Ian Melin-Jones

Lucart continues to focus on sustainability with the new recycled and recyclable packaging of the Natural lines developed at its research centre

Lucart, Europe’s leading manufacturer of tissue, airlaid and MG paper for flexible packaging, continues to focus on sustainability and on researching environmentally-friendly and innovative solutions with a view to reducing the environmental impact of its products.

In fact, the products in the Grazie Natural line for domestic use and those in the EcoNatural lines for professional markets are now even more eco-friendly thanks to the use of new recycled and recyclable paper packaging, which is designed for a more sustainable, natural choice.

With this new paper packaging, the company aims to contribute to the general policy of reducing the use of virgin plastics, replacing them with eco-friendly recycled packaging. This is an extremely important goal, especially considering the fact that as many as 570,000 tonnes of plastic end up in the Mediterranean Sea every year, which is equivalent to throwing 33,800 plastic bottles into the sea every minute.[1]

Guido Pasquini, Lucart’s Sales and Marketing Director, explains: “Consumers are becoming increasingly aware of the importance of making sustainable choices when it comes to buying products and are always looking for practical ways to help save the planet on a daily basis, but we must play a part in this too. This is why we aim to gradually replace the plastic packaging we use for our products with flexible recycled and recyclable paper packaging produced by us. We are particularly proud of this project, which was also made possible through excellent teamwork. By applying the principles of cooperation on which the circular economy is based, our R&D department has brought the Porcari plant (in the province of Lucca) – our historical headquarters where we produce paper for flexible packaging – into line with the requirements of the group’s other plants – where hygiene paper products are produced – by sharing the same goals and overcoming the technical problems associated with paper development and the use of printing inks. In fact, even the latter are compostable and biodegradable.

The products in the Natural lines, which are the only ones on the market made from recycled Tetra Pak® type beverage cartons and “wrapped with love” in recycled and recyclable paper packaging, are a practical way for our customers to make an active contribution to protecting the environment”.

The growing interest of consumers in sustainability issues and in making more responsible environmental choices is also reflected in recent data: in fact, according to the European Consumer Packaging Perceptions study by Pro Carton, 75% of Italian consumers claim that the environmental impact of a product’s packaging influences their purchasing decisions.

[1] Source: WWF

Valmet develops its field services operations – invests in a new digital platform

Valmet is investing in a new digital platform to support, streamline and develop its strategically important field services. The global implementation of the new platform will be completed by spring 2020, and it will replace multiple current platforms.

Valmet’s vision is to become the global champion in serving its customers. One step toward the vision is to further improve field services as an important part of Valmet’s customer service, support and local presence. Valmet Field Services offering consists of maintenance and process supporting services, annual shutdowns, and remote assistance.

“The new platform will further improve Valmet’s capability to provide world-class services to our customers by providing workforce transparency and connecting our on-site field service professionals with Valmet Performance Centers through remote connections. This makes delivering desired services at customers’ sites faster and more accurate. It also allows us to better predict and advise services and develop shared maintenance and service roadmaps for our customers’ equipment and processes,” says Anders Öhrblad, Director, Field Services Growth, Valmet.

“The new platform will further improve Valmet’s capability to provide world-class services to our customers by providing workforce transparency and connecting our on-site field service professionals with Valmet Performance Centers through remote connections. This makes delivering desired services at customers’ sites faster and more accurate. It also allows us to better predict and advise services and develop shared maintenance and service roadmaps for our customers’ equipment and processes,” says Anders Öhrblad, Director, Field Services Growth, Valmet.

The investment supports Valmet’s strategy to become a frontrunner in field services

The investment is part of Valmet’s strategic decision to develop its field services through a dedicated program. The focus is on new field services offerings, improved service capacity and availability, developing competencies, and harmonization of processes. Today, Valmet has more than 1,100 field services professionals, an increase of 11 percent in the past year.

The platform will be delivered by ServiceMax, a leading provider of Field Service Execution Software.

“We’re honored to support Valmet’s vision for field service excellence and the strategic importance of service for the company’s asset-intensive customers,” says Neil Barua, CEO of ServiceMax. “Our partnership with Valmet will help not only deliver a world-class industrial field service program, but also provides Valmet’s technicians with the tools to better predict service requirements. The partnership will also help in developing shared maintenance and service roadmaps around customers’ industrial equipment and processes for the long-term.”

