Ian Melin-Jones

Pasaban upgrades one of OKAB Group’s cardboard sheeters

Pasaban upgrades the electrical cabinets of a cardboard sheeter for Okab in order to improve the machine’s performance.

The Okab Group has been providing cardboard and paper converting services to European market since 1969. It originally started converting envelopes, cutting paper sheets and currently provides tailormade converting services such as, sheeting, rewinding and ream wrapping across the entire continent from its plants in France, Germany and Sweden.

Pasaban has been working with the Okab group designing and manufacturing their paper and cardboard sheeting machines for more than two decades. During this time, we have manufactured more than 10 machines, just two of which are now more than 15 years old. That is the case of the KDD 1700, designed to work with high quality coated cardboard.

After analysing the possibilities for upgrading the sheeter, it was decided to update the electronic components. The PLCs, the hardware of the machine’s computer, and the electrical cabinets were replaced.

With this update, all the Okab’s sheeters now use the same technology.

For more information about upgrades to improve your old paper converting equipment performance, check our Upgrades section table at www.pasaban.com

Safety first! Efficiency, too

How a manufacturer of paper-based office material, operating its converting line mainly with blind or visually impaired employees, is able to combine the highest operational safety requirements with an impressive increase in output, reliability, and product quality.

AVRE[1] is a private, non-profit organization[2] reliably supplying its main customer, federal government agencies, with copy paper. Like other manufacturers of paper-based office products, AVRE pays utmost attention to product quality, reliability, and equipment efficiency. Yet, their most important requirement is operational safety. This is certainly what makes AVRE special as a manufacturer of office supplies. The converting line must be handled primarily by employees who are blind or visually impaired operators, making up over 75 percent of AVRE’s direct labor force.[3]

AVRE needs to be prepared for new product requirements in the future. Therefore, modernizing its existing converting line was urgently needed back in 2015. AVRE wanted to increase its production with a reliable, more flexible solution, guaranteeing higher output without losing product quality. Today, an SHM Digicut sheeter[4] operates in line with a Model 32 ream wrapper[5] from BW Papersystems. Both machines are customized to AVRE’s accessibility requirements and operational safety, yet they reach an average output of 12 tons of paper in a 7.5-hour shift.

How to combine efficiency, increased output, and quality with the highest operational safety?

AVRE used to manufacture its products on two Lenox sheeters. Lenox is a historical brand of BW Papersystems for which the company still offers parts and service support. In 2012, AVRE had already invested in a modern and customized Model 32 ream wrapper[6] from BW Papersystems. They mainly produced 8.5x11 copy paper with occasional changes to a 9x12 format. On good days, AVRE converted 8 to 9 tons of paper. But it wasn’t only time-consuming format changes that caused trouble. Growing quality and output issues of the two sheeters became more and more of a problem. AVRE had difficulties keeping the sheeters running at capacity. In addition, AVRE wanted to create additional business through a broader product portfolio, including digital formats.

Higher output, better product quality, and varied size flexibility were not the only requirements AVRE had. The new sheeter had to be equipped in such a way that it could be operated by blind or visually impaired operators, as well as by sighted maintenance staff. A potential equipment supplier would thus have to manage balancing apparently conflicting objectives: highest operational safety and special accessibility requirements with higher output and efficiency.

Designing a modern converting line for visually impaired operators requires some innovative engineering.

In 2012, AVRE became aware of a possible solution to their problems when they came to Sheboygan, WI for machine acceptance of the ream wrapper. BW Papersystems’ project managers had linked the Model 32 to an SHM Digicut sheeter to demonstrate its full potential. AVRE was immediately taken with the idea to have both ream wrapper and sheeter from the same manufacturer, guaranteeing an easy and well-proven linkage between both systems.

Using leading dual rotary cross-cutting technology from BW Papersystems, the SHM Digicut is designed to meet any quality requirements. The size flexible crosscutter and the quick-change gripper discharge offer maximum size flexibility for cut sizes and digital sizes. Using several collating boxes for different formats allows for gripper discharge changes within 15 minutes or less. All other sections of the line involved when changing formats can easily be adapted via touch panel. Only the slitters are adjusted manually. Auto-slitters are available if required.

