Ianadmin

Valmet strengthens its presence in Asia Pacific by opening new service center in Indonesia

Valmet has opened a new service center in Cikarang, located 30 kilometers from Jakarta on the island of Java in Indonesia to serve its customers in the Asia Pacific area. The inauguration ceremony was held on September 27th, 2017 and was attended by customers, local authorities and Valmet's management.

"Indonesia and the whole Asia Pacific area is a fast-growing market and Valmet has many big projects ongoing in the area. Establishing a service center close to customers is an important step in strengthening our local presence. We are now able to serve our customers in Indonesia and the Asia Pacific area better than ever before," states Hannu T. Pietilä, Area President, Asia Pacific at Valmet.

Inauguration ceremony at Cikarang Service Center

Inauguration ceremony at Cikarang Service Center

Valmet's Indonesian service center offers services to improve the reliability and performance of the customers' processes in the energy, pulp and paper industries. Through the center Valmet provides its customers also with new technologies to take their production to the next level. The Indonesian service center's range of offering comprises among others roll services, fiber line services, field services, machine section upgrades and improvement projects.

"The Indonesian service center supports Valmet's strategy to be close to customers and growth markets and to move our customers' performance forward in line with Valmet's new services approach called Shared Journey Forward. We can provide significant customer benefits by utilizing our expertise in process technology, automation and services, and by continuously developing our local and remote services," says Jukka Tiitinen, Business Line President, Services at Valmet.

Cikarang. Indonesia Service Center

Cikarang. Indonesia Service Center

The new service center is the latest addition to Valmet's global network of over 100 service centers. The new center employs more than 100 Valmet professionals.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Arjowiggins campaign showcases vibrant colour capabilities of cyclus offset

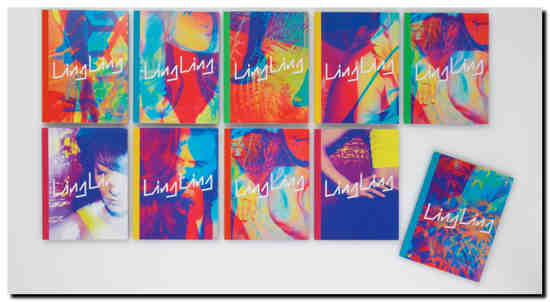

Arjowiggins Graphic and Antalis have today launched a new campaign to showcase the superb colour capabilities of recycled paper. The campaign will see 2,500 brand books from Hakkasan Group’s Ling Ling bar and club concept distributed to printers, designers and corporates highlighting the excellent print capabilities of Cyclus Offset and Antalis’ Digigreen Gloss.

The award winning brand books, designed by North, were originally created to support the global launch of the naughtier and more vivacious sister to Hakkasan restaurants, Ling Ling. Designed to represent the unique and hedonistic atmosphere of Ling Ling, the design featured stand-out bright and beautiful photography, 10 different covers and five different spines with variable text and a high level of vibrant colour.

The book covers have been printed on Digigreen Gloss 350gsm while inside pages feature Cyclus Offset 100% recycled 140gsm. The campaign, which incorporates digital promotion and PR and also features substantial direct mail, with each book accompanied by a personalised card of eight different designs printed on Cyclus Offset 300gsm.

On paper selection, Jeremy Coysten from North Design says: “For the original print run for Ling Ling we used a high gloss laminated cover to achieve a high-end fashion magazine feel, with Cyclus Offset selected for the inside because of its remarkable print performance which allowed us to keep the richness and colour really punchy. The challenge was applying binding tapes to the spine as the glue wasn’t sticking to the gloss lamination so the printer had to sand back the gloss laminate by hand. To overcome the problem for this longer print run we used Digigreen gloss for the cover”.

The book, which was printed by FE Burman using their HP Indigo presses, won Best in Digital Print at the Antalis Review in 2016.

