Displaying items by tag: valmet

Valmet renews its sustainability reporting

Valmet renews its sustainability reporting practices. Since 2013 the company has published an annual sustainability report in line with the international GRI framework and reported to several leading sustainability ratings.

In the current renewal, Valmet will focus on comprehensive reporting according to the EU's Corporate Sustainability Reporting Directive (CSRD), invest in the development of sustainability data and information systems required by this extensive reporting framework, and streamline participation in different sustainability ratings. As part of the renewal, Valmet has decided not to pursue inclusion in the Dow Jones Sustainability Index (DJSI) anymore. The company has been included in the index for ten consecutive years.

”Valmet has since 2013 been among the leaders in sustainability reporting and has proactively incorporated new elements into its reporting. Sustainability reporting is undergoing major changes and requires more resources from companies than before. At Valmet, we want to support this continuous improvement in transparency, while ensuring that we focus our resources as efficiently as possible on the things that best help the company to move forward and meet the expectations of our stakeholders. We are very proud that Valmet has been included in the Dow Jones Sustainability Index since 2014. Over the years, the DJSI has encouraged us to continuously improve our sustainability performance and highlighted new areas for improvement. I would like to warmly thank the large number of Valmet employees who have contributed to this great work every year,” says Anu Salonsaari-Posti, SVP, Marketing, communications, sustainability and corporate relations at Valmet.

”Valmet has since 2013 been among the leaders in sustainability reporting and has proactively incorporated new elements into its reporting. Sustainability reporting is undergoing major changes and requires more resources from companies than before. At Valmet, we want to support this continuous improvement in transparency, while ensuring that we focus our resources as efficiently as possible on the things that best help the company to move forward and meet the expectations of our stakeholders. We are very proud that Valmet has been included in the Dow Jones Sustainability Index since 2014. Over the years, the DJSI has encouraged us to continuously improve our sustainability performance and highlighted new areas for improvement. I would like to warmly thank the large number of Valmet employees who have contributed to this great work every year,” says Anu Salonsaari-Posti, SVP, Marketing, communications, sustainability and corporate relations at Valmet.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our more than 19,000 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. Valmet’s net sales in 2023 were approximately EUR 5.5 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to invest in filter fabric manufacturing in South America

Valmet has decided to invest in filter fabric manufacturing in Belo Horizonte, Brazil, in order to better respond to the growing demand of high-performing filter fabrics in both the mining and pulp and paper industries in South America. The value of the new investment will not be disclosed.

“The investment includes the relocation of the current office and manufacturing facility in Belo Horizonte, new machinery, and improvements in the operations’ energy efficiency and emission reduction. It gives us the necessary assets to further develop sustainable services close to customers,” says Jarkko Syrjälä, Director, Filtration at Valmet.

The new facility will be in operation during the first half of 2025.

The new facility will be in operation during the first half of 2025.

“Improved delivery times will strengthen our position in the South American market. The investment will also ensure our capacity for the coming years to deliver filter fabrics that respond to customer needs and provide maximized reliability and optimized performance for their filtration process,” says Felipe Floriani, Services Director, South America, Valmet.

Valmet is one of the leading suppliers of filter fabrics and industrial textiles globally. Valmet’s filtration offering covers filter fabrics and felts for the mining and chemical, pulp and paper, and laundry industries, as well as for the variety of dry filtration applications.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our more than 19,000 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. Valmet’s net sales in 2023 were approximately EUR 5.5 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to supply consistency measurements to DS Smith in Italy

Valmet will supply consistency measurements to DS Smith Paper Italia S.r.l’s site in Lucca, Italy to complement the wide automation package to be delivered with the new container board making line (PM3).

The order was included in Valmet’s orders received of the fourth quarter 2023. The measurements will be delivered during the fourth quarter 2024. The value of the order will not be disclosed.

The customer chose Valmet because of the company’s extended experience and relevant references in advanced applications for recycled fibers with microwave and optical measurement technologies, and solid blade technology.

“We have agreed with DS Smith to develop a wide range of collaborations with Valmet’s measurements solutions, and this project is one part of the collaboration. This is also one of the largest projects for Valmet’s measurements in Italy in the last 10 years,” says Luigi Caggiano, Country Manager, Automations Systems business line, Valmet.

“We have agreed with DS Smith to develop a wide range of collaborations with Valmet’s measurements solutions, and this project is one part of the collaboration. This is also one of the largest projects for Valmet’s measurements in Italy in the last 10 years,” says Luigi Caggiano, Country Manager, Automations Systems business line, Valmet.

