Displaying items by tag: cortec

Forget about Supply Chain Shortages: Four Reasons to Get Your VCI Paper from CCP!

In an era of supply chain shortages (and always), Cortec® Coated Products (CCP) is an outstanding source of VCI (vapor corrosion inhibitor) coated paper for four reasons.

1. Vertical Integration

1. Vertical Integration

Cortec® oversees the VCI paper coating process from start to finish, first by blending its own proprietary VpCI® paper coating at its Cortec® headquarters plant, then by coating it at up to 1200 feet (366 meters) per minute on the wide-width coater at CCP in Eau Claire, Wisconsin. In this way, Cortec® is able to oversee every stage of the process for quality control. The resulting paper is perfect for wrapping or interleaving metal parts to protect them against rust during storage or shipment.

2. Flexible Options

CCP is also noteworthy for its flexibility and wide selection range. While CCP has many stock options for paper weight, rolls, and sheeting; customers can also request custom sizes and perforations (for greater convenience) or order jumbo rolls to convert at their own plant (for greater economy). CCP even offers large format paper widths that are difficult or impossible to find elsewhere.

3. Fast Turnaround

In addition to flexible options, CCP has fast shipping turnaround on all stock items. This is a welcome relief at a time when supply chain shortages seem to be everywhere. The CCP shipping office operates 10 hours a day, four days a week, to quickly fill orders on its many in-stock coated papers. For instance, CorShield® VpCI®-146 Paper is ready to order in a variety of sheet and roll sizes and weights. It also comes in creped and reinforced paper versions for cushioning or anti-tear needs.

4. Environmental Initiatives

Another noteworthy feature is CCP’s membership in the Wisconsin Green Tier Program since 2010. As such, CCP has been an example of practical environmental initiatives, such as reducing paper scrap. CCP also produces several USDA Certified Biobased Products, of which one (EcoShield®

VpCI®-144) is a VCI paper with a recyclable moisture barrier coating (not plastic). Depend on Us for VCI Packaging! CCP is here to serve with a wide range of options when it comes to naturally biobased corrosion protection packaging. Whether your interest is wide-width coated VpCI® paper, custom perforated rolls, or fast turnaround when no one else has what you are looking for, CCP is ready to help.

Contact Cortec® today to let us know your coated paper needs and take full advantage of your dependable resources at CCP:

https://www.cortecvci.com/contact-us/

Cortec® Introduces EcoShield® Super Barrier Paper and Linerboard

An Environmentally Friendly Replacement for Polycoated and Waxed Papers!

Moisture is a major threat to raw materials and finished goods of all kinds—particularly those made of metal and prone to rust and corrosion. Greases and oils sometimes used as lubricants or rust preventatives on metal components add another problem by threatening to leak through packaging and contaminate surrounding areas. Waxed or polycoated papers are traditional moisture-resistant packaging options for problems like these. However, such coated papers pose an environmental problem because they are not recyclable and repulpable. Even if recycled back into the pulp and paper stream, they would first have to go through a costly process of separating the paper base from the coating.

To avoid this environmental problem, Cortec® Corporation has developed an environmentally acceptable replacement to unrecyclable polycoated and waxed papers. Cortec’s new high gloss EcoShield® Super Barrier Paper and Linerboard relies on a water-based moisture barrier coating for moisture resistance. The technology makes the paper fully recyclable and repulpable without requiring costly processes to remove the coating from the paper. In addition to recyclability, Cortec’s EcoShield® Super Barrier Paper and Linerboard demonstrated better water vapor barrier properties than polycoated paper and waxed paper during testing.

