Displaying items by tag: Walki

Walki announces appointment in Paper Packaging Business Area

Carlo van Houtum has been appointed Vice President, Sales and Marketing for the Paper Packaging Business Area and Business Line Reel Wrap as of June 11, 2012. Carlo has worked for several years in Sales and Marketing Management positions at Myllykoski Group, Sappi Group, and now joins us from delfortgroup in Tervakoski.

Carlo van Houtum has been appointed Vice President, Sales and Marketing for the Paper Packaging Business Area and Business Line Reel Wrap as of June 11, 2012. Carlo has worked for several years in Sales and Marketing Management positions at Myllykoski Group, Sappi Group, and now joins us from delfortgroup in Tervakoski.

The Walki Group is an international company, which produces wrappings for the paper and metal industries. We also have decades of experience manufacturing food and consumer packaging materials as well as decorative and functional laminates. In addition to this, we create specialist liners for solid and corrugated packaging, facings for the insulation and construction industries, and solutions for technical applications. To make working with Walki as easy as possible, our company structure is based on three business areas: Paper Packaging, Consumer Board and Technical Products. If you need help in any of these areas, you can rest assured that Walki has your business covered.

Walki has production facilities in Finland, Germany, the Netherlands, Poland, the UK and China. To best cater to our global customers, we aim to continue investing in state-of-the-art production facilities and promoting our tradition of innovation and exceptional service worldwide. The combined annual net sales of our factories exceed 320 million Euros.

Walki gains stronger foothold in Russia

Walki Group, the leading producer of technical laminates and protective packaging material, has taken an important step in realizing its strategic growth plan for the emerging markets as the new plant in Svetogorsk in Russia celebrated its opening. The next step is already in the pipeline: establishing Walki’s own sales office in Moscow.

Walki Group, the leading producer of technical laminates and protective packaging material, has taken an important step in realizing its strategic growth plan for the emerging markets as the new plant in Svetogorsk in Russia celebrated its opening. The next step is already in the pipeline: establishing Walki’s own sales office in Moscow.

Establishing dedicated production facilities in Russia is a logical consequence of Walki’s close co-operation with many of its customers as well as a first step towards entering new business areas in the Russian market as a domestic supplier. The new Walki plant is located at the ZAO “International Paper” pulp and paper mill, cementing further our long-standing and successful partnership. For years Walki has been supplying ream wrapping for International Paper Russia’s well-known office paper brands Svetocopy and Ballet.

“We have plenty of experience in the Russian market when it comes to, for example, products for the paper industry, flexible laminates and packaging material for steel products. Our new establishment in Svetogorsk will enable us to provide faster and more flexible service to our existing customers,” says Timo Finnström, Vice President Paper Packaging and Sourcing, Walki.

Walki’s high quality products, solutions-focused attitude and service are the company’s competitive edge in the Russian market, and the local presence offers an excellent platform for entering the market with new products. In this, the Svetogorsk plant constitutes an important part of Walki’s long-term commitment in Russia.

“We have a range of products that in due time could be very interesting for the Russian market. A good example is flexible packaging applications and another is our range of high-class insulation facing materials and membranes,” Timo Finnström says.

Advantages of being local

In Svetogorsk Andrzej Kluczek, Managing Director, is happy to see the extrusion and printing capacity installed and running.

“Establishing a local base is a decisive step for us in building an even closer partnership with our key customers in the paper industry. An ability to act fast and with great flexibility is crucial in many cases. Ream wrappers are a good example of this; here designs are frequently switched and orders have to be met immediately,” Kluczek says.

The town of Svetogorsk is situated in western Russia, close to the Finnish border. Thanks to its location Walki Svetogorsk provides an excellent bridgehead into the huge Russian market; the nearby St Petersburg area has a population of 5 million.

Franz Marx, President of International Paper Russia, commented: «Our long-standing partnership with Walki has now reached a new level: this project of Walki packaging production plant at Svetogorsk site will advance International Paper's commitment to the operational excellence and therefore to our customers by improving the flexibility and security of supplies of our key product – multifunctional office papers. We also believe that this opening will have a positive impact for the region, creating new jobs, attracting investments and economic prosperity to the city of Svetogorsk”.

