Displaying items by tag: arjowiggins

Cyclus is poster child for Jacknife and Arjowiggins graphic collaboration

Arjowiggins Graphic, the leading manufacturer of recycled papers, and Antalis UK, a distributor of the Cyclus range, have launched a new creative campaign to showcase the quality of Cyclus paper as a poster application. The campaign centres on a creative collaboration with Jacknife studios, the company behind iconic gig and tour posters for bands including Blur, Queens of the Stone Age and the Foo Fighters.

Jacknife founder and lead designer, Chris Hopewell, has produced a bespoke, limited edition striking poster inspired by the forest and designed to showcase the quality of Arjowiggins Graphic leading 100% recycled range, Cyclus. The poster, known as ‘The Guardian’, will be hand silk screen printed by Jacknife on CyclusOffset 300gsm 100% recycled in a limited edition.

Chris Hopewell says: “To capture the qualities of Cyclus I chose a figurative design, featuring a non-aggressive guardian at the entrance to a forest. Her look is both ancient and modern. She is young but wise and holds the future in her hands.”

As part of the campaign, the limited edition prints of The Guardian will be distributed to designers, who, along with the broader design community, will also be invited to enter a poster design competition by designing a poster of their choice and posting this on instagram or twitter using #cycluspaper to be automatically entered. The winning poster, judged by Chris Hopewell, will be hand silk screen printed by Jacknife, framed and awarded at the Antalis Review at The Village Underground in Shoreditch on 29th September 2016.

Commenting on the campaign, Angela De Vorchik, Operational Marketing Manager, Arjowiggins Graphic UK says, “This Cyclus campaign is one of our most ambitious yet. We want to creatively inspire the design community to consider using recycled paper to add something unique and environmentally sustainable to their designs. We are very proud to work with Jacknife who are the perfect partner to showcase how Cyclus can be used in printing and to inspire other designers.”

Mike Bennett, Marketing Manager, Antalis UK says, “We are proud to be stockists of Cyclus. The superb quality allows designers to have their work represented in the highest quality finish without compromising their environmental credentials.”

About Arjowiggins Graphic

Arjowiggins Graphic is a leader in the development of innovative environmental paper solutions, offering consistently high quality coated and uncoated recycled papers. The branch is part of Arjowiggins, the world's leading manufacturer of creative high-tech materials and papers. With over 4,000 employees and 20 paper mills around the world, Arjowiggins generates sales of around €1 billion. Arjowiggins is the manufacturing arm of Sequana

About Cyclus

Cyclus is a highly sustainable, 100% recycled paper with FSC® Recycled certification*. Made without optical brightening agents (OBAs), it has an authentic natural appearance, yet offers the printing performance and texture of a modern virgin fibre paper. Cyclus is available in uncoated (CyclusOffset), coated (CyclusPrint), inkjet (Cyclus Jet Premium) and envelope (CyclusEnvelope) varieties, all in a uniquely subtle natural shade.

*FSC® Recycled Certified fibres for sheets, available on request for reels

About Antalis

Antalis is one of the leading distributors of communication support materials in the UK and Ireland. Their market leading range of over 13,000 products includes papers, envelopes and consumables, as well as packaging, promotional and visual communication products. Antalis has 16 logistic centres across the UK and Ireland.

Antalis is the leading paper, packaging and visual communications merchant in Europe. As number 2 worldwide with a turnover of 2.585€ billion in 2014, the Group employs 5,585 people serving over 120,000 clients, companies and printers, in 44 countries via their 118 distribution centres. Antalis carries out 14,000 deliveries each day in the world and distributes 1.8 million tonnes of paper per year on a global level. Antalis is the distribution branch of Sequana.

Antalis and Arjowiggins are fully owned subsidiaries of Sequana

About Jacknife:

Jacknife first started producing hand screenprinted gig posters back in 2006 when founding member Chris Hopewell visited Flatstock at SXSW in Austin, Texas. He was so impressed by the work he saw there that he went straight home and bought an old French screenprinting deck. At that point Chris was making music videos so he had a whole bunch of contacts in the industry.

