Ian Melin-Jones

Emtec Electronic with its innovations at the IMPS 2019 in Munich

Also this year, emtec Electronic GmbH will have a booth at the International Munich Paper Symposium from March 27th to 29th. The company will present a variety of testing instruments by which the complete production process can be controlled and guided in the right direction. From the wet end to the finished product, the application of the equipment enables an efficient process, to get the best possible quality with the lowest possible costs.

The ACA Ash Content Analyzer enables the determination of the mineral filler content without combustion, that means without destruction of the samples, within seconds. Both, the total mineral filler content, as well as the individual filler components (e.g. calcium carbonate, kaolin/talcum, titanium dioxide, iron oxide) and their percentage distribution are measured.

The ACA Ash Content Analyzer enables the determination of the mineral filler content without combustion, that means without destruction of the samples, within seconds. Both, the total mineral filler content, as well as the individual filler components (e.g. calcium carbonate, kaolin/talcum, titanium dioxide, iron oxide) and their percentage distribution are measured.

Furthermore, the CAS touch! to measure the particle charge and the FPA touch! to measure the surface charge of fibers (zeta potential) will be displayed at the booth. Both devices help to get information about the efficiency of the chemicals, which are added during the paper, board and tissue production.

Besides this, the EST12 emtec Surface & Sizing Tester is shown. A device to determine important and for the converting relevant paper surface properties such as surface hydrophobia / sizing as well as the surface porosity, which influence printability, coatability and gluability of paper and board.

Especially for tissue and nonwoven products, the TSA Tissue Softness Analyzer gives reliable and objective information about the three basic parameters, which determine the human feeling, the softness, roughness and stiffness. From these three, an overall hand feel value can be calculated. The availability of these values opens a huge amount of chances to optimize the tissue production and converting processes. New for hand sheet measurements: an updated version of the TSA and an improved measuring method for hand sheets (made in the lab) enables a reliable prediction of the final product quality in the lab without expensive trials at the tissue machine.

Skills gap provides foreign-born engineers with route into Swedish labour market

Sweden needs more engineers: over recent years, ÅF has worked actively to recruit newly immigrated and foreign-born engineers through standard recruitment channels as well as via the company’s own investment, New Immigrated Engineers.

Since 2016, 150 people have started work at ÅF within the framework of the initiative.

For the past three years, ÅF has offered hands-on coaching to foreign-born engineers and matched their skills with those sought by the company. Over the course of those three years, ÅF’s investment in New Immigrated Engineers has succeeded in attracting 150 new employees, almost half of them women.

In 2018 alone, ÅF recruited 53 newly arrived engineers. Of these, 16 were women, equating to 30% of recruitments, which is in line with ÅF’s goal for the proportion of women in the workforce.

- ÅF and the industry in general sees a continued high demand for engineers and we will need to take advantage of all available competences if we are to meet future needs and the social challenges we are currently facing. The pace of change is high and our strategic investment in newly immigrated and foreign-born engineers is crucial if we are to continue to be a leader in sustainable solutions.

- ÅF and the industry in general sees a continued high demand for engineers and we will need to take advantage of all available competences if we are to meet future needs and the social challenges we are currently facing. The pace of change is high and our strategic investment in newly immigrated and foreign-born engineers is crucial if we are to continue to be a leader in sustainable solutions.

Jonas Gustavsson, President and CEO.

At the start of the programme, those admitted were primarily newly immigrated engineers. Today, recruitment has been widened to include foreign-born long-term residents of Sweden who had difficulty establishing themselves in the Swedish labour market, overseas students and those recruited directly from abroad. In addition to addressing the skills gap, developing ÅF as a business and reflecting the needs of ÅF’s clients are also vital aspects of the project.

Since Amir Nazari took up the post of Diversity Coach in 2016, tasked with attracting and recruiting more engineers, the company’s recruitment of newly immigrated and foreign-born employees has gained momentum. In spring 2018, Sofia Klingberg joined as ÅF’s second Diversity Coach with responsibility for driving the project in the west and south of Sweden and together they will be developing and scaling up recruitment activities.

About ÅF Pöyry

ÅF Pöyry is a leading company within engineering, design and advisory services. We create sustainable solutions for the next generation through talented people and technology. We are more than 16,000 devoted experts within the fields of infrastructure, industry and energy operating across the globe to bring value to our customers and the society.

Making Future.