Technical information about the delivery

Valmet’s delivery includes seven Valmet Microwave Consistency Measurements (Valmet MCA), six Valmet Blade Consistency Measurements (Valmet SP) and six Valmet Optical Consistency Measurements (Valmet OCR and OC2R) from the latest generation to measure total consistency as well as ash content.

Measuring total consistency in the process, the Valmet MCA and Valmet OCR enable better control for more efficient production, improved quality and economic savings with fewer process upsets, and Valmet OC2R allows total and ash consistency measurements for advanced process optimizations. This will help the mill to reach its high-performance targets.

This order is furtherly integrating the Valmet’s automation systems solutions under delivery for the PM3, an 8,600 mm wide (wire) container board machine. The PM3 will produce recycled liner grades with a basis weight range of 70–135 g/m2 at production speed of 1,500 m/min and mechanical design speed of 1,700 m/min. The annual capacity is approximately 450,000 tons.

About the customer

Located in the Tuscany region in Italy, DS Smith Paper Italia S.r.l is part of a world leading provider of sustainable packaging solutions, paper products and recycling services worldwide. Today DS Smith operates in more than 30 different countries employing over 30,000 people.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our more than 19,000 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. Valmet’s net sales in 2023 were approximately EUR 5.5 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

Valmet will supply key technology to Shandong Jin Tian He Paper’s board machine PM 13 food grade folding boxboard line in China. The delivery will include headboxes, a former and press section, finishing technologies, automation and services.

The order is included in Valmet’s orders received of the fourth quarter 2023. The value of the order will not be disclosed, but such an order is typically worth of EUR 20 million to EUR 30 million.

The start-up of the folding boxboard machine is scheduled for the second quarter of 2025.

“Shandong Jin Tian He Paper develops high-end food grade coated white cardboard to meet the people’s yearning for a better life and the social demand for high-end packaging products. We chose Valmet because they are one of the best pulp and paper equipment manufacturers in the world, with reliable quality, proactive service and good communication, which helps us reach our goals,“ says Xu Zhenli, Chairman, Shandong Jin Tian He Paper.

“Valmet’s offering, including high performance coating technology, and unique advantages combining process technologies, services and automation are confirmed and trusted by the customer to meet their high-quality targets. Valmet and Shandong Jin Tian He Paper are working closely together, not only executing a successful project but also deepening partnership,” says Daniel Li, Sales Manager, China, Valmet.

Shandong Tianhe Paper Co., Ltd. office building in Tai’an, China

Shandong Tianhe Paper Co., Ltd. office building in Tai’an, China

Technical information about the delivery

Valmet’s delivery for the board machine PM 13 will include three OptiFlo Fourdrinier headboxes, IntelliTop Former forming section, IntelliPress Linear press section, five OptiCoat Roll coating stations, OptiDry Coat air drying technology and two OptiCalender Soft calenders.

The delivery will also include Valmet DNA Machine Controls (MCS), Cross Direction (CD) and Machine Direction (MD) controls, headbox dilution profilers, basic engineering, spare parts packages, and Valmet Industrial Internet solutions with connectivity.

The 6,320 mm wide (wire) PM 13 will produce food grade folding boxboard with basis weight range of 170-400 g/m2 at production speed of 800 m/min.

About the customer

Shandong Jin Tian He Paper Co., Ltd., established in 2022, is a subsidiary of Shandong Tianhe Paper Co., Ltd. which was established in 1978. Shandong Tianhe Paper Co., Ltd. is a pulp-paper integrated enterprise. Its main products include, for example, mechanical pulp, fine paper, package paper and specialty paper. The company has more than 1,500 employees.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our more than 19,000 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to supply IQ Web Inspection System to Yueyang Forest & Paper Co., Ltd. in China

Valmet has received an order from Yueyang Forest & Paper Co., Ltd. to supply IQ Web Inspection System for its paper machine PM 8. The IQ Web Inspection System will replace an existing system from another supplier. Yueyang Forest & Paper’s PM 8 has already been equipped with Valmet IQ Web Monitoring System in 2019. After the implementation, Valmet’s machine vision systems will improve the operating efficiency and optimize the final paper quality of the PM 8.

The order is included in Valmet’s orders received of the fourth quarter 2023. The delivery will take place in July 2024. The value of the order will not be disclosed.

“We have been using Valmet IQ Web Monitoring System since 2019 and we are pleased with its performance. That is why we continue our cooperation with Valmet. The new investment of IQ Web Inspection System will help us to quickly detect quality defects and identify their root causes quickly and easily, which will improve our runnability and product quality,” says Mingyi Yu, Automation Manager at Yueyang Forest & Paper Co., Ltd.