Over the last nine years Jacknife have produced gig and tour posters for hundreds of bands including Queens of the Stone Age - Wilko Johnson and Roger Daltrey - Beirut - Midlake - the Horrors - Eagles of Death Metal – Black Rebel Motorcycle Club - Blur - Spinnerette - Brody Dalle – to name but a few.

Founding Chris Hopwell ran a production company Collision Films for ten years producing and directing over a hundred music videos. He’s now independently directing commercials, music promos and feature films.

Chris has worked with all the major record labels as well as the coolest indies and has been lucky enough to work with some of the most outstanding acts of the last decade, including The Killers, Radiohead. Franz Ferdinand, The Knife, Scissor Sisters, Graham Coxon and The Offspring. In 2003 he won MTV’s Moon Man award for best art direction in Radiohead’s “There, there” a video which he also directed/ It also picked up Video of the Year at the NME awards that same year and about 30 Silver Pencils.

www.jacknifeprints.com

www.chrishopewell.com

ARJOWIGGINS GRAPHIC BECOMES COP21 OFFICIAL PARTNER

Arjowiggins Graphic, the European leader in the development of environmental paper solutions, has just announced that it will be an Official Partner of COP21 taking place in Paris from 30 th November to 11th December 2015.

Arjowiggins Graphic, the European leader in the development of environmental paper solutions, has just announced that it will be an Official Partner of COP21 taking place in Paris from 30 th November to 11th December 2015.

In 2015 COP21, will, for the first time in over 20 years of UN negotiations, aim to achieve a legally binding and universal agreement on climate, with the aim of keeping global warming below 2°C. The conference is expected to attract close to 40,000 participants including 20,000 official delegates from government, intergovernmental organisations, UN agencies, NGOs and civil society.

As an official event partner, Arjowiggins Graphic aims to promote and develop the use of recycled papers – in Europe recycled paper only accounts for 12%* of paper usage and yet omits 38% less CO2 than a non recycled paper.

The company pioneered eco-responsible paper solutions embracing the principles of the Circular Economy and significantly reducing the impact of paper manufacture on the environment. Arjowiggins Graphic in partnership with La Poste will provide an immediate demonstration of this approach at the COP21 event. It will provide 4,000,000 sheets of 100% recycled A4 paper to used by negotiators and attendees. At the end of COP21 La Poste will then collect and sort the waste paper and transport it directly to Arjowiggins Graphic Greenfield mill, just 100km away, the waste paper will then be deinked and transformed into a high white paper pulp which will then be manufactured into reams of high white office paper at the Le Bourray paper mill.

Jean-Charles Monange, Commercial and Marketing Director, Arjowiggins Graphic says : “Arjowiggins Graphic has pioneered a strategy combining innovation and sustainable development, with the widest range of high quality recycled papers of the European market. It was both natural and important for us to be associated with COP21 and to contribute to this worldwide event by supplying of our recycled papers, with low environmental impact.”

In addition to the COP21 negotiations, Arjowiggins Graphic is also an Official Partner of Solutions COP21, an exhibition open for the general public that will showcase the impacts of and solutions for climate change, which takes place in Paris from 4th to 10th December 2015. Informative panels will be used to showcase recycled paper and the circular economy at the exhibition. In collaboration with La Poste, Arjowiggins Graphic will also host education workshops.

