Displaying items by tag: södra

Södra raises softwood pulp price to USD 840 per tonne

The market balance will improve further in 2013. Södra will raise the price of its softwood pulp in Europe to US$ 840.00 per tonne, effective from 1st January 2013.

The market balance will improve further in 2013. Södra will raise the price of its softwood pulp in Europe to US$ 840.00 per tonne, effective from 1st January 2013.

In Södra’s world everything starts with the forest. The forest provides our constant supply of raw materials and is the essential requirement for Södra’s many different operations.

More than 51,000 forest owners in southern Sweden are members of the economic association that is Södra. They own just over half of all privately owned forest in the area, as well as a group of companies that are successful in both Swedish and international markets. This gives them a market for their raw materials from the forest and at the same time provides the foundation for profitable forestry.

Södra is also a large employer. 4,000 people work for the Group, in areas that range from forestry management and environmental conservation to accounting, sales and product development. The Group’s four business areas produce sawn and planed timber goods, interior products, paper pulp and biofuel. In recent years Södra has also become such a large producer of electricity that the Group now produces more electricity than it uses.

Lars Idermark named Södra's new Group President and CEO

Södra's executive committee has named Lars Idermark as the new Group President and CEO. Lars Idermark is currently the CEO of PostNord.

Södra's executive committee has named Lars Idermark as the new Group President and CEO. Lars Idermark is currently the CEO of PostNord.

"Lars Idermark is a person with outstanding experience of various elements of trade and industry, and he has a good insight into the cooperative form of business. He has many years of experience in senior positions, and he is well equipped to lead Södra," said Christer Segerstéen, Chairman of the Södra Board.

Lars Idermark is currently the President and CEO of PostNord, Chairman of Swedbank and a board member of the Chalmers University of Technology Foundation. Lars Idermark has previously held positions as Group President and CEO of Kooperativa Förbundet/Coop, President of the Second Swedish National Pension Fund, Acting Group President of the Capio healthcare group and Deputy CEO and acting CEO of Föreningssparbanken (Swedbank), and before that Föreningsbanken.

Lars Idermark is very familiar with Södra: he has been a member for many years and he also served on the Södra Board of Directors from 1999 to 2009. His experience of agricultural cooperative operations also goes back a long way: in addition to his duties at Södra, he was also the CEO of LRF Holding.

As Lars Idermark has a six-month notice period in his present job, when he will be able to take up his new position is unclear as yet. Gunilla Saltin will continue in her position as Acting Group President and CEO until then.

Södra Cell Mörrum keeps on adding Metso Kappa Q analyzers

Södra Cell Mörrum enhances process management in kraft pulping with new Metso Kappa Q analyzers.

Metso has delivered a second order for a large Kappa Q analyzer unit to Södra’s Mörrum plant. The delivered analyzer replaces Mörrum’s retiring Metso Kappa analyzers after a long service of over fifteen years. The new analyzer includes the online Kappa and Brightness measurements and, as a new feature to the previous ones, online Fiber and Shives measurements. The fiber properties measurements open a new door to even tighter pulp quality and process control through the whole fiber line from cooking to baling.

“The start up was successful and now the production has got an additional strong tool to improve both quality and capacity. Metso’s way of managing and running things for the installation and start up is very professional,“ says Project Manager Sigurd Björkman, Södra Cell Mörrum.

A first order for a new Metso Kappa Q analyzer was placed in May 2011 to replace the existing analyzer installations. The analyzer had two cabinets both with separate washing and measuring chambers. One of the cabinets was equipped with brightness and the other with kappa and brightness measurements. Additionally, there was online fiber and shive measurement for all process sampling locations.

Södra Cell Mörrum mill is a Nordic pioneer in using Metso Kappa and Brightness analyzers as the key online measurements to manage kraft pulping in producing high quality pulp for global markets. The Mörrum mill purchased their first Kappa analyzer from Metso over fifteen years ago, and Mörrum’s impact on solutions development of the online brightness analyzer, in cooperation with Metso in the mid-nineteen-nineties, was substantial. During their lifecycle, the analyzers carried out altogether 4.5 million measurements. After well over a decade’s usage of two Kappa analyzers and a Brightness analyzer the mill decided to gradually replace the old analyzers with recently released modern Metso Kappa Q technology.