The next step for Walki will now be the opening of its own sales office in Moscow.

Changes in Walki's organization

To realize Walki's strong growth ambitions in the Asia Pacific region, it has been decided that as of January 1, 2012 Mikael Nováky will fully concentrate on growing the business in the Asian markets in his role as Vice President, Asia Pacific. Mikael's responsibilities include all sales and business development activities of the Group in the APAC area and the Changshu plant.

To realize Walki's strong growth ambitions in the Asia Pacific region, it has been decided that as of January 1, 2012 Mikael Nováky will fully concentrate on growing the business in the Asian markets in his role as Vice President, Asia Pacific. Mikael's responsibilities include all sales and business development activities of the Group in the APAC area and the Changshu plant.

As a consequence, Timo Finnström has been appointed Vice President, Paper Packaging and Sourcing, as of January 1, 2012. Both Timo and Mikael will continue to report to Leif Frilund.

As a consequence, Timo Finnström has been appointed Vice President, Paper Packaging and Sourcing, as of January 1, 2012. Both Timo and Mikael will continue to report to Leif Frilund.

Starting January 1, 2012 the Operational Excellence model will be strengthened by bringing together our Lean and Supply Chain operations into one organization. The Operational Excellence function will concentrate on improving Walki's competitiveness and customer service, and further developing and implementing Lean practices and continuous improvement.

Tuomo Wall, currently Vice President, Sales and Marketing, Technical Products has been appointed Vice President, Operational Excellence as of January 1, 2012. In this new role Tuomo will report to Leif Frilund.

Tuomo Wall, currently Vice President, Sales and Marketing, Technical Products has been appointed Vice President, Operational Excellence as of January 1, 2012. In this new role Tuomo will report to Leif Frilund.

Arno Wolff, currently Vice President, Sales and Marketing, Paper Packaging has been appointed Vice President, Sales and Marketing, Technical Products as of January 1, 2012. Arno will transfer to the new role gradually by April 1, 2012. Arno will report to Wolfgang Thissen, Vice President and General Manager, Technical Products; and concerning Paper Packaging to Timo Finnström.

Arno Wolff, currently Vice President, Sales and Marketing, Paper Packaging has been appointed Vice President, Sales and Marketing, Technical Products as of January 1, 2012. Arno will transfer to the new role gradually by April 1, 2012. Arno will report to Wolfgang Thissen, Vice President and General Manager, Technical Products; and concerning Paper Packaging to Timo Finnström.

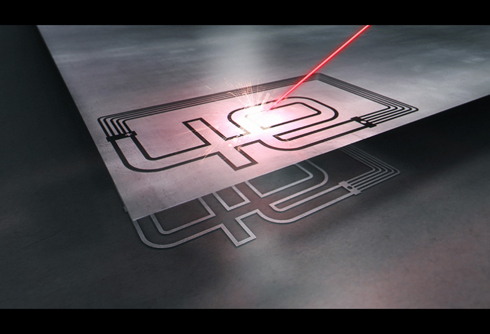

Walki-4E technology: a new, sustainable way of producing RFID antennas

The manufacturing of RFID antennas through the process of etching is now being challenged by a new patented technology: Walki-4E, a new way of producing flexible circuit boards efficiently and sustainably. This is possible through a dry production process, involving no liquid chemicals and using paper as the substrate. It also allows for computer to antenna production and extremely accurate laser cutting of the circuit board patterns.

Walki-4E technology is a new way of producing flexible circuit boards using a dry process and paper as the substrate, the first real alternative to the wet, chemical based process of etching.

The traditional way of producing RFID antennas by etching has for a long period undergone only modest development. Walki, a leading producer of technical laminates, looked for ways to simplify the manufacturing process, while making use of their knowledge in lamination.

“We think that Walki-4E technology is the first feasible alternative to etching and that it will bring new dimensions of cost efficiency and sustainability to the industry,” says Sami Liponkoski, Global Product Manager at Walki.

In brief, the idea is to make a special laminate of aluminium and paper substrate, then aluminium foil is cut in patterns using a laser.