* source: CEPI 2014

The production of recycled paper, compared to the production of a virgin fibres paper:

Requires up to 2,5 times less water and energy

Reduces CO2 emissions up to - 38%

Diverts waste paper from landfill

*Source: Water and energy (BREF, Arjowiggins Graphic), CO2 (Labelia Conseil)

About Arjowiggins Graphic

Arjowiggins Graphic is the leader in environmental and innovative solutions for paper based communication. Its priority is the development of recycled papers, eco-responsible, integrating latest technology breaktrhroughs, allowing to offer to its customers unrivaled performance and technical levels. The branch is part of Arjowiggins, the world’s leading producer of technical and creative papers. With more than 4,000 employees and 19 plants around the world, Arjowiggins generated pro forma sales of €1 billion in 2014. Arjowiggins is a Sequana subsidiary.

Kaleidoscope of Colours Inspires Arjowiggins Graphic latest Cocoon campaign

Arjowiggins Graphic, the leading manufacturer of recycled papers, has announced the launch of a new Cocoon global campaign. The campaign, which uses the tagline, “white, recycled and so much more” showcases a spectrum of colour and range of print finishes on Cocoon Offset.

The campaign features the iconic Cocoon butterfly, inspired by how a caterpillar in a cocoon transforms into a beautiful butterfly. In the new campaign, the Cocoon butterfly appears in a geometrical, technical and coloured design, like that of a kaleidoscope. It reflects the colour and print potential of Cocoon, an established high performing, extra-white and 100% recycled paper.

The campaign features the iconic Cocoon butterfly, inspired by how a caterpillar in a cocoon transforms into a beautiful butterfly. In the new campaign, the Cocoon butterfly appears in a geometrical, technical and coloured design, like that of a kaleidoscope. It reflects the colour and print potential of Cocoon, an established high performing, extra-white and 100% recycled paper.

The campaign, which will be rolled out by Antalis in the UK and target designers, printers and end users, will run from October 20th until December 4th across 26 countries. It includes an elegant mailer, which features embossing on the front cover and an insert with detachable paper butterfly stickers. The mailers will be printed on Cocoon Offset 300 gsm 4 colour Komori energy efficient H-UV offset and will be presented in Cocoon Offset 100gsm envelopes.

The campaign is supported by HTML emails and a dedicated website - www.white-and-recycled.co.uk, where customers are encouraged to answer a simple question correctly to be entered into a free prize draw with the chance to win one of two long weekends for two in the colourful Italian village of Cinque Terre. 20 boxes of Italian wine (mix of red, white and rose) will also be available for the lucky runner up winners.

Angela DeVorchik, Operational Marketing Manager at Arjowiggins Graphic UK, comments: “Our campaign is a great way to showcase the outstanding print performance of Cocoon paper which is high performing, versatile and 100% recycled. We hope the Cocoon campaign will demonstrate to printers and businesses that they can produce high quality printed marketing materials without compromising environmental credentials.”

Mike Bennett, Marketing Manager, Antalis UK says, “We are pleased to be exclusive stockists of Cocoon. It’s range of 100% and 50% Recycled* FSC® certified uncoated and coated papers have the qualities and appearance of virgin fibre paper but with superior environmental credentials. The printed mailer is a fantastic demonstration of the versatility and print finish of this excellent product.”

About Arjowiggins Graphic

Arjowiggins Graphic is a leader in the development of innovative environmental paper solutions, offering consistently high quality coated and uncoated recycled papers. The branch is part of Arjowiggins, the world's leading manufacturer of creative high-tech materials and papers. With over 4,000 employees and 20 paper mills around the world, Arjowiggins generates sales of around €1 billion. Arjowiggins is the manufacturing arm of Sequana

About Cocoon

Cocoon consists of a comprehensive range of coated and uncoated recycled papers manufactured from 100% and 50% FSC certified recycled de-inked pulp produced using pioneering methods at Greenfield S.A.S. mill. The products offer the same performance standards as virgin fibre papers, with excellent runnability, printability and whiteness and are available in weights ranging from 80 gsm - 400gsm. Cocoon satisfies the strictest environmental standards and has been certified as follows: European Ecolabel, FSC Recycled-certified, OHSAS 18001, ISO14001 and ISO 50001.

