Displaying items by tag: Walki

Walki Group partners with The Paper Lid Company to make recyclable and printable paper lids

Walki Group has invested in Finnish start-up The Paper Lid Company (‘TPLC’). TPLC’s sustainable paper lid manufacturing site in Masku, Finland, is ready for scaling up production volumes supported by Walki’s material conversion and printing capabilities.

End users of hot and cold cup lids are increasingly looking for alternatives to replace plastic lids with more sustainable solutions. While the use of plastic lids has not yet been widely banned by regulation, restaurants, coffee chains, retailers and others are already taking action to transition away from single-use plastic lids.

TPLC has developed a unique way of manufacturing high-quality recyclable paper lids. The lid developed by TPLC fits firmly to the cup, has a pleasant touch and feel, can be customprinted and comes at a competitive price compared to plastic alternatives. The raw material for the lids is produced with dispersioncoating technology which makes the lid recyclable in paper waste streams.

Walki's startup investment initiative Walki Ventures has invested in TPLC and established a strategic partnership to support TPLC in implementation of the ambitious growth plan the founders have laid out. Walki will support TPLC in several areas, including development of recyclable raw material for the lids and printing services for custom and single-color printed lids. TPLC will also become a member of Walki’s R&D Community, helping the company to articulate sustainability benefits towards the customers in a fact-based manner.

“We are very excited to partner with Walki and get access to the resources that come with this partnership. Raw material plays a very important role both in our production process and quality of the end product. With Walki’s material knowhow, printing capabilities and other support, we are ready to start supplying the market in larger scale”, says Matti Salonoja, CEO and co-founder of TPLC.

About Walki

At Walki, we believe in a sustainable and circular tomorrow. Our mission is to accelerate the world’s transition into a zero-waste future in packaging and promote the use of energy efficient materials across industries. Walki’s product solutions are designed to bring value to customers in many different markets; from sustainable materials for packaging applications to energy saving performance materials.

Walki is a fast growing international group organized in three business areas: Consumer Packaging, Industrial Packaging and Engineered Materials, with operations in twelve different countries, both in Europe and Asia. Our production facilities are located in Finland, Germany, Belgium, France, Spain, the UK, Poland, Russia and China. We are employing about 1 500 people globally and we expect a turnover for this year of more than 700 MEUR. To best cater to our global customers, we aim to continue investing in state-of-the-art production facilities and promoting our tradition of innovation and exceptional service worldwide.

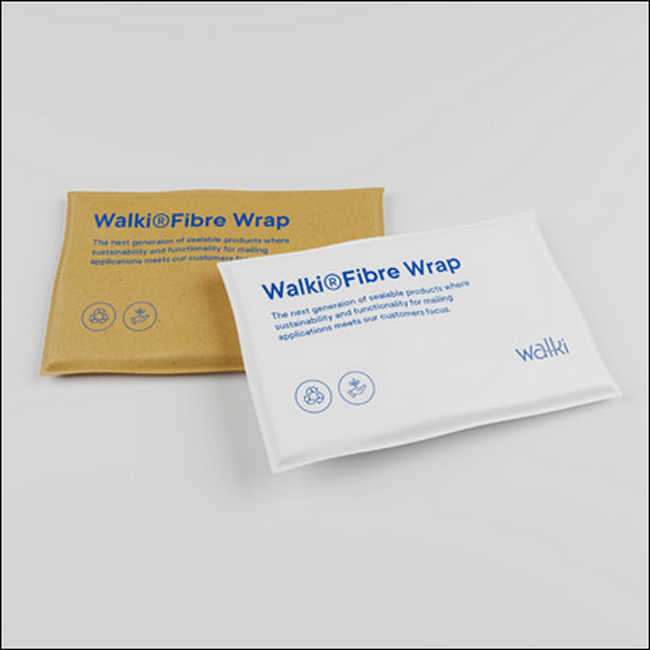

Walki introduces Walki®Fibre Wrap: a new, paper-based heat-sealable and fully recyclable packaging material for non-food applications

Walki’s brand new Walki®Fibre Wrap is the ideal sustainable solution for packaging non-food and e-commerce products that do not require demanding barrier properties.