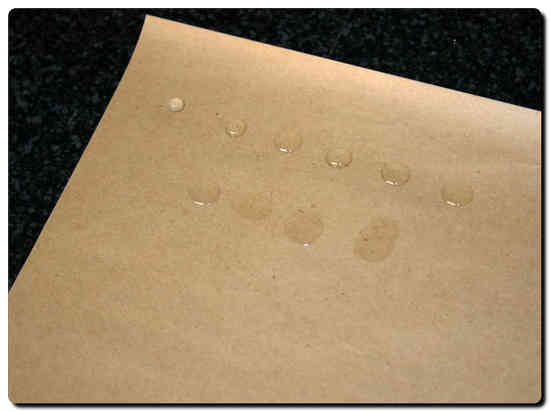

To evaluate the moisture resistance of EcoShield® Super Barrier and Linerboard, the barrier paper was tested against a comparable polyethylene coated paper and a commercial waxed paper according to ASTM E-96 at 73°F (23°C) and 50% relative humidity. The EcoShield® Super Barrier Paper and Linerboard showed a water vapor transfer rate of 0.32-0.37 grams per hour on a square meter of paper. A polycoated paper in the same test allowed slightly more water vapor to pass through in the same time frame, at the higher rate of 0.47-0.71 grams per hour. The waxed paper was much less resistant to water vapor, allowing it to transfer at a rate of 6.5-6.9 grams per hour on the same size of paper. Though it is not intended for applications involving constant water contact, the shiny side of EcoShield® Super Barrier Paper and Linerboard also has the ability to repel liquid water. Its TAPPI T-441 Cobb Water Absorption rate is less than 0.3 grams of water per square meter in 2 minutes.

EcoShield® Super Barrier Paper and Linerboard also has excellent oil and grease resistance. It registers a high kit test value of 12, representing the highest amount of an aggressive liquid solution to remain on the paper surface without causing the paper to fail. The high gloss paper not only protects against the ingress of moisture or grease into a package, but it also protects against the leaching of oil and grease out of a package. This is important when manufacturer’s specifications require the use of greasy rust preventatives, or when the metal equipment being wrapped, packaged, or shipped contains lubricated parts. EcoShield® Super Barrier Paper and Linerboard can discourage these oils and greases from seeping out of the package and causing packaging failure or contamination of nearby materials.

The versatility of EcoShield® Super Barrier Paper and Linerboard as a flexible, moisture barrier material allows it to be used for a variety of packaging applications and beyond:

• Protecting moisture sensitive components

• Wrapping oily or greasy parts

• Lining wood pallets or corrugated boxes

• Packaging products

• Keeping work surfaces clean with a disposable cover

EcoShield® Super Barrier Paper and Linerboard is available in custom sizes and as sheets or perforated rolls for the convenience of the user.

Whether moisture threatens from the inside or the outside of a package, EcoShield® Super Barrier Paper and Linerboard is a more environmentally friendly way to protect against damage from moisture, grease, and oil. By coating water based barrier technology onto biobased material, Cortec® has made a fully recyclable, environmentally acceptable, and competitively performing replacement for polycoated and waxed papers.

To find out more about EcoShield® Super Barrier Paper and Linerboard, please visit: https://www.cortecvci.com/Publications/PDS/EcoShield_Super_Barrier_Paper.pdf

To find out more about Cortec’s innovative packaging products, please visit: http://www.cortecpackaging.com/

Cortec® Corporation is the global leader in innovative, environmentally responsible VpCI® and MCI® corrosion control technologies for Packaging, Metalworking, Construction, Electronics, Water Treatment, Oil & Gas, and other industries. Our relentless dedication to sustainability, quality, service, and support is unmatched in the industry. Headquartered in St. Paul, Minnesota, Cortec® manufactures over 400 products distributed worldwide. ISO 9001, ISO 14001:2004, & ISO 17025 Certified.

Cortec’s EcoShield® Heat Sealable Paper Offers Flexible Custom Recyclable Packaging Solutions!

Cortec® has made it easy for industries to create their own custom-sized recyclable bags and envelopes with EcoShield® Heat Sealable Paper! Whether a company needs to manufacture its own standard or custom bag for a specific product, or whether extra wide paper is needed to make paper bags, sleeves, or envelopes on demand, EcoShield® Heat Sealable Paper is ready to use. Simply cut the paper to the desired size; fold and shape into an envelope, sleeve, or bag; and apply heat to seal.

EcoShield® Heat Sealable Paper is coated with a water-based heat sealable adhesive coating. When the coated sides are placed together and heat is applied, the paper seals and forms a bond that is stronger than the paper. The paper is non-toxic, fully repulpable, and readily recyclable, making it ideal for environmentally friendly disposal considerations. These properties also make it an excellent choice for packaging situations where a product can be left in the bag and thrown into application conditions that will disintegrate the paper (e.g., certain concrete mixing situations).

EcoShield® Heat Sealable Paper is coated with a water-based heat sealable adhesive coating. When the coated sides are placed together and heat is applied, the paper seals and forms a bond that is stronger than the paper. The paper is non-toxic, fully repulpable, and readily recyclable, making it ideal for environmentally friendly disposal considerations. These properties also make it an excellent choice for packaging situations where a product can be left in the bag and thrown into application conditions that will disintegrate the paper (e.g., certain concrete mixing situations).