The Södra Cell Mörrum mill has several other Metso analyzers and sensor installations, such as Metso Alkali analyzers in the caustification plant and Polarox inline-measurements of residual chemicals.

Södra Cell is a leading paper pulp producer in the world.

DuraPulp won prize in the competition "Plastovationer"

Södra Cell and the composite - material DuraPulp won a prize this week in the category "Bio" in the competition "Plastovationer".

Södra Cell and the composite - material DuraPulp won a prize this week in the category "Bio" in the competition "Plastovationer".

The prize is awarded annually by the magazine Plastforum to a company or person who has used plastic, rubber or a composite material in a product or a detail in a way that replaces other materials and thereby making the product in question better, cheaper and more environmentally friendly.

"It is really nice that the material has gained recognition from the plastic industry", says Anna Altner, Project Manager DuraPulp.

Jan-Eric Hedberg, process engineer, received the prize on Södra's behalf.

The composite - material DuraPulp is based on fibre pulp in combination with a renewable biopolymer. Thus far the material has been used in the production of a designer lamp and a children's chair and has gained a great deal of attention for its properties in several different contexts.

You can read more about the price at www.plastovationer.se

Södra Cell Mörrum keeps on adding Metso Kappa Q analyzers

Södra Cell Mörrum enhances process management in kraft pulping with new Metso Kappa Q analyzers.

Metso has delivered a second order for a large Kappa Q analyzer unit to Södra's Mörrum plant. The delivered analyzer replaces Mörrum's retiring Metso Kappa analyzers after a long service of over fifteen years. The new analyzer includes the online Kappa and Brightness measurements and, as a new feature to the previous ones, online Fiber and Shives measurements. The fiber properties measurements open a new door to even tighter pulp quality and process control through the whole fiber line from cooking to baling.

Metso has delivered a second order for a large Kappa Q analyzer unit to Södra's Mörrum plant. The delivered analyzer replaces Mörrum's retiring Metso Kappa analyzers after a long service of over fifteen years. The new analyzer includes the online Kappa and Brightness measurements and, as a new feature to the previous ones, online Fiber and Shives measurements. The fiber properties measurements open a new door to even tighter pulp quality and process control through the whole fiber line from cooking to baling.

"The start up was successful and now the production has got an additional strong tool to improve both quality and capacity. Metso's way of managing and running things for the installation and start up is very professional," says Project Manager Sigurd Björkman, Södra Cell Mörrum.

A first order for a new Metso Kappa Q analyzer was placed in May 2011 to replace the existing analyzer installations. The analyzer had two cabinets both with separate washing and measuring chambers. One of the cabinets was equipped with brightness and the other with kappa and brightness measurements. Additionally, there was online fiber and shive measurement for all process sampling locations.

Södra Cell Mörrum mill is a Nordic pioneer in using Metso Kappa and Brightness analyzers as the key online measurements to manage kraft pulping in producing high quality pulp for global markets. The Mörrum mill purchased their first Kappa analyzer from Metso over fifteen years ago, and Mörrum's impact on solutions development of the online brightness analyzer, in cooperation with Metso in the mid-nineteen-nineties, was substantial. During their lifecycle, the analyzers carried out altogether 4.5 million measurements. After well over a decade's usage of two Kappa analyzers and a Brightness analyzer the mill decided to gradually replace the old analyzers with recently released modern Metso Kappa Q technology.