Gunilla Saltin leaving Södra

Gunilla Saltin, President of Södra Cell, is leaving Södra for a new role as Technical Director at the packaging and paper company Mondi, based in Vienna.

Gunilla Saltin“I would like to thank Gunilla for all of her years at Södra with many successes, excellent results and hard work and would also like to wish her the best of luck in her future endeavours,” said Lars Idermark, President and CEO of Södra.

Gunilla Saltin“I would like to thank Gunilla for all of her years at Södra with many successes, excellent results and hard work and would also like to wish her the best of luck in her future endeavours,” said Lars Idermark, President and CEO of Södra.

“I have had a wonderful time at Södra Cell and would especially like to thank all the competent and dedicated employees for these successful and exciting years,” said Gunilla Saltin.

A recruitment process will begin immediately.

Magnus Björkman, President of Södra Cell International, has been appointed Interim Business Area President and will also, therefore, be a member of Group Senior Management.

Founded in 1938, Södra is Sweden’s largest forest-owner association, with nearly 52,000 forest owners as its members. We conduct modern and responsible forestry, and operate state-of-the-art mills in which we process our raw material. In 2018, sales amounted to SEK 24 billion and employees totalled 3,100. Through value-generating relationships and a long-term approach, Södra shows the way for the next generation of forestry.

Stora Enso ranked the best in a new diversity comparison in Finland

Stora Enso received the highest scores in the FINDIX report, which was published for the first time today. The study examined the diversity of 89 Finnish companies through five different variables. These include gender distribution, age distribution, international background, educational background and industry-specific background of management teams and board of directors. The variables are based on the Finnish Securities Market Association’s corporate governance code, where they are highlighted as factors promoting diversity.

“At Stora Enso, we believe diversity strengthens our competitiveness and we aim to reflect the societies in which we operate. Diverse working teams enable us to explore different perspectives and challenge our way of thinking, contributing to better decision-making,” says Karl-Henrik Sundström, Stora Enso’s CEO. “To benefit from diverse working teams, we need inclusive work environments that respect and appreciate individual differences. Dimensions such as skills and experiences, gender, age, cultural background and personality are important to Stora Enso when we strive for diversity.”

“At Stora Enso, we believe diversity strengthens our competitiveness and we aim to reflect the societies in which we operate. Diverse working teams enable us to explore different perspectives and challenge our way of thinking, contributing to better decision-making,” says Karl-Henrik Sundström, Stora Enso’s CEO. “To benefit from diverse working teams, we need inclusive work environments that respect and appreciate individual differences. Dimensions such as skills and experiences, gender, age, cultural background and personality are important to Stora Enso when we strive for diversity.”

You can read more about the diversity of Stora Enso’s Board of Directors and Group Leadership Team in the recently published Governance report. For more information on diversity work, please read the company’s Sustainability 2018 report. Both reports are published on the company’s website.

For further information, please contact:

Ulrika Lilja, EVP, Communications, tel. +46 72 221 9228

Part of the bioeconomy, Stora Enso is a leading global provider of renewable solutions in packaging, biomaterials, wooden constructions and paper. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has some 26 000 employees in over 30 countries. Our sales in 2018 were EUR 10.5 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Nasdaq Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com

A new cash flow to local farmers

Local farmers’ ability to sell biomass to Iggesund Paperboard’s paperboard mill at Workington will return over 1.5 million pounds annually to the local agricultural industry. The initiative has created a totally new source of income for close to 200 farms in Cumbria and Scotland. It was recently given Rushlight Bioenergy Award. The Rushlight Awards is a set of awards designed specifically to support and promote all the latest clean technologies, innovations, initiatives and deployment projects for businesses and other organisations throughout UK, Ireland and internationally.

In 2013 Iggesund invested in a biomass-fired combined heat and power plant for the primary purpose of being able to run its paperboard mill on renewable energy. Overnight the mill switched its energy supply from fossil natural gas to biomass, and thereby reduced its fossil carbon dioxide emissions by 190,000 tonnes a year, the equivalent to the annual emissions of about 65,000 cars. In conjunction with this move, the idea was born to offer local farmers the opportunity to grow and sell energy crops to Iggesund.

“Nearly 1.6 million pounds flows annually from our paperboard mill at Workington to the local farming community”, says Ulf Löfgren, Managing Director for the mill. In January 2019 the project was given the Rushlight Bioenergy Award.