EcoShield® Heat Sealable Paper comes in large stock rolls of 600’ (182.88 meters) by 36” or 48” wide (1-1.22 meters), with customizable widths available up to 68” (1.73 meters), making it easy to construct standard or custom envelopes, bags, or sleeves in a variety of sizes. The paper can be printed with product identification and details before assembly.

EcoShield® Heat Sealable Paper conforms to the following test methods: TAPPI T-410 (Basis Weight), TAPPI T-411 (Caliper), TAPPI T-452 (Brightness of pulp, paper, and paperboard), and ASTM F88-99 (Seal strength of flexible barrier materials).

To learn more about EcoShield® Heat Sealable Paper, please visit:

http://www.cortecvci.com/Publications/PDS/EcoShield_Heat_Sealable_Paper.pdf

To find out more about Cortec’s innovative packaging solutions, please visit:

http://www.cortecpackaging.com/

Cortec® Corporation is the global leader in innovative, environmentally responsible VpCI® and MCI® corrosion control technologies for Packaging, Metalworking, Construction, Electronics, Water Treatment, Oil & Gas, and other industries. Our relentless dedication to sustainability, quality, service, and support is unmatched in the industry. Headquartered in St. Paul, Minnesota, Cortec® manufactures over 400 products distributed worldwide. ISO 9001, ISO

14001:2004, & ISO 17025 Certified.

CorShield® VpCI®-146 Creped Paper: Packaging For Multi-Metal Corrosion Protection!

Cortec® values our clients’ well-crafted products and continues to create corrosion protection solutions to protect these assets. With this in mind, Cortec® introduces CorShield® VpCI®-146 Creped Paper powered by Nano VpCI® - a premium corrosion inhibiting paper that is environmentally safe, non-toxic, biodegradable, and does not contain nitrites, phosphates, or silicates. CorShield® VpCI®-146 Creped Paper utilizes Cortec’s patented Vapor phase Corrosion Inhibiting (VpCI®) technology to provide a revolutionary way to protect metals in enclosed packages.

CorShield® VpCI®-146 Creped Paper is made from the highest quality Neutral Natural Kraft (NNK) paper without any chemical bleaching and is fully recyclable and repulpable. Without any chemical concentrations to calculate or a chemical tank or application system to maintain, CorShield® VpCI®-146 Creped Paper is easy to use. Once a product is wrapped in the creped paper, the VpCI® technology goes to work to protect it from corrosion while the structure of the paper provides protection from damage during transportation by delicately cradling the product.

The VpCI® coating on the creped paper vaporizes to reach all metal surface areas and provides complete corrosion protection. The unique Cortec® VpCI’s form a very thin and effective protective layer that does not alter the appearance of products or require removal before further processing or use. The protective layer does not influence properties of most sensitive electrical parts, including conductivity and resistance. Parts protected with CorShield® VpCI®-146 Creped Paper can be painted, welded, and soldered.

This biobased, sustainable, and renewable Creped Paper can be used to protect products for storage and shipment in a variety of ways: single item packaging, interleaving, end closures for shipping tubes, inserting strips for recessed areas in large packages, and as sheet liners or separators between products. It is particularly suitable for the bearing industry as CorShield® VpCI®-146 Creped Paper offers cushioning, multimetal corrosion protection, and causes the “pooling” effect for RP oils. CorShield® VpCI®-146 Creped Paper protects carbon steel, stainless steel, galvanized steel, cast iron, aluminum alloys, copper, brass, and solder.

Applications include:

- Bearing Protection During Storage and Shipment

- Metal Producing: Coils, Wire Reels, Plate, Bar, Etc.

- Metal Forging and Die Casting: Raw and Machined Forgings and Castings

- Metalworking: Stamping, Sheet Metal Work, Springs, Bearings, Fasteners, Tube, Pipe, Nails, Etc.

- Finished Products: Engines, Machinery, Equipment, Tools, Hardware, Appliances, Instruments, Motors, Etc.

- Electrical and Electronic Components, Controls, Etc.

Cortec’s CorShield® VpCI®-146 Creped Paper conforms to NACE Standard RP0487-2000 and is RoHS compliant.