Walki has introduced a new recyclable material for non-food packaging that does not need demand separation of the coating prior to recycling.

Traditionally, most paper-based packaging solutions are coated with polyethylene (PE). Some countries have considered these solutions to be recyclable if the plastic content is very low. With an increased demand from consumers, retailers, brand owners and e-commerce providers for fully recyclable packaging, Walki innovated a material that is recyclable without separating the coating.

The most important requirements for packaging e-commerce or non-food applications such as household goods, toys or games are strength and sealing properties. "Walki®Fibre Wrap delivers on strength and is also heat sealable, unlike many other paper-based packaging solutions which are glued", explains Bernd Gelder, Business Development Manager for Industrial Packaging.

“The major advantage of heat-sealable paper solutions is that they allow producer to use the same equipment used to seal plastic,” adds Gelder.

All grades of Walki®Fibre Wrap are also all printable.

“We can offer a base material with heat-seal properties on the back and high-quality flexo printing on the front. There is no need to use a separate printing provider since we can deliver the final packaging material in reels.”

Walki®Fibre Wrap is available on bleached or unbleached craft paper grades, ranging from 50 to 90 gsm. It is also available on Paptic®, an ultra-high end biobased, recyclable and reusable packaging material with outstanding haptics that is especially suited to luxury applications.

Further information, please contact:

Bernd Gelder, Business Development Manager, Industrial Packaging

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

At Walki, we believe in a sustainable and circular tomorrow. Our mission is to accelerate the world’s transition into a zero waste future in packaging and promote the use of energy efficient materials across industries. Walki’s product solutions are designed to bring value to customers in many different markets; from sustainable materials for packaging applications to energy saving performance materials. Walki is a growing international group organized in three business areas: Consumer Packaging, Industrial Packaging and Engineered Materials, with operations in twelve different countries, both in Europe and Asia. In 2021, the Group’s annual turnover was approx. 550 million euros employing around 1500 people.

walki.com

Walki Group starts as a distributor and converter for Paptic® materials

Paptic Ltd and Walki Group have announced their strategic distribution and converting partnership today. Walki is the first exclusive distributor for the Paptic® materials. This agreement iterates companies’ willingness to drive growth and build stronger relationships with customers globally. Walki and Paptic share a strong sustainability mindset, which served as the basis of the collaboration.

“We are confident that our partnership with Walki will significantly improve our customer service level, enhance the material availability and it will also increase the offering of converted Paptic® materials available on the market,” says Katja Jokiaho, Chief Sales Officer, Paptic Ltd. “Walki is well placed to supply a wide variety of converting solutions and we are very excited to offer them our full range of sustainable materials. I would like to thank the Walki team for straightforward negotiations and I am looking forward to our co-operation. We see that Walki is an ideal global partner for us to drive our growth in the coming years.”

“We are confident that our partnership with Walki will significantly improve our customer service level, enhance the material availability and it will also increase the offering of converted Paptic® materials available on the market,” says Katja Jokiaho, Chief Sales Officer, Paptic Ltd. “Walki is well placed to supply a wide variety of converting solutions and we are very excited to offer them our full range of sustainable materials. I would like to thank the Walki team for straightforward negotiations and I am looking forward to our co-operation. We see that Walki is an ideal global partner for us to drive our growth in the coming years.”

“Walki is excited to start the partnership with Paptic. The combination of Paptic’s unique, sustainable material, made of renewable wood fibres, and Walki’s experience in barriers, heat-sealing, and printing opens many interesting new applications, for example in plastic replacement. The cooperation is an important part of our zero-waste future innovation platform,” says Marko Siltala, EVP, Industrial Packaging.