“Nearly 1.6 million pounds flows annually from our paperboard mill at Workington to the local farming community”, says Ulf Löfgren, Managing Director for the mill. In January 2019 the project was given the Rushlight Bioenergy Award.

“It’s been an exciting journey. We began in a situation where many farmers were sceptical, as farmers often are. But gradually, as they saw our commitment and our calculations for how they could earn more from their less-fertile land, more and more of them have joined our project, which we call Grow Your Income,” explains Neil Watkins, Alternative Fuels Manager at Iggesund in Workington.

The goal was to bring in 25,000 tonnes of biomass from the farming industry. After five years, it is clear that this goal will be exceeded when all the contracted crops are ready to harvest.

Like so many other countries, the UK has an ageing rural population. Most farmers’ sons and daughters want to move to the big cities to become rock stars, computer geniuses or TV personalities. The older generation that remains must find less work-intensive crops which bring in a reliable income. Iggesund’s offer to the farming community involved helping with planting and also handling the harvest and transport to the mill. All these steps help to reduce the workload on the individual farms. Iggesund has also signed long index-linked contracts, which have helped to make the future income predictable.

When the project began, DEFRA, the Department for Environment, Food & Rural Affairs, had made recommendations that parts of Cumbria have land highly suitable for energy crops. As the project developed, it became evident that the crops also help to counteract the effects of flooding and lead to greater biodiversity.

“Yet another advantage of energy crops – in our case Short Rotation Coppice willow – is that they give a good yield on less fertile land and do not lay claim to land that is better suited to food production,” Neil Watkins underlines.

Ulf Löfgren, Mill Director, who was involved in creating Grow Your Income, points out additional effects than just having ensured a supply of the fuel needed to run the mill.

“Cumbria and the parts of Scotland where we are active are dominated by agriculture,” he says. “Our interaction with farmers in working alongside them to grow energy crops, plus the fact that we meet with them at agricultural fairs and they come to us on study visits, has meant that we now have a far better-defined identity in the region.

“In addition, we can also give ourselves a joint pat on the back for being a good example of the UN’s sustainable development goal 17, a partnership for achieving one of the other sustainable development goals. In this case, we have a collaboration between a large process industry and over 100 farmers to jointly reduce fossil emissions.”

Iggesund Paperboard is growing its own eight-hectare energy crop on the land surrounding the mill.

Iggesund

Iggesund Paperboard is part of the Swedish forest industry group Holmen, one of the world’s 100 most sustainable companies listed on the United Nations Global Compact Index. Iggesund’s turnover is just over €500 million and its flagship product Invercote is sold in more than 100 countries. The company has two brand families, Invercote and Incada, both positioned at the high end of their respective segments. Since 2010 Iggesund has invested more than €380 million to increase its energy efficiency and reduce the fossil emissions from its production.

Iggesund and the Holmen Group report all their fossil carbon emissions to the Carbon Disclosure Project. The environmental data form an integral part of an annual report that complies with the Global Reporting Initiative’s highest level of sustainability reporting. Iggesund was founded as an iron mill in 1685, but has been making paperboard for more than 50 years. The two mills, in northern Sweden and northern England employ 1500 people. www.iggesund.com

New embossing solutions presented at Paper One Show in Lebanon

Ghost, Smoothie, Ex-press by Engraving Solutions: new embossing lines that meet actual market requirements

Engraving Solutions, a leader in the production of embossing rolls for the tissue industry and part of the Tissue Business Area of the Körber AG Group, has presented at Paper One Show held in Beirut on January 28-30, 2019, the latest products in the field of embossing: innovative and highly competitive products that meet the actual needs of the market.

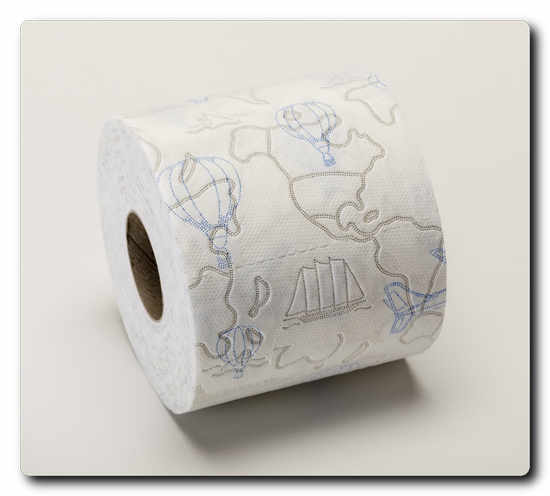

Ghost is designed to satisfy the current trend in the tissue market, i.e. premiumisation, namely the tendency among purchasers to buy higher-end products at higher prices.

