing tissue.

In the booth they exposed the most fascinating and beautiful dresses; made of tissue paper. One more attractive than the other with embroideries and other fantastic decorations.

The most valuable I suppose was the one made of 500 Euro bills. Who wouldn’t want to own that? But on the other hand I hope they were fake 500 Euro bills or otherwise there will not be much left of the dress when the exhibition closes!

The most valuable I suppose was the one made of 500 Euro bills. Who wouldn’t want to own that? But on the other hand I hope they were fake 500 Euro bills or otherwise there will not be much left of the dress when the exhibition closes!

There might be one small disadvantage with these dresses though. You have to stay indoors.

Imagine what would happen if you went out wearing a dress made of tissue paper and it started to rain…

What is best in tissue?

However, most of the people were at Tissue World Barcelona exhibition to learn about new developments and the latest in tissue technology. They wanted to meet the supplier who can provide a machine that produces the best tissue paper with highest softness and bulk and of course to the lowest price!?

Most of the big machine suppliers were exhibiting in Barcelona (except the Italians who boycotted the event this year for various reasons). All tissue machine suppliers provided paper samples.

We are of course stating that our Advantage NTT paper is the best in the market and we are also offering paper rolls to potential customers. But one thing is for sure. Our competitors do not provide as attractive packages as we do. In fact they don’t have any packages at all.

Maybe Metso’s toilet paper gift box will be the next collector's item?

Metso to supply paper-to-packaging grade conversion rebuild for Blue Paper in France

The target is to produce packaging materials based on recycled raw materials

Metso will supply Blue Paper with a grade conversion rebuild of their paper machine at their mill site in Strasbourg, France. The target is to produce packaging materials on a paper machine that previously produced LWC, light weight coated paper, a grade that is suffering from a drastic decline in demand. The start-up of the rebuilt machine is scheduled for the last quarter of 2013.

“This delivery is an example of much called-for innovative approach to the structural change the paper industry is facing. By retrofitting the existing printing paper machine with a few new key components Metso is able to provide the customer and the Strasbourg papermaking community with a solution that enables continuation of industrial operations on-site,” says Markus Laitila, Vice President of Paper Mills business unit, Metso.

The main part of the order is included in Metso’s Pulp, Paper and Power fourth quarter 2012 orders received. The automation system modification is included in Automation’s fourth quarter 2012 orders received.

Technical information

Metso’s delivery will comprise headbox and forming area modernizations and modernization of the press, dryer and sizing sections and reel. Metso will also modify air systems and automation systems.

The original paper machine has a trimmed width of 8.5 m and it produced LWC paper at a speed of 1,500 m/min. After the grade conversion rebuild, the paper machine will have a high annual capacity of fluting and testliner grades in the basis weight range of 70-130 g/m².

Blue Paper SAS is a joint venture established by the Belgian VPK Packaging Group NV and the German Klingele Papierwerke. VPK Packaging Group NV is an integrated packaging group with 33 companies across twelve European countries. Klingele, a German family-owned company, is one of the leading independent producers of containerboard and packaging made of corrugated board. The company consists of one paper mill, six integrated corrugated plants and seven converting plants in Europe and Africa. Klingele and VPK have a combined corrugated packaging production of more than 1 million tonnes per year and a paper production of 600,000 tonnes per year.

CNIM selects Metso’s automation solution to maximize efficiency in a greenfield waste-to-energy plant in UK

Proven automation solution and information management helps waste-to-energy plants to maximize performance and operate safely.

Metso has been awarded its 5th repeated order from the CNIM group for the automation of another greenfield waste-to-energy plant in Great Blakenham (Suffolk, UK). Metso will supply an extensive Metso DNA automation system and safety system to the new plant. This order comes after similar ones for WtE plant in Turin (Italy), Tallin (Estonia), North Hykeham (Lincolnshire, UK) and Four Ashes (Stafford, UK).

Metso DNA provides one system for all process controls and plant information management. The integrated process automation system covers all plant processes from boilers to turbines. High-level reliability is ensured through an integrated, TÛV certified safety solution.

