Displaying items by tag: ametek

AMETEK Surface Vision to showcase its color-based inspection technology expertise at TAPPICon Live! 2021

AMETEK Surface Vision, a leading provider of online surface inspection solutions, will be both exhibiting and presenting its technical expertise at next month’s TAPPICon Live! pulp and paper industry conference.

Held in in Atlanta, Georgia, from October 3-6, TAPPICon Live! is the foremost pulp and paper industry conference in the US, and offers a comprehensive technical program, multiple networking opportunities, and exhibitions.

AMETEK Surface Vision will exhibit its surface inspection solutions on Booth 908. Francois Levac, the company’s Business Director, America, will also discuss ‘Detection of Subtle Streaks and Classification of Defects based on Color’ as part of the show’s New Technology Showcase.

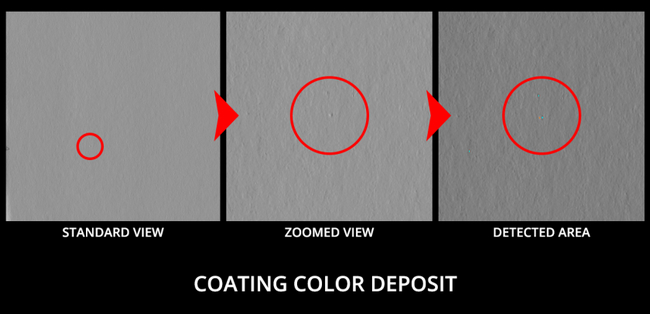

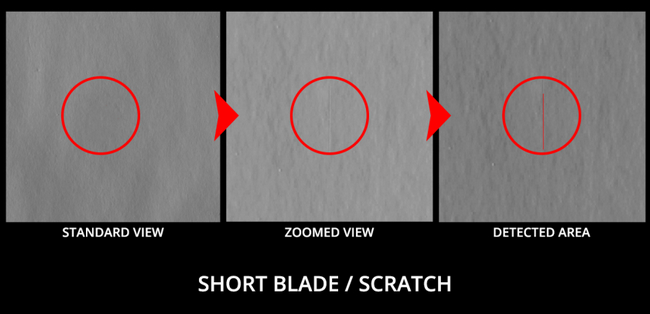

This presentation will highlight AMETEK Surface Vision’s new coating applications inspection feature, which detects subtle streaks and classifies defects based on color. This allows faster, more accurate defect detection and classification, allowing immediate action to avoid scrap material being produced.

It is based around the proven SmartView® inspection system, which has more than 2,500 installations around the world, providing product visibility and process quality to a wide range of industries. Around 950 of these installations are in the pulp and paper sector.

As a modular system, SmartView can be configured with the best-fit technology for each application, including color cameras to enable better identification of defects and to distinguish them from harmless spots that may be falsely flagged as defects by a monochrome system.

Francois Levac, Director of Sales – Americas, said: “TAPPICon Live! provides an excellent opportunity for us to demonstrate the benefits of our color camera inspection systems in pulp or paper contaminant detection applications. I’m looking forward to explaining how this new technology allows us to accurately classify defects based on color, including blood, insects, dye clumps versus dirt, and more, reducing scrap material.”

Visit AMETEK Surface Vision’s expert team on Booth 908. For more information visit www.ameteksurfacevision.com. To register for TAPPICon Live! go to https://tappicon.org/?_TAPPICon_ .

About AMETEK Surface Vision

AMETEK Surface Vision is a world leader in automated online surface inspection solutions with a broad product portfolio optimized for web and surface inspection as well as monitoring and process surveillance applications.

Its product portfolio includes two distinct product lines: SmartView® systems and SmartAdvisor® systems. Each product line uniquely enables customers to inspect the surfaces of materials processed in a continuous fashion across the metals, paper, plastics, nonwovens, and glass industries. Learn more by visiting ameteksurfacevision.com.

AMETEK Surface Vision is a unit of AMETEK Process and Analytical Instruments, a division of AMETEK, Inc., is a leading global manufacturer of electronic instruments and electromechanical devices with 2020 sales of more than $4.5 billion.