Once these conditions were met, discussions about finding solutions for AVRE’s unique requirements could begin.

In order to meet AVRE’s accessibility requirements, BW Papersystems’ engineers developed individually designed screens. They combined default display screens for maintenance people and larger screens for visually impaired operators. Those displays use strong color contrast and extra-large characters and symbols that are easy to read and familiar to people who are blind or visually impaired. In addition, plexiglas stencils with tactile symbols can be placed over the screens, for example, at the ream wrapper unit.

Additional support in the event of disturbances is provided by voice output. Multiple sensors, safety locks, and other control systems monitor both the sheeter and the ream wrapper. Operators are immediately informed verbally about low paper rolls, sheet transfer faults, or if a door is opened while the machine is running, to name just a few of them.

In order to avoid serious injuries and to guarantee the highest level of operational safety, BW Papersystems has placed additional guarding at the slitter and crosscutter, at the entire tape section, and the gripper discharge. On the drive side of the machine, guarding is placed around the main drive to avoid accidental access.

Output records meet highest acceptance amongst operators

The result is impressive! While AVRE used to process 8 to 9 tons of paper with two sheeters on a good day, the company today produces an average of 12 tons of copy paper in a 7.5-hour shift. "During normal operation, we were able to increase output by more than 30 percent. And we are really proud of the records our operators set with the SHM Digicut,” says Charles Gardner, Director of Manufacturing at AVRE. “In a 9-hour shift, we have already achieved several times 18 tons of paper, once even 20 tons. Our record with the old sheeters was 13 tons of paper in 13 hours."

One important factor is certainly the generally higher uptime of the line. The wear of parts is considerably lower, too. And, if parts or services are needed, BW Papersystems is available around the clock. In most cases, replacement parts, coming from warehouses in the US, can be shipped within 24 hours. In case of an unscheduled machine downtime, BW Papersystems offers fast support via online diagnostics and remote services.

The high acceptance of the customized production line among the operators contributes to the fact that the system delivers top performance again and again. “The machine’s accessibility for visually impaired operators makes working on the line a pleasure,” says John Skinner, Team Lead at AVRE. He adds: “The additional guarding on areas with high risk of injury completely meet our high standards for a safe working environment.”

Furthermore, changeover times are dramatically reduced. Instead of over an hour, a new format can now be converted only after 15 minutes or less. "Looking ahead, this gives us all the necessary strategic flexibility we need," says Ken Fernald, President/CEO of AVRE. "Even though we are focusing on 8.5x11 commodity cut-size papers right now, we wish to keep the option open to serve new markets and customers with additional formats in the future, including digital sizes.”

Reaching boundaries, moving boundaries

Today, AVRE runs its converting line at 751 fpm, equaling 87 percent of maximum speed. Most of the time, the company is making production requirements, but they are very close to maxing out their capabilities. AVRE is thinking about adding a second roll stand to the line to double production if required.

"We are looking forward to being able to expand production on the AVRE line with a second roll stand," says Sven Gruenwoldt, Sales Director at BW Papersystems. "Both the SHM Digicut and the Model 32 ream wrapper offer sufficient capacity to handle double the production volume resulting from an additional unwind. And he proudly adds: "We are already hearing of new production records set by the operators from AVRE".

[1] Link to: http://www.avreus.org/

[2] Link to: http://www.avreus.org/about/about-avre-1.html

[3] Link to: http://www.avreus.org/about/about-avre-1.html

[4] Link to: https://bwpapersystems.com/product-groups/machine/folio-size-sheeters-packaging/digital-size-sheeting-machines/shm-digicut

[5] Link to: https://bwpapersystems.com/product-groups/subgroup/cut-size-sheeters-packaging/cut-size-packaging-machines

[6] Link to https://www.bwpapersystems.com/product-groups/machine/cut-size-sheeters-packaging/cut-size-packaging-machines/model-32