About Antalis

Antalis is one of the leading distributors of communication support materials in the UK and Ireland. Our market leading range of over 13,000 products includes papers, envelopes and consumables, as well as packaging, promotional and visual communication products. Antalis has 16 logistic centres across the UK and Ireland.

Antalis is the leading paper, packaging and visual communications merchant in Europe. As number 2 worldwide with a turnover of 2.585€ billion in 2014, the Group employs 5,585 people serving over 120,000 clients, companies and printers, in 44 countries via their 118 distribution centres. Antalis carries out 14,000 deliveries each day in the world and distributes 1.8 million tonnes of paper per year on a global level. Antalis is the distribution branch of Sequana.

Antalis and Arjowiggins are fully owned subsidiaries of Sequana

Arjowiggins Graphic Scoops Award for recycled-papers.co.uk

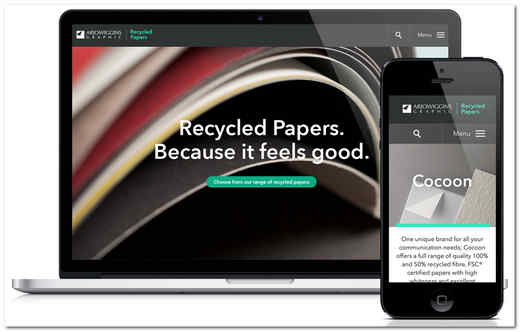

Arjowiggins Graphic, the leading environmental paper manufacturer, is pleased to announce that it’s re-launched UK website, www.recycled-paper.co.uk, has won Best Environmental Website at the 2015 WebAwards. In addition, the website has been shortlisted for Best Website at the B2B Marketing Awards.

Since launching in February, www.recycled-paper.co.uk has seen record results, which includes the highest ever recorded web traffic, sample orders enquiries and environmental benefit statement requests.

In the months of February and March 2015 alone, the business saw more website visits than the previous 12 months of 2014, with a 750% year on year increase in website traffic in the first three months. Sample requests increased 350% with interaction on social media channels boosted by 130%.

Will Green, Digital Marketing Manager, Arjowiggins Graphic UK says: "The development of the new recycled-papers website has been an astounding success. Not only does Arjowiggins Graphic have one of the leading websites in our field, we also have delivered outstanding brand and business results."

In awarding the prestigious WebAwards Best Environment Website award, an evaluation of the Arjowiggins Graphic UK website was conducted by independent expert judges that included representatives from Google, Yahoo! and Disney.

The website features ground breaking imagery and design, with a dynamic interface that is fully compatible with mobile devices. This means that printers, designers and end users can easily order samples and calculate Environmental Benefit Statements on the go. A new innovative ‘paper finder’ feature, selects the perfect paper fit, providing users detailed information on the environmental efficiency and technical specification of each paper manufactured by Arjowiggins Graphic.

The website features ground breaking imagery and design, with a dynamic interface that is fully compatible with mobile devices. This means that printers, designers and end users can easily order samples and calculate Environmental Benefit Statements on the go. A new innovative ‘paper finder’ feature, selects the perfect paper fit, providing users detailed information on the environmental efficiency and technical specification of each paper manufactured by Arjowiggins Graphic.

Featuring original photography of all of Arjowiggins Graphic papers throughout the site - including Cocoon, Cyclus and Eural - as well as examples of end products in a dedicated paper showcase, the website offers visitors the opportunity to explore the range in an increasingly visual and dynamic format. The Green Matters section of the website includes new videos and animations depicting the lifecycle of recycled paper and behind the scenes footage of the Arjowiggins Graphic manufacturing mills, emphasising the benefits of recycled paper and engaging customers in environmental concerns.