SMARTADVISOR® UPGRADE PROVIDES NEW BENEFITS FOR MONITORING CONTINUOUS PROCESSES

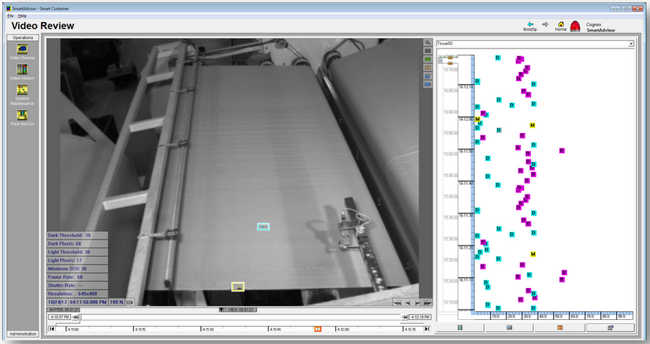

AMETEK Surface Vision, a leading provider of online surface inspection solutions, has upgraded its SmartAdvisor® web and process monitoring system, providing additional benefits for customers.

Versatile and easy to use, SmartAdvisor is a video monitoring solution that helps maximize machine efficiency and yield rates. It provides high-speed, high-definition video monitoring, and process analysis to the paper, board, and tissue industries.

Camera synchronization technology delivers real-time root cause analysis of defects and process interruption. This is supported by simultaneous video capture and review that provides multiple hours of footage for troubleshooting.

Key benefits of the SmartAdvisor system include:

- Increased line efficiency and yield

- Accurate image synchronization

- Multiple views across the process line

- Seamless integration with the SmartView web inspection system

Additionally, SmartAdvisor’s customizable system configuration can be applied in a flexible, scalable way to fit individual production requirements, delivering the most capable and cost-effective solution for each user.

Volker Kölmel, Global Manager Plastic, Nonwovens and Paper at AMETEK Surface Vision comments, “Designed for today’s hands-on troubleshooter, SmartAdvisor delivers proven and significant benefits from the moment it’s installed. Using perfectly synchronized high-speed cameras, strategically placed along the paper machine, SmartAdvisor accurately syncs video frames from each camera to generate a complete overview that helps identify the root cause of web defects and breaks.”

The latest version of SmartAdvisor has a new user interface that improves ease of use and supports Windows 10 and Windows 7 for installation on mill networks. The upgrade also increases storage capacity for video review, allowing more than three days of image storage all at full resolution and framerate. Higher-definition cameras and multi-light control further improve image quality and the capability to identify the root cause of web breaks.

Installation costs are lowered by the introduction of a fiber-optic backbone for the cameras, which offers higher system reliability and performance. This further facilitates the modification of camera locations if required.

AMETEK Surface Vision’s process experts will help customers select the best web and process video monitoring solution for their individual process, with modular hardware and advanced technical support.

Find out more about the SmartAdvisor solution at www.ameteksurfacevision.com.

About AMETEK Surface Vision

AMETEK Surface Vision is a world leader in automated online surface inspection solutions with a broad product portfolio optimized for web and surface inspection and monitoring and process surveillance applications.

Its product portfolio includes two distinct product lines: SmartView® systems and SmartAdvisor® systems. Each product line uniquely enables customers to inspect the surfaces of materials processed in a continuous fashion across the metals, paper, plastics, nonwovens and glass industries. Learn more by visiting ameteksurfacevision.com.

AMETEK Surface Vision is a unit of AMETEK Process and Analytical Instruments, a division of AMETEK, Inc., a global manufacturer of electronic instruments and electromechanical devices with annual sales of approximately $5 billion.

Keeping customers working safely with advanced technical support from Ametek surface vision

AMETEK Surface Vision, a world leader in automated online surface inspection solutions, has extended its global service and technical support for industrial customers to ensure operations continue safely and effectively.

The pandemic has seen an increased demand in critical industries such as nonwovens, paper, and food packaging. AMETEK Surface Vision has fast-tracked its enhanced plans for remote support to ensure maximum productivity and efficiency in these areas.

Surface Vision’s two surface inspection and monitoring product lines, the SmartView® and SmartAdvisor® systems, are in use by customers around the world, requiring continual support in a range of industries including metal, paper, plastics, and non-wovens.

Surface Vision’s two surface inspection and monitoring product lines, the SmartView® and SmartAdvisor® systems, are in use by customers around the world, requiring continual support in a range of industries including metal, paper, plastics, and non-wovens.

