Displaying items by tag: BillerudKorsnäs

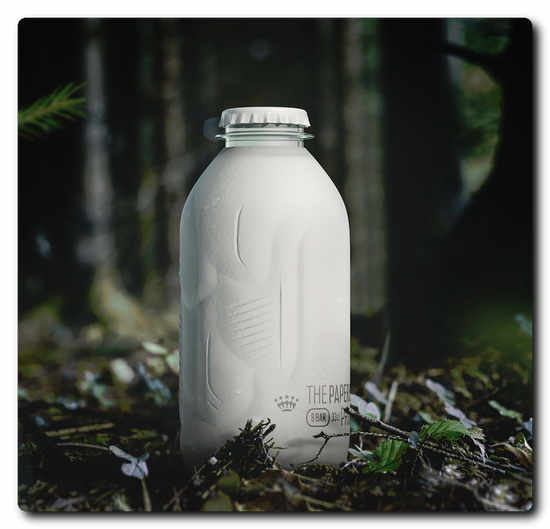

BillerudKorsnäs joint venture Paboco, introduce the Paper bottle community to advance packaging innovation

BillerudKorsnäs, together with partners, proudly presents Paboco, the paper bottle company, uniting leading experts in material, design and technology, and supported by world-leading consumer brands to bring sustainable progress to the bottling industry.

Building on years of experience, the development journey towards a sustainable paper bottle first began in 2015 by innovation expert EcoXpac in collaboration with Carlsberg Group and BillerudKorsnäs, with support from project partners.

Now in 2019, Paboco represents a joint venture between paper packaging material developer BillerudKorsnäs and bottle manufacturing specialist Alpla.

To support the initiative and explore further development and commercial opportunities, Paboco is officially launching the Paper bottle community with participation from the partners below

This is our Paper bottle community:

Pioneer owner Pioneer brands Pioneer partners

Building lasting change takes time and any challenge to the norm carries equal amounts of risk. To provide the best system for success, we are building a community of partners that share our vision, understand the complexity of innovation and the crucial importance of introducing smarter and more sustainable packaging solutions.

Our ambition is matched by the challenges we are facing: Challenging the traditional bottling industry and indirectly sparking a movement for a more sustainable everyday.

“It is all about the team! We are collaborating across the value chain, sharing the risks and are united in our vision that the Paper Bottle will become a reality and fundamentally change this industry for good”, says Mrs. Gittan Schiöld, interim CEO of Paboco.

Our long-term goal: a sustainable choice for the future.

The Paper Bottle is a step-by-step innovation concept focused on scaling and product functionality. It is the first of its kind for liquid goods such as carbonated and still drinks, beauty products and more.

Alongside the scaling of the production technology, Paboco works for the transition to a bottle solution for the future circular society, a 100% bio-based and recyclable paper bottle that can harmlessly degrade if accidentally put in nature. Our vision will always drive us further than the expectations of today and push us to improve the paper bottle to become fully sustainable and optimized for material reuse and circularity.

This work is undertaken in generations of the Paper Bottle, building on existing barrier technologies of today and exploring those of tomorrow. Each pioneer brand will develop and design their own paper bottle to meet the needs of their category.

About the Paper bottle community:

The paper bottle community unites a group of pioneering partner brands and experts in materials, design and technology. Together, we are shaping sustainable everyday life by contributing to the making of a fully bio-based and recyclable bottle made from wood fibres. A long-term innovation project run by Paboco®, the paper bottle company.

