Displaying items by tag: Stora Enso

Stora Enso begins trading on the OTCQX market

Stora Enso Oyj has upgraded the trading of its American Depository Receipts (ADRs) and Ordinary Shares to the OTCQX® Best Market from the Pink® market. Stora Enso begins trading today on OTCQX under the symbols “SEOAY, SEOFF, SEOJF”.

Upgrading to the OTCQX Market is an important step for companies seeking to provide transparent trading for their US investors. To qualify for OTCQX, companies must meet high financial standards, follow best practice corporate governance, and demonstrate compliance with applicable securities laws.

Upgrading to the OTCQX Market is an important step for companies seeking to provide transparent trading for their US investors. To qualify for OTCQX, companies must meet high financial standards, follow best practice corporate governance, and demonstrate compliance with applicable securities laws.

Citibank acted as Stora Enso’s OTCQX sponsor.

About OTC Markets Group Inc.

OTC Markets Group Inc. (OTCQX: OTCM) operates regulated markets for trading 12,000 U.S. and international securities. Its data-driven disclosure standards form the foundation of its three public markets: OTCQX® Best Market, OTCQB® Venture Market and Pink® Open Market.

Part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials, and wooden construction, and one of the largest private forest owners in the world. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 21,000 employees and our sales in 2022 were EUR 11.7 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs and ordinary shares (SEOAY, SEOFF, SEOJF). storaenso.com/investors

European Commission closes its investigation into the wood pulp sector

As announced by Stora Enso on 12 October 2021, it was included in the European Commission's inspection of the wood pulp sector and subject to inspections at its premises. Today, the European Commission has announced that after a thorough and careful assessment, it has decided to close its investigation.

As announced by Stora Enso on 12 October 2021, it was included in the European Commission's inspection of the wood pulp sector and subject to inspections at its premises. Today, the European Commission has announced that after a thorough and careful assessment, it has decided to close its investigation.

Investor enquiries:

Anna-Lena Åström

SVP Investor Relations

Tel. +46 70 210 7691

Part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials and wooden construction, and one of the largest private forest owners in the world. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 21,000 employees and our sales in 2022 were EUR 11.7 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com/investors

STORA ENSO OYJ

Stora Enso completes negotiations at Anjalankoski production unit concerning the closure of one paper line

Stora Enso has completed the negotiations concerning the consolidation of its book paper production and the permanent closure of one of the two paper machines at the Anjalankoski site in Finland. The closure will take place during the fourth quarter of 2023.

In April 2023, Stora Enso announced a plan to permanently close one of the two paper machines and concentrate all book paper production to one line at the integrated Anjalankoski site due to the prevailing weak paper demand and high input costs.

The closure of the line producing uncoated mechanical grades will reduce the site’s annual capacity by 250,000 tonnes and sales with approximately EUR 100 million. The closure will take place during the fourth quarter of 2023 and affect 89 people, of whom 50 will be made redundant. The majority of these redundancies are managed through pension arrangements.

“While it is very unfortunate that redundancies have to be made, we are pleased that the number of employees affected is significantly lower than anticipated. Stora Enso will continue to harness the Anjalankoski site’s synergies between board and paper production and with the remaining paper machine, the Group will be able to continue producing its selection of book paper grades,” says Hannu Kasurinen, EVP Packaging Materials division.

The integrated Anjalankoski site is reported under the Packaging Materials division since the beginning of 2023. The site includes the Ingerois packaging board production unit and the Anjala paper production unit, the latter of which was previously reported under the, now dissolved, Paper division.

Part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials and wooden construction, and one of the largest private forest owners in the world. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 21,000 employees and our sales in 2022 were EUR 11.7 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY).storaenso.com/investors

Stora Enso successfully starts up energy efficient ANDRITZ LimeCool system at Imatra pulp mill, Finland