Co-operation guarantees better customer service and material availability for customers

The cooperation improves both the customer service level and material availability for customers using Paptic® materials. Both companies’ global sales teams do close cooperation and assist customers in finding the right solution for their packaging applications.

Paptic Ltd is a high-growth company established in 2015 with headquarters in Espoo, Finland. The company has developed wood-fibre-based and recyclable Paptic® packaging materials to replace plastics in packaging. The industrial-scale production started in 2018. Today Paptic is a company with close to 30 professionals, and Paptic® materials are delivered to over 50 countries. www.paptic.com

At Walki, we believe in a sustainable and circular tomorrow. Our mission is to accelerate the world’s transition into a zero-waste future in packaging and promote the use of energy-efficient materials across industries. Walki’s product solutions are designed to bring value to customers in many different markets; from sustainable materials for packaging applications to energy-saving performance materials. Walki is a growing international group organized in three business areas: Consumer Packaging, Industrial Packaging, and Engineered Materials, with operations in twelve different countries, both in Europe and Asia. In 2021, the Group’s annual turnover was approx. 550 million euros employing around 1500 people.

Walki introduces a broad portfolio of recyclable materials for the growing frozen food segment

Walki is answering to the growing demand for frozen food by expanding its portfolio of recyclable materials.

The global market for frozen food is expected to grow to 322 billion euros by 2026. Although the demand is growing globally across all age groups, it is especially popular among younger consumers.

- Walki®EVO Seal and Walki®Opti Seal are recyclable paper-based packaging intended especially for pillow-pouches for frozen food.

- Lamibel®MDO-PE is a film-based material for pillow pouches made of reverse printed MDO-film and solvent-free laminated with low sealing LDPE.

- Walki®Pack Tray is a board-based tray suitable for frozen ready-made meals, designed to replace aluminium, plastic or plastic-coated trays.

The global market for frozen food is expected to grow to 322 billion euros by 2026. Although the demand is growing globally across all age groups, it is especially popular among younger consumers.

"Frozen food is an ideal way to prolong shelf life without losing out on the vitamins. It is also an excellent way to combat food waste. This is important as up to 9 % of global carbon emissions can be attributed to food waste, especially fruit and vegetables", says Dudley Jones, Consumer Sales at Walki.

Walki is introducing a broad portfolio of different materials, including printed solutions, to suit the needs of the frozen food market with the aim of making the packaging fully recyclable in the paper stream.

"Frozen food places high demands on the packaging. It needs to be both sturdy and puncture-resistant to handle diverse situations like pressures of sealing and mechanical tear during transportation. The packaging also needs to withstand variability in temperatures as some frozen food is defrosted in its packaging", explains Jones.

Walki®EVO Seal and Walki®Opti Seal are recyclable paper-based packaging intended especially for pillow pouches for frozen food. Walki®EVO Seal has a dispersion coating as a barrier against water vapour and grease while Walki®Opti Seal has an optimised PE-extrusion coating.

"The dispersion coating makes Walki®EVO Seal recyclable in the waste-paper stream without any separation process, while the minimised PE-coating on Walki®Opti Seal makes it suitable to be recycled with paper with an acceptable fibre yield", says Andreas Rothschink, Head of Product Development at Walki.

Both are suitable for all kinds of frozen food: vegetables, seafood, and bakery products to name a few.

Lamibel®MDO-PE is a film-based material for pillow pouches made of reverse printed MDO-film and solvent-free laminated with low sealing LDPE. Thanks to the MDO technology, the film thickness is minimized while performance is maximized by replacing other sorts of materials such as PP- or PET-films.

"This combination of two PE-films makes the packaging fully recyclable in the plastics stream. The stretched film has better optics with high stiffness and mechanical properties than standard PE. The film can also be transparent, allowing the consumer to see the product", says Rothschink.