Södra Cell Mörrum mill is a Nordic pioneer in using Metso Kappa and Brightness analyzers as the key online measurements to manage kraft pulping in producing high quality pulp for global markets. The Mörrum mill purchased their first Kappa analyzer from Metso over fifteen years ago, and Mörrum's impact on solutions development of the online brightness analyzer, in cooperation with Metso in the mid-nineteen-nineties, was substantial. During their lifecycle, the analyzers carried out altogether 4.5 million measurements. After well over a decade's usage of two Kappa analyzers and a Brightness analyzer the mill decided to gradually replace the old analyzers with recently released modern Metso Kappa Q technology.

The Södra Cell Mörrum mill has several other Metso analyzers and sensor installations, such as Metso Alkali analyzers in the caustification plant and different versions of Cormec and Polarox inline-measurements of pulp brightness and residual chemicals.

Södra Cell Mörrum is a leading paper pulp producer in the world and part of the Södra company. Annually, Södra Cell produces 360,000 tons of pulp of which 87% is exported.

Weak economy and strong krona have negative impact on Södra's results

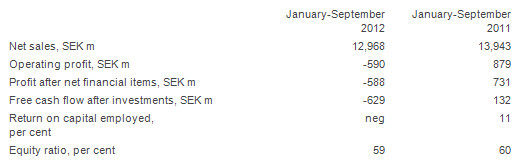

A weak international economic situation and massive fluctuations in currency exchange rates have adversely affected the markets for Södra's primary products and contributed to a negative result for the first three quarters of the year.

However, price levels have stabilised on the pulp market and a price increase was implemented in October.

Södra's operating profit for the first nine months of the year amounted to SEK -590 million, compared with SEK 879 million for the same period last year. Profit after net financial items amounted to SEK -588 million. The corresponding figure last year was SEK 731 million. Net sales over the first three quarters of the year amounted to SEK 12,968 million, SEK 975 million lower than for the same period last year.

The weak economic situation and concern about the euro have led to continued weak demand in Europe. As a result, 2012 has been characterised by weak development on the markets for Södra's products. Production in Södra's mills has also fallen as a result of stoppages at the start of the year. Reported results also include non-recurring items.

"We have decided to implement a number of measures to strengthen our earning capacity. These measures, combined with Södra's strong financial position, place us in a favourable position from which to deal with the challenges we face on our markets. We are also seeing signs of gradual improvement in the pulp market in particular," said Gunilla Saltin, acting Group President and CEO of Södra Cell.

A decision was made in August to liquidate Södra's holding in the Follafoss pulp mill, Norway. This mill produces CTMP (chemi-thermomechanical pulp) which has a variety of uses including paperboard and tissue production. The mill will be closed down on 1 November unless a new owner is found.

In September, a decision was made to make 260 people redundant at the company's Swedish operations. This measure will affect all business areas, and staff at all levels. Negotiations with the trade unions have begun.

Södra is also continuing to seek out new market segments. One such example is the launch of a new brand, Move Home, by Trivselhus in October. This new concept, which the company is using to target a younger customer category, offers quality homes at lower prices.

Paper pulp

Falling pulp prices in USD are affecting profitability in the pulp business. However, price levels stabilised in September, with the price of softwood sulphate pulp being increased to USD 790 per tonne in October. Further price increases are to be expected. Production at Södra's pulp mills was down slightly on the same period last year.

"We can see that the pulp market has strengthened. A price increase has taken place in October, and world stocks are at a good level. Therefore, we are of the opinion that the outlook for market pulp will improve gradually," commented Saltin.

Timber products

European consumption of timber products remains low and the market is still weak. Production at Södra's sawmills was slightly lower over the first three quarters of the year compared with the same period last year.

"Profitability at the sawmills is characterised by a sawn timber product market that remains weak. At the same time, our competitiveness is being affected by the strengthening of the krona against the euro, and by high raw material costs in relation to the price of finished products," said Saltin.

Interior products

The market for interior products is also being affected by the poor economic situation. Södra Interiör's main markets are characterised by reduced volumes and prices that are being forced down.

"The general economic decline and concern about the Eurozone's stability are contributing to reduced consumption in Europe. This is affecting us because Europe is our most important market," Saltin added.