ABOUT BW PAPERSYSTEMS

BW Papersystems, part of Barry-Wehmiller, combines extremely strong brands, innovative technologies and long-standing global experience in the corrugating and finishing, sheeting and packaging, and stationery, book-binding and security-documents industries. BW Papersystems brings together 10 brands - BW Bielomatik, BWP Zerand, Curioni, JAG SYNCHRO, Kugler-Womako, MarquipWardUnited, SHM, VortX, WillPemcoBielomatik and Wrapmatic - that synthesize manufacturing in the paper process industries. We offer market-leading technology for full corrugators in a variety of configurations, rugged rotary die cutters and flexo folder gluers, as well as starch-mixing systems. Customers rely on us for folio-size, cut-size and digital-size sheeting and packaging of paper, board and other materials. In addition, BW Papersystems’ portfolio includes stationery, passport production and specialized paper-converting applications, as well as book-on-demand binding lines, digital print finishing and RFID processing technology. For more, go to bwpapersystems.com.

ABOUT BARRY-WEHMILLER

Barry-Wehmiller is a diversified global supplier of engineering consulting and manufacturing technology for the packaging, corrugating, sheeting and paper-converting industries. By blending people-centric leadership with disciplined operational strategies and purpose-driven growth, Barry-Wehmiller has become a $3 billion organization with nearly 12,000 team members united by a common belief: to use the power of business to build a better world. CEO Bob Chapman shares the story of the company’s transformation in his book, Everybody Matters: The Extraordinary Power of Caring for Your People Like Family. To learn more, go to barrywehmiller.com

Skjern Papirfabrik A/S, Denmark selects Toscotec to rebuild the dryer section of its PM1

Skjern Papirfabrik A/S chose Toscotec for the complete rebuild of its paper machine’s dryer section at Skjern mill, Denmark. The delivery is scheduled for the third quarter of 2019. PM1 has a wire width of 3,200 mm and produces core board from 90 to 450 gsm using 100% recycled fibres.

Toscotec will supply a new frame for the entire dryer section and 19 TT SteelDryers, designed for an operating steam pressure of 10 barg, and equipped with bearing housings, steam fits and turbulence bars. The TT SteelDryers will replace most of the mill’s existing cast iron cans. The scope of supply also includes: a new tail blowing system in the press section and new mechanical drives for the entire paper machine. An interesting feature of this project is the supply of blowing doctors, which will improve air circulation in the pockets. The services package consists of onsite erection, supervision, commissioning and start-up assistance.

The target of the rebuild is to increase the drying capacity by over 20%, without increasing the paper machine’s length, thanks to the advantages of TT SteelDryers and the higher steam pressure. The upgrade will also aim to improve the stability of the web run. The tail threading will increase the machine efficiency, thanks to the new tail blowing system in the press and new ropes system throughout the entire dryer section. As a result, Toscotec expects to boost both the efficiency and ease the run ability of the paper machine.

Enrico Fazio, Toscotec’s P&B Head of Sales, says “This is Toscotec’s first paper & board reference in Denmark. We are happy to enter the northern European market, because it is very high-tech oriented. We are proud that Skjern mill chose our technical solution. Thanks to Toscotec’s advanced technology, the rebuild will meet the targets of the customer, maintaining the same machine length.”

Kurt Larsen, Project Manager of Skjern Papirfabrik A/S, says, “We are very much focused on the environmental sustainability of our mill. Toscotec’s technology will boost efficiency and production, as well as meet our targets of specific consumption reduction.”

For further information, please contact:

Enrico Fazio, Head of Sales, Toscotec Paper & Board division, This email address is being protected from spambots. You need JavaScript enabled to view it.

Valmet to supply a containerboard line for GS Paperboard & Packaging in Malaysia

Valmet will supply OptiConcept M containerboard making line with automation solutions and a winder for GS Paperboard & Packaging (GSPP) Sdn., Bhd. in Selangor, Malaysia. With the new production line PM 3, GSPP will produce high-quality testliner and fluting grades as well as strengthen its position in the Malaysian market. The start-up of PM 3 is scheduled for 2021.

The order is included in Valmet's first quarter of 2019 orders received. The value of the order will not be disclosed. The total value of order of this type is typically around EUR 60-70 million.