About Paboco:

Paboco®, the paper bottle company, is a joint venture between paper packaging materials- and solutions provider BillerudKorsnäs and bottle manufacturing specialist Alpla, grown from the start-up and innovation expert ecoXpac. Our aim is to provide consumers with a fully bio-based and recyclable paper bottle, that ultimately will change the industry and impact the environment for good. www.paboco.com

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world-leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production units in Sweden, Finland and the UK and about 4300 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

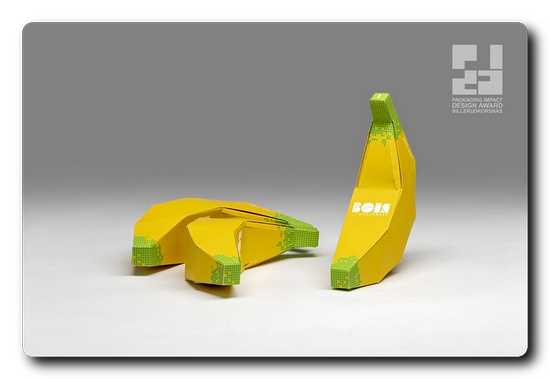

Congratulations, banana-shaped design! Winner of the Grand Finale of PIDA – Packaging Impact Design Award

For 15 years running, BillerudKorsnäs has arranged and hosted PIDA - Packaging Impact Design Award, a competition among design students in France, Germany, Sweden and the UK. For the first time in the history of the competition, an all-European winner has been selected. The Grand Finale was held at Luxe Pack Monaco, the world’s leading trade fair for luxury packaging, and the title went to “Bois Underwear” by Swedish students from design college Nackademin.

The students behind the winning design are Natasha Bosnjak, Alicia Lundgren and Christian Koch. Their design qualified for the Grand Finale by winning the Gold Award at the Swedish PIDA event. They suggested that packaging design in the future may very well be fun, playful and edgy. The winner is a retail pack for men’s underwear in the shape of a banana, which you peel to open.

“We are so happy about this prize,” says Alicia Lundgren. “It means everything. And it means a lot that we just followed our hearts, never held back, and disregarded the usual Scandinavian design conventions. We managed to make sustainability look fun, and we are very pleased with that.”

A glimpse of the future

For every year, the competition has a new theme. This year’s brief was "Bring the Future" and the students’ challenge was to develop a sustainable packaging concept for the year 2030. The jury looked at the innovativeness, sustainability, user-friendliness, concept and communication of the contesting design projects. Bois Underwear received high marks on all points, and its colourful appearance drew a lot of attention. In total, 36 design projects were nominated and four of them made it to the Grand Finale.

The Grand Finale winner was elected by a jury comprising a mix of industry professionals – designers, converters, brand owners and other specialists – all of whom have been on the jury at one of the previous PIDA-events this year.

“The brief presented to students at the PIDA 2019 was ambitious. Imagining the packaging of the future seems simple at first sight, but that is without counting the current trends that are the new technologies, the sustainable development and the aging of the population,” says Sophie Lindhe, Brand Project Coordinator, at BillerudKorsnäs.

Young talents become tomorrow’s packaging designers

The international competition PIDA is a BillerudKorsnäs initiative and is carried out in collaboration with leading universities and colleges in Sweden, the UK, France and Germany. Each year, about 200 design students participate.

“With PIDA we achieve several different purposes at the same time,” says Anders Gathu, Marketing Manager at BillerudKorsnäs. “We aim the spotlight on the importance of packaging for brands, consumer benefits and the environment. We want to shine light on the young talents who will become tomorrow’s packaging designers and bring them together with industry professionals. By offering a meeting place for ideas, innovation and inspiration, we help push industry development forward.”

Natasha Bosnjak, Alicia Lundgren and Christian Koch won the PIDA Grand Finale.

For more information about PIDA, please contact:

Sophie Lindhe, Brand Project Coordinator, BillerudKorsnäs

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world-leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production sites in Sweden, Finland and the UK and about 4300 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

Lower pace of KM7 start-up affects third quarter result

Due to a lower pace in the initial start-up of the new board machine at Gruvön, the effect on the result in the third quarter is adjusted by approximately SEK 150 million. The effects in the fourth quarter and the full year 2020 are expected to be unchanged. The machine is still expected to make a positive contribution to EBITDA in 2021.

The customer response on produced and sold material is positive and the technical quality is satisfactory. However, production volumes from KM7 in 2019 are expected to be lower than previously planned. This is mainly due to lower pace in the initial start-up in combination with the complexity of the integration with the existing mill. The market demand for the material produced continues to be good and the machine is still expected to run at full production capacity in 2023.

