Ian Melin-Jones

SEALS DELIVER LONG LIFE IN CHEMICAL PROCESSING APPLICATIONS

Based on a proprietary and patented crosslinking system that has been developed specifically for the chemical processing industry, DuPont™ Kalrez® Spectrum™ 7275 seals exhibit minimal swelling and improved retention of physical properties when exposed to aggressive chemicals such as concentrated nitric acid, organosilanes, chlorosilanes, pure ethylene oxide, butyraldehyde, amines, vinyl monomers and acrylic monomers. Kalrez® 7275 seals are available in the UK from authorised distributor Dichtomatik Ltd.

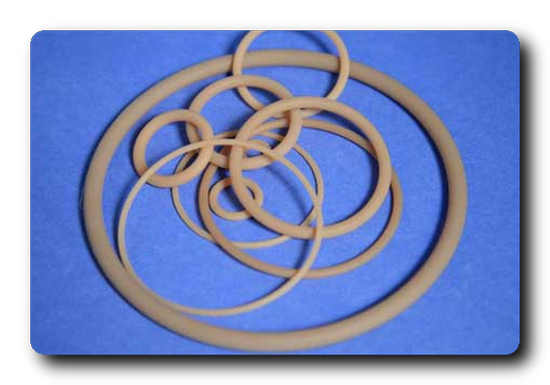

DuPont™ Kalrez® Spectrum™ 7275 seals exhibit minimal swelling and improved retention of physical properties when exposed to aggressive chemicals.

DuPont™ Kalrez® Spectrum™ 7275 seals exhibit minimal swelling and improved retention of physical properties when exposed to aggressive chemicals.

Any process plant that uses chemicals as an inherent part of its operations knows the importance of reliable, long-lasting seal technology. With Kalrez® 7275, which is a special perfluoroelastomer product, users enjoy excellent compression set resistance and good retention of physical properties after ageing at high temperatures. In fact, the seals will deliver a higher level of performance in any aggressive chemical processing application with temperatures up to 300°C, especially where high resistance to strong oxidisers such as nitric acid, chlorine and chlorine dioxide is required.

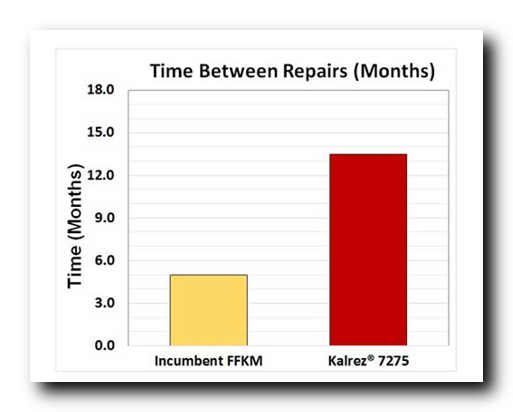

Durability of Kalrez® Spectrum™ 7275 relative to the MTBR of the incumbent FFKM in a chlorine dioxide/water stream.

Durability of Kalrez® Spectrum™ 7275 relative to the MTBR of the incumbent FFKM in a chlorine dioxide/water stream.

Among those able to vouch for the benefits of Kalrez® 7275 is a paper mill in North America that relies on chlorine dioxide for its pulp bleaching operations. The paper mill was experiencing frequent failures of a pump handling chlorine dioxide in water. According to the reliability engineer, the incumbent non-black FFKM seal typically failed within 5 months of installation because of the extremely aggressive nature of the stream. However, following replacement of the seals with Kalrez® 7275, seal life doubled to more than 12 months, removing the pump from the paper mill’s list of “bad performers” and into routine yearly maintenance. Increasing the MTBR (mean time between repair) in this way contributes to reduced maintenance costs and longer equipment life, while improving process safety.

Aside from pumps, Kalrez® 7275 will benefit many other applications which depend on mechanical seals as part of their critical processes, including valves, compressors, filtration columns and analytical equipment.