Metso’s automation solutions play a significant role in managing waste-to-energy plants successfully and help them reaching their goals of maximizing incineration capacity, keeping combustion and steam production stable while allowing high availability of the production processes.

The new Suffolk waste-to-energy plant is owned by the Suffolk County Council and will be operated by Sita Suffolk limited. It will have an electric output of 20 MWe enough to power 30 000 homes and it is designed to handle an annual amount of 269 000 tons of residual waste. The plant is planned to go on line by the end of 2014.

The CNIM group acts as a contractor in the Suffolk project. Established in 15 countries, the CNIM Group designs and produces turnkey industrial solutions and offers expert research, expertise and operations services in the fields of environment, energy, defense and industry. The group has 3,000 employees, and its turnover was 665 million euros in 2011.

Metso aims to improve strategic focus and accelerate growth

The Board of Directors of Metso Corporation has decided to commence a process to study the potential separation of the company’s Pulp, Paper and Power businesses into a new company, which would be listed on the NASDAQ OMX Helsinki stock exchange. Metso’s current Mining and Construction and Automation businesses would remain in the current company after the possible separation. The contemplated transaction would be designed to help the two companies to capitalize on their strengths in their respective markets faster and more efficiently.

Jukka Viinanen, Metso’s Chairman of the Board, says that Metso has developed its businesses purposefully during the past years to the point where entering the next stage of development would be smoother as separate companies. “Both of them are strong global businesses with well-established positions in their customer industries. By separating the two, we would seek to accelerate strategy implementation, as clearer business structures would increase the focus and ambition of the two companies with distinct growth strategies. The Board also believes that both companies would be seen as attractive investments, which has the potential to increase value for our shareholders.”

”Developing Mining, Construction and Automation and Pulp, Paper and Power businesses separately would help the already strong two entities to fully realize their potential. This would in turn benefit our customers and personnel through more focused management, superior competence development and customer services, and through enabling both companies to cultivate their technology and services offering that would match their goals perfectly,” says Matti Kähkönen, Metso’s President and CEO.

The study relating to the possible separation will concentrate on a range of issues, including certain matters pertaining to taxation and financing. Metso will also discuss the potential demerger with its customers, suppliers, rating agencies, creditors, employees and other relevant third parties. The Metso Board aims to finalize the study process and announce further details about the possible separation by the end of the second quarter of 2013.

Although no decisions have been taken, the separation, if carried out, would likely be by means of a demerger (i.e. partial demerger as defined in the Finnish Companies Act), after which the Mining, Construction and Automation businesses would remain with Metso, whereas Pulp, Paper and Power businesses would constitute the new company, which would be listed on the NASDAQ OMX Helsinki stock exchange. The new company would initially have the same ownership structure as Metso and would be totally independent from it without any cross-ownership between Metso and the new company. This strategy study will be headed by Metso’s President and CEO Matti Kähkönen.

If implemented, the demerger would leave Metso shareholders’ ownership in the company unchanged. In addition, Metso shareholders would receive shares in the new company as demerger consideration in proportion to their shareholding in Metso.

If Metso decides to pursue the demerger, the Board of Metso would expect to approve and register a demerger plan by the end of the second quarter of 2013.Metso’s Extraordinary General Meeting would be expected to make its final decision on the potential demerger during the second half of 2013. The demerger and listing of the new company’s shares would be expected to take place before the end of 2013.

Significant shareholders of Metso (Solidium, Cevian Capital, Varma Mutual Pension Insurance Company and Ilmarinen Mutual Pension Insurance Company) have expressed their support to the Board’s decision to commence a strategy study relating to the possible demerger.

Metso receives repeat order for tissue production line from Syktyvkar Tissue Group, Russia

Metso has once again received an order for a complete tissue production line for Syktyvkar Tissue Group in Russia. The new tissue machine will be installed at the company’s new site in Semibratovo, located some 220 km from Moscow. The start-up of the machine is scheduled for mid 2014. The value of the order will not be disclosed.