In particular, the company has seen an increase in requests to optimize systems detection and classification as industrial mills have changed their product mixes in response to the pandemic. Surface Vision provides a full-featured remote support platform to facilitate these requests, allowing mills to adapt to changing priorities.

With travel restrictions in place due to the COVID-19 pandemic, Surface Vision customer support engineers are working more remotely, which has allowed the team to be more responsive as they are available online for longer.

Technical services have been extended with a new Preventive Maintenance Remote Check-up Service. This service will ensure that the equipment is proactively reviewed on a regular basis, uncovering potential issues before they become a costly problem.

Yamina Lansari, Global Manager of Technical Services at AMETEK Surface Vision, comments, “The pandemic has prompted us to evaluate how effectively we deliver services to our customers.

Our support service is built as a partnership with our customers, who often have mission-critical systems that need our help. Our service engineers are well versed in, and available for, remote service delivery. On-site service is also available to supplement and augment our remote offerings where it is business-critical and where regulations allow.”

Additional extended services include a secure remote portal where Surface Vision can quickly and safely restore service to critical surface inspection and monitoring equipment. The company will also provide customers access to internal expertise and a large product knowledge database.

AMETEK Surface Vision has a broad product range optimized for the monitoring and inspection of webs and surfaces, as well as process surveillance applications. For more information, visit www.ameteksurfacevision.com.

About AMETEK Surface Vision

AMETEK Surface Vision is a world leader in automated online surface inspection solutions with a broad product portfolio optimized for web and surface inspection as well as monitoring and process surveillance applications.

Its product portfolio includes two distinct product lines: SmartView® systems and SmartAdvisor® systems. Each product line uniquely enables customers to inspect the surfaces of materials processed in a continuous fashion across the metals, paper, plastics, nonwovens and glass industries. Learn more by visiting ameteksurfacevision.com.

AMETEK Surface Vision is a unit of AMETEK Process and Analytical Instruments, a division of AMETEK, Inc., a global manufacturer of electronic instruments and electromechanical devices with annual sales of approximately $5 billion.

Ametek Surface Vision strengthens leadership team with several key appointments

AMETEK Surface Vision, a world leader in surface inspection technologies, has announced sweeping appointments across its senior global team to support the business’s worldwide growth plans.

Ben Wileman has been promoted to the new role of Division Vice President and Business Manager for Surface Vision. Moving from his last role as Division Vice President — Global Sales and Marketing for Surface Vision and its sister business, AMETEK Land, Ben will now focus on growing Surface Vision’s business through the application of AMETEK’s four core growth strategies of global and market expansion, new products, operational excellence and acquisitions.

“Combined, these four strategies deliver sustained business growth while continually bringing customers improved benefits at all levels. I look forward to bringing this philosophy into Surface Vision, so the business continues to flourish within the constructive, consistent and mutually successful approach customers want,” said Wileman.

The newly-appointed senior leadership team (clockwise, from top left): Mike Hevey, Alan Tarry, Ben Wileman, Jason Zyglis

The newly-appointed senior leadership team (clockwise, from top left): Mike Hevey, Alan Tarry, Ben Wileman, Jason Zyglis

With a Bachelor of Engineering degree in Electronic Engineering from Sheffield Hallam University, Ben holds more than 14 years of experience at AMETEK in a variety of technical, sales and customer-facing roles. Additionally, he’s an AMETEK-certified Growth Kaizen Facilitator, further strengthening his drive for Surface Vision’s growth.

On the operational end of the spectrum, Alan Tarry is now Division Vice President - Operations for AMETEK Land and Surface Vision. Alan will be fully responsible for operational strategies and performance across both businesses. Formerly the Director of Operations at AMETEK Land since 2015, Alan’s continuous improvement and specialist supply chain experience will transform operational efficiencies across both companies’ manufacturing operations.

Prior to joining AMETEK, Alan held senior operational and supply chain transformational roles at ABB and has a Higher National Certificate in Electrical and Electronic Engineering from Doncaster Technical College. Like Ben, Alan is an AMETEK-certified New Product Growth Kaizen Facilitator and has facilitated several AMETEK operational and new product events.