Pump seal life was more than doubled when using Kalrez® 7275 seals at a paper mill in North America.

Pump seal life was more than doubled when using Kalrez® 7275 seals at a paper mill in North America.

Uniquely identifiable by its light brown colour, Kalrez® 7275 offers: a Shore hardness (A) of 75 (on the slab) and 81 Shore M (on the O Ring); 100% Modulus of 9.7 MPa; tensile strength at break of 14.5 MPa; elongation at break of 160%; and compression set of 22% (70 hours at 204°C). The product is available in a broad series of standard O-ring sizes and custom parts for a wide range of sealing applications.

Lenzing Group builds world’s largest lyocell fiber plant in Thailand

Lenzing – The Lenzing Group is substantial increasing its production of lyocell fibers to meet the strong demand for these products and further strengthening its position as an industry leader in specialty fibers. Over the next years, it plans to invest more than EUR 1 bn in new production facilities for lyocell fibers. The first expansion phase of this ambitious growth plan, the construction of a state-of-the art lyocell fiber production plant in Prachinburi (Thailand), has now been approved. The plant will have a capacity of 100,000 tons and feature investments of approximately EUR 400 mn.

The plant sets a new milestone in the history of lyocell fibers and will be the largest site of its kind. Site grading at Industrial Park 304 around 150 kilometers east of Bangkok has been completed successfully and the investment is fully supported by the Board of Investment (BOI) of Thailand. Construction will start this fall and production will commence towards the end of 2021.

The plant sets a new milestone in the history of lyocell fibers and will be the largest site of its kind. Site grading at Industrial Park 304 around 150 kilometers east of Bangkok has been completed successfully and the investment is fully supported by the Board of Investment (BOI) of Thailand. Construction will start this fall and production will commence towards the end of 2021.

“TENCEL™ lyocell fibers are considered a benchmark in ecologically responsible fibers. This expansion underscores Lenzing’s commitment to improve the ecological footprint of the global textile industry”, says Stefan Doboczky, Chief Executive Officer of the Lenzing Group. “This investment in Thailand represents the next consistent step in the implementation of our sCore TEN strategy and will help to further transform Lenzing into a specialty fibers company”, Doboczky adds.

Thailand has favorable trade agreements with the major Asian economic blocks. The selection of Industrial Park 304 in Prachinburi was based on its excellent overall infrastructure and the sustainable biogenic energy supply, which leads to low CO2 emissions to protect the climate. Over the coming years Lenzing will further expand at the site in Thailand, which has space for several plants. The investment in the first phase already includes the general infrastructure that will benefit future expansion. Lenzing will continue to look for potentially expanding lyocell production in other parts of the world as well.

“The project has received very good attention in the engineering market. Lenzing aims at implementing the project in a strategic partnership with an international engineering company also chosen for its capability to support Lenzing’s further organic growth worldwide. Integrated teams including an international and highly skilled Lenzing workforce will work together with the engineering contractor, which will be selected soon. Commissioning of the plant and start of production will take place in the second half of 2021”, says Heiko Arnold, Chief Technology Officer of the Lenzing Group.

About the Lenzing Group

The Lenzing Group stands for ecologically responsible production of specialty fibers made from the renewable raw material wood. As an innovation leader, Lenzing is a partner of global textile and nonwoven manufacturers and drives many new technological developments.

The Lenzing Group’s high-quality fibers form the basis for a variety of textile applications ranging from elegant ladies clothing to versatile denims and high-performance sports clothing. Due to their consistent high quality, their biodegradability and compostability Lenzing fibers are also highly suitable for hygiene products and agricultural applications.

The business model of the Lenzing Group goes far beyond that of a traditional fiber producer. Together with its customers and partners, Lenzing develops innovative products along the value chain, creating added value for consumers. The Lenzing Group strives for the efficient utilization and processing of all raw materials and offers solutions to help redirect the textile sector towards a closed- loop economy.

