Displaying items by tag: lenzing

Facial masks with fibres from FSC® certified wood

A range of innovative facial masks by Forest Stewardship Council® (FSC) Chain of Custody certified cosmetics company Kose now contain FSC certified materials in their products and packaging. The facial mask range contains now the fibre TENCEL® by Lenzig, which is made from wood and can decompose completely in soil burial or waste water treatment plants due to its botanic origin. Pioneered in Japan this product is now available all over Asia.

A range of innovative facial masks by Forest Stewardship Council® (FSC) Chain of Custody certified cosmetics company Kose now contain FSC certified materials in their products and packaging. The facial mask range contains now the fibre TENCEL® by Lenzig, which is made from wood and can decompose completely in soil burial or waste water treatment plants due to its botanic origin. Pioneered in Japan this product is now available all over Asia.

A range of innovative facial masks by Forest Stewardship Council® (FSC) Chain of Custody certified cosmetics company Kose now contain FSC certified materials in their products and packaging. The facial mask range contains now the fibre TENCEL® by Lenzig, which is made from wood and can decompose completely in soil burial or waste water treatment plants due to its botanic origin. Pioneered in Japan this product is now available all over Asia.

Kose have a strong ethical ethos, expressed by their corporate banner “Wisdom and Beauty for People and the Earth”. To reinforce this message Kose Cosmeport have now upgraded their entire facial mask product range to include the FSC label, indicating that their products and packaging are derived from responsibly managed forests.

All products within the Kose Cosmeport Clear Turn facial mask range include the botanic fiber TENCEL®, based on the renewable raw material wood. TENCEL® is the leading edge cellulosic fiber from Lenzing which was awarded the European eco-label. As part of the certified chain of custody both Lenzing and Kose Cosmeport are well aware of the need to help customers make responsible choices in the products for their everyday life. The well-recognized FSC logo is a key part of this message. A spokesperson for product development within Kose Cosmeport states: “Using TENCEL® from Lenzing helps Kose Cosmeport to deliver the highest quality cosmetic product to our customers whilst the FSC logo ensures we maintain our corporate commitment to protect the global environment.”

Elisabeth Stanger, Global Marketing Director from Lenzing, adds: “We are excited and proud to work with Kose Cosmeport and see TENCEL® used in facial mask applications. We are glad to see that ingredients are disclosed on the packages to inform consumers and let them make an educated choice. Quality proven by certificates and the botanic origin of TENCEL® makes it a perfect fibre for Kose Cosmeport’s Clear Turn facial masks.”

Lenzing Now Owns 100% Stake in Pulp Producer Biocel Paskov

Lenzing AG, listed on the benchmark index ATX of the Vienna Stock Exchange and global market leader for man-made cellulose fibers, has now acquired a 100% shareholding of the Czech pulp producer Biocel Paskov A.S. Up until now Lenzing has held a 75% stake in the company. The seller of the remaining 25% of the shares is the Austrian Heinzel Group, which had already disposed of its 75% majority stake to Lenzing in April 2010.

Lenzing AG, listed on the benchmark index ATX of the Vienna Stock Exchange and global market leader for man-made cellulose fibers, has now acquired a 100% shareholding of the Czech pulp producer Biocel Paskov A.S. Up until now Lenzing has held a 75% stake in the company. The seller of the remaining 25% of the shares is the Austrian Heinzel Group, which had already disposed of its 75% majority stake to Lenzing in April 2010.

Since 2010 Lenzing has been restructuring the Biocel Paskov facility to become a “swing capacity” producer of pulp, involving total investments of about EUR 100 mn. Starting in the year 2013 Biocel Paskov will be able to completely produce both paper pulp as well as high quality dissolving pulp used in the manufacturing of cellulose fibers. A total of 60,000 tons of dissolving pulp were already produced in the previous year, with plans calling for a production volume of about 115,000 tons of this pulp quality in the current year.

In the course of 2013 Biocel Paskov will operate as one of the world‘s most high-performance and advanced manufacturing plants for this special pulp thanks to a further debottlenecking program, increased energy efficiency and new recovery facilities. The nominal capacity of the plant will amount to 260,000 tons of dissolving pulp at that time. The pulp will mainly be used by the Lenzing Group for its fiber production operations. This vertical backward integration represents an important means for the Lenzing Group to safeguard its raw material base, both in terms of prices and volumes.