The technology can be used for any production of flexible circuits boards, ranging from RFID antennas to boards for radiators and flexible displays. The first product to be launched using Walki-4E technology is Walki-Pantenna, a UHF RFID antenna.

One step shorter

The four E’s of Walki-4E stand for efficient, exact, economical and ecological. Compared with etching, the technology eliminates a whole step from the tag production process or from the converter’s process, thus combining efficiency and economy.

“Since paper is used as a substrate, the RFID manufacturers can leave out the insertion of the PET inlay into paper, a necessary step when the antenna has been produced by etching. Moreover, the computer to antenna production method speeds up design and development, an advantage especially when it comes to producing short series, involving a fewer number of antennas,” Sami Liponkoski says.

Cost efficiency comes hand-in-hand with environmental benefits. The dry process does not involve any chemicals, thus resulting in process residue that is easily recyclable. The absence of liquid chemicals also leaves the RFID manufacturers with a product, the ready antenna, that is 100 % recyclable.

“Since the antenna is free from plastics, made of paper and aluminium only, it is easily recycled in a fibre recycling process, where metal detectors sort out the aluminium.” Sami Liponkoski says.

Computer to antenna production and laser cutting of the flexible board patterns allow for a speedy production process and extremely high accuracy. An example: the laser cuts with an accuracy of 20 microns while a human hair has the thickness of 100-120 microns.

Towards digitalisation

The precision of the laser cutting of the patterns allows for smaller chips, greater repeatability in the production process and higher accuracy of the antenna.

“This does not only overcome certain accuracy problems that etching brings, but also gives new possibilities for developing the antennas and the chips,” Sami Liponkoski says.

Digitalisation of the production process, i.e. computer to antenna production, brings efficiency and allows for an endless number of variations in the patterns.

“Our vision is that the antenna production eventually will be completely digital. Laser cutting can speed up the production process by ten times, and taking into account the development that laser technology undergoes every year, the possibilities of producing flexible circuit boards with lasers are almost limitless,” Sami Liponkoski says.

Walki’s first product, Walki-Pantenna, will be ready for mass production in 2012.

“We are now in the ramp-up phase for our new production line in Pietarsaari, Finland, and we are looking forward to introduction in the market. There is a lot of interest in our product and we strongly believe it has the capacity to change the industry,” Liponkoski says.

Walki Group sells its shares in Converflex Ab

Walki Group, the leading producer of technical laminates and protective packaging materials, today announced the sale of its 52 % share holding in Converflex Ab. The transaction was made as a local investor backed management buyout (MBO).

Converflex is a flexo printing company in Sweden with a focus on the printing of ream wrapping and flexible packaging. The company generated a turnover in 2010 of 6,6 million Euros and employed 16 persons.

It has been agreed that Walki will continue to supply Converflex with barrier materials. The parties have agreed not to disclose the acquisition price.

Walki Group buys Meuwissen and strengthens its leading position in multi-layer laminates

Walki Group, a leading producer of technical laminates and protective packaging materials, today announced the completion of the acquisition of Meuwissen Industrie B.V., a producer of flexible packaging materials, and Meuwissen Bouwprodukten B.V., a specialist distributor of building and construction materials. Both businesses are located in The Netherlands, employing 65 persons in total, with net sales of 21 million Euros in 2010.

"The acquisition of Meuwissen is an important step for Walki as it will allow us to further develop our position as a leading producer of technical laminates and protective packaging materials", commented Leif Frilund, President and CEO of Walki Group. "Their location in the Netherlands is an excellent fit to Walki's existing plant network and they will increase our local coverage in the important central European markets".

Walki Group has announced that the Meuwissen businesses will be integrated into their Technical Products business area, which currently has production in Finland, Germany, Sweden, the UK and China.

"The knowledge, technical capability and flexible way of working at Meuwissen fits perfectly with Walki and together we will continue to offer the creative solutions that bring the value our customers expect from us", says Wolfgang Thissen, Vice President and General Manager of the Technical Products business area. "Additionally, their network of distribution channels will provide enhanced access to markets in Central Europe for the combined business, bringing benefits for the whole supply chain".