“Ghost – Giacomo Bianchi, Product Engineer of Engraving Solutions states – is the new generation of embossing obtained by combining, for the first time ever, two different micro-embossing techniques – chemical and mechanical – thereby bringing together the benefits of each one. This innovative technology, unique to this market, results in a product that is more pleasing to the touch compared to the traditionally embossed one. Ghost is ideal for all high-yield products with refined embossing but is at the same time resistant, bulky and featuring excellent softness, independently from the number of plies and for every product type: toilette paper, kitchen towel and away from home segments”.

The name Ghost evokes the special shape of the points similar to a ‘ghost sheet’. Actually, the profiles of the engravings have been softened, and therefore act with less cutting aggressiveness on the paper. This allows to reduce the strength loss that usually occurs during embossing when traditional rhomboid points are used.

Ex-press is a technology that allows to obtain double-colour products using embossing alone. By simply adding coloured water to the pre-embossing station, on first pass the ply is decorated with one colour, and when it is passed through the second embosser using coloured glue, the final product is featured with 2 different colours providing a stunning aesthetic effect.

The last novelty presented by Engraving Solutions is Smoothie, the embossing system specifically designed for entry-level products that is capable of making the paper smoother and softer to the touch. This helps improve products made using traditional or recycled and unstructured paper, featuring low weight and low quantities of long fiber paper that usually is less appealing to the consumer.

With a single pass, the ply is embossed on the side portions, with or without the use of glue, and calendered on the central portion. All this is obtained using a single embossing station

instead of requiring a pair of rolls or a machine dedicated to the calendering of the entire ply.

The final result is a roll that is smooth on most of its surface and aesthetically pleasing thanks to the application of (coloured or non-coloured) decorations. A small retribution for entry-level products that have always privileged price and convenience over aesthetics and quality.

“In Beirut, in addition to the request for new technologies – comments Giacomo Bianchi – clients showed renewed interest in Pixel, Octopus and 4D, the exclusive embossing

technologies launched by our company in recent years and that today represent the premium segment for many tissue paper manufacturers”.

Valmet revises upwards its net sales guidance for 2019 due to the acquisition of GL&V

Valmet announced the acquisition of GL&V, a global provider of technology and services to the pulp and paper industry, by press release on February 26, 2019. Following the acquisition, Valmet revises upwards its net sales guidance for 2019. The new guidance is subject to the completion of the acquisition, which is estimated to take place on April 1, 2019 at the earliest.

New guidance for 2019:

Valmet estimates that net sales in 2019 will increase in comparison with 2018 (EUR 3,325 million) and Comparable EBITA in 2019 will increase in comparison with 2018 (EUR 257 million). The guidance is subject to the completion of the acquisition of GL&V.

Valmet estimates that net sales in 2019 will increase in comparison with 2018 (EUR 3,325 million) and Comparable EBITA in 2019 will increase in comparison with 2018 (EUR 257 million). The guidance is subject to the completion of the acquisition of GL&V.

Previous guidance for 2019 (as announced in the Financial Statements Review 2018 on February 7, 2019):

Valmet estimates that net sales in 2019 will remain at the same level as in 2018 (EUR 3,325 million) and Comparable EBITA in 2019 will increase in comparison with 2018 (EUR 257 million).

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

International Paper Named One Of The 2019 World's Most Ethical Companies® By Ethisphere For The Thirteenth Time

International Paper (NYSE: IP) a world leader in renewable fiber based packaging, pulp and paper products, has been recognized by the Ethisphere Institute, a global leader in defining and advancing the standards of ethical business practices, as one of the 2019 World's Most Ethical Companies.

![]() International Paper has been recognized for thirteen consecutive years, and is one of only two honorees in the forestry, paper and packaging industry, underscoring their commitment to leading with integrity and prioritizing ethical business practices.

International Paper has been recognized for thirteen consecutive years, and is one of only two honorees in the forestry, paper and packaging industry, underscoring their commitment to leading with integrity and prioritizing ethical business practices.