“We are very happy that our advanced technology can support Yueyang Forest & Paper stay competitive in the market. The upgrade will significantly improve image quality and provide a good basis for analysis and precaution for defects,” says Zhifeng Pan, Sales Manager, Automation Systems business line, Valmet.

Valmet has received an order from Yueyang Forest & Paper Co., Ltd. to supply IQ Web Inspection System for its paper machine PM 8.

Valmet has received an order from Yueyang Forest & Paper Co., Ltd. to supply IQ Web Inspection System for its paper machine PM 8.

Technical information about the delivery

Valmet IQ Web Inspection System (WIS) delivery includes ultra-high resolution 8K dual-line cameras with advanced image processing and synchronized high power stroboscopic LED lighting. Real-time and history defect maps with defect details and trends are available on operator stations. IQ Web Inspection System also supports both rule-based classification as well as classification based on artificial intelligence (AI) with easy drag and drop teaching. In addition, a two-year optimization service is also included.

About the customer Yueyang Forest & Paper Co., Ltd.

Yueyang Forestry & Paper Co., Ltd., formerly known as Yueyang Paper Mill, was founded in 1958 and listed on the Shanghai Stock Exchange in May 2004. The company is a subsidiary of China Paper Corporation, part of China Chengtong Holdings Group Co., Ltd. China Paper Corporation is the only state-owned company mainly engaged in the forest-pulp-paper business.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our more than 19,000 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet invests in roll cover production in the Columbus service center in the United States

Valmet is investing in state-of-the-art process equipment at its roll service center in Columbus, Mississippi, United States to broaden the scope of process covers being manufactured.

The value of the new investment will not be disclosed. Main equipment installations and commissioning took place during the third quarter 2023 and the new process is currently fully operational.

Valmet inspecting a Press Roll Cover PP – one of the cover types included in the upgrade of the covering operation in Columbus, Mississippi. “This strategic investment shows our commitment to enhance our rubber, composite and polyurethane manufacturing capabilities and strengthens Valmet’s position as an industry leader for roll covers. It also responds to the growing demand for roll services that we have seen with the investments our customers continue to make in North America. Being close to our customers is one of our core commitments,” says Jonathan Demers, Director, Roll Services, North America, Valmet.

Valmet inspecting a Press Roll Cover PP – one of the cover types included in the upgrade of the covering operation in Columbus, Mississippi. “This strategic investment shows our commitment to enhance our rubber, composite and polyurethane manufacturing capabilities and strengthens Valmet’s position as an industry leader for roll covers. It also responds to the growing demand for roll services that we have seen with the investments our customers continue to make in North America. Being close to our customers is one of our core commitments,” says Jonathan Demers, Director, Roll Services, North America, Valmet.

The Columbus service center operates process equipment of the latest technology to increase production and energy efficiency, improve quality, broaden the product portfolio and shorten lead times. The safety and environmental aspect of the processes has also been in focus in the investment. As an example, the covering processes are now conducted in a dedicated climate-controlled room, ensuring zero risks of cross-contamination.

“We now offer our customers a more precise and superior quality casting for polyurethane and composite covers facilitated by the machinery equipped with an accurate data entry interface. This ensures a higher degree of uniformity in the cover’s properties and characteristics. The investment also contributes to enhanced operational consistency, reliability, and flexibility throughout the cover production process to better respond to customer needs,“ says David Williams, Roll Cover Maintenance Technical Unit Leader, North America, Valmet.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our more than 19,000 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet reaches two significant milestones in its Climate Program

Valmet’s Climate Program – Forward to a carbon neutral future – was launched in 2021. The program covers the entire value chain and includes four key targets for the supply chain, Valmet’s own operations and the use of Valmet’s technologies by its customers for 2030. Year 2023 marks two significant milestones for the program.

Carbon neutral production enabled for pulp and paper industry customers

Valmet has estimated that around 95 percent of its carbon footprint originates from the use phase of Valmet’s technologies by its customers and the program emphasizes this part of the value chain with two targets: to enable 100 percent carbon neutral production for all pulp and paper industry customers and to improve the energy efficiency of Valmet’s current technology offering by 20 percent by 2030. Valmet has now reached the first one of these two targets.

Valmet has estimated that around 95 percent of its carbon footprint originates from the use phase of Valmet’s technologies by its customers and the program emphasizes this part of the value chain with two targets: to enable 100 percent carbon neutral production for all pulp and paper industry customers and to improve the energy efficiency of Valmet’s current technology offering by 20 percent by 2030. Valmet has now reached the first one of these two targets.