Arjowiggins graphic launches teknocard

- LARGEST RANGE OF A PREMIUM BOARD AND PACKAGING AVAILABLE IN THE MARKET -

Arjowiggins Graphic today announces the launch of a brand new premium board and packaging range called Teknocard. The new range is the widest available in the market for packaging and graphical applications and has the added benefit of Arjowiggins Graphic market leading sustainability credentials.

Arjowiggins Graphic today announces the launch of a brand new premium board and packaging range called Teknocard. The new range is the widest available in the market for packaging and graphical applications and has the added benefit of Arjowiggins Graphic market leading sustainability credentials.

The entire Teknocard range is FSC® certified and guarantees outstanding bulk, stiffness and dimensional stability. Products are available in uncoated, one side coated, two-side coated, wood-free, 50% recycled and 100% recycled. The entire range boasts perfect surface smoothness to ensure exceptional colour reproduction and converting performance.

To spearhead the launch and support Arjowiggins entry into this new market, the company has appointed Malcolm Sinclair as Business Development Manager. Previously sales director at Tullis Russell, and one of the architects behind the Trucard brand, Malcolm brings with him 30 years of experience in the premium board and packaging industry.

Commenting on the launch Malcolm Sinclair says, “I am incredibly excited to be part of creating the Teknocard brand and product offer. We have a fantastic opportunity to give the market what they want in board choice, coated and uncoated, FSC as standard and premium recycled as an option, offset and digital. And all from a producer who can offer the scale and service to allow our customers to be competitive in the marketplace of today and tomorrow.”

Teknocard is available to order now in a wide range of grammages and qualities. For further information and samples customers should contact This email address is being protected from spambots. You need JavaScript enabled to view it. or Malcolm Sinclair at This email address is being protected from spambots. You need JavaScript enabled to view it.

Range detail:

| Teknocard 0: | Uncoated premium board FSC® Mix certified |

| Teknocard 0 recycled 50%: | Uncoated premium board 50% recycled fibre FSC® Mix certified |

| Teknocard 0 recycled 100%: | Uncoated premium board 100% recycled fibers, FSC® Recycled certified |

| Teknocard 1: | Coated 1 side premium board FSC® Mix certified |

| Teknocard 1 recycled 50%: | Coated 1 side premium board 50% recycled fibre FSC® Mix certified |

| Teknocard 1 recycled 100%: | Coated 1 side premium board 100% recycled fibers, FSC® Recycled certified |

| Teknocard 2: |

Coated 2 side premium board FSC® Mix certified |

| Teknocard 2 recycled 50%: | Coated 2 side premium board 50% recycled fibre FSC® Mix certified |

| Teknocard 2 recycled 100%: | Coated 2 side premium board 100% recycled fibers, FSC® Recycled certified |

Arjowiggins Graphic is a leader in the development of innovative environmental paper solutions, offering consistently high quality coated and uncoated recycled papers. The branch is part of Arjowiggins, the world's leading manufacturer of creative high-tech materials and papers. With over 4,000 employees and 20 paper mills around the world, Arjowiggins generates sales of around €1 billion. Arjowiggins is the manufacturing arm of Sequana

Cyclus rebrand supports education in Africa

Cyclus rebrand supports education in Africa

- Arjowiggins Graphic campaign partners with charity to help support education in Africa through a rebrand of its Cyclus paper range -

Arjowiggins Graphic, a leading manufacturer of environmental paper solutions, today reveals a new look and feel for its leading-edge Cyclus paper range via a campaign that will support access to education for children in Vontovorona, Madagascar.

Partnering with SOS Children’s Villages France the company is launching a new innovative nine-week campaign that showcases the brand new Cyclus logo and identity across the various communication tools.

One of Cyclus’s biggest campaigns to date and the first new logo since the products launch in the 1990’s, the communication tools consist of 56,950 mailers, a notepad, a new swatch brochure, web banners, adverts and a dedicated website. Investing in its leading recycled paper brand, the campaign is targeting designers, printers and corporates in 36 countries across the world.

