Displaying items by tag: cristini

Cristini Diagnostic Systems will be present at the MIAC Show in Lucca

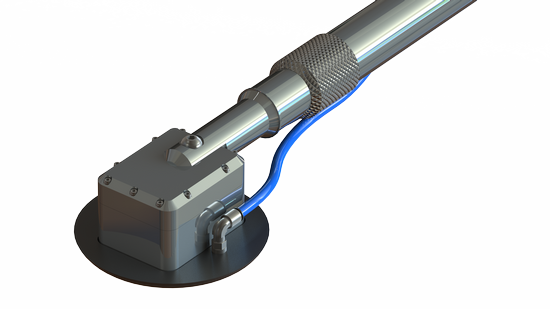

SmartScan™ LM, a new compact microwave sensor for measuring the humidity in the sheet will be presented.

SmartScan™ LM is a sensor based on ultra-short microwaves, for the accurate measurement of humidity in the sheet on low weights and humidity, typical of post-size positions.

SmartScan™ LM complete the SmartScan™ family targeted for the press section already on the market, a success installed in numerous machines across Europe and North America.

SmartScan™ sensors are engineered to overcome the typical limits of the NIR (Near Infrared) technologies. This new generation of sensors is characterized by the most compact construction on the market, with single side measurement. These characteristics and the absence of reflectors and/or sensors on the reverse side of the sheet, allows a wider freedom in installation solutions than all the sensors currently on the market.

Cristini Diagnostic Systems will be present at stand 110.

2 more world speed records for Cristini press fabrics.

Line 2 Pro Eisenhuttenstad Papier, Germany (the world's widest and fastest machine for the production of paper packaging paper) broke again two world speed records in a row, with 100% Cristini press fabrics.

Line 2 Pro Eisenhuttenstad Papier, Germany (the world's widest and fastest machine for the production of paper packaging paper) broke again two world speed records in a row, with 100% Cristini press fabrics.

On March 18th at a speed of 1680 m / min, production 77g / m², and April 23rd at a speed of 1704 m / min, production 70g / m², were broken again the speed barriers of for packaging papers.

The event is even more significant considering that in both cases the efficiency of the machine has achieved 96.6 and 96% respectively.

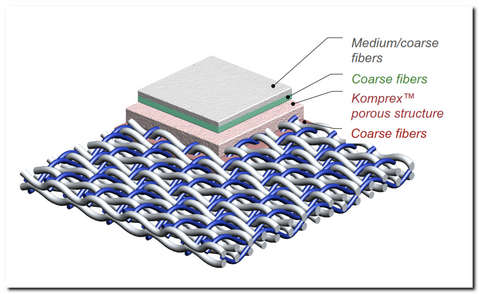

These records have been also possible thanks to the know-how and continuous refinement of the Cristini press fabrics, that place the Company as one of the world leaders for these productions.

Cristini S.p.A. this year will be 100 years old; 2 world speed records in a row are one of the best way to celebrate the event. www.cristini.com