“When it comes to the first target, we have had excellent progress as we already reached our goal this year. We now offer carbon neutral production opportunities for our pulp, paper, board, and tissue customers, with the precondition that the customer has bioenergy or carbon neutral electricity in use. Carbon neutral production can be achieved by combining the best available technologies, optimizing mill design and selecting the right automation, Industrial Internet and service solutions,” says Janne Pynnönen, VP, R&D at Valmet.

“Among the key innovations in reaching this final stage has been the development of electrical heating of paper and board coating machines, while for tissue machines we have developed a fossil-free alternative for Yankee cylinder and Hood heating,” he continues.

Furthermore, many of Valmet’s customers’ chemical pulp mills using the company’s technologies are bioenergy self-sufficient, enabling carbon neutral pulp production and even selling of excess renewable energy.

“Lime kilns are typically the biggest source of fossil CO2 in pulp mills. Over the years, we have developed and delivered several fossil-free lime kilns based on biomass gasification or wood powder firing,” says Ari Saario, VP, Strategy and R&D, Pulp & Energy at Valmet.

For energy customers, Valmet has already long enabled carbon neutral heat and power production with biomass-based energy solutions.

100 percent carbon neutral electricity purchases reached in Finland and Sweden

In its own operations, Valmet targets to reduce CO2 emissions by 80 percent by 2030. The emissions from fuels, heating and electricity have already been reduced by 50% since the baseline year 2019. A major new milestone will be achieved by end of 2023 as Valmet reaches 100% carbon neutral electricity purchases in Finland and Sweden.

“The impact is significant, as these countries represent 60% of Valmet’s total electricity consumption and about 30% of the company’s total CO2 emissions from electricity usage. Through this, we are saving a total of 32,000 tonnes of CO2 annually, which is equivalent to driving almost 223 million kilometers by car,” says Victoria Larsson, VP, HSE at Valmet.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our more than 19,000 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet introduces a new rotating consistency measurement for pulp and paper producers

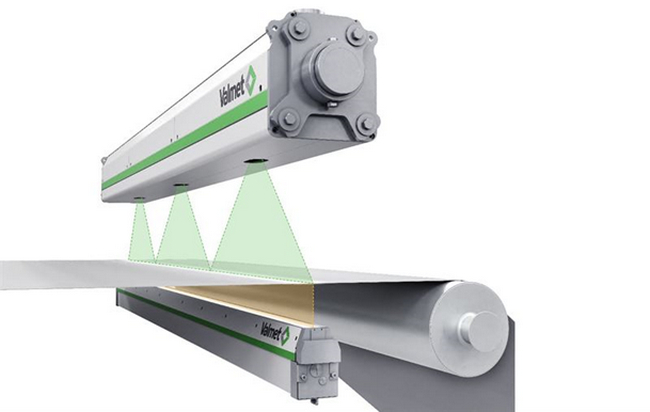

Valmet introduces a redesigned Valmet Rotating Consistency Measurement (Valmet Rotary) for pulp and paper producers. With the latest technology, a new user interface and easier maintenance, the transmitter continues to offer highly accurate fiber consistency measurement for critical applications.

“Built on well-known technology and the long experience, the new measurement is robust and built to last. The patented technology ensures rapid measurement response and fast reaction to consistency variations,” says Sami Laaksonen, Product Manager, Automation Systems business line, Valmet.

Reliable fiber consistency measurement

The redesigned Valmet Rotating Consistency Measurement has a new mechanical design and an electronic solution to improve reliability. Thanks to high sensitivity, the third generation is as accurate as the previous one. The simplified design makes on-site maintenance easier and faster for low overall lifetime costs.

Valmet Rotating Consistency Measurement and Valmet Link user interface

Valmet Rotating Consistency Measurement and Valmet Link user interface

Based on shear force measurement technology, Valmet Rotating Consistency Measurement has excellent performance even in challenging environments with high temperature or pressure and abrasive chemicals. A modular design secures a universal use covering consistency range from 1,5 to 16 percent.

New user interface for enhanced operation

Commissioning, calibration, and operation have been enhanced with a new Valmet Link user interface, a flexible platform with secure remote connection possibilities. With a graphical display and a clear menu structure, set-up and operation are fast and easy. The intuitive user interface and bigger display enable easier calibration and give a better overview of the calibration data. The user interface is prepared for different communication protocols and can be updated for future functionalities.