The order follows the previous Metso installation of an Advantage DCT 100 tissue machine in 2007 and a major tissue machine rebuild during 2012.

”We consider Metso not only to be a supplier of first-class equipment. Over the years friendly relations have been established and we are happy that our cooperation is going on,” says Mark Reznik, Managing Partner, Syktyvkar Tissue Group.

”We are very pleased that Syktyvkar has ordered their third consecutive major project from us. This is proof that our way of working as partners with our customers is rewarding for both sides,” says Leif Forsberg, Senior Vice President, Sales, Tissue Mills business unit, Metso.

The main part of the order is included in Metso’s Pulp, Paper and Power first quarter 2013 orders received. The automation package is included in Automation’s first quarter 2013 orders received.

Technical information

Metso’s delivery will comprise a complete high-speed tissue production line featuring an Advantage DCT 100 HS tissue machine equipped with an OptiFlo headbox, a Metso cast iron Yankee cylinder and an Advantage AirCap Yankee hood. Metso will also supply stock preparation equipment including an OptiFiner conical refiner, OptiScreen cleaning and screening technology and converting broke equipment.

In addition, Metso’s scope of supply will comprise an electrification package, pumps, agitators, instruments, a vacuum system and white water handling. The delivery will include basic and detail engineering for the new tissue machine and services for installation and start-up of the machine. Furthermore, Metso will supply Metso DNA automation for process, machine and drive controls and Metso IQ quality controls.

The new line will have a width of 2.7 m and an operating speed of 2,000 m/min and it will add another 30,000 tonnes per year of bathroom tissue, napkin and towel grades to the company's existing production.

Syktyvkar Tissue Group is today one of the best known companies on the Russian market for tissue products with a market share of around 10 %. Today the company employs 385 people and produces approximately 45,000 tonnes of tissue. Headquarters and existing production facilities of the company are located in Syktyvkar, capital of the republic of Komi in the northwestern part of Russia.

World's largest biomass gasification plant inaugurated in Vaasa - plant supplied by Metso

Vaskiluodon Voima Oy has inaugurated the world's largest biomass gasification plant, which was supplied by Metso, in Vaasa, Finland. The plant was inaugurated by the Finnish Minister of Labour Lauri Ihalainen on March 11th.

Vaskiluodon Voima's plant is ground-breaking in many ways, as this is the first time in the world that biomass gasification is being adopted on such a large scale for replacement of fossil fuels.

Clean gas from biomass

The technology of the new plant is based on Metso's long-term development work. Metso's delivery included fuel handling, a large-scale dryer and a circulating fluidized bed gasifier, modification work on the existing coal boiler and a Metso DNA automation system. The bio-gasification plant was constructed as part of the existing coal-fired power plant, and the produced gas will be combusted along with coal in the existing coal boiler.

Metso's pioneering role is illustrated by the fact that the company delivered its first plant using gasification technology back in the 1980s. A major challenge in the Vaskiluoto project was the sheer scope - the now inaugurated plant is the world's largest biomass gasification plant.

The plant started up at the turn of the year. The contract for the new plant was announced in June 2011, and Metso started the construction at Vaskiluoto in April of the following year, making the actual construction phase fairly short.

"The operational experiences so far indicate that the 140-MW bio-gasification plant functions as planned, and the produced gas burns cleanly in the coal boiler and reduces emissions," says Mauri Blomberg, Managing Director, Vaskiluodon Voima.

Sights set on energy turnaround

Nearly half of the coal used by the plant can be replaced with gasified biomass. This makes the solution highly environmentally friendly, enables the flexible use of different fuels and significantly extends the life of the current power plant. "The commissioning of the gasification plant is a major step in our company's target of using mainly domestic fuels for heat and electricity production. This can be considered a complete energy turnaround," says Rami Vuola, Chairman of the Board of Vaskiluodon Voima and CEO of EPV Energia Oy, joint owner of Vaskiluodon Voima.