In 2019, 128 honorees were recognized spanning 21 countries and 50 industries. The thirteenth class of honorees illustrate how companies continue to be the driving force for improving communities, building capable and empowered workforces, and fostering corporate cultures focused on ethics with a strong sense of purpose.

"It is an honor once again to be included on this list and to be among companies whose principles and practices uphold the highest standards of ethics and corporate social responsibility," said Sharon Ryan, General Counsel and Corporate Secretary. "Our work does not stop inside International Paper, we expect our business partners to share our values and principles as described in our Supplier Code of Conduct. Throughout our global supply chains, we promote safe and healthy working conditions; high ethical standards; protection of human rights and dignity; responsible use of natural resources and compliance with all applicable laws."

"Today, employees, investors and stakeholders are putting their greatest trust in companies to take leadership on societal issues. Companies that take the long view with a purpose-based strategy are proven to not only outperform but last," said Ethisphere's Chief Executive Officer, Timothy Erblich. "I congratulate everyone at International Paper for earning this recognition."

Methodology & Scoring

The World's Most Ethical Companies assessment is based upon the Ethisphere Institute's Ethics Quotient® (EQ) framework, which offers a quantitative way to assess a company's performance in an objective, consistent and standardized manner. The information collected provides a comprehensive sampling of definitive criteria of core competencies rather than all aspects of corporate governance, risk, sustainability, compliance and ethics.

Scores are generated in five key categories: ethics and compliance program (35 percent), culture of ethics (20 percent), corporate citizenship and responsibility (20 percent), governance (15 percent) and leadership and reputation (10 percent). All companies that participate in the assessment process receive their scores, providing them with valuable insights into how they stack up against leading organizations.

Honorees

The full list of the 2019 World's Most Ethical Companies can be found at https://worldsmostethicalcompanies.com/honorees.

Best practices and insights from the 2019 honorees will be released in a report and webcast in March and April of this year. Sign up to receive the report.

About International Paper

International Paper (NYSE: IP) is a leading global producer of renewable fiber-based packaging, pulp and paper products with manufacturing operations in North America, Latin America, Europe, North Africa, India and Russia. We produce corrugated packaging products that protect and promote goods, and enable world-wide commerce; pulp for diapers, tissue and other personal hygiene products that promote health and wellness; and papers that facilitate education and communication. We are headquartered in Memphis, Tenn., employ 53,000 colleagues and serve more than 25,000 customers in 150 countries. Net sales for 2018 were $23 billion. For more information about International Paper, our products and global citizenship efforts, please visit internationalpaper.com.

About the Ethisphere Institute

The Ethisphere® Institute is the global leader in defining and advancing the standards of ethical business practices that fuel corporate character, marketplace trust and business success. Ethisphere has deep expertise in measuring and defining core ethics standards using data-driven insights that help companies enhance corporate character and measure and improve culture. Ethisphere honors superior achievement through its World's Most Ethical Companies recognition program and provides a community of industry experts with the Business Ethics Leadership Alliance (BELA). More information about Ethisphere can be found at: https://ethisphere.com

Valmet strengthens its stable business by acquiring GL&V, a global provider of technologies and services to the pulp and paper industry

Valmet has on February 26, 2019 entered into an agreement to acquire North American-based GL&V, a global provider of technologies and services to the pulp and paper industry. The enterprise value of the acquisition is approximately EUR 113 million on a cash and debt free basis subject to ordinary post-closing adjustments. The acquisition is estimated to be completed at the earliest on April 1, 2019.

GL&V supplies technologies, upgrades and optimization services, rebuilds, and spare parts for the pulp and paper industry globally. The net sales of the acquired operations were approximately EUR 160 million and the EBITA margin was around 11 percent in calendar year 2018. The acquired operations employ about 630 people of whom approximately 65 percent are in North America and the rest mainly in Europe, South America and India.

GL&V supplies technologies, upgrades and optimization services, rebuilds, and spare parts for the pulp and paper industry globally. The net sales of the acquired operations were approximately EUR 160 million and the EBITA margin was around 11 percent in calendar year 2018. The acquired operations employ about 630 people of whom approximately 65 percent are in North America and the rest mainly in Europe, South America and India.

GL&V's washing, oxygen delignification and bleaching operations with Compact Press®, pumps and mixers technology for chemical pulping as well as the related Product Center in Karlstad Sweden are not included in the transaction scope.