Biocel Paskov commenced production in the year 1985 and was subsequently modernized and expanded during the 1990s in line with ecological standards. The Group led by the Austrian industrialist Alfred Heinzel acquired the plant in 2001, and continued the modernization drive. Since

2004 Biocel Paskov has been cooperating with the neighboring sawmill operating by the Austrian Mayr-Melnhof wood industry group, which contributes part of the raw materials needed to manufacture pulp in the form of wood chips. Biocel Paskov employs a work force of close to 400 people.

Lenzing AG Once Again Tops Upper Austrian Ranking

For the 14th time the business daily WirtschaftsBlatt set out to identify the most successful companies in Austria together with the credit reference agency KSV1870 and PwC. The Austrian Leading Companies Award focuses on the solid performance of a firm over a period of years, and not just short-term performance indicators. The current analysis took account of business results over the years 2009 to 2011, but also attached great importance to how the companies dealt with the issue of sustainability. Lenzing AG once again convinced the jury in Upper Austria and won in the category Big Player for the second straight year.

For the 14th time the business daily WirtschaftsBlatt set out to identify the most successful companies in Austria together with the credit reference agency KSV1870 and PwC. The Austrian Leading Companies Award focuses on the solid performance of a firm over a period of years, and not just short-term performance indicators. The current analysis took account of business results over the years 2009 to 2011, but also attached great importance to how the companies dealt with the issue of sustainability. Lenzing AG once again convinced the jury in Upper Austria and won in the category Big Player for the second straight year.

For years the Lenzing Group has achieved good results and has operated extremely successfully. Demand for cellulose fibers from the renewable raw material wood continues to be intact. The global megatrends of population growth (especially in the emerging markets) and the growing awareness of the advantages of ecological products are the driving forces for the ongoing increase in the Lenzing Group’s fibers sales. Lenzing has taken this development into account by implementing an ambitious expansion program at all its global production sites, involving investments of EUR 1.6 bn between 2011 to 2015.

A total of more than EUR 350 mn alone will be invested in the coming years at the Lenzing site in Upper Austria, headquarter of the Lenzing Group. A visible sign clearly in view is one of the biggest industrial construction sites in Austria located at the Lenzing facility, where a highly modern plant for producing the high-tech fiber TENCEL® is being built and which will provide jobs to 110 new employees starting in 2014.

Lenzing Extends Management Board Mandate of Peter Untersperger until 2016

The Supervisory Board of Lenzing AG has extended the Management Board mandate of Peter Untersperger (52) for a further three years until April 2016.

The Supervisory Board of Lenzing AG has extended the Management Board mandate of Peter Untersperger (52) for a further three years until April 2016.

Peter Untersperger started his career in Lenzing in 1985 as Assistant to the CFO. In 1994 he was appointed to the Board of Directors of Lenzing’s Indonesian subsidiary PT. South Pacific Viscose, and from 1998 he served as its President. In 1999 he was named Chief Financial Officer of Lenzing AG. Since 2009, Peter Untersperger has been Chairman of the Management Board of Lenzing AG.

As a result of this decision, the Management Board of Lenzing AG will continue to consist of Peter Untersperger (Chairman and CEO), Friedrich Weninger (COO) and Thomas G. Winkler (CFO).