Key Facts & Figures Lenzing Group 2018

Revenue: EUR 2.18 bn

Nameplate capacity: 1,034,000 tons

Employees: 6,839

TENCEL™, VEOCEL™, LENZING™, REFIBRA™, ECOVERO™, LENZING MODAL™, LENZING VISCOSE™, MICROMODAL™ and PROMODAL™ are trademarks of Lenzing AG

Publishing of Valmet's Half Year Financial Review January - June 2019 on July 23, 2019

Valmet's Half Year Financial Review for January 1 - June 30, 2019 will be published on Tuesday, July 23, 2019 at approximately 3:00 p.m Finnish time (EET). The stock exchange release and presentation material in Finnish and in English will be available at that time on Valmet's website at www.valmet.com/investors.

News conference for analysts, investors and media

Valmet will arrange a news conference in English for investment analysts, investors, and media on Tuesday, July 23, 2019 at 4:00 p.m. Finnish time (EET). The news conference will be held at Valmet Head Office in Keilaniemi, Keilasatama 5, 02150 Espoo, Finland. President and CEO Pasi Laine and CFO Kari Saarinen will be presenting at the news conference.

Valmet will arrange a news conference in English for investment analysts, investors, and media on Tuesday, July 23, 2019 at 4:00 p.m. Finnish time (EET). The news conference will be held at Valmet Head Office in Keilaniemi, Keilasatama 5, 02150 Espoo, Finland. President and CEO Pasi Laine and CFO Kari Saarinen will be presenting at the news conference.

Webcast

The news conference can also be followed through a live webcast at www.valmet.com/webcasts. The live webcast starts at 4:00 p.m. (EET) and a recording of the webcast will be available shortly after the event at the same address.

Conference call

It is also possible to take part in the news conference through a conference call. Conference call participants are requested to dial in at least five minutes prior to the start of the conference, at 3:55 p.m. (EET), at +44 2071 928000. The participants will be asked to provide the following conference ID: 2883129.

During the webcast and the conference call, all questions should be presented in English. After the webcast and the conference call, media has a possibility to interview the management in Finnish.

The event can also be followed on Twitter at www.twitter.com/valmetir.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

ANDRITZ receives a major order for an extensive rebuild from Stora Enso in Finland

International technology Group ANDRITZ has received an order from Stora Enso to supply production technologies and key process equipment for rebuild of the fiberline and drying machine as well as for modernization of the stock preparation system at its Oulu Mill, Finland. Start-up is scheduled for the fourth quarter of 2020.

The order is part of Stora Ensoʼs project to convert the mill’s existing fine paper production to containerboard production based on virgin fiber kraftliner as well as to increase the capacity of the pulp mill and pulp drying line. The typical end uses for kraftliner are in packaging segments that require high strength, quality and purity, such as food, fruit and vegetables as well as heavy duty packaging.

ANDRITZ will convert the existing fiberline to produce high-Kappa unbleached pulp, rebuild the pulp drying machine and modernize the stock preparation system at Stora Enso’s Oulu Mill. Photo: ANDRITZ

ANDRITZ will convert the existing fiberline to produce high-Kappa unbleached pulp, rebuild the pulp drying machine and modernize the stock preparation system at Stora Enso’s Oulu Mill. Photo: ANDRITZ

“Conversion of the Oulu Mill will enable Stora Enso to further improve its position in the growing packaging market and take a major step forward in our transformation. ANDRITZ has proven experience in similar rebuilds, and its strong position in pulp drying further contributed to this supplier selection,” says Ari Saarnio, Project Director, Stora Enso Oulu Conversion Project.

ANDRITZ GROUP

ANDRITZ is an international technology group providing plants, systems, equipment, and services for various industries. The company is one of the technology and global market leaders in the hydropower business, the pulp and paper industry, the metal working and steel industries, and in solid/liquid separation in the municipal and industrial segments. Other important fields of business are animal feed and biomass pelleting, as well as automation, where ANDRITZ offers a wide range of innovative products and services in the IIoT (Industrial Internet of Things) sector under the brand name of Metris. In addition, the company is active in power generation (steam boiler plants, biomass power plants, recovery boilers, and gasification plants) and environmental technology (flue gas and exhaust gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard, as well as recycling plants.