Charged with developing strategy to remain competitive in current markets while identifying diversification opportunities, Mike Hevey has been appointed Division Vice President – Engineering and Product Management. Joining Surface Vision from SEASPAN Shipyards in Vancouver, Canada, Mike will implement an effective engineering structure to develop and support the world leading SmartView® and SmartAdvisor® surface inspection and monitoring systems, identify new product opportunities, manage the product lifecycle and introduce new products to the market.

Mike holds a Bachelor of Science degree in Electrical and Electronic Engineering from the University of Manchester Institute of Science and Technology, and a Master of Business Administration degree in Engineering and Industrial Management from the University of Loughborough.

Finally, Jason Zyglis will assume responsibility for global sales as Division Vice President of Sales and Project Management. With a deep knowledge of Surface Vision products and applications, Jason will lead the sales and project teams in addressing complex customer challenges as well as implementing a customer-first culture across the organization.

“I’m very pleased to announce these senior appointments at Surface Vision, who will maintain and develop our market-leading position into the next decade,” said Justin Smith, Division Vice President and Business Unit Manager for Surface Vision. “Their combined technical, business and customer experience will provide leadership across Surface Visions’ global sales and marketing, engineering and operational functions, effectively transforming the opportunities and benefits for our customers worldwide.”

About AMETEK Surface Vision

AMETEK Surface Vision (formerly Cognex Surface Inspection Systems Division) is a world leader in automated online surface inspection solutions with a broad product portfolio optimized for web and surface inspection and monitoring and process surveillance applications.

Its product portfolio includes three distinct product lines: SmartView® systems, SmartAdvisor® systems and Slit Inspection. Each product line uniquely enables customers to inspect the surfaces of materials processed in a continuous fashion across the metals, paper, plastics, nonwovens and glass industries. For more information, visit ameteksurfacevision.com

AMETEK Surface Vision is unit of AMETEK Process and Analytical Instruments, a division of AMETEK, Inc., a global manufacturer of electronic instruments and electromechanical devices.

Ensuring paper quality - web monitoring and inspection on a high-speed paper coating line

AMETEK Surface Vision has delivered a reliable, comprehensive state-of-the-art solution for early defect detection and classification on a major paper manufacturer’s premium paper coating line, increasing productivity and winder throughput.

Mitsubishi HiTec Paper Europe GmbH is a paper manufacturer based in Bielefeld, Germany. Known for high-quality products, it is part of the Japanese company Mitsubishi Paper Mills Ltd, and produces coated inkjet, thermal, carbonless, label and barrier papers.

The Bielefeld site operates two paper machines, three coating machines, and seven winders. The premium coating machine, designated SM3, is the most productive coating line at the plant, used for the coating of thermal paper for different applications, so defects need to be detected as early as possible.

The coated paper produced by the SM3 line has to meet the quality standards demanded by customers. The existing web inspection system was aging and no longer able to meet Mitsubishi’s increased requirements, and so had to be replaced with a state-of-the-art web inspection solution that delivered the best available results.

Marco Saitta, Sales Account Manager at AMETEK Surface Vision, said: “Over the years, Mitsubishi assessed the best service and support to be delivered by AMETEK Surface Vision directly. They also found our inspection systems were the easiest to use and provided the most accurate results in terms of defect detection and classification.”

The AMETEK Surface Vision solution

To provide the highest-quality solution for SM3, AMETEK Surface Vision supplied the company’s SmartView and SmartAdvisor® inspection systems, which offers a complete and integrated set of web inspection and web monitoring tools on the same machine.

SmartView is AMETEK Surface Vision’s versatile, modular system for the detection, monitoring and reporting of surface defects on a range of products. It combines powerful software, linescan camera technology, high-intensity lighting and industry-leading engineering to deliver a trusted, automatic solution.

SmartAdvisor is an easy-to-use, reliable video monitoring and process analysis solution for continuous production lines. Using high-speed video and camera synchronization technology, it boosts machine efficiency, finds defects and detects process upsets from startup.

These products can also be coupled together in a comprehensive Smart System configuration. This allows synchronization of the final quality camera images with the over-the-line, distributed process monitoring cameras, so final defects can be traced through the line, identifying the root cause of the defect.

The Smart System is supported by the Advanced Winder Advisor (AWA), a precision marking solution developed specifically for SmartView systems operating in the paper industry.