"We have built a strong and long-lasting relationship with Valmet, which set a very good base for the negotiations. Valmet's excellent references were another important cornerstone. OptiConcept M boardmaking lines stand out with their energy- and resource-efficient processes and high-speed production. We are convinced with Valmet's technology, which is reliable throughout the whole boardmaking line," says Sia Boon Soon, President of GS Paperboard & Packaging.

"We have built a strong and long-lasting relationship with Valmet, which set a very good base for the negotiations. Valmet's excellent references were another important cornerstone. OptiConcept M boardmaking lines stand out with their energy- and resource-efficient processes and high-speed production. We are convinced with Valmet's technology, which is reliable throughout the whole boardmaking line," says Sia Boon Soon, President of GS Paperboard & Packaging.

"The customer had a clear idea about the machine concept from the very beginning. Thanks to our close cooperation and interactive discussions with the PM3 project team, we were able to find together a solution that fits well for the customer's needs," says Timo Puijola, Senior Sales Manager, Valmet.

Technical details about the delivery

Valmet's delivery will include equipment for stock preparation system with broke and approach flow systems. The delivery for the new high-capacity containerboard machine will include an OptiConcept M containerboard machine, which is already the 26th OptiConcept M line sold globally. The delivery consists of a complete machine from headbox to reel followed by an OptiWin Drum two-drum winder with transfer rails. The delivery will also include an OptiAir Hood high humidity hood, OptiAir Recovery heat recovery with other related air and ventilation systems, a surface starch preparation system and supply system for sizer as well as Valmet Paper Machine Clothing package for start-up. The automation delivery includes Valmet DNA Automation System for process and machine controls and Valmet IQ Quality Management Solution.

The 7,250-mm wide (wire) containerboard machine will produce fluting and testliner grades with a design basis weight range of 70-180 g/m2. The design speed of the machine will be 1,200 m/min and the design daily capacity 1,445 tonnes.

About the customer GS Paperboard & Packaging

GS Paperboard & Packaging Group Sdn., Bhd. (GSPP) is the largest containerboard and integrated paper and packaging manufacturer in Malaysia with 2 paper machines and 18 converting machines. It operates as a subsidiary of Oji Holdings Corporation, which is Asia's biggest and the world's fourth largest pulp and paper company.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Domtar Corporation Connects Old Pointe Elementary Students and Local Law Enforcement Through PaperPal™ Handwriting Program

Old Point Elementary students and officers from York County Sheriff’s Department and Rock Hill Police exchanged handwritten letters for six months. Domtar employees host event for them to meet face-to-face for the first time.

Domtar Corporation announced that employee volunteers from the company’s converting facility in Rock Hill, SC visited Old Pointe Elementary School to host a PaperPal™ event for Fifth Grade students and local York County Sheriff’s Department and Rock Hill Police officers. The PaperPal program brings generations together through handwritten letters. The officers and students exchanged letters for six months and met in person for the first time today. Research shows that handwriting has tremendous neurological benefits for the developing minds of young children, and it is an effective way to communicate on a more emotional level. Domtar makes a wide variety of every day products from sustainable wood fiber, and it is one of the world’s largest producers of uncoated freesheet papers, as well as a complete line of absorbent hygiene solutions. The company’s Rock Hill converting facility employs 50 people in the local community.

Domtar Corporation announced that employee volunteers from the company’s converting facility in Rock Hill, SC visited Old Pointe Elementary School to host a PaperPal™ event for Fifth Grade students and local York County Sheriff’s Department and Rock Hill Police officers. The PaperPal program brings generations together through handwritten letters. The officers and students exchanged letters for six months and met in person for the first time today. Research shows that handwriting has tremendous neurological benefits for the developing minds of young children, and it is an effective way to communicate on a more emotional level. Domtar makes a wide variety of every day products from sustainable wood fiber, and it is one of the world’s largest producers of uncoated freesheet papers, as well as a complete line of absorbent hygiene solutions. The company’s Rock Hill converting facility employs 50 people in the local community.