The reprinted radiant books are an excellent demonstration of the high quality colour results recycled materials can achieve. Paul Regan, Director of FE Burman, says: “The mix of print quality of both Digigreen and Cyclus Offset and also the efficiency and technology of the HP Indigo presses, has enabled us to produce a product of excellent quality and colour vibrancy”.

Angela DeVorchik, Operational Marketing Manager, Arjowiggins Graphic UK, says: “We are thrilled to have the opportunity to re-print the award-winning Ling Ling book, and are very proud of the performance of Cyclus Offset in such a demanding colour print project. We’re excited to share the re-printed book with printing and design experts, and to demonstrate the stunning results achieved when using recycled materials in vibrant and colourful printing”

Mike Bennett, Marketing Manger, Antalis UK says: “This is an exceptionally well designed and printed book that truly reflects the character of the brand and how it appeals to its core audience. We’re really pleased with the role our paper plays in achieving the overall quality of the printed product”

Metsä Board celebrates winners in 2017 European Carton Excellence Awards

Metsä Board’s paperboards were used by winners in three categories at the 2017 European Carton Excellence Awards: Food & Beverages, Healthcare & Pharmaceuticals and the Public Award. The Award Gala was held on 21 September in Salzburg, Austria.

“We are delighted that our products have been an integral part of the winning packages. This demonstrates the important part that the packaging plays in creating maximum shelf-impact and can help differentiate a brand from the competition. Sustainability too should be an integral part of the packaging design, so that the packaging is not only made of sustainable materials but it is also lightweight, right-sized, functional and easy to recycle; our products also helped achieve these goals”, states Mika Paljakka, VP Sales EMEA, Metsä Board. “We would like to extend our congratulations to everyone who participated in the vision, design and production of the winning cartons.”

The jury looked for excellence in design, convenience, brand communication and the major role paperboard plays as an innovative packaging material. In total Metsä Board paperboard featured in eight of the finalist packages.

The winning cartons, using Metsä Board products, were the following:

FOOD & BEVERAGES

JDE Z1 Packaging

Carton producer: STI Group

Brand owner: JDE – Jacobs Douwe Egberts

Paperboard: MetsäBoard Classic FBB

HEALTHCARE & PHARMACEUTICALS AND PUBLIC AWARD

Ventofor-Combi Pack

Carton producer: Lithosan Basim Yayim Ambalaj Sanayl ve Tic.

Brand owner: Bilim llac San. ve Tic.

Paperboard: MetsäBoard Pro FBB Bright

Metsä Board

Metsä Board

www.metsaboard.com

Metsä Board is a leading European producer of premium fresh fibre paperboards including folding boxboards, food service boards and white kraftliners. Our lightweight paperboards are developed to provide better, safer and more sustainable solutions for consumer goods as well as retail-ready and food service applications. We work together with our customers on a global scale to innovate solutions for better consumer experiences with less environmental impact. The pure fresh fibres Metsä Board uses are a renewable resource, traceable to origin in sustainably managed northern forests.

The global sales network of Metsä Board supports customers worldwide, including brand owners, retailers, converters and merchants. In 2016, the company’s sales totalled EUR 1.7 billion, and it has approximately 2,500 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Metsä Group

www.metsagroup.com

Metsä Group is a forerunner in bioeconomy utilising renewable wood from sustainably managed northern forests. Metsä Group focuses on wood supply and forest services, wood products, pulp, fresh fibre paperboards and tissue and cooking papers.

Metsä Group’s sales totalled EUR 4.7 billion in 2016, and it employs approximately 9,300 people. The Group operates in some 30 countries. Metsäliitto Cooperative is the parent company of Metsä Group and owned by approximately 104,000 Finnish forest owners

Valmet's new scanner for converting lines lifts process control to a new level

Valmet launches a new scanner, Valmet IQ Converting Scanner, at Labelexpo Europe 2017 in Brussels, Belgium. It complements Valmet's quality management control concept for self-adhesive laminates and other paper and board converting machines.