A passion for innovative technology, absolute customer focus, partnership, reliability, and integrity are core values to which ANDRITZ is committed. The listed Group is headquartered in Graz, Austria. With almost 170 years of experience, 29,000 employees, and more than 280 locations in over 40 countries worldwide, ANDRITZ is a reliable and competent partner and helps its customers to achieve their corporate and sustainability goals.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, board, and tissue. The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers; recovery and reuse of chemicals; preparation of paper machine furnish; production of paper, board, and tissue; sizing, calendering and coating of paper; as well as treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam and recovery boilers for power production, gasification and flue gas cleaning plants, systems and plants for the production of nonwovens and absorbent hygiene products, dissolving pulp, and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

James Smith joins Toscotec North America.

Toscotec North America, Inc. Green Bay, WI and Toscotec S.p.A. Lucca, Italy announced that James Smith has joined the group as Paper & Board Sales Manager for North America.

James Smith, Paper & Board Sales Manager for North America

James Smith, Paper & Board Sales Manager for North America

James has a Mechanical Engineering degree from the University of Wisconsin and more than 30 years of experience in the paper industry with various roles of technical and sales leadership for key industry players. These include Beloit Corporation for North America and Asia Pacific, Mitsubishi Heavy Industries, Paperchine and PMT Italia for the North American market.

James will actively contribute to Toscotec’s growing paper and board business in North America, catering to new customers in the U.S. and Canada.

PMP to support Convertipap’s tissue business expansion in the Americas!

The Tissue sector is performing a continuous growth worldwide, and this trend is about to even strengthen in the coming years. Currently tissue papers are daily necessities of every human being. Taking current trends into account, Latin America and Eastern Europe are the key areas that are ready to grow.

Convertidor de Papel, S..A de C.V. (Convertipap) is a paper producer that decided to follow above trends and to expand its tissue business. Now, the family business has strategically expanded and has two plants located in the Mexican Republic; but it’s not over, currently Mexican producer decided about another investment, that will shift its business to the next level.

Convertidor de Papel, S..A de C.V. (Convertipap) is a paper producer that decided to follow above trends and to expand its tissue business. Now, the family business has strategically expanded and has two plants located in the Mexican Republic; but it’s not over, currently Mexican producer decided about another investment, that will shift its business to the next level.

The company just announced a market expansion that will be possible thanks to the investment in the new tissue machine, that will be added to its already impressive fleet. Convertipap decided to award PMP (Paper Machinery Producer) with an order for a delivery of Intelli-Tissue® Advanced 2100 Tissue Machine.

PMP will supply a new Crescent Former Intelli-Tissue® Advanced 2100 machine with a maximum capacity of 41,000 tpa, reel trim of 2850 mm and the maximum balance speed of 2100 mpm. Machine will produce high quality tissue with the basis weight range of 12.5-40 gsm at the reel.

The new project will be an exciting step in the Mexican’s market development. Convertipap presents an aggressive development strategy with a plan to continue its increase of the market share. One of the main goals is to become the preferred tissue supplier in the Mexican region, offering a wide span of premium tissue products.

PM6 will be equipped with state-of-the-art equipment designed and manufactured by PMP, including core technological units, such as hydraulic headbox Intelli-Jet V®, Intelli-Former® CF type, Intelli-Press®, gas heated yankee hood Intelli-Hood®, 15’ steel Yankee Dryer Intelli-YD® as well as reel Intelli-Reel® with extended rail storage. Scope of supply will cover also stock preparation system, dust & mist removal systems, recovery steam generator, mechanical & electrical drives, steam & condensate system, vacuum system, lubrication system, TM controls, baseplates, start-up supervision and training services. Delivery and start-up are scheduled for the middle of 2020.