The customer response on produced and sold material is positive and the technical quality is satisfactory. However, production volumes from KM7 in 2019 are expected to be lower than previously planned. This is mainly due to lower pace in the initial start-up in combination with the complexity of the integration with the existing mill. The market demand for the material produced continues to be good and the machine is still expected to run at full production capacity in 2023.

The negative full year effect 2019 on EBITDA for the start-up of KM7 is adjusted from SEK 500 million to SEK 650 million. The effect on the result impacted the first half year by SEK 190 million and is estimated to impact the third quarter by approximately SEK 300 million and the fourth quarter with approximately SEK 160 million.

For further information, please contact:

Ivar Vatne, CFO, +46 8 553 335 07

Lena Schattauer, Head of Investor Relations, +46 8 553 335 10

This information constituted inside information prior to publication. This is information that BillerudKorsnäs AB (publ) is obliged to make public pursuant to the EU Market Abuse Regulation. The information was submitted for publication, through the agency of the contact persons set out above, at 08:45 CET on 16 September 2019.

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production units in Sweden, Finland and the UK and about 4,500 employees in over 13 countries. BillerudKorsnäs has an annual turnover of approximately SEK 24 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

Cost reduction programme with positive result effects of SEK 600 million with full effect 2021

BillerudKorsnäs introduces a cost reduction programme to ensure long-term efficiency and profitability. The measures include staff cuts in mainly administration, purchasing-related savings and efficiency improvements throughout the business.

As a part of a strategic update, BillerudKorsnäs is introducing a cost reduction programme expected to generate positive effects on earnings of around SEK 600 million with lasting effects beginning in 2021. The positive effects in 2020 are expected to amount to approximately SEK 250 million. As part of the programme, BillerudKorsnäs has decided to reduce the number of employees by up to 300. This decision affects the entire operation and negotiations with the trade unions will begin shortly.

As a part of a strategic update, BillerudKorsnäs is introducing a cost reduction programme expected to generate positive effects on earnings of around SEK 600 million with lasting effects beginning in 2021. The positive effects in 2020 are expected to amount to approximately SEK 250 million. As part of the programme, BillerudKorsnäs has decided to reduce the number of employees by up to 300. This decision affects the entire operation and negotiations with the trade unions will begin shortly.

“There is considerable potential to increase our cost efficiency within BillerudKorsnäs. We are a well-positioned, fundamentally stable company that continuously improves our operational efficiency. This programme will ensure long-term efficiency and profitability,” says Petra Einarsson, CEO and President of BillerudKorsnäs.

In addition to increasing the efficiency of the business operations, the updated strategy also involves BillerudKorsnäs accelerating its innovation and repositioning solutions. The strategy focuses on clearer priorities and concrete initiatives that enable strong execution with the aim of continuing to challenge conventional packaging for a sustainable future.

For further information, please contact:

Ivar Vatne, CFO, +46 8 553 335 07

Lena Schattauer, Head of Investor Relations, +46 8 553 335 10

This information constituted inside information prior to publication. This is information that BillerudKorsnäs AB (publ) is obliged to make public pursuant to the EU Market Abuse Regulation. The information was submitted for publication, through the agency of the contact persons set out above, at 08:45 CET on 16 September 2019.

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production units, in Sweden, Finland and the UK, and about 4,500 employees in over 13 countries. BillerudKorsnäs has an annual turnover of approximately SEK 24 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

Lower pace of KM7 start-up affects third quarter result

Due to a lower pace in the initial start-up of the new board machine at Gruvön, the effect on the result in the third quarter is adjusted by approximately SEK 150 million. The effects in the fourth quarter and the full year 2020 are expected to be unchanged. The machine is still expected to make a positive contribution to EBITDA in 2021.