"With IQ Converting Scanner, we can maximize customer benefits, namely high and stable quality as well as excellent productivity. The solution enables the use of Valmet IQ CD/MD controls to lift process control to a new level for converting lines," says Mikko Talonen, Business Manager, Automation, Valmet.

Valmet IQ Converting Scanner

Valmet IQ Converting Scanner

Valmet IQ Converting Scanner can be easily installed in different process locations, thanks to its innovative sensor support technology. The scanner enables direct adhesive and silicone measurements as well as moisture measurements to be positioned in an optimum process location from a quality and performance point of view.

The new scanner with online measurements enables the utilization of machine and cross-direction controls for moisture, adhesive and silicone in converting machines. These control solutions improve and stabilize the end-product quality, decrease the amount of broke and allow operators to concentrate on quality management and production optimization.

A comprehensive quality management solution for self-adhesive laminate machines

Valmet offers a comprehensive quality management solution for self-adhesive laminate machines. The solution features a wide range of online quality measurements to get accurate and fast information from the process, web inspection and monitoring systems to help detect quality defects and identify their root causes. It also includes a water spray system to control curl and moisture levels, as well as CD/MD controls.

All IQ solution components are based on Valmet's extensive process knowledge and experience in the pulp & paper industry and backed by expert services.

Labelexpo Europe 2017, the largest event for the label and package printing industry in Europe, will be held at Brussels Expo in Brussels, Belgium, on 25-28 September 2017. Valmet will be exhibiting at stand 5D51.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

International Paper to Convert Riverdale Paper Machine

Conversion will Support Customer Growth and Enhance System Flexibility

![]() International Paper has just announced plans to invest approximately $300 million to convert its No. 15 paper machine at the Riverdale Mill in Selma, Ala. from uncoated freesheet to high quality whitetop linerboard and containerboard. The conversion is targeted to be completed by mid-year 2019. The investment will add 450,000 tons of annual capacity, with flexibility to shift between containerboard products.

International Paper has just announced plans to invest approximately $300 million to convert its No. 15 paper machine at the Riverdale Mill in Selma, Ala. from uncoated freesheet to high quality whitetop linerboard and containerboard. The conversion is targeted to be completed by mid-year 2019. The investment will add 450,000 tons of annual capacity, with flexibility to shift between containerboard products.

Converting Riverdale No. 15 will position International Paper to grow its Industrial Packaging business, continue to provide attractive jobs to Riverdale team members and remain a significant supplier of uncoated freesheet in North America.

"Our customers expect us to support their growth and this machine conversion will meet their needs," said Tim Nicholls, IP's senior vice president, Industrial Packaging the Americas. "Our Industrial Packaging business continues to focus on our customers in strategic channels including our box business, domestic and export containerboard and specialty grades."

Nicholls added its Industrial Packaging mill system allows the business to optimize product mix, increase service and reduce costs. "Our system runs most effectively when there is flexibility, and this conversion will also help us define a more streamlined and balanced system overall."

As a result of the machine conversion, the company will reduce its annual uncoated freesheet capacity by 235,000 tons. The remaining machine at the Riverdale Mill will continue to produce uncoated imaging paper products.

"International Paper's uncoated freesheet business remains a strategic part of the company and we are well positioned to support current and future customer demand," said Mike Amick, Jr., IP's senior vice president, Paper the Americas & India. "This investment proactively repositions Riverdale No. 15 to serve our growing packaging business, while enabling us to optimize our North American Papers business."

About International Paper

International Paper (NYSE: IP) is a leading global producer of renewable fiber-based packaging, pulp and paper products with manufacturing operations in North America, Latin America, Europe, North Africa and Russia. We produce packaging products that protect and promote goods, and enable world-wide commerce; pulp for diapers, tissue and other personal hygiene products that promote health and wellness; papers that facilitate education and communication; and paper bags, cups and food containers that provide convenience and portability. We are headquartered in Memphis, Tenn., and employ approximately 55,000 colleagues located in more than 24 countries. Net sales for 2016 were $21 billion. For more information about International Paper, our products and global citizenship efforts, please visit www.internationalpaper.com