Jan Gerritsen, owner of Meuwissen Group, confirmed "I am convinced that Meuwissen has a good business platform which can be further developed with Walki's knowledge and expertise, and will become an important contributor to the future success of the Walki Group. We are pleased to be part of this exciting new development".

Wolfgang Thissen, Vice President and General Manager Technical Products will be appointed Managing Director of the acquired entities in addition to his present duties and he will be located in Haarlem.

Changes in Walki Group Executive Team (GET)

In order to speed up the growth development of the Walki Group and to increase the share of value added products like multilayer laminates, a new Group function has been created. This new function which will be called Corporate Strategy will focus on both strategy development and strategy implementation. Other focus areas will be the further refinement of different support processes, such as business intelligence, pricing excellence and development of IT tools. An important part of the new function will be the present ICT organization, which will be integrated into the Corporate Strategy function.

Jarkko Tuominen, presently Vice President and General Manager of Business Area Technical Products will be appointed Vice President, Corporate Strategy, as of September 1, 2011. John Aspnäs, head of the ICT function will start to report to Jarkko Tuominen as of September 1, 2011.

Wolfgang Thissen, presently Vice President and General Manager of Business Area Consumer Board will be appointed Vice President and General Manager of Business Area Technical Products, as of September 1, 2011.

Frank Grossmann will be appointed Vice President and General Manager of the Business Area Consumer Board as of September 1, 2011. Frank Grossmann joins Walki Group from the Swiss based BTG Group, where he has worked as Vice President of the Duroblade Division.

Walki invests in Russia

Walki Group, the leading producer of technical laminates and protective packaging materials, will establish a plant in Svetogorsk, Russia, with production set to start during autumn 2011.

The investment in a new plant in western Russia, close to the Finnish border, is part of the Groups strategic plan to expand in emerging markets. The initiative will offer enhanced support to existing key customers in the Russian paper industry, as well as creating a platform for growth in other business areas.

The first phase of development will see investment to install both extrusion and printing capability in the new plant.

"This is an exciting development for Walki Group and provides an ideal platform for us to build our business in a growth region. Furthermore, we are delighted to be able to announce the creation of the new plant and to think of all the opportunities that this development will facilitate with both existing and new customers ", says Leif Frilund, President and CEO of Walki Group.

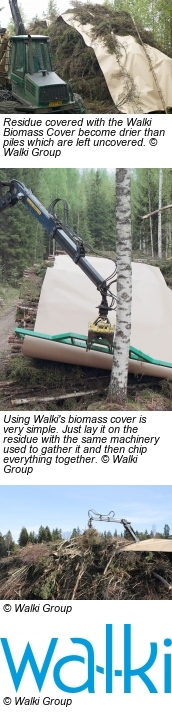

Walki Biomass Cover: Easy cover-up improves drying process and energy content of energy wood.

Logging residue is an inexpensive and easily accessible source of biofuel, but to improve the energy content it must first dry on the ground and after that it can be stored in piles for several months. To shelter the piles from moisture through rain, snow and ice, Walki has developed a paper-based, waterproof cover that can be chipped and burned together with the residue.

The importance of biofuels is increasing globally due to tightening emissions restrictions. Interest in wood-based biofuels has also increased because there are new combustion technologies available on the market that are suitable for solid biofuels.

The importance of biofuels is increasing globally due to tightening emissions restrictions. Interest in wood-based biofuels has also increased because there are new combustion technologies available on the market that are suitable for solid biofuels.

At first glance, Walki’s biomass cover doesn’t look very high-tech, but it’s an ingenious invention that very efficiently improves the energy content in logging residue. The cover itself is a four-meter wide laminate, mainly produced from renewable fibrous materials. It shelters the top of the pile but leaves the sides open, allowing moisture to evaporate.

A very thin plastic layer within the cover makes it both waterproof and very strong, but thanks to the characteristics of the plastic, the cover can be chipped along with the residue and used as fuel as well.

“The biomass cover is already the widest of its kind on the market and the production is constantly growing. Now we are also developing a six-meter wide version that can cover even bigger piles of logging residue and other wood-based biofuels,” says Hannu Nieminen, Product Line Manager at Walki.