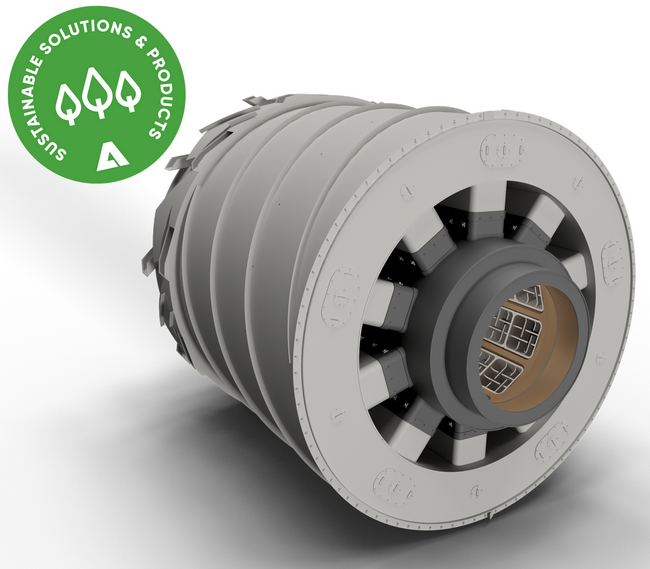

International technology group ANDRITZ has successfully delivered, installed and commissioned an energy efficient LimeCool system at Stora Enso’s pulp mill located in Imatra, Finland. The start-up took place at the end of 2022.

The innovative ANDRITZ LimeCool system is designed to use the heat of the processed hot lime in the lime kiln. This enables to achieve higher energy efficiency of the white liquor plant and an increase in the production of high-quality lime when compared to conventional separate satellite coolers.

With more than 50 installations globally, the ANDRITZ LimeCool system comprises a stainless-steel integrated structure which is designed for mechanical strength, energy efficiency and easy maintenance. © ANDRITZ

With more than 50 installations globally, the ANDRITZ LimeCool system comprises a stainless-steel integrated structure which is designed for mechanical strength, energy efficiency and easy maintenance. © ANDRITZ

Mika Varis, Project Manager, Stora Enso, says: “We selected the LimeCool system due to the state-of-the-art technology combined with ANDRITZ’s flexibility and fast response. This was the complete package that met our needs.”

This project demonstrates the ongoing solid business relationship between Stora Enso and ANDRITZ. ANDRITZ has just recently supplied production technologies and key process equipment to other Stora Enso locations in Finland and Sweden.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Stora Enso completes the divestment of its Maxau paper site to Schwarz Produktion

Stora Enso has completed the divestment of its Maxau paper production site in Germany, and all related assets to Schwarz Produktion, part of Schwarz Group. The divestment announced on 13 September 2022 was completed today after regulatory approvals. The enterprise value of the transaction is approximately EUR 210 million.

The transaction will reduce Stora Enso’s annual SC (supercalendered) paper capacity by 530,000 tonnes. Based on the 2022 figures, the divestment is expected to reduce Stora Enso’s annual sales by approximately EUR 385 million. Subject to closing date adjustments, Stora Enso will book a one-time disposal gain of approximately EUR 55 million in its IFRS operating profit in the first quarter of 2023, considered as an item affecting comparability.

The transaction will reduce Stora Enso’s annual SC (supercalendered) paper capacity by 530,000 tonnes. Based on the 2022 figures, the divestment is expected to reduce Stora Enso’s annual sales by approximately EUR 385 million. Subject to closing date adjustments, Stora Enso will book a one-time disposal gain of approximately EUR 55 million in its IFRS operating profit in the first quarter of 2023, considered as an item affecting comparability.

This transaction is part of the earlier announced plan to divest four of Stora Enso’s five paper production sites. The plan was concluded earlier this year when Stora Enso signed an agreement to divest its paper production site in Hylte and discontinued the Anjala site divestment process. The divestment of the Nymölla paper site in Sweden was completed on 2 January with ownership transferred to Sylvamo. In line with its strategy, Stora Enso’s focus is on long-term growth potential for its renewable products in packaging, building solutions and biomaterials innovations.

About Schwarz Produktion

Schwarz Produktion is the umbrella brand for the production companies of Schwarz Group. In total, more than 4,500 employees in the Schwarz Produktion companies produce high-quality food as well as sustainable packaging and materials for the retail companies Lidl and Kaufland. In addition to mineral water and soft drinks, the Schwarz Produktion companies also produce chocolate, dried fruit, baked goods, coffee and ice cream. In addition, three plastic and recycling plants are a central component of a unique PET materials cycle. Further information about Schwarz Group here: gruppe.schwarz/en.