Childhood, but specifically a child’s education, is the other focus of this latest Arjowiggins Graphic campaign. For each customer that orders a free Cyclus notepad, Arjowiggins Graphic will gift one child from Vontovorana SOS Children’s Villages Madagascar their fees for one complete school year*.

Included in the mailer is an origami fortune teller that invites customers to step back into their childhood and have some fun by personalising it with their own text.

Angela De Vorchik, Operational Marketing Manager at Arjowiggins Graphic comments: "Taking inspiration from a declaration made by Nelson Mandela who once said, “Education is the most powerful weapon which you can use to change the world,” we wanted to create a mailer campaign that could support a child’s education in a really simple way. Each time our customers request a notepad they will be supporting access to education in a less-privileged part of the world and making a positive contribution to a child’s future. We’re delighted to be able to continue our long-standing partnership with SOS Children’s Villages for this campaign and raise awareness of the great work the charity is doing.”

Using CyclusOffset 140gsm for the fortune teller, 90 gsm for the envelope, Cyclus Print 250gsm for the mailer, and for the notepad a combination of Cyclus Print 350gsm and CyclusOffset 90gsm, all of the communication tools have been manufactured from 100% de-inked pulp and showcases the unique natural shade and finish that can be achieved from recycled waste paper. Both papers are 100% recycled, FSC®, Recycled Certified. Cyclus Offset is an uncoated, natural white paper, whilst Cyclus Print is a matt-coated printing paper for use in both full colour and black and white printing. With Cyclus Print the non-reflective matt surface is especially suitable for publications with a combination of large text areas and high quality pictures.

The campaign is being rolled out in the UK by Antalis a distributor of Cyclus.

Natalie Thomas Marketing Manager Antalis UK, comments: "The Cyclus paper range enable us to deliver the shade and finish businesses need for their printed communications, such as high-end marketing brochures and mailers, whilst also conveying their green credentials. When compared to the manufacture of non-recycled papers the manufacturing process reduces energy consumption, uses less water, diverts waste from landfill and CO2 emissions are substantially lower. It is a paper with an environmental story that contributes to a business’s message – superb quality, a beautiful texture and a unique subtle shade. The Ultimate Recycled!”

Customers are able to use Arjowiggins Graphic’s Eco Calculator to produce their own Environmental Benefit Statement (EBS), which is a great way to bring the decision to use Cyclus recycled paper to life and engages people with the benefits of printing on recycled paper. The EBS reveals the savings on landfill, greenhouse gases, litres of water, energy and wood and are tailored to specific print runs.

*Arjowiggins Graphic commits to provide education for one year to the 500 children of the Vontovorona SOS Children’s Village School

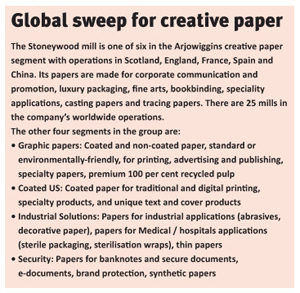

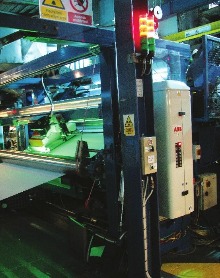

ABB and Arjowiggins team together on Stoneywood’s PM10 Machine

Transparency is key to improving performance.

A project to upgrade the PM10 machine at the stoneywood fine paper mill of Arjowiggins in Scotland has transformed its operation. Vince Maynard Editor of Pulp Paper & Logistics Magazine was there to see the project signed off.

Real-time information about the operational performance of any paper-making line is key to improving quality and productivity.