The customer response on produced and sold material is positive and the technical quality is satisfactory. However, production volumes from KM7 in 2019 are expected to be lower than previously planned. This is mainly due to lower pace in the initial start-up in combination with the complexity of the integration with the existing mill. The market demand for the material produced continues to be good and the machine is still expected to run at full production capacity in 2023.

The customer response on produced and sold material is positive and the technical quality is satisfactory. However, production volumes from KM7 in 2019 are expected to be lower than previously planned. This is mainly due to lower pace in the initial start-up in combination with the complexity of the integration with the existing mill. The market demand for the material produced continues to be good and the machine is still expected to run at full production capacity in 2023.

The negative full year effect 2019 on EBITDA for the start-up of KM7 is adjusted from SEK 500 million to SEK 650 million. The effect on the result impacted the first half year by SEK 190 million and is estimated to impact the third quarter by approximately SEK 300 million and the fourth quarter with approximately SEK 160 million.

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production units in Sweden, Finland and the UK and about 4,500 employees in over 13 countries. BillerudKorsnäs has an annual turnover of approximately SEK 24 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

BillerudKorsnäs appoints EVP Sustainability

BillerudKorsnäs Sustainability Director Malin Ljung Eiborn will on the 1st of October take place in the Executive Leadership Team of BillerudKorsnäs. Sustainability thus becomes a separate function at group level instead of, as previously, part of the communication department.

Malin Ljung EibornIn BillerudKorsnäs, supplier of sustainable packaging materials and solutions, sustainability is integrated in the business. The company's purpose “we challenge conventional packaging for a sustainable future” becomes even clearer when the group wide responsibility now becomes part of the Executive Leadership Team (ELT).

Malin Ljung EibornIn BillerudKorsnäs, supplier of sustainable packaging materials and solutions, sustainability is integrated in the business. The company's purpose “we challenge conventional packaging for a sustainable future” becomes even clearer when the group wide responsibility now becomes part of the Executive Leadership Team (ELT).

- Sustainability is today at the heart of our business. We will continue to take the lead and to include sustainability in the ELT as its own group function therefore feels natural. The fact that Malin in her relatively short time in the company has already contributed strongly to our development made including here in the ELT an easy decision to take, says Petra Einarsson President and CEO.

- I am very happy about this opportunity and look forward to now stepping into the ELT and continue to develop sustainability as a strong driving force for our company's continued development. Since sustainability is part of everything we do, this is also an important step in getting the whole company moving in the same direction towards a sustainable future, says Malin.

Malin Ljung Eiborn has been Director Sustainability and public affairs at BillerudKorsnäs since January 2018. Before that she worked for the communications agency Prime where she was partner and part of developing the sustainability offering. Malin has previously worked for many years at the Swedish Ministry of Foreign Affairs and has a Master’s degree in EU law.”

For further information, please contact:

Malin Ljung Eiborn, +46 (0) 76 797 35 30, This email address is being protected from spambots. You need JavaScript enabled to view it.

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world-leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production units in Sweden, Finland and the UK and about 4300 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

Bosch Packaging Technology and BillerudKorsnäs intensify innovation collaboration

The demand for sustainable packaging among consumers and brand owners all over the world is growing at an exponential rate, which in many cases drives a strong need to replace plastic packaging. Strong partnerships are required to bring about the development and innovation needed to meet this demand. A good reason for Bosch Packaging Technology and BillerudKorsnäs to intensify their successful collaboration.

Already in 2016, Bosch and BillerudKorsnäs presented their first major joint innovation - Sealed Paper Packaging on a vertical form, fill and seal machine (VFFS). The ZAP module from Bosch makes it possible to process mono-material Axello® ZAP paper from BillerudKorsnäs on VFFS technology with dust-tight sealing. Now Bosch Packaging Technology and BillerudKorsnäs are developing new sustainable paper-based packaging innovations. Both companies are further strengthening their approach to work closely with partners along the value chain to find better solutions for a sustainable future.

“Developing sustainable packaging solutions is an urgent and challenging topic. New solutions must be sustainable and at the same time ensure efficient processing. By combining the expertise of BillerudKorsnäs in the field of paper-based packaging material with our technological know-how, we will be able to answer both challenges,” says Dr Stefan König, president of Bosch Packaging Technology.