“Authentic handwriting is not just practice for our students, its how we can relate to and connect with the real world”

“Authentic handwriting is not just practice for our students, its how we can relate to and connect with the real world,” said Bill Cook, superintendent of Rock Hill Schools. “Our partnership with Domtar has been a great way to connect our students to the larger community. We are grateful for partners like Domtar who demonstrate through action that we are on one team with one mission for one Rock Hill.”

“The PaperPal program was a great way for our officers to meet students on a personal level and let them know that we care and we’re here to protect them,” said Kevin R. Tolson, York county sheriff.

Domtar started the PaperPal program in 2015 with a school and retirement community in Van Nuys, Calif. The idea, chronicled in a short video, was so successful that the groups wanted to continue writing letters even after the initial two-month program officially ended.

“Besides the educational and cognitive benefits of PaperPal, we are excited to see how this program sparks smiles and hugs for both children and adults,” said Michelle Osborne, Domtar Rock Hill’s administrative coordinator.

To understand more about the benefits of handwriting for different generations, consider the research and expert opinions cited below:

- Experts at Indiana University conducted brain scans on pre-literate children to determine whether printing letters, tracing them or typing is the most effective method in the learning process. The children tried each method, and then received a functional MRI scan in a device designed to look like a spaceship. The results? If children wrote by hand, the experts saw neural activity in three areas of the brain that was far more enhanced. These areas get activated in adults when they read and write.

- A study in the Journal of Cognitive Neuroscience shows how hand-writing can help adults learn new symbols – anything from music notes to Mandarin. Researchers found that if adults wrote the symbols, there was a stronger, longer-lasting recognition.

- Good handwriting can play a role in classroom performance. It can take a generic classroom test score from the 50th percentile to the 84th percentile, while bad penmanship could tank it to the 16th, said an education professor at Vanderbilt University.

- Handwriting can be a useful cognitive exercise for baby boomers trying to keep their minds sharp as they grow older, according to a neuroscientist at Duke University.

- Children in grades two, four and six wrote more words, faster, and expressed more ideas when writing essays by hand instead of with a keyboard, according to a study by a University of Washington professor of educational psychology.

About Domtar

Domtar is a leading provider of a wide variety of fiber-based products including communication, specialty and packaging papers, market pulp and absorbent hygiene products. With approximately 10,000 employees serving more than 50 countries around the world, Domtar is driven by a commitment to turn sustainable wood fiber into useful products that people rely on every day. Domtar’s annual sales are approximately $5.5 billion, and its common stock is traded on the New York and Toronto Stock Exchanges. Domtar’s principal executive office is in Fort Mill, South Carolina. To learn more, visit www.domtar.com.

ANDRITZ launches new PrimeLineTEX tissue machine for textured tissue

International technology Group ANDRITZ has officially launched its new tissue machine for textured tissue, the “PrimeLineTEX”, enabling customers to produce textured tissue of a quality superior to dry crepe and very close to structured (TAD) tissue, while at the same time achieving significant cost savings.

PrimeLineTEX is available with widths of 5.6 or 2.8 m and produces high-quality tissue for towel and sanitary applications. The machine offers up to 25% fiber savings compared to dry crepe and consumes up to 50% less energy than a TAD machine. The PrimeLine TEX is substantially shorter in length than other market solutions and uses only one additional fabric instead of two. Furthermore, the PrimeLineTEX machine can switch between production of textured and dry crepe tissue within a much shorter time than comparable solutions.

The ANDRITZ tissue pilot plant in Graz, Austria – the PrimeLineTIAC – is currently configured as a PrimeLineTEX machine and offers customers the opportunity to test and develop their future textured tissue. © ANDRITZ

The ANDRITZ tissue pilot plant in Graz, Austria – the PrimeLineTIAC – is currently configured as a PrimeLineTEX machine and offers customers the opportunity to test and develop their future textured tissue. © ANDRITZ

As a turnkey supplier, ANDRITZ can offer the complete textured tissue production line, including stock preparation, pumps, and the automation system.

“Our new PrimeLineTEX tissue machine enables customers to produce high-quality tissue close to TAD but with substantially reduced investment and operating costs. It is available to all markets worldwide, without any restrictions. This new machine offers profitable advantages for our customers,” says Klaus Blechinger, Vice President Tissue at ANDRITZ.