Recent releases about Stora Enso’s paper assets:

27 January 2023: Stora Enso signs an agreement to divest its Hylte paper site and will discontinue the Anjala site divestment process

2 January 2023: Stora Enso completes the divestment of its Nymölla paper site to Sylvamo

13 September 2022: Stora Enso has signed an agreement to divest its Maxau paper site to Schwarz Produktion

29 March 2022: Stora Enso plans to divest four paper sites to focus on strategic growth areas

Part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials and wooden construction, and one of the largest private forest owners in the world. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 21,000 employees and our sales in 2022 were EUR 11.7 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com/investors

Stora Enso contributes to a sustainable FIS Nordic World Ski Championships in Planica

As the presenting sponsor of the FIS Nordic World Ski Championships in Planica, Slovenia taking place between 21 February and 5 March 2023, Stora Enso will provide wood-based renewable and recyclable products and innovations to contribute to a world-class sustainable and climate-friendly event.

“The ski championships in Planica will reach a total audience of around 450 million people, enabling the opportunity to promote Stora Enso’s renewable materials while demonstrating that people can make real carbon reductions in their everyday choices. In addition to contributing renewable products and solutions at the games, we engage with the local Planica community to make a difference when it comes to awareness around sustainable sporting event actions,” says René Hansen, Stora Enso’s EVP Brand and Communications.

Stora Enso is Supporting Green Planica 2023 with eco-friendly products

Stora Enso will also support the Green Planica 2023 commitment through its renewable products designed to replace plastic and other fossil-based materials. Eco-friendly products used at the games by athletes, volunteers, media, and event staff include wooden podiums and building materials for the arenas, drinking cups, catering trays for volunteers, and 3D-printed bio composite furniture for the VIP area, all made from renewable and recyclable materials. Moreover, flowers in the medal ceremony will be replaced by spruce seedlings, devoted for planting in growing forests.

Sustainability engagement with the local community

Stora Enso will support the local community in Planica with two activities; supporting spectators with their walk from Kranjska Gora to Planica to advance sustainable mobility, and promoting a local competition between 21 schools on how to become an environmentally friendly fan at sports events. Both actions are taken together with the Planica organizing committee.

Long-term commitment

Stora Enso has committed to long term sponsorship support of the FIS Nordic World Ski Championships. Planica 2023 marks the fifth time the Group will sponsor the championships, having served as presenting sponsor for the 2021 event in Oberstdorf, Germany, 2019 in Seefeld, Austria, and 2017 in Lahti, Finland, as well as being the main sponsor in Falun, Sweden in 2015. Stora Enso will also be the presenting sponsor Trondheim, Norway 2025.

For more information about Stora Enso’s presence in the FIS Nordic World Ski Championships in Planica 2023, visit: Stora Enso in Planica 2023

Part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials and wooden construction, and one of the largest private forest owners in the world. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 21,000 employees and our sales in 2022 were EUR 11.7 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com

Stora Enso signs an agreement to divest its Hylte paper site and will discontinue the Anjala site divestment process

Stora Enso has signed an agreement to divest its paper production site in Hylte, Sweden and all its related assets to Sweden Timber, a Sweden-based sawmill and planing mill company. The enterprise value is approximately EUR 18 million. The completion of the transaction is expected in the first half of 2023. Concerning the Anjala paper site in Finland, Stora Enso has decided to discontinue the divestment process.

The Hylte site transaction, along with the discontinuation of the Anjala divestment, concludes Stora Enso’s plan announced in March 2022 to divest four of Stora Enso’s five paper production sites. In line with its strategy, Stora Enso’s focus is on long-term growth for its renewable products in packaging, building solutions and biomaterials innovations.

“I am pleased that Sweden Timber will continue to serve Hylte’s paper customers with the intent to further develop the operations. For the Anjala site, we have concluded that the benefits from retaining the site within the Group exceed the value of explored divestment opportunities,” says Seppo Parvi, CFO at Stora Enso.

“I am pleased that Sweden Timber will continue to serve Hylte’s paper customers with the intent to further develop the operations. For the Anjala site, we have concluded that the benefits from retaining the site within the Group exceed the value of explored divestment opportunities,” says Seppo Parvi, CFO at Stora Enso.