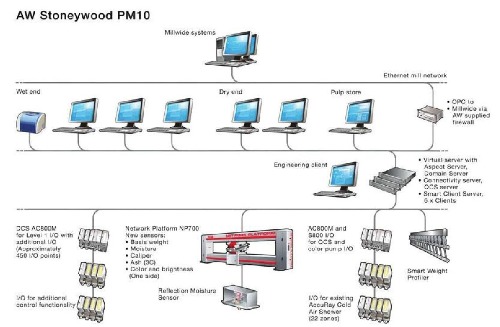

When hardware upgrades were installed at one of the four lines at the Stoneywood fine paper mill operated by Argowiggins near Aberdeen in Scotland, a parallel project to install state-of-the-art quality-control systems provided new-found transparency into the line’s improved performance.

In a collaborative QCS/DCS project with ABB worth £1 million, the improvements to the PM10 machine – capable of sophisticated processes such as watermarking and colour variations – demonstrated how new life can be injected into an already well-established process.

At the end of May, the six- month project was signed off to the satisfaction of development engineer Ian Kilgour, along with documentation that showed the positive effects of the hardware improvements.

In April, PPL magazine was exclusively invited to witness the outcome of the project. While in the PM10 control room mill operations manager Alex McAllan entered with charts showing the production improvements, key performance indicators that spoke for themselves. Time taken for a total change was down by 12 percent; weight and moisture change down by 13.2 per cent and an impressive reduction in breaks.

In April, PPL magazine was exclusively invited to witness the outcome of the project. While in the PM10 control room mill operations manager Alex McAllan entered with charts showing the production improvements, key performance indicators that spoke for themselves. Time taken for a total change was down by 12 percent; weight and moisture change down by 13.2 per cent and an impressive reduction in breaks.

Following the sign off, MacAllan was fulsome in his praise, complimenting ABB for the quality of the project. “The mill is very pleased with the outcome of the project,” he said “It was a great job very well executed. What is particularly pleasing is how enthusiastic the operations team on PM10 is with the system.”

As an example of how the newly-completed QCS/DCS Project offers immediate operational benefits, the way in which it highlighted the outcome of replacing earlier designs of drives was an eye-opener.

Says ABB’s Mick Cowdroy, who worked on the project with colleague Nick Evans: “ The mill upgraded two old drive units at the wet-end of the machine with two new drive units and linked them electronically to the remainder of the machine drive system, thus allowing all sections of the machine to be fully synchronised and controlled more accurately. “ This allowed the advanced controls in the ABB system to be fully optimised and generate increased production benefits through more precise speed optimisation control, faster grade, shade and brightness change control, plus fewer web breaks and faster start-up.”

The new system replaced a QCS (Accuray 1180) dating from the early 1980s and with a Taylor MOD300 (also and ABB product) was mainly used as a data gatherer for process signal for collating all the machine process data and sending it to the mill’s management Information Syetem (MIS). It was also the interface between the QCS and the MIS as the 1180 was incapable of direct linking to the outside world.

All of the machine’s process controllers were ‘stand alone’ units from a number of manufactures: Fisher ac2 (circa 1970s), Turnbull Control Systems (TCS, and eventually part of Eurotherm) were also late-1980s technology. There were two distinct models of single-loop controllers. On top of this there were a few field-mounted controllers plus Refiner KW controllers. All dating from themed-1990s

It was decided to replace all of these systems and in addition install slice lip profile actuators (to replace the manually-set ones) plus remove all Start/Stop buttons for the wet end pumps and the like.

Working with ABB on the project was the continuation of a long history of collaboration between the Stoneywood Mill and Accuray/Combustion Eng/ABB since the mid 1970s. Most recent was the successful installation of an 800xA system on the mill’s PM08 line in 2009.

Working with ABB on the project was the continuation of a long history of collaboration between the Stoneywood Mill and Accuray/Combustion Eng/ABB since the mid 1970s. Most recent was the successful installation of an 800xA system on the mill’s PM08 line in 2009.

Work on the latest project started in the spring of 2010 with Tom and Neil Gordon, of Process Instrumentation Ltd, carrying out preparatory work and then producing a User Requirment Specification (URS) with input from the mill production team, utilising their extensive knowledge of the older system’s functionality.