PrimeLineTEX – FEEL THE DIFFERENCE

The ANDRITZ tissue pilot plant in Graz, Austria – the PrimeLineTIAC – is currently configured as a PrimeLineTEX machine and now offers customers the opportunity to test and develop their future textured tissue. The first paper samples will be available during the Tissue World Milan trade show from March 25 to 27, 2019 at the ANDRITZ booth, F680.

With the new PrimeLineTEX machine, ANDRITZ once again confirms its strong position as one of the global market leaders for the supply of complete tissue production lines and the right partner for innovative solutions.

For more information, please visit andritz.com/primelinetex

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, board, and tissue. The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers; recovery and reuse of chemicals; preparation of paper machine furnish; production of paper, board, and tissue; sizing, calendering and coating of paper; as well as treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam and recovery boilers for power production, gasification and flue gas cleaning plants, systems and plants for the production of nonwovens and absorbent hygiene products, dissolving pulp, and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

Clearwater Paper Launches NuVo® Cup Paperboard Solution

Clearwater Paper Corporation (NYSE: CLW) has just introduced NuVo®, a new brand of cup stock paperboard that provides foodservice operators choice and differentiation through customized material to fit their specific brand needs. The newly-branded cup stock paperboard is now available to Clearwater Paper’s customers.

“We are excited to introduce NuVo to our customers, with a quality standard that we believe stands apart from any other paperboard cup product in the market,” said Steve Bowden, senior vice president of the pulp and paperboard division. “Our newly-branded NuVo products are an important part of our plan at Clearwater Paper to offer innovative and sustainable solutions that fit the evolving needs of our customers.”

NuVo is distinct, offering an option of up to 32% post-consumer recycled fiber. Operators may also choose an enhanced surface technology which offers uniform and consistent ink coverage, a premium white shade and a high definition process print capability. The brand also offers Forest Stewardship Council (FSC®) chain of custody certification which helps operators show their commitment to sustainability.

NuVo is a brand promise that Clearwater Paper intends to continually evolve to provide customers innovative choices to maximize differentiation and sustainability.

ABOUT CLEARWATER PAPER

Clearwater Paper manufactures quality consumer tissue, away-from-home tissue, parent roll tissue, bleached paperboard and pulp at manufacturing facilities across the nation. The company is a premier supplier of private label tissue to major retailers and wholesale distributors, including grocery, drug, mass merchants and discount stores. In addition, the company produces bleached paperboard used by quality-conscious printers and packaging converters, and offers services that include custom sheeting, slitting and cutting. Clearwater Paper's employees build shareholder value by developing strong customer relationships through quality and service.

Source: Clearwater Paper Corporation

Papermaking 4.0 - Experience Virtual Reality solutions by Voith at Tissue World Milan

Voith is taking part at the Tissue World in Milan from March 25 to 27, 2019. The innovative solutions for tissue production from Voith will be displayed at booth F500 in hall 3.

- Voith will participate at the Tissue World exhibition in Milan

- XcelLine tissue machine can be experienced in Virtual Reality at Voith booth. Also at the booth: Papermaking 4.0 solutions and the CleanLine Excell cleaning technology.

- Presentations at the conference about “The smart evolution for Tissue 4.0” on March 27 further insights into “Performance and Safety in the Yankee area” on March 26

As a full-line supplier, Voith generates crucial added value especially for the tissue industry. From BlueLine stock preparation lines to the XcelLine tissue machines the systems are designed from a single source and cover all areas of tissue manufacturing. The interactions are perfectly matched to make the tissue production as valuable as possible.