Axel Kümper, Mitsubishi’s Production Manager for SM3, said: “We have found the AWA to be a very impressive tool, because it stops within a maximum of 10 centimetres from the defect. While there are other solutions available, this has proven to be the most effective one for identifying defect locations for easy removal or patching.”

Meeting customer requirements

Mitsubishi HiTec Paper Europe Gmbh reported excellent results from using the new system on SM3.

Axel Kümper said: “With this new system, we are able to meet the highly demanding quality requirements of the thermal paper market, delivering defect-free material to our customers.”

About AMETEK Surface Vision

AMETEK Surface Vision is a world leader in automated online surface inspection solutions with a broad product portfolio optimized for web and surface inspection and monitoring and process surveillance applications.

Its product portfolio includes two distinct product lines: SmartView® systems and SmartAdvisor® systems. Each product line uniquely enables customers to inspect the surfaces of materials processed in a continuous fashion across the metals, paper, plastics, nonwovens and glass industries. Learn more by visiting ameteksurfacevision.com.

PIONEERING SURFACE INSPECTION SOLUTION GIVES MANUFACTURERS GREATER PRODUCTION ADVANTAGE

AMETEK Surface Vision, a world leader in automated online surface inspection solutions, continues to evolve its highly successful SmartView® surface inspection solution, greatly enhancing production capabilities for manufacturers globally with significant software improvements.

SmartView’s superior performance in detecting surface flaws and defects has enabled it to maintain its position as a market-leading materials inspection solution for three decades. Key to this dominance is the modular system design, supported by an ongoing program of updates that ensures SmartView remains at the forefront of inspection technology.

The SmartView system combines powerful software, state-of-the-art camera technology, high-intensity lighting and unparalleled application engineering services, to deliver a high-performance, automated solution that detects, classifies and visualizes surface defects, and ensures that the highest quality standards are maintained. Existing hardware can be easily switched out to meet the latest technological developments, and AMETEK Surface Vision ensures its Windows-based software suite keeps pace, seamlessly integrating into existing systems.

Shean McMahon, Vice President of Research & Development, AMETEK Surface Vision, explained: “We realize that real-time control of the manufacturing process is critical to our customers, so this remains key to our system’s performance. 2019 is shaping up to be an exciting year for Surface Vision as we embark on the road to expanding our core technologies.

“We expect the combined impact of new capabilities, novel product designs, and optimizations, all borne out of our significant industry experience, will deliver a paradigm shift in the surface inspection industry and serve up unprecedented value, flexibility, and inspection results to our current and future customers.

“SmartView’s latest design enhancements are immediately visible, making highly detailed surface inspection capabilities achievable, ensuring a long system life without requiring a costly system redesign These significant upgrades, already available to SmartView users, include a refreshed, more intuitive user interface, parts-per-million data calculations, and developments to SmartView’s ability to detect defects and parallel classification capabilities – and this is just the beginning of our 2019 development program.”

Multiple views for total control

Introduced in the latest upgrade is the Synchronized Web Viewer, which allows multiple views to be displayed simultaneously. It provides the user with total control of the interface, which could help reduce scrap product in the event of a process issue. This enables different process views, or the same view with a variety of queries in grading, using intuitive drop-down menus and customizable windows to help narrow down results with precision.

Real-time defect density calculations

SmartView’s new Parts Per Million (PPM) application expresses the defect area as a ratio of the total product area. This real-time calculation provides easy visualization of defect density in table and graph formats, making it simpler to identify regions that need closer review.

Increased flexibility in detection and classification

A number of new processing modes have been added and optimized in SmartView for specific inspection requirements, such as detecting quiet areas on coated products, removal of defects that match a target shape, enhanced repeating defect algorithms, and more.

Classification testing without process interruption

A new Parallel Classification function enables SmartView to run up to four alternate classifiers on an inspection file, enabling seasonal or test classifiers to operate alongside established classifiers. This allows potential changes to be evaluated without interrupting current production inspection.

To find out how SmartView can improve your production process, contact a sales engineer in your area by visiting ameteksurfacevision.com

About AMETEK Surface Vision

AMETEK Surface Vision (formerly Cognex Surface Inspection Systems Division) is a world leader in automated online surface inspection solutions with a broad product portfolio optimized for web and surface inspection and monitoring and process surveillance applications.