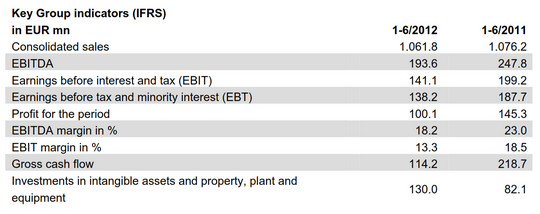

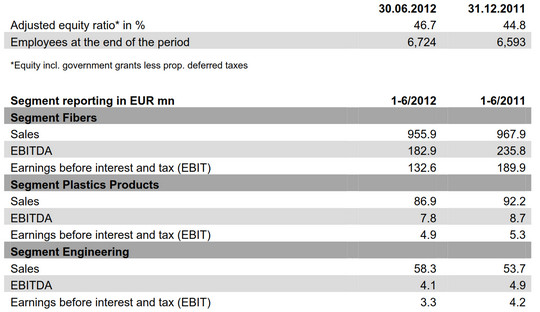

Lenzing Group: Good Half-Year Results in a Difficult Market Environment

Lenzing AG Intensifies Pulp Cooperation with Sappi

Lenzing AG, global market leader for man-made cellulose fibers, is intensifying its longstanding cooperation with the paper and pulp group Sappi. Both companies have concluded a multi-year pulp delivery contract at comparable terms and conditions with pricing linked to paper pulp as in the existing supply contract. The agreement is related to the construction of new dissolving pulp capacities by Sappi.

Lenzing AG, global market leader for man-made cellulose fibers, is intensifying its longstanding cooperation with the paper and pulp group Sappi. Both companies have concluded a multi-year pulp delivery contract at comparable terms and conditions with pricing linked to paper pulp as in the existing supply contract. The agreement is related to the construction of new dissolving pulp capacities by Sappi.

Sappi is the world’s largest manufacturer of dissolving pulp with an annual capacity of 800,000 tons at present growing to 1.3 million tons. Dissolving pulp is used in producing cellulose fibers, amongst other purposes. The raw material is wood mainly derived from certified eucalyptus plantations. Lenzing has already been sourcing high quality pulp for its non-integrated fiber production plants in Indonesia, China, Europe and the USA for several decades, including from the Sappi Group.

source: Lenzing AG

Construction Start of the New TENCEL® Production Facility

Following the successful completion of the environmental impact assessment process for the new TENCEL® production plant in Lenzing/Upper Austria nine months after the formal filing of the project, Lenzing AG was formally granted a legally binding building permit by the Office of the Provincial Government of Upper Austria. Construction work has now commenced on the new production facility which will manufacture 67,000 tons p.a. of the specialty fiber TENCEL® in Upper Austria in the future. Construction time has been calculated at 24 months.

Lenzing AG will invest approximately EUR 130 mn in the new factory, making it one of the largest individual industrial investments in Austria at the present time. This project will be accompanied by considerable infrastructure investments. Moreover, once it is put into operation the TENCEL® production plant will generate 110 additional highly qualified jobs in Lenzing in the long term, as well as a large number of other jobs in the region. The planning and construction of the facility also leads to a corresponding value creation.

Specialty fiber site in Lenzing

“With the TENCEL® plant the fiber technology of the future and the latest generation of man-made cellulose fibers is returning to our corporate headquarters in Lenzing. The Lenzing pilot plant was the place where 20 years ago the first marketable lyocell fibers in the history of the Lenzing Group were produced. They are now marketed around the world under the TENCEL® brand name”, says a pleased Friedrich Weninger, Member of the Management Board of the Lenzing Group and Chief Operating Officer responsible for the fiber business.

The new TENCEL® facility is of major strategic importance to the Lenzing site due to the fact that TENCEL® will also be produced on the premises in addition to the specialty fibers Lenzing Modal® and Lenzing FR®. Thus the facility in Lenzing will further expand its position as the main specialty fiber production site for the Lenzing Group. The geographical proximity to the European growth market for TENCEL®, the attractive energy costs as a consequence of the company’s own on-site power generation capabilities as well as the availability of a sufficient pool of qualified personnel and the closeness to the TENCEL® pilot plant were the main reasons underlying the decision to locate the new plant in Upper Austria.

TENCEL®: The fiber of the future

TENCEL® fibers are used in the textile industry and for nonwovens. The production process is particularly environmentally compatible, and is characterized by the practically complete closed cycle of the solvent in use. Lenzing continues to be the only industrial-scale supplier of TENCEL®. The fibers are already being manufactured at the plants in Heiligenkreuz/Burgenland, Grimsby/U.K. and in Mobile/Alabama/USA. However, up to the present time production lines with an annual capacity of not more than 20,000 tons have been used. The current nominal production capacity of TENCEL® in the Lenzing Group totals approximately 140,000 tons p.a., which will be increased to 150,000 tons p.a. thanks to the expansion program now being implemented at the Mobile/Alabama site.