Lamibel®MDO-PE is an ideal material for all types of packaging (doypack, flowpack, pouches, etc.) as well as all kinds of frozen food like vegetables, sharp-edges seafood and bakery.

Walki®Pack Tray is a board-based tray suitable for frozen ready-made meals, designed to replace aluminium, plastic or plastic-coated trays.

"The tray is easy to fill, transport and store, and is also the convenient choice for the consumer as the fibre-based tray is safe to use in microwaves and in conventional ovens up to 220 degrees for up to 60 minutes," says Jones.

The tray material is 100% PET free and recyclable in the paper stream.

Company Profile Walki

At Walki, we believe in a sustainable and circular tomorrow. Our mission is to accelerate the world’s transition into a zero-waste future in packaging and promote the use of energy-efficient materials across industries. Walki’s product solutions are designed to bring value to customers in many different markets; from sustainable materials for packaging applications to energy-saving performance materials.

Walki is a growing international group organized in three business areas: Consumer Packaging, Industrial Packaging and Engineered Materials, with operations in twelve different countries, both in Europe and Asia.

Walki's significant printing machine investment in Pietarsaari answers to the growing demand of fibre-based packaging

The demand for fibre-based packaging is growing rapidly. To answer to this demand Walki has invested in a state-of-the-art printing machine in Pietarsaari, that provides high-quality prints for fibre-based packaging solutions.

Walki has made a significant investment in its Pietarsaari plant by purchasing a 10-colour flexographic printing press. The new 10-colour flexographic printing press enables better and more accurate printing, which is important particularly in the highly competitive food industry.

“The need for sustainable packaging is growing in the food industry. In addition to sustainability criteria, customers are also expecting high-quality, photographic printing and reproducibility,” says Petteri Pihajoki, Production Manager at the Pietarsaari plant.

Consumer brands are increasingly reducing the use of plastic and are hence looking for solutions that do not compromise food safety while still being fit for recycling in fibre streams. Walki's fibre-based packages with high-quality printing are also suitable for the demanding frozen food segment, where the package needs to be puncture resistant and be able to withstand large varieties in temperature.

The printing machine is also suitable for heat-sealable solutions for non-food items and e-commerce packages. The printing width of the Allstein press is 1600 millimetres, which is sufficient for large packages, like corrugated cardboard packaging.

“We want to offer environmentally friendly alternatives that minimize waste in line with our mission to accelerate the world towards a zero-waste future,” Pihajoki says.

The printing technology is efficient in energy as well as in the use of colours and water.

At Walki, we believe in a sustainable and circular tomorrow. Our mission is to accelerate the world’s transition into a zero waste future in packaging and promote the use of energy efficient materials across industries. Walki’s product solutions are designed to bring value to customers in many different markets; from sustainable materials for packaging applications to energy saving performance materials. Walki is a growing international group organized in three business areas: Consumer Packaging, Industrial Packaging and Engineered Materials, with operations in twelve different countries, both in Europe and Asia. In 2021, the Group’s annual turnover was approx. 500 million euros employing around 1400 people.

walki.com

Walki introduces Lamibel®Recycled: made from recycled plastics and fully recyclable

Walki is answering to the market's growing demand for materials made from recycled plastics by introducing Lamibel®Recycled, a non-food monomaterial packaging material.

Making the plastics stream become more circular is critical to reduce the use of plastics. It has been particularly challenging to find ways to put post-consumer plastic waste to good use. Walki is introducing Lamibel®Recycled, a non-consumer material that uses up to 70 % post-consumer plastic waste. Typically, non-food packaging products only has between 30 and 50% recycled material, mainly from industrial processes.

“We transform post-consumer plastic waste into valuable objects, using recycled materials to create high-quality packaging", explains Juan Pedro Hernández, Head of sales South-West, Films & Bags with Walki Plasbel.