The whole project will definitely open the door to success both for Convertipap, that is continuously developing in the Mexican market, but also for PMP, as their first tissue project in Mexico will be its flag reference in the Latin American market.

Minerals Technologies Initiates ENVIROFIL® PCC Production

First Commercial Deployment for Innovative Minerals Recycling Technology

Technology Provides Environmental and Cost-Reduction Solutions for Customers

Minerals Technologies Inc. (NYSE: MTX) (“MTI” or “the Company”) have just announced that it has completed the installation and deployment of ENVIROFIL® PCC at UPM-Kymmene Corporation’s (“UPM”) paper mill in Schongau, Germany. This is the first commercial deployment of ENVIROFIL® PCC and follows extensive collaboration with UPM. 50,000 dry metric tons of recovered pigments are scheduled for paper production annually at UPM’s satellite plant.

ENVIROFIL® PCC is a new, innovative recycling technology that allows papermakers to recover mineral pigments from deinking residue by converting these raw materials to ENVIROFIL® PCC. This process has proven to substantially improve waste paper yield, mitigating solid waste disposal costs and reducing the environmental impact of the deinking process.

ENVIROFIL® PCC is a new, innovative recycling technology that allows papermakers to recover mineral pigments from deinking residue by converting these raw materials to ENVIROFIL® PCC. This process has proven to substantially improve waste paper yield, mitigating solid waste disposal costs and reducing the environmental impact of the deinking process.

“We are very pleased to work with UPM to deploy our newest recycling technology, which helps to address important sustainability challenges that our customers are facing at the paper mill,” said Douglas T. Dietrich, Chief Executive Officer of Minerals Technologies. “This collaboration with UPM demonstrates the value ENVIROFIL® PCC can provide our customers who are seeking ways to recover waste from the production process. We continue to develop innovative new solutions across our portfolio to meet evolving demands from customers, who require products geared towards environmental and recycling issues in addition to cost reduction solutions.”

Wolfgang Ohnesorg, General Manager of UPM Schongau, added, “The circular economy and resource efficiency offer solutions to the scarcity of natural resources, climate change and many other environmental challenges. Many of the challenges we face could be solved if materials and products were recycled and used more efficiently. In the value chain of forest industry products, UPM is involved in creating circular economy solutions.”

“UPM’s research into paper mill side streams aims to find more efficient ways to utilize by-products. In line with UPM’s Biofore approach, we continuously develop innovative ways to reduce our own waste and residues and to recycle waste into new products. The collaboration with MTI is an excellent example of our efforts to promote a circular economy. The project is part of UPM’s Zero Solid Waste target, which aims to develop solutions for recycling surplus materials to ensure that they produce added value. We already recycle or recover 90% of the process waste at UPM with our goal to further reduce the emissions and waste related to our production,” Mr. Ohnesorg concluded.

D.J. Monagle III, MTI Group President, Specialty Minerals and Refractories, commented, “We have a longstanding relationship with UPM, and we are excited to further strengthen our partnership. Through this new solution, we are providing an enhanced process for our customers to convert waste material that would normally be deposited to a landfill into a valuable pigment for producing paper. We see additional opportunities to commercialize ENVIROFIL® PCC to support our customers’ efforts to reduce process waste as well as to deploy our other high-value paper technologies.”

About Minerals Technologies Inc.

New York-based Minerals Technologies Inc. (MTI) is a resource- and technology-based growth company that develops, produces and markets worldwide a broad range of specialty mineral, mineral-based and synthetic mineral products and related systems and services. MTI serves the paper, foundry, steel, construction, environmental, energy, polymer and consumer products industries. The company reported sales of $1.808 billion in 2018. For further information, please visit our website at www.mineralstech.com. (MTI-G)

About UPM Communication Papers

UPM Communication Papers is the world's leading producer of graphic papers, offering an extensive product range for advertising and publishing as well as home and office uses. The high performing papers and service concepts of UPM add value to our customers' businesses, while actively fulfilling demanding environmental and social responsibility criteria. With headquarters in Germany, UPM Communication Papers employs approximately 8,000 people. More about UPM Communication Papers and its products at www.upmpaper.com