New applications are continually being developed. The optimal moisture management of the TENCEL® fibers makes it attractive for use in high quality home textiles such as quilts and bed linen, but also in ladies’ outerwear and activewear. TENCEL® is also designed for sensitive segments such as cosmetics, hygiene and medicine, for example in wound dressings and baby wipes. TENCEL® is even used in the technical segment, for example to enhance the strength of plastics or to manufacture electro-technical components. The latest technical application is TENCEL® powder. It is deployed as a moisture regulator in foam mattresses and as additives to building materials, amongst other uses.

Lenzing AG Produces the Five Millionth Ton of Sodium Sulfate

For more than 70 years Lenzing AG has been manufacturing fibers from the renewable raw material wood. The environmentally-friendly production process, the maximum attainable closed cycle as well as the optimized use of beech wood as a raw material are unique in the industry, and make Lenzing a global trailblazer.

It is less well-known that for each ton of fiber produced, approximately the same amount of sodium sulfate is also derived (NA2SO4) from the manufacturing as a white crystalline powder. This means that the enormous increase in fiber production in recent years has also expanded Lenzing's role as a "salt factory." In the middle of April, the Lenzing, Austria plant reached the milestone of having produced five million tons of this substance. The product is delivered to the detergent and cleaner industry, the glass industry and the food and pharmaceutical industries, to name a few examples.

"This comprises an outstanding achievement of the production team at the site. In addition to the very successful fiber production, it also contributes to the overall output of the Lenzing facility", says Friedrich Weninger, Member of Management Board and Chief Operating Officer with responsibility for fiber production.

CEO Peter Untersperger says: "The sale of co-products of Lenzing AG derived from beech wood within the context of Lenzing's biorefinery, such as acetic acid, furfural and xylose, also encompasses the marketing of large amounts of sodium sulfate. This is an important part of the business carried out at the Lenzing site, and generates a significant share of the positive results achieved by the plant".

Recently in December 2010, Quality Austria carried out an official audit in accordance with the principles of a HACCP concept in addition to the existing ISO certifications. The HAACP1 system focuses on ensuring food and consumer safety. For Lenzing AG the HAACP certificate is a further important step in the company's development as a supplier of high quality products for the food, animal feed and pharmaceutical industries.

Lenzing subsidiary SPV (Indonesia) takes up test operation of fourth fiber production line

The Indonesian subsidiary of Lenzing AG, PT. South Pacific Viscose (SPV) has started up first successful trials of its new fourth production line. Regular operation is expected to commence in the course of the second quarter. The new line will produce viscose fibers for textile applications and for the nonwovens industry. Production is intended for the domestic Indonesian market, as well as for export.

A total investment of about USD 150 mill. makes the construction of the fourth SPV line the biggest individual investment project of the Lenzing Group in recent years. Up to now a total of more than USD 500 mill. have been invested into SPV. The project took 18 months to complete, with key components supplied by Lenzing's subsidiary Lenzing Technik.

A total investment of about USD 150 mill. makes the construction of the fourth SPV line the biggest individual investment project of the Lenzing Group in recent years. Up to now a total of more than USD 500 mill. have been invested into SPV. The project took 18 months to complete, with key components supplied by Lenzing's subsidiary Lenzing Technik.

The additional 60,000 tons of nominal annual capacity of this jumbo line boost total SPV capacity to 220,000 tons of viscose fibers per year, maintaining SPV's position as the leading Asian, and the world's second-biggest viscose fiber production site after Lenzing in Upper Austria with its annual capacity of about 255,000 tons. SPV's sales are going to exceed USD 400 mill. over the next years. The overall production capacity of the Lenzing Group with fiber productions sites in Austria, Indonesia, China, Great Britain and the United States will for the present be increased to about 670.000 tons of cellulose fibers.

Due to the strong demand for Lenzing fibers, a further debottlenecking program will be started along with the start-up of regular production. This will, still in 2010, increase SPV's total annual capacity by another 18,000 tons to 238,000 tons.

For more information please contact:

Angelika Guldt

Head of Corporate Communications

Mobile: +43 (0) 7672 701-2713

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.