For further information, please contact:

Anders Öhrblad, Director, Field Service Growth, Services, Valmet, tel. +46 705 32 85 22

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

E-WIND® P100H – The XXL paper winders

From Monday 11th to Friday 15th November, at A.Celli Paper facilities in Tassignano (Lucca), two E-WIND® P100H winding machines will be shown.

The two winders are equipped with sophisticated technological innovations and have an attractive design.

Our new state-of-the-art E-WIND® P100H have been designed to make an efficient winding process, they manage a very large width (8 meters) and they are able to accommodate large reels on the unwinder, with diameters up to 3800 mm and weighing about 65t.

They are ideal for processing high-quality flat-papers and test-liner papers of the lowest basis weights at high speeds (up to 2500 mpm). They are equipped with highly innovative solutions, such as the Slittomatic® dual-motor cutting unit positioning system and the built-in automatic Spool-Parking.

This email address is being protected from spambots. You need JavaScript enabled to view it. to organize your visit!

Södra Cell creates Paper Pulp and Bioproduct categories after organisational change

Södra Cell International will be split into two product categories – Paper Pulp and Bioproducts - to strengthen Södra’s market position as a first-class supplier of paper pulp, while increasing the underlying earnings potential of new products. The change will come into effect on 1 October.

Henrik Wettergren, currently the Interim President of Södra Cell International, will lead the paper pulp category named Södra Cell International.

“Henrik has many years of experience in paper pulp sales and has deep insight into the market and our customers,” said Magnus Björkman, President of the Södra Cell Business Area. “His strong business acumen and industry knowledge will be a great asset as we build on the strengths of our paper pulp business.” Henrik holds an Economics Degree specialised in marketing, and an MBA from the Stockholm School of Economics.

Johannes Bogren, currently the Technical Product Director, will lead Södra Cell Bioproducts. Bioproducts from Södra Cell’s pulp mills will be marketed and sold in this category, including dissolving pulp.

“Johannes is ideally placed for this role, having been involved throughout the development of dissolving pulp at Mörrum,” said Magnus Björkman. “Johannes is highly innovative and has taken Södra Cell’s customer collaborations for dissolving pulp to a whole new level.”

Johannes holds a PhD in Forest Products Chemical Engineering from the Chalmers University of Technology, and an Economics Degree from the Stockholm School of Economics.

Both Henrik Wettergren and Johannes Bogren will report to Magnus Björkman, and be included in Södra Cell’s management team.

Stora Enso has completed the divestment of its stake in the Dawang paper mill

Stora Enso has completed the divestment announced on 25 July 2019 of its 60% equity stake in the Dawang Mill in China to its joint venture partner, Shandong Huatai Paper.

The transaction will not have any material impact on Stora Enso’s operational EBIT. Following the transaction, Stora Enso’s net debt will decrease by approximately EUR 22 million and annual sales by approximately EUR 60 million.

The transaction will not have any material impact on Stora Enso’s operational EBIT. Following the transaction, Stora Enso’s net debt will decrease by approximately EUR 22 million and annual sales by approximately EUR 60 million.

After this transaction, Stora Enso has no paper production in China.

Investor enquiries:

Ulla Paajanen

SVP, Investor Relations

tel. +358 40 763 8767

Part of the bioeconomy, Stora Enso is a leading global provider of renewable solutions in packaging, biomaterials, wooden constructions and paper. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has some 26 000 employees in over 30 countries. Our sales in 2018 were EUR 10.5 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Nasdaq Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com

Sappi and IGEPA announce major launch of Magno range to the German market

Sappi Europe in partnership with IGEPA group are delighted to announce that as from January 1st 2020 the Sappi Magno range will be available across Germany.

IGEPA group is Germany’s leading paper merchanting group with the widest product range and an unrivalled reputation for service to its large and loyal customer base.

Magno is the leading global brand for coated woodfree paper, offering exceptional quality and consistency along with an unrivalled range of weights and finishes, paired with worldwide distribution. The full Magno range includes 6 coated products, from 80 to 450 gsm. As part of this new distribution agreement, additional Magno stocks will be put in place in strategic locations throughout Germany to ensure rapid access to in-depth stocks for printers nationwide.

Magno is the leading global brand for coated woodfree paper, offering exceptional quality and consistency along with an unrivalled range of weights and finishes, paired with worldwide distribution. The full Magno range includes 6 coated products, from 80 to 450 gsm. As part of this new distribution agreement, additional Magno stocks will be put in place in strategic locations throughout Germany to ensure rapid access to in-depth stocks for printers nationwide.