About UPM

We deliver renewable and responsible solutions and innovate for a future beyond fossils across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Specialty Papers, UPM Communication Papers and UPM Plywood. We employ around 19,000 people worldwide and our annual sales are approximately EUR 10.5 billion. Our shares are listed on Nasdaq Helsinki Ltd. UPM Biofore - Beyond fossils. www.upm.com

ANDRITZ to supply two tissue production lines with stock preparation to MG TEC Industry

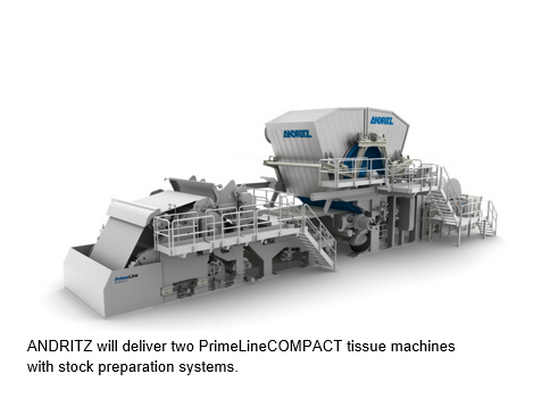

International technology Group ANDRITZ has received an order from MG TEC Industry to supply two complete tissue production lines for their mill in Dej, Romania. Start-up is scheduled for 2020 (TM1) and 2022 (TM2), respectively.

The turnkey order comprises two PrimeLineCOMPACT V tissue machines with steel Yankee as well as complete stock preparation systems, pumps, automation, hall ventilation, and electrification.

Photo: ANDRITZ

Photo: ANDRITZ

Each production line will be equipped with an ANDRITZ stock preparation line including approach flow system and broke handling. The proven TwinFlo disc refiner technology is used in a separate long-fiber line to achieve optimum development of fiber properties. The approach flow systems feature the ANDRITZ ShortFlow concept, which allows a minimized number of equipment items and very low storage volume as well as fast grade changes at the tissue machine.

The ANDRITZ tissue machines have a design speed of 1,900 m/min and a width of 2.85 m. They are equipped with a 15 ft. PrimeDry Steel Yankee for energy-efficient and safe operation. The drying components PrimeDry Hood G, PrimeDustEXT dust extraction system, and PrimeMistEXT mist extraction system as well as the hall ventilation system will be delivered by ANDRITZ Novimpianti.

The ANDRITZ pumps with efficiencies of up to 90% enable long life cycles at highest cost-effectiveness.

The ANDRITZ automation system combined with the latest drive technology ensures modern and efficient plant operation.

This order once again confirms ANDRITZ’s excellent position as a global tissue machine supplier. Ioan Tecar, Project Coordinator, says: “Decisive criteria for the order were the innovative technologies of ANDRITZ that enable easy and safe operation with high quality and the capability to deliver everything from a single source.”

MG TEC Industry is a newly formed company focusing on innovation and sustainable tissue production.

ANDRITZ Pulp & Paper is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, board, and tissue. The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers; recovery and reuse of chemicals; preparation of paper machine furnish; production of paper, board, and tissue; sizing, calendering and coating of paper; as well as treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam and recovery boilers for power production, gasification and flue gas cleaning plants, systems and plants for the production of nonwovens and absorbent hygiene products, dissolving pulp, and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

Humanized technology and its transformations in the pulp and paper sector is the theme of the ABTCP 2019 Congress

In the Industry 4.0 or Fourth Industrial Revolution that all productive sectors are currently experiencing, space takes on life in real time through man-machine integration and its interconnections, generating innovation in products, equipment design and transforming the organizational culture of companies. Within this context, the Brazilian Pulp and Paper Technical Association (ABTCP) based itself to define this year’s theme: HUMANIZED TECHNOLOGY: products, innovation, design and culture in Industry 4.0 for the 52nd Pulp and Paper International Congress.