Cost review will lead to redundancies at Södra

This measure will affect all Swedish business areas, and staff at all levels. Trade union negotiations will commence with immediate effect. These redundancies are part of the group's initiative to reduce its overall costs.

"Södra operates in an international market. Just like other companies, Södra is affected by the prevailing economic situation and trading conditions. The outlook for our main markets remains uncertain. To be able to face up to international competition, we have to undertake measures to reduce our costs," said Gunilla Saltin, Acting CEO at Södra.

DuraPulp - the feel of paper with the strength of plastic

Södra's DuraPulp has attracted a lot of interest around the world and already won a number of awards for its winning combination of the feel of paper with the durability of plastic.

Södra's DuraPulp has attracted a lot of interest around the world and already won a number of awards for its winning combination of the feel of paper with the durability of plastic.

In late October, Södra will be exhibiting DuraPulp at the Scandinavian packaging fair, Scanpack.

DuraPulp is a composite material made up entirely of renewable and biodegradable components. This material has unique properties: it is durable, water repellent and heat sealable. Examples of end uses include interior and design products, a wide range of speciality papers and packaging solutions for special requirements.

There are many options, and depending on the manufacturing process, DuraPulp can be used to create unique solutions.

Södra will be exhibiting in Scanpack's Innovation Packaging section to pave the way for new partnerships. Visit us on stand H04:09 at the Scandinavian packaging fair, Scanpack, on 23-26 October.Södra decides to divest Södra Cell Folla

The Södra Cell Folla management has been given the task of creating a divestment plan for Södra's ownership of the mill.

The Follafoss mill produces CTMP (chemithermomechanical pulp) which has a variety of uses including the manufacture of paperboard and tissue. Södra Cell is planning to leave the CTMP market from 1 November 2012.

"We've been struggling to create profitability in CTMP for several years. In spite of all the measures we've taken, we've found it increasingly difficult to find a profitable market for what we produce," explained Gunilla Saltin, President of Södra Cell.

Södra has used considerable resources to reverse the negative trend, including energy efficiency improvements, product development and cutting the workforce.

"We've been trying for a long time to find a solution to make operating the mill profitable but we now have to accept that previous conditions for profitable CTMP production at Follafoss no longer exist. We deeply regret that this is the case," said Saltin.

"The flexibility and creativity of Folla's employees have kept quality and productivity at a high level and they've fought valiantly to keep production costs low," she added.

The Folla mill produced 83,500 tonnes of pulp in 2011. Average annual production has been 107,000 tonnes. There are currently 51 employees at the mill. If it closes, a career transition process will be initiated that will include all employees.

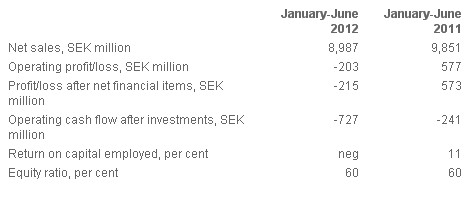

Negative result for Södra in the first half of the year

The first half of the year was characterised by weak economic development in the markets for Södra's products. Production in Södra's business sectors also declined as a result of the market stoppages that were implemented at the beginning of the year. The result was also impacted by one-off items.

The economic crisis in Europe is causing anxiety which is affecting all major markets for Södra's main products. The recession has had an adverse effect on European paper demand, in turn reducing demand for pulp. The consumption of wood products in Europe, meanwhile, has also remained at a very low level, while the interior products market, too, has been hit by the weak performance of the construction and the Swedish home renovation sectors.

"We expect to see our markets gradually growing stronger in the second half of the year. We have also implemented a series of measures to strengthen our earnings potential. As a result, we anticipate that the capacity utilisation at our pulp mills and sawmills will be normal. Despite this, the full-year financial result for 2012 is forecast to be significantly lower than in the last few years," said Saltin.

"Despite the negative result and global economic uncertainty, Södra is in a strong financial position. With an equity ratio of around 60 per cent, we are primed to handle longer and deeper crises than the one we are currently experiencing."