“Developing sustainable packaging solutions is an urgent and challenging topic. New solutions must be sustainable and at the same time ensure efficient processing. By combining the expertise of BillerudKorsnäs in the field of paper-based packaging material with our technological know-how, we will be able to answer both challenges,” says Dr Stefan König, president of Bosch Packaging Technology.

“The collaboration with Bosch Packaging Technology offers new perspectives for sustainable packaging. Bosch brings many years of experience in technology and implementation into the cooperation. By joining forces, we can realize our ideas in a more targeted way and shape the future of packaging together,” says Petra Einarsson, president and CEO of BillerudKorsnäs.

The first concrete result of this enhanced collaboration is the development of a new packaging concept called Pearl. It aims to show how uniquely formed and right-sized small packages, called shaped paper pods, can contribute to a more sustainable future by utilising the unique formability of the FibreForm® material (the leading 3D-formable paper on the market, patented by BillerudKorsnäs). The material is processed on machinery from Bosch Packaging Technology, who not only contributes long-standing expertise in forming, filling and sealing of a wide variety of materials to the cooperation but also ensures the subsequent industrialization of the newly developed technologies for commercial production.

In industries like beauty and personal care, bread spreads, savoury and confectionery, single-use plastic packaging is widespread. “The goal is to support these industries with a sustainable packaging system and replace plastic in product samples, inserts, refills, portion packs and disposable packaging,“ says Simon Johansson, project manager Packaging Solutions at BillerudKorsnäs. “We have already passed several milestones in the project,” Torsten Sauer, project manager sustainability at Bosch Packaging Technology adds. “Now we are inviting selected brand owners to join our journey towards a sustainable future.”

The Pearl concept will be shown for the first time at FOOMA (International food & technology exhibition), South hall, booth 3C-34, in Tokyo July, 9 to 12, 2019.

Together with further sustainable packaging solutions and developments, the Pearl concept will also be exhibited at the leading packaging tradeshows such as FachPack (September 24 to 26, 2019 in Nuremberg, Germany), PackExpo (September, 23 to 25, 2019 in Las Vegas, USA) and Interpack (May 7 to 13, 2020 in Dusseldorf, Germany).

About Bosch Packaging Technology

Based in Waiblingen near Stuttgart, Germany, and employing 6,300 associates, the Bosch Packaging Technology division is one of the leading suppliers of process and packaging technology. At over 30 locations in more than 15 countries worldwide, a highly-qualified workforce develops complete solutions for the pharmaceuticals, food, and confectionery industries. These solutions are complemented by a comprehensive after-sales service portfolio. A global service and sales network provides customers with local points of contact. More information is available online at www.boschpackaging.com

Sustainable Sake-packaging winner of PIDA UK 2019

For the first time, the British edition of PIDA – Packaging Impact Design Award – got its own event, held on 5 June in Leeds. This year, sustainability and recycling were in focus. The contesting design students presented creative and fun ideas on how to package flowers, drinks and accessories in a more environmentally friendly way. And the design that had the best concept according to the jury, was Ekitai Sake, created by students from Sheffield Hallam University.

“We are surprised, chocked an honored. We made a recyclable, sustainable bottle and we’ve completely removed the glass. It’s the most sustainable product we could think of and we really tried to push it and make it look luxurious” says Will Sutton who together with teammates Chao-Lun Cheng and Jiaming Gong won the Gold Award of PIDA UK 2019. Their design Ekitai Sake is now qualified for the European final in Monaco this fall, at Luxe Pack - the world's largest luxury packaging fair.

High quality all around

This year’s brief was "Bring the future" and the students’ challenge was to develop a sustainable packaging concept for the year 2030. The jury looked at the innovation, sustainability, user-friendliness, concept and communication of the contributions. Ekitai Sake received high marks on all points and the students were praised for their attention to detail, the branding and the functionality of the packaging.