The demand for packaging material made from recycled plastics is spurred by the European Commission’s Circular Economy Action Plan, one of the key components of the European Green Deal. It includes a revision of the Packaging and Packaging Waste Directive (PPWD) that seeks to ensure that all the packaging on the EU market will be recyclable or reusable in an economically viable way by 2030.

The demand for packaging material made from recycled plastics is spurred by the European Commission’s Circular Economy Action Plan, one of the key components of the European Green Deal. It includes a revision of the Packaging and Packaging Waste Directive (PPWD) that seeks to ensure that all the packaging on the EU market will be recyclable or reusable in an economically viable way by 2030.

"Flexible packaging products made from fully recyclable monomaterials like Lamibel®Recycled, will play an important part in achieving the ambitious European goals", says Juan Pedro Hernández.

The post-consumer material used to make Lamibel® Recycled typically comes from three main sources: stretch film for pallet wrapping, PE packaging material, and film used to bundle bottles, cans and Tetra Briks. These products are all collected by certified suppliers from supermarkets, warehouses, shops and so on. They then go through a careful selection process through which the materials suitable to continue into the production process are identified.

Made at Walki Plasbel’s plant in Murcia, Spain, Lamibel®Recycled is primarily used to package non-food household products like toilet rolls, hand rolls and hand towels.

Lamibel®Recycled, being a monomaterial, is also a fully recyclable.

“By being both recycled and recyclable, this material enables a true circular economy."

At Walki, we believe in a sustainable and circular tomorrow. Our mission is to accelerate the world’s transition into a zero waste future in packaging and promote the use of energy efficient materials across industries. Walki’s product solutions are designed to bring value to customers in many different markets; from sustainable materials for packaging applications to energy saving performance materials. Walki is a growing international group organized in three business areas: Consumer Packaging, Industrial Packaging and Engineered Materials, with operations in twelve different countries, both in Europe and Asia. In 2020, the Group’s annual turnover was approx. 355 million euros employing around 1000 people.

www.walki.com

New flexoprinting machine in Jatne will answer to growing demand for sustainable food packaging

The demand for flexible packaging materials is growing amid the transition towards sustainable food packaging. Walki has answered to this need by investing in a brand new flexo printing machine in its Jatne plant in Poland.

“This new investment will significantly increase our capacity and we will be able to answer to the fast growing demand in flexible packaging”, says Andreas Rothschink, Sales Director, Consumer End Uses at Walki.

The high-speeed machine is a 10-colour, state of the art flexographic printing machine that offers top quality and low change-over waste. The investment includes a fully automatic plate mounting machine to further ensure superior printing accuracy on both paper and film and a system for fully automatic job setting in the printing machine. The inks used are water-based and hence environmentally friendly.

As the food industry is shifting to recyclable food packaging, paper-based materials come up as a strong contender. The look and feel of the packaging is an important differentiating factor for end consumers. This sets high demands on the print quality.

“The new flexoprinting machine assures great accuracy of the printouts and a very high quality”, says Jakub Gunert, Plant Manager in Jatne.

The importance of flexible packaging will grow substantially in the coming years as paper-based packaging is efficient both in terms of the amount of materials used and easy recyclability.

“With this investment we are strenghtening our capabilities to further improve the quality and efficiency in all of our product categories, ”, says Andreas Rothschink.

In addition to food packaging, the new machine in Jante will also serve ream wrapper customers.

For further comments, please contact:

Marko Siltala

Executive Vice President Industrial Packaging and Lean Operations

Tel. +358 40 585 2796

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

At Walki, we believe in a sustainable and circular tomorrow. Our mission is to accelerate the world’s transition into a zero waste future in packaging and promote the use of energy efficient materials across industries. Walki’s product solutions are designed to bring value to customers in many different markets; from sustainable materials for packaging applications to energy saving performance materials. Walki is a growing international group organized in three business areas: Consumer Packaging, Industrial Packaging and Engineered Materials, with operations in twelve different countries, both in Europe and Asia. In 2019, the Group’s annual turnover was approx. 400 million euros employing around 1000 people.

walki.com

Walki Group strengthens the Zero Waste Future Platform and licenses Earth Coating technology from Smart Planet Technologies

Walki Group has entered into a license agreement with Smart Planet Technologies, for the use of Earth Coating™ in a number of next generation environmental packaging applications. Earth Coating™ is a plastic reduction technology providing superior performance and improved recyclability for all types of plastic, paper, and paperboard packaging applications.