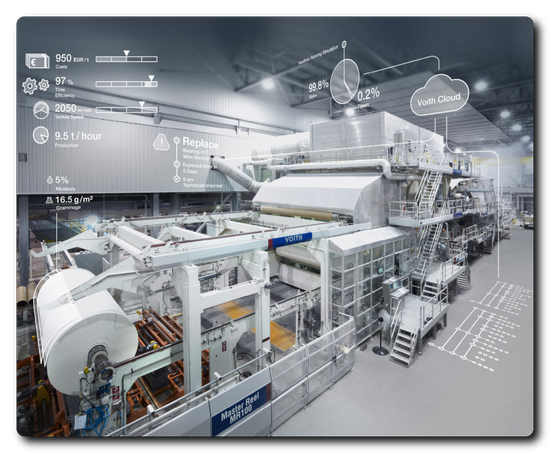

papermaking 4.0- digital Tissue Machine

papermaking 4.0- digital Tissue Machine

Presentations at the conference

Marcus Schwier, Director Tissue Sales & Application and Christian Schmid, Head of Process Line Package at Voith Paper will give a joint presentation about “The smart evolution for Tissue 4.0” on March 27, from 11:40 a.m. to 12:00 a.m. in the official conference session "Smart and Sustainable – Strategies to Stay Sharp as a New Decade Dawns”.

Marco Pettena, Sales Director Tissue at Voith Paper will provide further insights into “Performance and Safety in the Yankee area” and will explain how to improve not only the energetic performance but increase as well the safety working with this key part of the tissue machine. March 26, from 8:35 a.m. to 9:00 a.m. session “Yankee Safety & Reliability Workshop“.

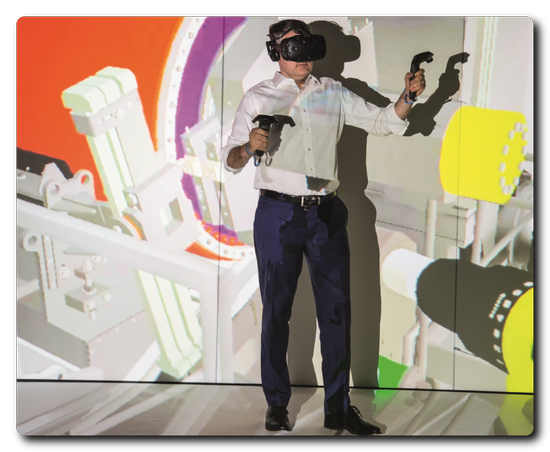

Virtual Reality Solutions by Voith

Virtual Reality Solutions by Voith

XcelLine Tissue Machines: Xcellent Performance.

XcelLine, the new generation of tissue machines by Voith, is the key to building an optimized, sustainable supply chain. With XcelLine tissue machines, Voith offers efficient paper production on a new level. All single components, technologies and services are perfectly coordinated and integrated. Their interplay leads to excellent performance over the entire lifecycle of the tissue machine. Perfect design, coordination and reliability of all secondary systems are also part of Voith’s scope of supply.

Papermaking 4.0: Virtual Reality Solutions for Tissue

Virtual Reality Solutions by Voith enable to experience your individual tissue machine easily in virtual reality. Also trainings can be carried out in virtual reality. The complete immersion in the virtual world enhances the training effect. The result: More transparency, efficiency and safety over the entire life cycle.

CleanLine Excell: Consistent and uniform cleaning

High fiber retention and uniform dewatering are key factors of performance in the forming and press sections of a tissue machine. CleanLine Excell cleans the surface and structure of forming and press fabrics more effectively than oscillating high-pressure needle jet showers or standard traversing showers. The especially for tissue machines developed CleanLine Excell cleaning head provides greater fabric permeability retention which leads to better uniformity, less water and energy consumption.

About the company

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the large family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, components and products on the market and offers paper manufacturers solutions from one single source. The company’s continuous stream of innovations takes papermaking to the next level and facilitates resource-conserving production. With its Servolution concept, Voith offers its customers tailored service solutions for all sections of the production process. Voith Papermaking 4.0 ensures that equipment is optimally connected, while the secure use of generated data enables paper manufacturers to improve plant availability and efficiency.

IGEPA’S Heaven 42 brand produced by Sappi as of January 2019

Specified by brand owners seeking a unique visual and haptic solution for their communications, Heaven 42 was initially launched in 2007 and is now being produced by Sappi through its sustainable manufacturing platform in Europe.