Its product portfolio includes three distinct product lines: SmartView® systems, SmartAdvisor® systems and Slit Inspection. Each product line uniquely enables customers to inspect the surfaces of materials processed in a continuous fashion across the metals, paper, plastics, nonwovens and glass industries. For more information, visit ameteksurfacevision.com

AMETEK Surface Vision is unit of AMETEK Process and Analytical Instruments, a division of AMETEK, Inc., a global manufacturer of electronic instruments and electromechanical devices.

Ametek surface vision engineer recognized for outstanding contribution at tappi awards

TAPPI Presents Leonard Fiore with Process Control Division Technical Award 2018

An expert engineer from AMETEK Surface Vision, a world leader in automated online surface inspection solutions, was presented by TAPPI (Technical Association of the Pulp and Paper Industry), with a prestigious technical award at its recent PaperCon event in Charlotte, NC.

Senior Hardware Engineer Leonard (Lenny) Fiore received the 2018 Process Control Division Technical Award, which is presented annually by TAPPI in recognition of outstanding contributions to paper industry science and technology.

from left to right): Paul Durocher, Chair TAPPI Board of Directors, ; Leonard Fiore, Senior Hardware Engineer AMETEK Surface Vision; and Larry Montague, TAPPI President & CEO

from left to right): Paul Durocher, Chair TAPPI Board of Directors, ; Leonard Fiore, Senior Hardware Engineer AMETEK Surface Vision; and Larry Montague, TAPPI President & CEO

Mr. Fiore has spent more than 40 years in the pulp and paper industry, starting in 1977 with Foxboro, and been involved with web-based monitoring and inspection for the past 25 years. He is responsible for many important design and technical developments for the paper sector and is named as an inventor on six US patents.

In presenting the award, the TAPPI Awards Committee noted Mr. Fiore’s exceptional accomplishments throughout his long paper industry career and his involvement in the development of landmark products and systems. Those include Champion video capture view, rheometer automation design, Sartell quality information control system, roll diameter prediction and AMETEK Surface Vision’s SmartAdvisor® web monitoring and inspection system, with its incorporation of high-definition cameras and board redesign.

“This award is a thoroughly deserved recognition of Lenny’s technical skills and achievements. Those include his integral role on the team that designed and developed AMETEK Surface Vision’s innovative SmartNet® scalable quality control solution,” commented Marius Westermann, AMETEK Surface Vision Business Manager.

“It acknowledges the dedication and expertise of Lenny and many others at AMETEK Surface Vision, who have made us a world leader in our field.”

Portable gas analyser from AMETEK Land for gas CHP, utilities, cement, glass, paper, pipelines, refineries

AMETEK Land, a leading industrial combustion efficiency and environmental pollution emissions monitoring specialist, has made its Lancom 4 Portable Gas Analyser even more affordable with a Euro price reduction following Britain’s vote to exit the European Union.

Lancom 4 is renowned as the world’s most versatile and accurate portable flue gas analyser whether for testing a boiler system or checking a process for a pollutant. The analyser is able to monitor up to nine different gases and a total of 17 measurement parameters using a single instrument. And, it has the ability to data log up to 250,000 records.

“We are delighted to make this popular product even more affordable by passing on savings post Brexit for customers purchasing in Euros through our offices in Germany, France, Spain and Italy. We are continually innovating within our ranges to ensure that we deliver the most advanced features and software to remain at the forefront of the market, whilst keeping prices competitive. Our aim is to provide even greater access to the most accurate information to make gas analysis as comprehensive as possible,” notes Derek Stuart, Global CE Product Manager for AMETEK Land.

Widely used across industries, including gas CHP (combined heat and power) plants, utilities, cement kilns, glass, paper mills, pipelines and refineries, the Lancom 4 analyser is renowned for its convenience and ease of use. A user simply switches on the analyser, allowing it to complete an automatic zero calibration, and it is ready for use.

Lancom 4 offers built-in data capture and storage of measurement data, plus a USB connection to download the data to a laptop or a PC. In addition, the product recently was updated with free Insight data acquisition software, a powerful tool that allows users to interface their analyser with a PC for remote control and data logging. Insight offers graphing and analysis tools for data visualisation and reporting purposes, providing even easier access to data.