Walki Group has entered into a license agreement with Smart Planet Technologies, for the use of Earth Coating™ in a number of next generation environmental packaging applications. Earth Coating™ is a plastic reduction technology providing superior performance and improved recyclability for all types of plastic, paper, and paperboard packaging applications.

With this technology Walki takes a big step towards a zero-waste future. Today above 80% of our products are made out of renewable or recyclable materials. Our goal is to reach 100 % by the year 2030.

“The technology agreement will contribute to accelerating some of the developments Walki is working on and further expanding our versatile Zero Waste Future Platform providing sustainable barrier solutions for our customers”, says Annika Sundell, Executive Vice President, Innovation

The license agreement is valid for the European markets and covers seven product application verticals, spanning from board packaging to flexible packaging.

Detergent packaging now even more sustainable

Walki offers solutions made of 100 percent renewable raw materials and soon also made of circular polymers

Walki, a leading manufacturer of packaging solutions, offers cardboard-based laminate constructions for washing powders and other hygroscopic products that are particularly sustainable – while at the same time providing optimum product protection and allowing perfect processing. Headquartered in Espoo, Finland, the company uses tall oil-based barriers instead of petroleum-based barriers and is already developing laminates with certified circular polymers to market readiness so as to close the material cycle.

Walki®Pack D is a solution developed especially for packaging washing powders. "D" stands for detergent. It consists of a strong grey cardboard as the base material, a barrier layer for protection from water vapour and a thin, coated paper for printing and finishing. Conventionally, this type of water vapour barrier is manufactured from petroleum-based polymers. As an innovator and pioneer in the field of sustainability, Walki has also developed an even more sustainable concept called Walki®Wood Pack-D, which uses alternatives made from tall oil for the barrier. Tall oil is a by-product of pulp production. As such, it is obtained from vegetable raw materials, but it does not compete with food production. Tall oil can be used to produce coatings with the same properties and barrier levels as those produced from crude oil.

Walki®Pack D is a solution developed especially for packaging washing powders. "D" stands for detergent. It consists of a strong grey cardboard as the base material, a barrier layer for protection from water vapour and a thin, coated paper for printing and finishing. Conventionally, this type of water vapour barrier is manufactured from petroleum-based polymers. As an innovator and pioneer in the field of sustainability, Walki has also developed an even more sustainable concept called Walki®Wood Pack-D, which uses alternatives made from tall oil for the barrier. Tall oil is a by-product of pulp production. As such, it is obtained from vegetable raw materials, but it does not compete with food production. Tall oil can be used to produce coatings with the same properties and barrier levels as those produced from crude oil.

Identical properties to conventional coatings

The tall oil-based barrier protects the product just as effectively against clumping, keeps it dry and free-flowing and responds identically in the course of further processing. "The laminate construction with the alternative barrier layer is exactly the same as the previous one and can be replaced without having to adapt packaging production or filling lines. It consists of 100 percent renewable raw materials and is completely recyclable," says Stefan Erdmann, Technical Service & Development Manager Barrier Board at Walki. Walki®Wood Pack D can be used to package any type of powdery, hygroscopic product, such as wallpaper paste or tile adhesive.