The Hylte site’s annual capacity is 245,000 tonnes of newsprint paper. Based on the 2021 figures, the divestment is expected to reduce Stora Enso’s annual sales by approximately EUR 90 million. Subject to closing date adjustments, Stora Enso will book a disposal loss of approximately EUR 35 million, in addition to the impairment loss of EUR 19 million recorded in Q4/2022, in its IFRS operating profit in Q1/2023, as an item affecting comparability. The transaction does not affect the Packaging Solutions division’s formed fiber and biocomposite operations located at the Hylte site.

The Anjala paper site, together with the retained Langerbrugge paper site in Belgium, were integrated into the Packaging Materials division on 1 January 2023. The Anjala site already today leverages integrated operations with Stora Enso’s neighbouring Ingerois packaging materials site, utilising synergies in raw material and energy supply. For the Langerbrugge site, the ongoing feasibility study for a potential conversion of one of the site’s two paper lines into a packaging materials line is expected to be finalised in the first half of 2023.

The retained Anjala and Langerbrugge sites will continue paper production and serving their respective customers. The agreement to divest the Hylte paper site to Sweden Timber has no immediate impact on production nor customer deliveries. The previously disclosed agreement to divest the Maxau paper site in Germany to Schwartz Produktion is expected to conclude at the beginning of this year. Divestment of the Nymölla paper site in Sweden was concluded on 2 January with ownership transferred to Sylvamo.

BofA Securities acted as Stora Enso’s financial advisor on this transaction.

About Sweden Timber

Sweden Timber is a Swedish-owned and growing wood industry company. The company produces and sells high-quality wood products to the construction industry and wood retailers, with customers in several export markets. The business today consists of sawmills and planing production sites in four Swedish locations, Malmbäck, Hjortkvarn, Skillingaryd and Mora. www.swedentimber.se/.

Recent releases on Stora Enso’s paper assets:

29 March 2022: Stora Enso plans to divest four paper sites to focus on strategic growth areas

7 June 2022: Stora Enso assesses growth opportunities in recycled packaging materials with a conversion in Langerbrugge

13 September 2022: Stora Enso has signed an agreement to divest its Maxau paper site to Schwarz Produktion

2 January 2023: Stora Enso completes the divestment of its Nymölla paper site to Sylvamo

Part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials, wooden construction and paper, and one of the largest private forest owners in the world. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 22,000 employees and our sales in 2021 were EUR 10.2 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com/investors

Stora Enso completes the divestment of its Nymölla paper site to Sylvamo

Stora Enso has completed the divestment of its Nymölla paper production site in Sweden, and all related assets to Sylvamo, a US-based global producer of uncoated paper. The divestment announced on 15 September 2022 was closed today after regulatory approvals. The enterprise value of the transaction is approximately EUR 150 million.

The Nymölla site’s capacity is 485,000 metric tonnes of woodfree uncoated office papers, with Multicopy as the leading paper brand. Based on the 2021 figures, the divestment is expected to reduce Stora Enso’s annual sales by approximately EUR 290 million. Subject to closing date adjustments, Stora Enso will book a one-time disposal loss of approximately EUR 25 million (including currency translation adjustments) in its IFRS operating profit in the first quarter of 2023, as an item affecting comparability.

This transaction is part of the earlier announced plan to divest four of Stora Enso’s five paper production sites. In line with its strategy, Stora Enso’s focus is on long-term growth potential for its renewable products in packaging, building solutions and biomaterials innovations.

The divestment process continues for the remaining paper sites in Hylte and Anjala with no committed timeline for conclusion. The process has no immediate effect on Stora Enso’s paper operations which continue to serve their respective customers.

About Sylvamo

Sylvamo (NYSE: SLVM) is a global paper company with mills in Europe, Latin America and North America. It transforms renewable resources into papers that people depend on for education, communication, and entertainment. Headquartered in Memphis, Tennessee, Sylvamo employs more than 7,500 people. Net sales for 2021 were $3.5 billion. For more information, please visit sylvamo.com.

Recent releases about Stora Enso’s paper assets:

15 September 2022: Stora Enso has signed an agreement to divest its Nymölla paper site to Sylvamo

13 September 2022: Stora Enso has signed an agreement to divest its Maxau paper site to Schwarz Produktion

7 June 2022: Stora Enso assesses growth opportunities in recycled packaging materials with a conversion in Langerbrugge

29 March 2022: Stora Enso plans to divest four paper sites to focus on strategic growth areas

Inside information: Stora Enso plans to divest its consumer board production site and forestry operations in China

Stora Enso has initiated a sales process for a possible divestment of its consumer board production site in Beihai, China. The divestment would also include the Group’s forestry operations in the surrounding region, which supply raw material to the Beihai site. The sales process supports Stora Enso’s strategy to focus on long-term profitable growth within the areas of renewable packaging, building solutions and biomaterials innovations.