Bringing together the two biggest names in the business will give German printers tremendous support, enabling fast access to stocks meeting all coated paper requirements for just in time delivery.

The majority of the Magno range has also recently been certified for HP Indigo digital printing, meaning that printers who produce both offset and digital can rely on the same consistent sheet standard across print technologies.

Speaking for Sappi, Flavio Froehli said: “we could not be happier to have Igepa on board as our distributor for the Magno range in Germany. Our partnership goes back decades and we greatly appreciate their commitment to the print market as well as to Sappi products”

For Igepa, Elmar Schätzlein said “With this decision, both partners will experience reciprocal strengthening, which will ensure a long lasting sustainable offering for our customers, today and in the future.”

About Sappi

Sappi is a leading global provider of sustainable woodfibre products and solutions, in the fields of Dissolving wood pulp, Printing papers, Packaging and speciality papers, Casting and release papers, Biomaterials and Bio-energy. As a company that relies on renewable natural resources, sustainability is at our core. Sappi European mills hold chain of custody certifications under the Forest Stewardship Council® (FSC®) and the Programme for the Endorsement of Forest Certification™ (PEFC™) systems. Our papers are produced in mills accredited with ISO 9001, ISO 14001, ISO 50 001 and OHSAS 18001 certification. We have EMAS registration at 8 of our 10 mills in Europe.

Sappi Europe SA is a division of Sappi Limited (JSE), headquartered in Johannesburg, South Africa, with 12,500 employees and 18 production facilities on three continents in nine countries, 37 sales offices globally, and customers in over 150 countries around the world.

Learn more about Sappi at www.sappi.com

Lucart wins the European Cleaning and Hygiene Awards 2019

During the 2019 European Cleaning and Hygiene Awards, event held in London by the European Cleaning Journal on October 17th, Municipal-Material-Cycle® has been awarded as Best European Initiative Raising the Profile of the Professional Cleaning Sector.

The project, born with the aim of developing a system of circular economy, durable and replicable, able to actively involve local communities, consists in recycling and converting beverage cartons into new paper products for hygienic and sanitary use.

Thanks to the cooperation of the local waste management company and the consortium that manage, separate and sort the materials on their platforms, Lucart has collected and collects the used beverage cartons and recycles them through an exclusive production process. The company is in fact able to separate the technical component (polyethylene and aluminium) from the biological component (cellulose fibers) of beverage cartons: the first is used to produce dispensers and pallets made of recycled plastic, the second to produce the tissue products in the Grazie Natural and Lucart Professional EcoNatural range. These tissue products (towels, toilet paper, napkins, etc.) are sold, together with their dispensers, to a local distribution partner who delivers the products to the bathrooms of public offices, schools, public companies and sports and recreation centres in the area from which the recycled beverage cartons come. The whole cycle is carried out with the approval of the competent municipal administration.

"We are proud to have received this award, which is for us a tangible recognition of our commitment to the environment and to a concrete circular paper economy.” said Francesco Pasquini, Sales & Marketing Director AFH of Lucart "The MMC® project is not only a model of Circular Economy, but also a virtuous example of partnership between companies. Our local distribution partner Valtex, in fact, believed in the project's potential right from the start and played a fundamental role in involving local communities and administrations".

The MMC® project, which started in 2015 in Slovenia with a trial period in the city of Novo Mesto and seven neighbouring municipalities, initially involved the local community (about 65,000 inhabitants), leading in three years to the recycling of about 105 tons of beverage cartons. In 2019 the project was also activated in Ljubljana, with a potential for recycling and consumption almost five times higher than that of Novo Mesto.

Today MMC® is also being internationalized in other countries, thanks to a team of professionals who will offer advice and support to distributors interested in proposing the project to their local communities.

About Lucart

Lucart, a leading company in Europe in the production of tissue paper products (paper items for daily use such as toilet paper, kitchen paper, napkins, tablecloths, handkerchiefs etc.), airlaid products and MG paper, was founded in 1953 by the Pasquini Family. The company's production activities are distributed over 3 Business Units (Business to Business, Away from Home and Consumer) operating in the development and sales of products with brands such as Tenderly, Tutto, Grazie Natural and Smile (Consumer area), Lucart Professional, Tenderly Professional, Fato and Velo (Away from Home area).

Lucart's production capacity exceeds 395,000 tonnes/year of paper on 12 continuous machines.