The Lancom 4 features Wake and Sleep functions, which allow measurements and data logs to be recorded over an extended period. It also is supplied with a rugged carry case as standard, ensuring that the instrument is protected at all times when in use.

In addition, upgrading to Lancom 4 has been made much easier. Hardware items, such as external printers or analogue output modules, can simply be plugged in, with no firmware configuration needed. This means that these items can be fitted in the field, avoiding the need to return the instrument to the factory.

Extremely compact and portable, the Lancom 4 weighs only 6 kg / 13 lb and can easily be carried around a plant, even allowing trouble-free access to remote locations via ladders or gantry work. It is also highly robust and ideal for daily use in harsh industrial environments.

For further information on the Lancom 4 and the Insight software package, visit https://www.landinst.com/products/lancom-4-portable-gas-analyser.

AMETEK Land (www.landinst.com) is a business unit of AMETEK, Inc. a leading global manufacturer of electronic instruments and electromechanical devices. AMETEK Land designs and manufactures a wide range of instruments for industrial non-contact temperature measurement, combustion efficiency and environmental monitoring.

For additional information, contact AMETEK Land, Stubley Lane, Dronfield, UK, S18 1DJ, tel +44 (0)1246 417691, fax +44 (0)1246 410585, email: This email address is being protected from spambots. You need JavaScript enabled to view it. , website: www.landinst.com.

AMETEK LAND releases gas analyser for gas oil, utilities, cement, glass, paper, refineries, pipelines

AMETEK Land, the leading industrial combustion efficiency and environmental pollution emissions monitoring specialist, announces a number of enhancements to its Lancom 4 Portable Gas Analyser to improve usability and provide attractive features as standard.

Now available as a free download, Lancom 4’s innovative data acquisition software, Insight, is a powerful tool that allows users to interface their analyser with a PC for remote control and data logging. Insight offers graphing and analysis tools for data visualisation and reporting purposes, providing even easier access to data. Communications between Insight and the user’s PC requires a USB-RS232 interface converter, which is now supplied with every Lancom 4 for quick and easy set up.

In addition, Lancom 4 now includes Wake and Sleep functions, allowing measurements and data logs to be recorded over an extended period, and a rugged Carry Case, ensuring that the instrument is protected at all times when in use. All are now supplied as standard at no extra charge.

Upgrading to Lancom 4 also has been made much easier. Hardware items, such as external printers or analogue output modules, can be simply plugged in, with no firmware configuration needed. This means that these items can be fitted in the field, avoiding the need to return the instrument to the factory.

Derek Stuart, Global CE Product Manager for AMETEK Land, said: “We are continually innovating within our ranges to ensure that we can deliver the most advanced features and software to our customers. Our aim is to provide even greater access to the most-accurate information to make gas data analysis as comprehensive as possible.”

Lancom 4 is renowned as the world’s most versatile and accurate portable flue gas analyser for checking or testing a boiler system or pollutant process. It has the capability to monitor up to 9 different gases, a total of 17 measurement parameters with one instrument as well as the ability to data log up to 250,000 records.

Widely used across industries including gas CHP (Combined Heat and Power) plants, utilities, cement kilns, glass, paper mills, pipelines and refineries, the Lancom 4 is known for its convenience and ease of use. The user simply switches on the analyser, allows it to complete an automatic zero calibration, and it is ready for use.

Lancom 4 has fully built-in data capture and storage of measurement data, plus a USB connection to download the data to a PC, along with free-to-download Insight data acquisition and analysis software for on-site record keeping, analysis and reporting.

Extremely compact and portable, the Lancom 4 weighs only 6 kg / 15 lb and can easily be carried around a plant, even allowing trouble-free access to remote locations via ladders or gantry work. It is also highly robust and ideal for daily use in harsh industrial environments.

For further information on the Lancom 4 visit https://www.landinst.com/products/lancom-4-portable-gas-analyser and for additional information on the Insight software package, visit https://www.landinst.com/products/insight-data-acquisition-analysis-software

AMETEK Land (www.landinst.com) is a business unit of AMETEK, Inc. a leading global manufacturer of electronic instruments and electromechanical devices. AMETEK Land designs and manufactures a wide range of instruments for industrial non-contact temperature measurement, combustion efficiency and environmental monitoring.