In addition to shielding the residue from water and snow, the biomass cover also protects the residue from freezing, which can transform the pile into an icy heap that’s almost impossible to handle and has low energy content.

“The phenomenon is familiar to anyone who has piled chopped firewood outside and forgotten to cover it,” says Mr. Nieminen. “In the wintertime, the wood is icy and heavy and produces much less heat than dry firewood.”

In phase with the environment

Finland and Sweden are pioneers in harvesting energy wood, but because energy saving and biofuels are the latest buzz, interest in the technology is increasing in other parts of the world as well.

“Energy wood is, in many countries, an almost unused resource for producing energy in an environmentally sound way,” says Mr. Nieminen. “Our product maximizes the energy value of logging residue; measurements have shown that the solids content of wood can be raised by as much as 15% by using the cover.”

In Finland, the main reseller of Walki’s biomass cover is Uittokalusto Oy, a Finnish company owned by Grube KG Forstgerätestelle of Germany. The company has been selling the cover for about five years now and is very pleased with the feedback from customers. The main customers are big forest companies in Finland and their subcontractors.

“The cover is easy to spread with the same machinery that gathers the residue in the woods,” says Ilkka Leskinen, Sales Manager at Uittokalusto. “Our customers are satisfied with the benefits of the biomass cover and how easy it is to use the product.” /ins

Walki expands in China and invests in a new glue laminator

The demand for polymer coated cutsize wrapping material is growing at a fast pace in China and the Asia-Pacific area, because of the rapidly growing demand for office paper. To meet the increasing demand Walki Group has started an ambitious investment program in the company’s plant in Changshu, the first major part of the investment being a 1.6m wide high-tech glue laminator.

The new machine produces mainly BOPP (bi-axially oriented polypropylene) laminates for A3/A4 size wrappings, but it can also be used in other sorts of wrapping materials, such as barrier board and aluminium laminates, and for other lamination combinations.

– One of the main advantages with the technology we have chosen is that the printing is actually made on the backside of the BOPP-film, which is then glued on the wrapping paper with the new laminator. As the film is very smooth and dense, and has an excellent printability and transparency, the result is a very glossy and good looking wrapping, where both the packaging and the printing is protected by the polymer film, says Timo Saahko, managing director of Walki Packaging Paper (Changshu), China.

The laminator is part of an ongoing investment program in the factory that serves not just China, where Walki is one of the most renowned producers of protective packaging materials, but the whole of the fast growing Asia Pacific region.

The laminator is part of an ongoing investment program in the factory that serves not just China, where Walki is one of the most renowned producers of protective packaging materials, but the whole of the fast growing Asia Pacific region.

– At the moment, we sell roughly 70 percent of our products in China and export the rest to nearby countries. Since the inauguration of the plant in 2006 our sales have been growing significantly every year. We have most of the big international paper manufacturers as our customers and we are now aiming at the growing amount of smaller paper manufacturers in Asia Pacific, states Mr. Saahko.

He emphasizes that the new machine is not just very efficient, but also environment friendly thanks to its advanced dry lamination technology. – It allows us to increase our production without affecting the environment, which is of great importance to Walki, says Mr. Saahko.

The Changshu factory was built in 2006, logistically well located by the Yangtze River, about 100 kilometres from Shanghai, and close to several paper mills. It primarily focused on reel and ream wrappers for the Chinese paper industry and barrier board for the Chinese and Asian packaging markets.

– The paper markets in China are growing at an incredible pace that we have to keep up with. Thanks to our local staff, which we have recruited for duties all the way to management, we have succeeded to deliver 98 percent of our sales according to schedule, which is an outstanding figure in the business, states Mr. Saahko. /ins

For further information, please contact:

Timo Saahko

Managing Director

Tel. +86 512 52655858

Mobile +86 13906236115

This email address is being protected from spambots. You need JavaScript enabled to view it.

or

Mikael Nováky,

Vice President and General Manager Paper Packaging,

Tel. +358 20 536 3007,

Mobile +358 40 582 8413,

This email address is being protected from spambots. You need JavaScript enabled to view it.