Its consolidated turnover amounts to more than €480 million, with more than 1,500 employees in ten production plants (five in Italy, one in France, one in Hungary and three in Spain).

Since 2018, Lucart has been part of the CE100 network, the pre-competitive innovation program designed by the Ellen Macarthur Foundation to give organizations the opportunity to develop new opportunities and achieve their circular economy goals as quickly as possible.

Valmet to supply a coated board machine to Graphic Packaging International in the United States

Valmet will supply a coated board machine for Graphic Packaging International’s (GPI) mill in Kalamazoo, Michigan, in the United States. With this investment in the latest coated board technology, GPI is committing to sustainable packaging with exceptional product quality and cost competitiveness for producing coated recycled board (CRB) grades. The start-up of the machine is scheduled for the first half of 2022.

The order is included in Valmet's orders received of the third quarter 2019. The value of the order is not disclosed.

“Valmet has offered us innovative yet proven technology to reach our high product quality targets. We have had a long and good cooperation with Valmet. Our relationship is based on mutual trust, which is very important in large projects like this one,” says Rusty Miller, Senior Vice President, Engineering and Technology, GPI.

“Valmet has offered us innovative yet proven technology to reach our high product quality targets. We have had a long and good cooperation with Valmet. Our relationship is based on mutual trust, which is very important in large projects like this one,” says Rusty Miller, Senior Vice President, Engineering and Technology, GPI.

“Valmet has a very good relationship with Graphic Packaging International, and we have had successful projects with them. We are happy to be involved in this important project to provide a new coated board machine in the United States,” says Dave King, Area President, North America, Valmet.

Technical details about the delivery

The board machine will produce coated recycled board (CRB) grades (white line chip board, WLC grades) with an annual capacity of approximately 500,000 short tons which corresponds to 454,000 metric tons.

Valmet’s operations in North America

Valmet’s operations in North America support the pulp, paper and energy industries with 1,334 employees and a network of 18 service, production and sales units across the United States, Canada and Mexico. Valmet’s machines produce 86 million tons of paper, board, tissue and pulp per year. This represents 70 percent of the North American production.

Information about the customer Graphic Packaging

Graphic Packaging International, headquartered in Atlanta, Georgia, is committed to providing consumer packaging that makes a world of difference. The company is a leading provider of paper-based packaging solutions for a wide variety of products to food, beverage, foodservice, and other consumer products companies. The company operates on a global basis, is one of the largest producers of folding cartons and paper-based foodservice products in the United States, and holds leading market positions in coated recycled paperboard, coated unbleached kraft paperboard and solid bleached sulfate paperboard. The company’s net sales in 2018 were approximately USD 6 billion. It has over 70 facilities and over 17,000 employees worldwide.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward – every day. Valmet's head office is in Espoo, Finland, and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Voith and SCA partner to build a world-leading, innovative production line at the Obbola paper mill

The new paper machine at the Obbola paper mill in Umeå, Sweden, will produce 725,000 tons of kraftliner per year. With a wire width of 10,200 mm and a design speed of 1,400 m/min, the PM 2 will be the most productive of its kind. The start-up of the machine is scheduled for the first quarter of 2023.

- Comprehensive project scope including BlueLine stock preparation system, XcelLine paper machine, long-term efficiency agreement and the Voith Process Line Package (PLP)

- Most innovative Papermaking 4.0 concept to increase efficiency, product quality and machine availability

- Excellent mechanical properties through a customized concept with intelligent controls

Taking full responsibility for the entire papermaking process and project handling

As full-line supplier for the entire papermaking process, Voith follows the Process Line Package (PLP) concept approach and assumes comprehensive responsibility for the project, covering the BlueLine stock preparation system and XcelLine paper machine. The comprehensive product scope includes detailed engineering and the supply of all sub-systems and components for the process line. The PLP reduces the number of required interfaces and contact persons and simplifies the entire project handling.

Highlights of the OCC plant include the IntensaPulper, the industry benchmark for energy efficient pulping, and the maintenance free Bagless Disc Filters. The production line will enable industry benchmarks in kraftliner strength and convertibility to be achieved through a unique combination of proven components and intelligent controls. The multi-ply forming section with the DuoFormer Base and the MasterJet Pro headbox are tools for the online control of critical product quality criteria. The well-proven TripleNipcoFlex press section has been adapted for the production of kraftliner in order to achieve the highest production rates and surface quality levels. The CombiDuoRun dryer section, including EvoDry steel dryers and an intelligent S&C system, will ensure maximum runnability and energy efficiency. The VariFlex Performance winder incorporating SmoothRun technology will provide consistent quality rolls at maximum operational efficiency.