The event, which will be held at the Hotel Transamerica in São Paulo, October 22-24, will not include the Exhibition of Technologies, and will have as guest president for the ABTCP 2019 Congress, Márcio Bertoldo, Manufacturing VP of International Paper Brazil in Latin America. “This Congress offers a unique opportunity for learning and networking, bringing together specialists to provide their different points of view and experiences to discuss business themes centered on the Pulp and Paper sector.” Bertoldo added that we are living in a scenario of constant changes and by gathering industry and academia professionals to discuss trends is of utmost importance for generating innovation and sharing good practices.

According to the president of the ABTCP 2019 Congress, the pulp and paper sector has always focused on the pursuit of product and process innovations to quickly respond to market changes and keep up with the evolution of customer needs. This further reinforces the relevance of the topic selected by ABTCP for this year’s event with a focus on boosting competitiveness. “The pursuit of new solutions is necessary for the survival of businesses and never stops. This pursuit refers to the ability to introduce and develop even better new products that satisfy customer demands and help conquer new markets, generating benefits for everyone,” said Bertoldo.

During the ABTCP Congress, says Bertoldo, a positive environment is created to show participants best practices in Management, Sustainability, Innovation, and the latest advancements in various technical areas. Additionally, International Paper Brazil’s executive points out that the event creates opportunities for developing knowledge and skills, promoting better operating efficiency and a lot of information exchanging, facilitating discussions about the latest technologies, operational improvements and business developments among the sector’s key players.

According to the president of the ABTCP 2019 Congress, Industry 4.0, also known as the Fourth Industrial Revolution, refers to a level of automation through the use of new technologies and use of intelligent machines, providing productivity gains, better quality and production, while also reducing costs. It is a new work model associated with technological progress.

“With evolution, industry is adopting technologies that will provide more operational flexibility for machinery and equipment, with greater capacity utilization and faster reaction times, to increase the productivity and profitability of businesses. However, it is important to point out that the use of human capabilities in processes is fundamental for everything to work in a seamless and efficient manner,” said Bertoldo, reflecting on the theme of this year’s ABTCP 2019 Congress: HUMANIZED TECHNOLOGY: products, innovation, design and culture in Industry 4.0.

For more information about ABTCP 2019: www.abtcp2019.org.br

Event date: October 22-24, 2019

Venue: Hotel Transamerica, in São Paulo/SP

Address: Av. Dr. Mário Villas Boas Rodrigues, 387 – Santo Amaro • São Paulo-SP-Brazil

Two Paper Rewinders E-WIND® P100 for Liensheng Paper (Shanying Group)

A.Celli Paper is pleased to confirm its ongoing and valuable collaboration with the Chinese group Shanying Huazhong Paper Industry Co., Ltd., enshrined in the agreement for the supply of two latest generation E-WIND® P100 rewinders, for the mill located in Zhangzhoi City, in Fujian province, China.

The E-WIND® P100 Paper Rewinders, highly developed in terms of design, will have a paper width of 6660 mm and will guarantee a maximum production speed of 2500 mpm (operating speed).

They are combined with sophisticated technological innovations including:

- Innovative Slittomatic® double motor cutting unit positioning system;

- Web-in technology, the automatic system that maximises the management of positioning cutting units without the need to break the web, with considerable time and safety savings for operators;

- Jumbo roll parking station and shuttle (mobile trolley on rail) for their handling.

These two rewinders have been selected by the Chinese group to process medium board paper, with basis weight range from 80 up to 160 gsm.

Liansheng Paper had already purchased two other rewinders, with the same width, in 2016 and Shanying Group, of which the paper mill is part, bought two large-width paper rewinders (8 meters) from A.Celli last year.

An important new confirmation of a consolidated partnership between Shanying Group and A.Celli, which underlines the success of the paper rewinders A.Celli E-WIND®.