“The content and quality of this URS enabled the ABB project engineers to programme and configure the control system functions to a high degree of accuracy and ensure an efficient Factory Acceptance Test (FAT). The order was raised in December 2010,” said Cowdroy.

With ABB starting work at its Dundalk base in Ireland. pre-installation at Stoneywood included remote I/O panel building, installation of truncking and cabling, re-housing crew’s ‘bothy’ to enable the old one to be re-built as a wet end control room and ABB rack room, all of which was carried out between January and June 2011.

At Dundalk, the QCS Factory Acceptance Test (FAT) was completed in May 2011 by ABB Project Manager Nick Evans and QCS expert Jim Matthews, all under the supervision of Niall Gairdner from the mill’s Process Control Department. Next stage was the DCS FAT which took place at Stoneywood at the end of June 2011 along with ABB representative Lucas Hedl.again led by Gairdner.

During the annual summer shut-down at Stoneywood in July 2011 the PM10 was stopped to enable dry testing, followed by wet testing which was completed on a Sunday at the end of month. The next morning, 1 August. Stock tests took until lunch time as steam from the boiler house was raised and at 2pm a sheet went through the machine for commissioning of the drying control loops. By. 6pm saleable paper was being produced. The same machine ran all night on the same grade and from 8am the next morning the second tuning of other grades began with colour control following a few days later, but ahead of schedule.

During the annual summer shut-down at Stoneywood in July 2011 the PM10 was stopped to enable dry testing, followed by wet testing which was completed on a Sunday at the end of month. The next morning, 1 August. Stock tests took until lunch time as steam from the boiler house was raised and at 2pm a sheet went through the machine for commissioning of the drying control loops. By. 6pm saleable paper was being produced. The same machine ran all night on the same grade and from 8am the next morning the second tuning of other grades began with colour control following a few days later, but ahead of schedule.

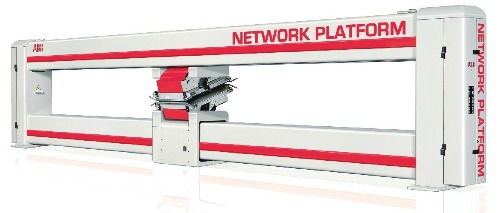

Another reason for working with ABB was the size of the scanner. Originally, ABB had suggested a direct replacement of an earlier ‘C’ frame for a later version. With very little space before the Reel-up Section the options were limited so, after an extensive review of all potential options ABB’s Network Platform 700 was chosen due to its industry-leading compact installation footprint. The result made space more available.

This greatly assisted Stoneywood in the mechanical installation of the scanner s major civil and mechanical work would have been necessary to install a Network Platform 1200. Had the NP1200, or similar, been only option this would have raised the overall project costs (ny about £250,000 or 25 per cent) but also extend the shutdown period by up to ten days with a huge knock-on effect due to lost revenue.

As an added bonus, Arjowiggins and ABB agreed to include the boiler controls within the project scope. This allowed the mill to remove the MOD30 controllers which controlled the drum level and the fuel loops. This has also been a great success. The overall result has been measurable improvements in net production, saleable paper and mill profitability. They are the result of Arjowiggins personnel having access to, and having confidence in, much more reliable and accurate information from the QCS 800xA system. The system is also automatically providing faster and more accurate measurements to the control algorithms which in turn are now calculating the required process changes much more quickly and with greater accuracy to get the process variables to target more quickly than the previous technology would have been able to accomplish.

More information from ABB, Finnabair Industrial Park, Dundalk, Co Louth, Ireland. Tel: +353 42 938 5100. Fax: +353 42 938 5124. Web: www.abb.co.uk

The above article was provided by Vince Maynard the Publisher and Editorial Director of Pulp Paper & Logistics magazine. Tel: +44 (0) 1732 505724 Web: http://www.pulppaperlogistics.com/