The motivation of the jury:

“A unanimous decision by the judges to give the PIDA Gold Award to this excellent innovative pack design, very strong in all categories. The combination of structure, branding and functionality proved a winning concept. The judges appreciated the attention to detail, the ergonomics of the bottle and use of the lid to drink with as a workable concept. Additional environmental impact reductions by replacing glass and reducing energy required to provide a stunning design that further enhanced the excellent packaging & product combined concept.”

A glimpse into the future of packaging

In addition to the PIDA Gold Award, winners were elected in three more categories. The prize for the Highest Level of Innovation went to the design Believers, dreamers and you for its unique playful design and great shelf impact. Winner of Highest Level of Sustainability and Highest Level of User Friendliness award was the design Lit Life for the economical use of the material and for the functionality of the packaging.

“The projects catapulted us into the future of packaging innovation and design and previewed ideas and concepts that we will one day see on our shelves and have in our homes. All of the projects were great and it was a very proud day for all involved as it had been a dream for three years to hold this event in the UK”, says Gareth Fisher, project leader of PIDA UK at BillerudKorsnäs.

Young talents become tomorrow’s packaging designers

The international competition PIDA is arranged by BillerudKorsnäs and is carried out in collaboration with leading universities and colleges in Sweden, the UK, France and Germany. Each year, over 200 design students participate. In this year’s edition of PIDA UK, students from Sheffield Hallam University competed. The jury consists of a mix of industry professionals – designers, converters, brand owners and other specialists.

“With PIDA we achieve several different purposes at the same time,” says Anders Gathu, Marketing Manager at BillerudKorsnäs. “We aim the spotlight on the importance of packaging for brands, consumer benefits and the environment. We want to shine light on the young talents who will become tomorrow’s packaging designers and bring them together with industry professionals. By offering a meeting place for ideas, innovation and inspiration, we help push industry development forward.”

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world-leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production sites in Sweden, Finland and the UK and about 4300 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

BillerudKorsnäs and ALPLA to join forces to pioneer paper bottles for a sustainable future

Paper packaging materials- and solutions provider BillerudKorsnäs and plastic packaging solutions provider ALPLA have just announced that they will embark on a joint venture. They do so with the vision to develop a fully biobased and recyclable paper bottle.

BillerudKorsnäs and ALPLA today announced that they will form a joint venture in the Danish paper bottle company ecoXpac. When the transaction has been completed, BillerudKorsnäs and ALPLA will own equal parts of ecoXpac. A minority post will be held by the founder family. BillerudKorsnäs is currently the majority owner and has been a shareholder in the company since 2015. BillerudKorsnäs has been a driving force in the ongoing development of a paper bottle, which was started by ecoXpac in 2010 and with Carlsberg Group since 2015.

ALPLA and BillerudKorsnäs share the ambition to drive packaging innovation in a sustainable direction. The two companies intend to leverage the development by combining their resources, competencies and strengths to support scaling ecoXpac in the commercialisation of a fully biobased and recyclable paper bottle.

Paper Bottle

Paper Bottle

In late 2016, Carlsberg Group revealed a first physical prototype of a paper bottle, the Green Fiber Bottle, and the first generation of paper bottles has since then been in a testing phase. The plan now is to continue the development to be able to launch and then scale up production. Following generations will be both fully biobased and have biodegradable barriers thereby fully realising the vision and enabling consumers all over the world to live more sustainably. It is to realise this vision the two companies come together on this journey of innovation.

- With BillerudKorsnäs we have found an ambitious partner creating a new packaging market segment that offers a complementary consumer experience to our current rigid packaging solutions. ALPLA is sharing the passion for technical challenges and innovation. I want to emphasise the long-term vision of the joint venture to introduce fully biobased paper bottles. ALPLA is contributing capital as well as technical know-how to the joint venture to accelerate the development and market introduction of the paper bottle, says Günther Lehner, CEO of ALPLA.