SOURCE International Paper

Verso Corporation Board of Directors Forms Strategic Alternatives Committee

Verso Corporation has just announced that its board of directors, as part of its ongoing efforts to maximize stockholder value, has formed a Strategic Alternatives Committee comprised of independent directors Eugene I. Davis, Alan J. Carr and Steven D. Scheiwe, with Mr. Davis serving as chairperson. The committee, with the assistance of Houlihan Lokey Capital, Inc., the company's financial advisor, will lead Verso's continuing efforts to identify and evaluate a range of potential strategic transaction alternatives, including the possible sale of some Verso mills, engage in discussions and oversee the due diligence process with parties potentially interested in transactions with the company, and recommend to the board whether any proposed transaction is in the best interests of the company and its stockholders.

"Verso is committed to exploring strategic transaction alternatives, and the committee will facilitate this process," said Verso Chairman of the Board Rob Amen. "The committee is charged with proceeding expeditiously, but will evaluate alternatives carefully for their ability to provide superior value to Verso's stockholders."

"Verso is committed to exploring strategic transaction alternatives, and the committee will facilitate this process," said Verso Chairman of the Board Rob Amen. "The committee is charged with proceeding expeditiously, but will evaluate alternatives carefully for their ability to provide superior value to Verso's stockholders."

There is no assurance that the review of strategic alternatives will result in any transaction or other strategic alternative. Verso does not intend to make any further disclosure concerning these matters until a definitive transaction agreement is reached or a determination is made that none will be pursued.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery, and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. For more information, visit us online at versoco.com.

FilmLube: Uniform moistening results in improved press felt performance

With FilmLube, Voith is offering a new kind of moistening principle for press felts upstream of the Uhle box. An integrated lubrication gap directly in front of the Uhle box ensures optimum application of water over the entire width of the machine. This protects the felt, ensures a more even CD cross profile and reduces water consumption by avoiding spray mist in the vicinity of the machine. As a result, the safety of machine operators is improved.

More uniform CD moisture profiles, a consistently high felt performance over a record lifetime and the reduction of mist: These were the results achieved by a customer of Voith during the first practical application of the new FilmLube on a tissue machine.

More uniform CD moisture profiles, a consistently high felt performance over a record lifetime and the reduction of mist: These were the results achieved by a customer of Voith during the first practical application of the new FilmLube on a tissue machine.

Previously the customer had used low pressure fan showers for lubricating the felts. However, their nozzles got blocked by dirt easily, preventing uniform moistening of the press felt. As a result of partial heating on the Uhle box, the felt could not perform as designed.

Instead of single nozzles that tend to block, FilmLube features an integrated lubricating gap over the entire width of the machine. This allows an even film application that prevents damage to the felt from hot Uhle box surfaces and reduces CD profile variations. Because the water is applied directly, this also avoids spray losses and cuts water consumption. Generally, on a single-width tissue machine, FilmLube uses less than 1.5 m³ water an hour. The targeted application of water ensures that less lubricating water collects next to the machine, reducing the risk of slipping and making work on the machine safer. The integrated lubricating gap also simplifies maintenance and cleaning of FilmLube.

Above all, Voith's FilmLube also reduces the uneven abrasion of the felt, because moistening upstream of the Uhle box prevents its hot surfaces from damaging the material. In a worst case scenario, such damage – e.g. felt fiber breakage – leads to residues in the paper that necessitate a reduction of the felt lifetime and a variation of the felt changing cycles for individual felt positions. Voith has designed FilmLube so that it can be retrofitted to almost all commonly used Uhle boxes.

About Voith Paper

Voith Paper is a Group Division of Voith and the leading partner and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About Voith

For 150 years, Voith technologies have been inspiring its customers, business partners and employees all over the world. Founded in 1867, Voith today has around 19,000 employees and earns 4.3 billion euros in sales. It has locations in more than 60 countries and is one of the largest family-owned companies in Europe. As a technology leader, Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets.