Pasi Laine, President and CEO of Valmet: The acquisition has an excellent strategic fit with Valmet and further strengthens our stable business and services capabilities

"The acquisition has an excellent strategic fit - it strengthens Valmet's global services business, complements our technology offering and builds further our local presence and capabilities especially in North America.The combination of Valmet's global reach and GL&V's product and services offerings for chemical pulping and paper production form a good basis to create new business opportunities and serve our customers even better. GL&V has a team of experts globally and I want to warmly welcome them to become part of Valmet," says Pasi Laine, President and CEO of Valmet.

GL&V is a global supplier of technologies and services for the pulp and paper industry

GL&V provides technologies, upgrade and process optimization services, rebuilds, and spare parts for the pulp and paper industry globally - especially in the areas of chemical pulping, stock preparation, papermaking and finishing. GL&V's key locations are in Nashua (New Hampshire), Lenox (Massachusetts), and Hudson Falls (New York) in the U.S., in Trois-Rivières (Quebec) in Canada, in Stockholm, Sweden, in Pune, India, and in Campinas, Brazil.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland, and its shares are listed on the Nasdaq Helsinki.

An early diagnosis for the crane under a microscope: A deep look into the crane machinery at Germany’s Palm paper factory

Konecranes investigates the hoisting gears of the critical overhead cranes at the Palm paper factory, with Oil Analysis and Crane Reliability Study (CRS)

Churning out corrugated base paper: The paper machine 6 (PM6) at the Palm paper factory in Wörth am Rhein, Germany, annually produces some 650,000 tons of the versatile packaging raw material with surface weights of up to 160 g/m2. In order to safely transport these huge paper rolls day and night, the double-girder bridge cranes inside the factory must always function flawlessly. For this reason, Konecranes has closely analyzed the gear oil of the cranes and used the endoscope to look deep inside the gears.

Paper remains one of the most important resources for the economy: According to the association of German paper factories, the paper industry sold approximately 23 million tons of paper, cardboard and paperboard in 2017 – up 1.4 percent from 2016. The packaging industry is especially hungry for paper. Sales in this sector increased by 3.4 percent last year alone. This is the area of operation for the paper machine 6 (PM6) at the Palm paper factory in Wörth am Rhein. The 650,000 tons of corrugated base paper it produces each year is handled at various stages by eleven double girder overhead cranes, all playing their own crucial role in the paper production on PM6. In order to safely transport these large paper rolls day and night, the hoisting gears of the eleven cranes inside the factory must always be in top operating condition. For this reason, Palm has asked Konecranes to look at eight of its most critical cranes.

A deep look inside the crane gear: With the Konecranes oil analysis, wear traces, such as rust or metal particles in the gear oil, can be identified and unplanned downtime can be prevented.

A deep look inside the crane gear: With the Konecranes oil analysis, wear traces, such as rust or metal particles in the gear oil, can be identified and unplanned downtime can be prevented.

Following the results of the oil analysis and subsequent endoscopic investigation, the maintenance experts identified a significant risk to future production and replaced one of the hoisting gears completely.

Record paper machine produces around the clock

At the Palm paper factory, located in Aalen in Baden-Württemberg, everything circles around recovered paper. Nine paper machines in five factories annually produce approximately 2.2 million tons of newsprint and corrugated base paper. The paper production continues around the clock. Correspondingly high are the demands from the eleven double-girder bridge cranes that have been in use in the factory in Wörth am Rhein since the start of production in 2002. Collectively, they handle and store the completed paper rolls that weigh many tons. “The cranes are in use day and night,” says Sven Bohrer, electrical engineer at the Palm paper factory. “If one should break one day, the production would have to stop, or at least greatly slow down, until the problem is solved. This would cost us time and money.” For this reason, Konecranes has closely investigated the gear oil of the hoisting gears of eight of the eleven double-girder bridge cranes at Palm. Because you can look deep inside the oil, the wear metals and waste substances it contains make it possible to draw conclusions about the state of the entire gear. Nico Zamzow, Vice President Industrial Service EMEA Central at Konecranes, comments on the method: “The oil analysis protects the crane. Any damage can be identified and treated early with its help. Moreover, system operators are able to optimize the maintenance and servicing of the cranes thanks to the detailed analysis report, and thus significantly increase their lifespan.”