About Valmet

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet has signed a EUR 175 million loan with European Investment Bank linked to company’s Research and Development activities

Valmet has signed a EUR 175 million loan agreement with the European Investment Bank (EIB). The loan will support Valmet’s Research and Development (R&D) activities to help finance technologies that replace fossil fuels with renewables. The loan agreement is linked to company’s R&D activities in 2023-2026.

The financing aims to enhance the resource and energy efficiency as well as the performance of Valmet’s technology, promote the use of recyclable raw materials and to improve the sustainability of Valmet’s operations. The financing is part of the EIB’s dedicated package of support to REPowerEU — the EU plan to eliminate dependence on fossil fuel imports.

Valmet’s R&D spending was EUR 95 million in 2022. Valmet has 28 research and developments centers around the world and approximately 1,300 protected inventions.

Valmet’s R&D spending was EUR 95 million in 2022. Valmet has 28 research and developments centers around the world and approximately 1,300 protected inventions.

"The aim of Valmet's research and development work is to create new technologies, products and services that address customer needs and help respond to some of the most important global megatrends: enhancing the efficiency of raw materials, water and energy, promoting the use of renewable raw materials and reducing emissions. We’re happy about this loan agreement as it improves Valmet’s readiness to support the green transition in Valmet’s customer industries,” says Janne Pynnönen, Vice President, R&D, Valmet.

About the European Investment Bank

The EIB is the long-term lending institution of the European Union and is owned by the EU Member States. The EIB Group has adopted a Climate Bank Roadmap to deliver on its ambitious agenda to support €1 trillion of climate action and environmental sustainability investments in the decade to 2030 and to devote more than half of EIB finance to climate action and environmental sustainability by 2025. As part of the roadmap, all new EIB Group operations have been aligned with the goals and principles of the Paris Agreement since the start of 2021.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Valmet to supply key pulp and paper technologies to Naini Papers in India

Valmet will deliver key technologies, automation and services to Naini Papers’ cooking and fiberline rebuild and new specialty paper machine PM 3 at their mill in Kashipur, India. The delivery will increase the mill’s capacity and support meeting the market demand of specialty coated paper. The delivery is scheduled for the first quarter 2025.

The order was included in Valmet’s orders received of the second quarter 2023. The value of the order will not be disclosed, but a delivery of this size and scope is typically valued between EUR 40 and 60 million.

“We have been successfully collaborating with Valmet in many projects, including pulp mills, and decided to choose them again for this rebuild expanding our pulp production capacity. The additional pulp will be used in the upcoming PM 3. We see big potential for specialty coated paper in the Indian market and are eyeing the environment-friendly flexible packaging segment. The paper produced by the PM 3 can replace plastics in packages,” says Pawan Agarwal, Managing Director, Naini Papers Limited.

“We’re delighted that Naini Papers chose Valmet again as the supplier of their project. Our sustainable technologies, references, local presence and trust built through the projects and various pilot trials at the Valmet R&D center were the keys to win the order. India is a growing market for specialty grades and Naini Papers has taken the right step forward to be a leading player in this segment,” says Varun Jain, Director, India Region, Asia Pacific, Valmet.

Technical information about the delivery

The cooking and fiberline rebuild targets to increase the capacity from the current 300 bone dry tonnes per day (BD t/d) to 370 BD t/d. The delivery includes key process equipment, such as a SuperBatch digester, a TwinRoll Press, a bleach plant upgrade, and other auxiliary equipment. Basic engineering, detailed process engineering and site services are included. The automation package includes analyzers and measurements for the fiberline, such as Kappa number, brightness, residual chemical, white liquor to cooking and residual alkali, as well as pulp consistency. The spare parts package includes critical spares and consumables for the start-up of the equipment.

The specialty coated paper machine PM 3 is the first of its kind in India, with a design speed of 1200 m/min, producing mainly woodfree coated and uncoated grades with a basis weight range of 40–170 g/m2. The raw material used will be mainly hardwood pulp, with an option to mix bale softwood and precipitated calcium carbonate as filler. The paper machine delivery includes all key technologies from headbox to reel, air systems and winder, as well as Valmet Industrial Internet applications and spare part packages.

Information about Naini Papers Limited

Naini Papers Limited, founded in 1995, is one of the few premier paper manufacturing companies in India. Naini Papers offers high quality writing and printing papers with improved physical and optical properties. Naini Papers is a market leader in producing single layer cup stock for the manufacturing of paper cups and saturating kraft for the manufacturing of laminates.

About Valmet

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com