Pulp

The pulp market recovered slightly in the first half of 2012. The world market price of bleached softwood sulphate pulp rose in the first quarter before dipping again slightly. The strengthening of the Swedish krona against the US dollar weakened the pulp price in Swedish krona. World stocks of hardwood and softwood pulp have decreased.

Production at Södra's five pulp mills during the period was 856,000 tonnes compared with 1,001,000 tonnes in the same period the previous year. This reduction was due to the market stoppages that were implemented at Södra Cell Tofte and Södra Cell Folla at the beginning of the year.

"World stocks are at a good level and we expect to see the chemical pulp market gradually grow stronger in the autumn," said Saltin.

In May, Södra Cell's board of directors authorised two energy investments at Södra Cell Värö, including a new lime sludge reburning kiln and a new pelletizing plant. These profitable investments capitalise on the synergies that already exist between Södra Cell and Södra Timber in Värö.

"Through these investments, we can further enhance the efficiency of the Värö combine while at the same time creating a profitable processing operation for our members' wood raw materials," continued Saltin.

Wood products

The consumption of wood products in Europe remains at a low level and the market continued its weak performance during the spring. Production in the largest producing countries has been constrained, which means that stocks of wood products are under control. A weak market combined with high raw material costs are weighing down on the profitability of southern Sweden's sawmills.

Södra produced 720,000 cubic metres of sawn wood products during the period, compared with 767,000 cubic metres in the same period the previous year. Södra Timber's profitability was under great pressure in the early part of the year. Production at the new sawmill in Värö has not proceeded according to plan.

"We have reviewed and analysed the profitability of each sawmill and have introduced a series of measures to strengthen our earnings potential. Logistics is another key area and we decided to re-open the distribution centre in Kinda. We expect some of these measures to bear fruit in the autumn but it could take longer for the other changes to take effect," said Saltin.

"The decision to shut down production that was made ahead of the summer has been reversed. We expect capacity utilisation at our sawmills to be normal for the rest of the year," she says.

The process of starting up the new sawmill in Värö continues but is lagging behind schedule. Additional measures are needed, mainly in the refinement area, before production can reach the planned rate. Supplementary investments are being made to ensure the scheduled completion of the sawmill, which is expected to reach full production capacity - i.e. with the sawmill operating on a three-shift basis - in the second quarter of 2013.

"Work on the new sawmill has not been proceeding according to plan. But the work of getting the sawmill completed on schedule is going full steam ahead and it has naturally been given the highest priority."

Interior products

The economic recession is also affecting the interior products market, causing a decline in volumes and pushing down prices. And while Södra Interiör has defended its market share, the market has shrunk because of the prevailing uncertainties about the economy.

At the beginning of the year Södra Interiör acquired parquet flooring manufacturer Berg & Berg in Kallinge which has some 90 employees. The company produces more than 500,000 m2 of high-quality parquet flooring per year and has net sales of around SEK 130 million. This acquisition will further increase the range of products available to Södra Interiör's customers, while at the same time providing good opportunities for synergies between the companies in areas such as marketing, logistics and product development.

Forestry

Timber volumes handled by Södra Skog fell as a result of the market stoppages at sawmills and pulp mills at the beginning of the year. Volumes were down by around 10 per cent compared with the same period in 2011. To increase the contracting rate, a local market premium was introduced during the spring with good results. With the exception of certain hardwood varieties, the standing stock is at a good level ahead of the autumn.

During the spring, Södra Skog launched a hardwood initiative which embraces the whole chain from forest management training for forest owners to acquisitions of saw timber. Despite the growing volumes from members there is a slight shortage of sawable birch and birch pulpwood.

The spring's seedling sales were excellent. Södra Skog is continuing to invest in both its nurseries to increase seedling volumes to 45 million seedlings per year. A campaign of discounts was introduced in the autumn to stimulate increased autumn planting. Investments in seedling operations are planned this autumn to increase the volume of seedlings with mechanical forms of protection so that the use of chemicals can be phased out.