- "I believe that with our shared and honest ambition to break new ground, ALPLA and BillerudKorsnäs now make an important commitment to contribute to a more sustainable future. The question is not “if” but rather “how soon” this joint venture will introduce a fully biobased and recyclable paper bottle to the market. When we do, it will enable a significant shift in consumer behaviour globally, says Petra Einarsson, CEO and President BillerudKorsnäs."

- EcoXpac was founded with a strong vision for the future. Today we are privileged to have the best players in their fields sharing our vision. It makes me proud of what we have achieved so far. The vision has never felt closer to reality than today, says Martin Grosen Petersen, CEO of ecoXpac.

The formation of the joint venture is subject to customary regulatory approvals such as merger control clearances. It is expected that the transaction is completed in Q3 2019.

ALPLA is one of the leading companies involved in plastic packaging. Around 20,800 employees worldwide produce custom-made packaging systems, bottles, closures and moulded parts at 178 sites across 46 countries. The high-quality packaging is used in a wide range of areas, including for food and drinks, cosmetics and care products, household detergents, washing and cleaning agents, pharmaceutical products, engine oils and lubricants.

ALPLA operates its own recycling plants: PET Recycling Team with a site in both Austria and Poland, and in the form of a joint venture in Mexico. ALPLA has been cooperating with Texplast (Germany) on PET recycling since July 2018. www.alpla.com

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world-leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production units in Sweden, Finland and the UK and about 4400 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. BillerudKorsnäs Venture AB, a fully owned subsidiary, accommodates several venture initiatives. www.billerudkorsnas.com

EcoXpac is an innovative Danish company specialised in designing, developing and implementing process solutions for moulded fibre bottles. The company follows a strategy striving to introduce fibre-based products in categories dominated by other materials and by so doing contributing to a more a sustainable future.

Students create packaging of the future in annual design competition PIDA arranged by BillerudKorsnäs

What will a sustainable and exciting packaging concept look like in 2030? Most likely we will see many and innovative answers to that question at PIDA (Packaging Impact Design Award), the international design competition arranged and hosted by BillerudKorsnäs. In this year’s edition of PIDA, the brief encourages the participating students to gaze into the future and create an innovative, functional and sustainable packaging concept to solve a problem of the future.

“We have to start today if we want to find tomorrow’s solutions. Change doesn’t happen overnight. Design for the future means to stop and think, question the way things are, identify problems and go to work to change things for the better. This year’s theme gives the students tons of opportunities to push the envelope of their creativity,” says Johanna Oderstad, Technical Sales Carton Solutions BillerudKorsnäs.

Bring the Future

Consumers of today demand more of a package than ever. They expect less plastic, unique design and sustainable solutions. 72% of all consumers say they are willing to pay more for a product packed in a sustainable way, according to a BillerudKorsnäs 2017 survey. The theme for this year’s PIDA is Bring the Future and the key word is “sustainability”. “A theme this broad gives the students ample possibilities to go their own way. They can fantasize about future scenarios that they are able to imagine. We hope to see innovative concepts that will give us new food for thought.”

Selecting an international winner

The Swedish part of PIDA will be held on 22 May in Stockholm. Here, students from Germany will participate as well. PIDA France will be held on 16 June in Reims. For the first time this year, UK students have their own PIDA event – in Sheffield on 4 June. And also for the first time, an international PIDA winner will be selected at the luxury packaging show Luxe Pack in Monaco on 30 September.

“We have arranged PIDA for many years now, with a similar setup over a long time. We want to take the competition to a new level. This way we can give the students an even greater incentive and introduce their design projects to a wider audience,” says Johanna Oderstad.

About PIDA

For the 15th consecutive year the international packaging design competition PIDA (Packaging Impact Design Award) is arranged by BillerudKorsnäs. Around 200 design students from France, Germany, Sweden and the UK participate. At each national event winners are selected in the following categories: Highest Level of Sustainability, Highest Level of Innovation, Highest Level of User Friendliness, and PIDA Gold Award. The competition aims to demonstrate the importance of packaging to products, brands and the environment.

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world-leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production sites in Sweden, Finland and the UK and about 4300 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com