Stora Enso’s strategic ambition is to build on its leading position in the fiber-based packaging market. The divestment of the Beihai operations would allow Stora Enso to accelerate its strategy by focusing on cost-efficient sites serving the growing global packaging market, such as the recently announced investment in Oulu, Finland and the pending acquisition of De Jong Packaging Group. The aim is to find a sustainable alternative for the future of the operations in Beihai and for the people working there.

The divestment of the board mill and forestry operations would be conducted separately or as a combined unit. Stora Enso has not committed to a timeline for the conclusion of the process. The divestment plan has no immediate effect on Stora Enso's financials or on the Beihai site’s production. The site continues to serve its customers.

The divestment of the board mill and forestry operations would be conducted separately or as a combined unit. Stora Enso has not committed to a timeline for the conclusion of the process. The divestment plan has no immediate effect on Stora Enso's financials or on the Beihai site’s production. The site continues to serve its customers.

Stora Enso’s Beihai production site started operations in 2016. It has a modern mechanical pulp mill and a premium consumer board line serving the Chinese market. The annual production capacity is 250,000 tonnes of mechanical pulp and 550,000 tonnes of consumer board. Stora Enso also operates 70,000 hectares of land in the Guangxi region for eucalyptus plantations, established in 2003, for fiber supply. The combined operations employ approximately 1,000 people including the forest operations. Stora Enso owns approximately 80% of the production site and forest operations, and its local partners and International Finance Corporation (IFC) own the remaining share. Stora Enso will work together with all stakeholders to complete the divestment process.

Stora Enso has retained J.P. Morgan S.E to act as its financial advisor in the sales process.

Part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials, wooden construction and paper, and one of the largest private forest owners in the world. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 22,000 employees and our sales in 2021 were EUR 10.2 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com/investors

Stora Enso invests to strengthen focus on specialised pulp grades

Stora Enso strengthens its focus on specialised pulp grades by investing EUR 38 million in unbleached kraft pulp (UKP) production at its Enocell site in Finland and EUR 42 million in fluff pulp production improvement at its Skutskär site in Sweden. These investments will support the growing consumer demand for non-bleached renewable packaging materials and hygiene products respectively.

By increasing the share of UKP in the pulp portfolio, Stora Enso continues on its strategic path to develop more specialised Nordic pulp grades while optimising its share in standard market pulp. The long-term trends point towards consumer preference for less bleached or brown fiber-based renewable packaging products. Following the investment, the Enocell site will be able to flexibly produce UKP and Nordic Bleached Softwood Kraft (NBSK) pulp. Due to the reduced use of bleaching chemicals, the carbon footprint per tonne of produced UKP will be more than 20% lower than the equivalent amount of bleached pulp produced at the Enocell site. The investment is expected to be completed during the last quarter of 2024.

The investment in fluff pulp production improvement at the Skutskär site strengthens Stora Enso’s position as the leading fluff pulp producer in Europe. Due to the upgrades made with the investment, the Group can meet customer demand for specific roll sizes, improve work safety, and grow fluff pulp production at the Skutskär site. The investment is expected to be completed during the second quarter of 2024.

“Through optimising our pulp portfolio, we advance the more specialised pulp offering, while also improving production and sustainability performance. This will allow us to meet the rapidly growing demand for using unbleached and less bleached pulp in packaging and hygiene applications,” says Johanna Hagelberg, Executive Vice President, Biomaterials division at Stora Enso.

Both investments fall within the Group’s capital expenditure guidance.

Stora Enso’s Enocell site’s annual capacity is 630,000 tonnes of softwood and hardwood pulp. The site employs approximately 280 people. Stora Enso’s Skutskär site’s annual capacity is 545,000 tonnes of fluff, softwood and hardwood pulps. The site employs approximately 420 people.

Part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials, wooden construction and paper, and one of the largest private forest owners in the world. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 22,000 employees and our sales in 2021 were EUR 10.2 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com