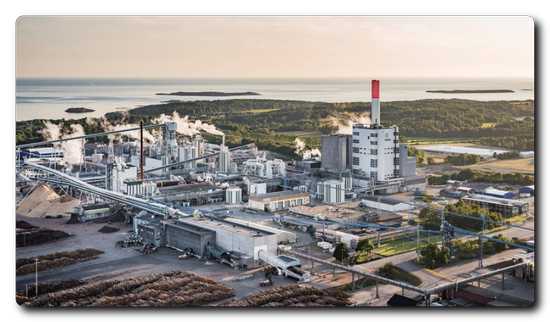

Obbola paper mill. Photo credit: Bergslagsbild

Obbola paper mill. Photo credit: Bergslagsbild

Long-term efficiency agreement

The long-term efficiency and service agreement will start right away. With digital applications on the existing PM 1 and a full-scale training program for the paper mill team supported by the Voith learning platform DRIVE as well as on-site services and trainings, a smooth start-up of PM 2 will be assured. The PM 2 will then be embedded in an extensive preventive maintenance program and efficiency optimization strategy for highest productivity of the production line.

“We know about the growing market for paper-based packaging. Our intention is to enable our customer to achieve excellent mechanical properties through a customized concept with intelligent controls,” states Christoph Mueller-Mederer, President, Projects EMEA at Voith. “The order from SCA means for us to provide the whole package consisting of safety, service, quality and efficiency partnership as well as to take full responsibility for the process line.”

Setting standards with digitalization and innovation

The scope of supply for SCA includes the biggest and most innovative package in Voith Paper history and sets a benchmark in digitalization. The Papermaking 4.0 technologies cover products of the OnEfficiency product family, which use machine learning to increase the efficiency of the plant. Furthermore, it stabilizes and improves product and process quality. The OnCare products – with monitoring applications as well as digital services like OnCall Video and the connectivity to the Voith Paper Webshop – complement the OnCumulus IIoT platform product portfolio and provide the foundation for a digital integration of the value chain and predictive maintenance. The new paper machine thereby benefits from the full digitalization scope.

“The market’s most advanced kraftliner machine PM 2 with the best available technology will considerably improve the mill’s competitiveness, cost position and product quality,” says Mats Nordlander, President, Paper of SCA. “We see the partnership with Voith as the next step of our digitalized future.”

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the large family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, components and products on the market and offers paper manufacturers solutions from one single source. The company’s continuous stream of innovations takes papermaking to the next level and facilitates resource-conserving production. With its Servolution concept, Voith offers its customers tailored service solutions for all sections of the production process. Voith Papermaking 4.0 ensures that equipment is optimally connected, while the secure use of generated data enables paper manufacturers to improve plant availability and efficiency.

Stora Enso plans to make organisational changes in the Paper division following the conversion of the Oulu Mill in 2020

Stora Enso plans to make organisational changes in the Paper division following the Oulu Mill conversion at the end of 2020. The planned changes could result in a reduction of a maximum of 135 employees in the Paper division.

Stora Enso’s Paper division is planning to make organisational changes to improve competitiveness and ensure efficient customer service after the Oulu Mill conversion for production of kraftliner for packaging. The planned changes would primarily affect commercial functions and operations support. The planned changes could result in a reduction of a maximum of 135 employees in the Paper division by the end of 2020.

Stora Enso’s Paper division is planning to make organisational changes to improve competitiveness and ensure efficient customer service after the Oulu Mill conversion for production of kraftliner for packaging. The planned changes would primarily affect commercial functions and operations support. The planned changes could result in a reduction of a maximum of 135 employees in the Paper division by the end of 2020.

The new organisational set-up is expected to be complete in the first quarter of 2021. The transition to the new organisation will take place in phases to ensure good customer service.

No decisions regarding the planned changes will be taken, nor will there be any redundancies until the appropriate co-determination negotiations have been concluded.

Part of the bioeconomy, Stora Enso is a leading global provider of renewable solutions in packaging, biomaterials, wooden constructions and paper. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has some 26 000 employees in over 30 countries. Our sales in 2018 were EUR 10.5 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Nasdaq Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com