As the owner of the Heaven 42 brand IGEPA wanted to ensure the long term availability and quality standards of the product and Sappi, as the leading producer of fine paper, was able to meet these stringent requirements and ensure continuity of supply.

As the owner of the Heaven 42 brand IGEPA wanted to ensure the long term availability and quality standards of the product and Sappi, as the leading producer of fine paper, was able to meet these stringent requirements and ensure continuity of supply.

Heaven 42 absolute white offers a 155 CIE whiteness enabling vibrant colour reproduction combined with the distinctive haptic of a soft-mat surface in basis weights 115g/m2 to 400g/m2.

Flavio Froehli, Sales Director at Sappi said: ‘’Sappi and IGEPA have a long and successful partnership, we are looking forward to supporting the brands future success by utilising Sappi’s leading manufacturing and service platform’’.

About Sappi

Sappi Europe SA is the leading European producer of coated fine paper used in premium magazines, catalogues, books and high-end print advertising. Headquartered in Brussels, Belgium, Sappi Europe is recognised for innovation and quality. Its graphic paper brands include Magno, Quatro, Vantage, Royal, Galerie and GalerieArt ranges. Algro®, Leine®, Parade®, Fusion® and Atelier™ are the brands for innovative solutions of speciality papers and boards.

Sappi papers are produced in mills accredited with ISO 9001, ISO 14001 and OHSAS 18001 certification and EMAS registration for all our mills in the EU. Sappi European mills hold chain-of-custody certification under the Forest Stewardship Council (FSC®) and/or the Programme for the Endorsement of Forest Certification (PEFC™) schemes.

Sappi Europe SA is a division of Sappi Limited (JSE), a global company headquartered in Johannesburg, South Africa, with 12,500 employees and manufacturing operations on three continents in nine countries, sales offices in 50 countries, and customers in over 100 countries around the world. Learn more about Sappi at www.sappi.com.

ANDRITZ presents PrimeScreen X for next-generation screening performance

International technology Group ANDRITZ launches the next generation of its highly successful ModuScreen family of pressure screens – the new PrimeScreen X. The newly developed screen has thoroughly been tested in most demanding OCC applications and shows significant improvements in energy efficiency, screening performance and maintainability.

ANDRITZ PrimeScreen X Photo: ANDRITZ

ANDRITZ PrimeScreen X Photo: ANDRITZ

The PrimeScreen X builds on the success of more than 5,400 globally installed ANDRITZ pressure screens in stock preparation applications and offers additional and innovative key benefits to our customers.

- Top-feed stock inlet. The top-down design takes advantage of gravity to remove heavy contaminants quickly and minimize wear on rotor and screen basket. Top-down also improves the removal of light rejects, preventing the accumulation in the feed area, which again extends the life of wearing components.

- New PrimeRotor and foil design. The PrimeScreen X can be equipped with the new PrimeRotor, which improves screening efficiency and reduces energy consumption by up to 25%, compared to a competitive screen in a comparable application. The PrimeRotor foils are interchangeable with any other ANDRITZ foils and the rotor could be installed in any screen type available on the market.

- Easier maintenance. The design of the new rotor attachment and basket fixing results in reduced downtime, as maintenance and replacement of rotor and basket is quick and easy.

- Enhanced geometry. The optimized screen basket height-to-diameter ratios comply with the requirements of different furnishes and applications, helping to reduce the thickening factors and leading to a better control of fiber loss.

- Versatile in application. The PrimeScreen X is suited to all screening applications independent of the raw materials.

Wolfgang Lashofer, Senior Vice President and Global Division Manager of Paper, Fiber and Recycling Division at ANDRITZ: “Our new PrimeScreen X reduces energy consumption significantly and improves performance of our customers’ plants, thus meeting exactly market demands”.

Information about the PrimeScreen X and PrimeRotor can be obtained at: andritz.com/primescreen

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, board, and tissue. The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers; recovery and reuse of chemicals; preparation of paper machine furnish; production of paper, board, and tissue; sizing, calendering and coating of paper; as well as treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam and recovery boilers for power production, gasification and flue gas cleaning plants, systems and plants for the production of nonwovens and absorbent hygiene products, dissolving pulp, and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.