The recent gasification technology projects are an indication of Metso's strategy of offering energy solutions in which technologies related to fuel refining have been brought forth alongside traditional combustion. In May 2012, a similar event was held in Lahti, Finland, with the inauguration of the world's first waste gasification plant.

"I'm sure that Vaskiluoto's investment in increasing the use of renewable energy will draw major international attention. Coal powered plants can be made greener, and Vaskiluoto's plant is leading the way," says Jyrki Holmala, President of Metso's Power business line. "Coal boilers still account for the majority of power production in the world. Bio-gasification technology of this scale offers a new, cost-effective option for increasing the share of biomass and, consequently, for significantly decreasing the use of and emissions from coal.

" Later on in the inauguration day, Metso organized a technology seminar in Vaasa, which was attended by some 50 customers from around Europe. A visit to the new gasification plant was also on the agenda.

Vaskiluodon Voima Oy is equally owned by the energy companies EPV Energia Oy and Pohjolan Voima Oy. The company's power plants, located in Vaasa and Seinäjoki, produce electricity and district heating. www.vv.fi

Metso-supplied tissue line successfully started up at Jeesr Industries in Morocco

On November 19, 2012, the first state-of-the-art tissue machine in Morocco was started up at Jeesr Industries in Berrechid, close to Casablanca. The Metso-supplied Advantage DCT 100+ line smoothly came on stream according to plan and has been producing high quality paper from the very start.

On November 19, 2012, the first state-of-the-art tissue machine in Morocco was started up at Jeesr Industries in Berrechid, close to Casablanca. The Metso-supplied Advantage DCT 100+ line smoothly came on stream according to plan and has been producing high quality paper from the very start.

“This investment is very important to us and we are of course pleased to see that the machine is operating according to our targets and that Metso have fulfilled our expectations,” says Souheil Badaa, Chief Marketing Officer, Novatis Group.

“We are very satisfied with what the Jeesr team and Metso have achieved here. The facility has a compact and efficient layout and both our crews have done a great job to ensure a smooth start-up as well as a continued optimal production,” says Gunnar Söderqvist, Project Manager, Metso.

Metso’s delivery included a complete production line with stock preparation equipment, an Advantage DCT 100+ tissue machine and a rewinder and wrapping equipment. The production line is optimized to produce top-quality tissue paper at low energy and water consumption levels. The delivery also comprised an extensive automation package including Metso DNA machine, process and integrated drive controls, and a Metso IQ quality control system with Metso IQ Fiber Weight Measurement.

The new production line is designed to produce around 30,000 tonnes a year of high-quality facial, toilet and towel grades mainly for the Moroccon market. The raw material for the new line is virgin pulp.

Jeesr Industries is a privately owned company, which is part of the Novatis Group, a producer and supplier of various consumer goods, among others baby diapers, for the Moroccon market.

Tissue World magazine: Metso to put the spotlight on Advantage NTT technology

From Tissue World magazine: Metso is to highlight its Advantage NTT technology at Tissue World 2013, the “new standard for premium quality tissue production”

The company said it hit an unmatched record last year when it announced that some 200 of its tissue machines were sold worldwide.

The technology development during these years has been significant and resulted in three main technologies: the Advantage Thru-Air concept for superior tissue quality and the Advantage DCT technology boosting high volumes and cost-efficient production.

In Barcelona, Metso will focus on its third and unique technology: the Advantage NTT concept for production of premium quality tissue with less energy and fibre consumption.

Its flexibility makes it possible to produce both high quality conventional and textured tissue using the same concept but with energy consumption below the level of conventional dry crepe machines.

Textured mode provides products with 50-80% more bulk and softness, with premium product quality while fibre savings of 10-30% can be achieved in the finished product.

The exhibition will also highlight the wide range of product offerings for the whole tissue mill from stock-preparation and tissue line to auxiliary equipment, automation, expert services and process improvements.

Metso is also proud to announce the first winner of Tissue Technology Award which is granted every second year, promoting sustainable development for the tissue making industry.

The first winner will be introduced at the Tissue World conference where visitors can also meet and discuss the innovation at Metso’s booth.