For the oil analysis at Palm, Konecranes experts took samples from the hoisting gears of the eight double-girder bridge cranes. “The samples are analyzed by our laboratory, which specializes in industrial drive train analysis. Here, the lab staff compares the current state of the oil with the samples taken in 2016 and against the OEM design limits,” says Nico Zamzow. “This way, we also use trend analysis to provide the best possible picture of any change within the condition of the gearbox.” The result for Palm: Seven of the eight cranes were found to be “healthy”, as in the gear oil contained few to no foreign elements or waste substances indicating contamination or wear. However, the gear oil of the automated number 5 crane, used in the roll warehouse, was found to have a noticeable increase in its wear partial count, triggering the lab to issue a “Caution” notification on the analysis report. Nico Zamzow: “Iron particles in the oil can be an indication of increased wear and a deeper look may be required for this particular hoist”.

A closer look: The cranes in the roll warehouse of the Palm paper factory are in use at all times. For this reason, one important element of the Konecranes CRS is inspecting the crane systems for signs of wear.

A closer look: The cranes in the roll warehouse of the Palm paper factory are in use at all times. For this reason, one important element of the Konecranes CRS is inspecting the crane systems for signs of wear.

Crane Reliability Study has the solution

If the reason for the wear is not clearly identified and removed, the gear may be permanently damaged. “If the gear is jammed while there is a roll on the hook, it becomes very difficult to recover it and repair the crane,” explains Nico Zamzow. In order to determine whether there is already damage, the Konecranes experts used the Crane Reliability Study (CRS). The modular analysis allows them to check safety-relevant components, such as the hoisting gear as well as the steel structure, the motors, and the electrical equipment of the crane. In addition, the maintenance experts pose questions to crane drivers and technicians. The analysis result flows into a detailed report for crane owners – with concrete recommendations for action. In the case of Palm, Konecranes used a high-definition video endoscope to investigate the hoisting gear. “Just like in medicine, we use the endoscope to reach inaccessible places without having to dismantle the entire gear,” says Nico Zamzow. “For the CRS, we use a special, oil-resistant model that was developed for industrial use and can be fitted with different lenses.”

Following the endoscopic investigation, the Konecranes service experts are certain: The hoisting gear must be replaced. In addition, the cable drum, the cable drum support, the slip-ring unit, the cylinder coupling, and the motor coupling must be renewed. “Thanks to discovering the wear early on, there was no risk to safety and we were able to replace the old gear with a new one without affecting production,” explains Nico Zamzow.

“The benefits of Oil analysis as a predictive maintenance tool for identifying problems early on is proven to minimize the risk to production and safety. We, in the United Kingdom, now offer this as a standard solution to support our existing customers,” says Mark Goringe, Konecranes Industrial Service - Area Director, Mid West Europe.

Task distribution: Konecranes experts analyze the gear oil of eight of the eleven double-girder bridge cranes that are used in the large paper machinery hall and in the fully automated roll warehouse.

Task distribution: Konecranes experts analyze the gear oil of eight of the eleven double-girder bridge cranes that are used in the large paper machinery hall and in the fully automated roll warehouse.

Transport will remain safe

The Palm paper factory will continue to use services such as maintenance and servicing from Konecranes. Jürgen Friedmann, head of Mechanics at the Palm paper factory, is happy with what has been achieved: “Konecranes experts have had a very flexible approach to our demands for the availability and productivity of our cranes. Thanks to the oil analysis and the endoscopic investigation, our cranes will now run without issues in the years to come.”

Konecranes is one of the world’s leading brands in Lifting Businesses™ and supplies production enterprises and process manufacturing, shipyards and harbors with innovative lifting technology solutions. Besides productivity-increasing lifting solutions, Konecranes also offers customized services across the whole spectrum of lifting machinery. Konecranes has 16,200 employees at 600 locations in 50 countries. Konecranes stocks are quoted on the Helsinki stock exchange (Nasdaq Helsinki Ltd) under the abbreviation KCR1V.

Konecranes is one of the world’s leading brands in Lifting Businesses™ and supplies production enterprises and process manufacturing, shipyards and harbors with innovative lifting technology solutions. Besides productivity-increasing lifting solutions, Konecranes also offers customized services across the whole spectrum of lifting machinery. Konecranes has 16,200 employees at 600 locations in 50 countries. Konecranes stocks are quoted on the Helsinki stock exchange (Nasdaq Helsinki Ltd) under the abbreviation KCR1V.