Certified circular polymers for a zero-waste future

One step further is a concept that is currently close to market maturity and is expected to be available on an industrial scale from 2020: Walki is a pioneer in the use of certified circular polymers, which allow the material cycle to be closed. This is because they are produced in an innovative process from low-value, mixed plastic household waste that would otherwise be incinerated or landfilled. They are manufactured by SABIC, a long-term Walki partner. “Walki is a pioneer when it comes to sustainability. Today, more than 80 percent of our products are made from renewable or recycled raw materials. Our goal is to increase this to 100 per cent by 2030," says Leif Frilund, President and CEO Walki Group. "We have already taken an important step with our tall oil based barrier solutions. Another step will be the introduction of products with circular polymers.”

For additional information, please contact:

Stefan Erdmann

Technical Service & Development Manager Barrier Board

Tel. +49 2551 6863

Walki develops new biodegradable mulching paper

Walki has developed a new fibre-based soil mulching solution that is completely biodegradable. This organic mulch type, which is used for weed control and to optimise soil conditions and crop yield, is the first of its kind on the market.

Walki’s new mulch product, Agripap, is the only solution on the market that is entirely biodegradable. © Walki

Walki, a leading global producer of technical laminates and protective packaging materials, has developed the first-ever organic mulching solution that is based on natural biodegradable fibres instead of plastic. Mulch is a layer of material applied to the surface of an area of soil. It is designed to conserve moisture, improve the fertility and health of the soil and control weed growth. Soil mulching also reduces the need for pesticides, fertilisers and irrigation.

Traditionally, soil mulching materials have been made from plastic, and, most typically, from polyethylene film. While effective, plastic mulch is not biodegradable and eventually becomes waste material that has to be removed from the field and dumped or recycled at a high cost.

It is estimated that more than a million tonnes of plastic films are used for mulching every year around the world. In addition to having to be collected from the fields, the mulch often leaves behind plastic residues, which pollute the soil and reduce its future growth potential. Yields from polluted soil are typically up to 20 per cent lower than those from non-polluted soil.

It is estimated that more than a million tonnes of plastic films are used for mulching every year around the world. In addition to having to be collected from the fields, the mulch often leaves behind plastic residues, which pollute the soil and reduce its future growth potential. Yields from polluted soil are typically up to 20 per cent lower than those from non-polluted soil.

“Walki’s Agripap solution is the only organic mulch type on the market that is made from paper instead of plastic. It is entirely biodegradable, does not contribute to plastic pollution and, instead, simply dissolves into the soil. It also reduces the need for the chemicals used to control weed growth,” says Walki’s Vice President Technical Products, Sales & Marketing, Arno Wolff.

Walki®Agripap is made from kraft paper that is coated with a biodegradable coating layer, which slows down the degradation of the paper. Without the coating, the paper would degrade in the soil within a few weeks.

Walki’s new organic mulching solution has been the subject of extensive field-testing in Finland. The tests, which were carried out in 2016 by independent research institute Luke Piikkiö, compared the performance of different biodegradable mulches for growing iceberg lettuce and seedling onions. The tests demonstrated that Walki’s Agripap was easy to lay on the fields and delivered excellent weed control. The results in terms of yield and durability were also good.

“Having seen the kind of environmental impact that plastic film can have on the soil, Walki has understood that there is a need for a more sustainable mulching solution. Walki®Agripap is the perfect alternative for the farmers who care about our environment,” says Peter Martin, Technical Service & Development Director, Industrial Packaging.

Following the successful testing and approval of Agripap in Finland and Sweden, the next step will be to complete testing in Europe’s main mulching markets: Spain, France and Italy. Farmers and equipment manufacturers wishing to participate in testing Walki’s new organic mulching solution are encouraged to get in touch with Arno Wolff.

Walki in brief

Walki Group is a leading producer of technical laminates and protective packaging materials, specializing in the production of fibre based, intelligent, multilaminate products for markets ranging from energy saving construction facings and construction membranes to barrier packaging applications. The Group has plants in Finland, Germany, the Netherlands, Poland, the UK, Russia and China with a workforce of about 900 people. Annual net sales for the Group are over 300 million Euros.