PCMC announces new 52-inch Fusion C flexographic press

The versatile Fusion C now will be available in 42- and 52-inch web widths

Paper Converting Machine Company (PCMC), part of Barry-Wehmiller and a worldwide leader in the design and manufacture of inline and CI presses, has announced that it will begin to offer its innovative Fusion C press in a new 52-inch web width.

The Fusion C was unveiled at an open house at PCMC in August of 2016, and has only been offered in a 42-inch width up until this point.

PCMC's Fusion C is now available in two widths, both offering customers efficiency and accessibility

PCMC's Fusion C is now available in two widths, both offering customers efficiency and accessibility

“We listened to our customers, and they told us they had a real need for a wider web width in our Fusion C press,” said Rodney Pennings, PCMC’s Printing, Coating and Laminating Sales Director. “Being able to offer a new size of the Fusion C will be a tremendous tool for our customers, and we’re excited that we can accommodate their changing needs.”

The Fusion C is a unique offering in the market because of its accessibility and ease of use. It is loaded with fast make-ready and waste-saving features, and has a smaller footprint and fewer parts—saving customers both space and cost.

ABOUT PAPER CONVERTING MACHINE COMPANY (PCMC)

Paper Converting Machine Company (PCMC) specializes in the design and manufacture of high-performance converting machinery for the tissue, nonwovens and package-printing industries worldwide. Our comprehensive product offerings include rewinding, laminating, printing, embossing, perforating and packaging equipment for tissue and towels; folding and converting machines; and a complete range of flexographic printing presses, serving the flexible-packaging, prime-label and carton-converting industries. For more about PCMC, which is part of Barry-Wehmiller, go to pcmc.com.

ABOUT BARRY-WEHMILLER

Barry-Wehmiller is a diversified global supplier of engineering consulting and manufacturing technology for the packaging, corrugating, sheeting and paper-converting industries. By blending people-centric leadership with disciplined operational strategies and purpose-driven growth, Barry-Wehmiller has become a $2.8 billion organization with more than 11,000 team members united by a common belief: to use the power of business to build a better world. CEO Bob Chapman shares the story of the company’s transformation in his new book, Everybody Matters: The Extraordinary Power of Caring for Your People Like Family. To learn more, go to barrywehmiller.com.

ANDRITZ successfully starts up Fibria’s new pulp mill in Três Lagoas, Brazil

International technology Group ANDRITZ has completed start-up of key production technologies and equipment for Fibria’s new pulp mill in Três Lagoas, Mato Grosso do Sul, Brazil. All ANDRITZ processes were started up successfully on schedule.

ANDRITZ successfully started up a complete pulp mill on schedule for Fibria in Brazil “Photo: ANDRITZ”.

ANDRITZ successfully started up a complete pulp mill on schedule for Fibria in Brazil “Photo: ANDRITZ”.

Fibria’s new pulp mill has a production capacity of 1.95 million tons of eucalyptus pulp per year. Combined with the existing mill at Três Lagoas the total production capacity reaches 3.25 million tons per year, thus making Três Lagoas one of the largest pulp production sites in the world.

With this successful EPC delivery and smooth start-up of the equipment, ANDRITZ has once again demonstrated its outstanding technological capabilities and its proven experience in handling very large projects.

Fibria pulp mill by night Photo: ANDRITZANDRITZ has supplied the following equipment to Fibria’s new pulp mill:

Fibria pulp mill by night Photo: ANDRITZANDRITZ has supplied the following equipment to Fibria’s new pulp mill:

- A complete wood processing plant with four chipping lines each consisting of the world’s biggest horizontally fed HHQ-Chippers with a capacity of 400 m3 solid-under-bark per hour. The scope also includes the chip screening station, chip storage with a round pile stacker-reclaimer, which also provides chips to the first pulp production line, and bark handling. The unique HHQ-Chipper contributes towards providing the highest and most uniform chip quality, which significantly increases fiber yield both in woodyard and in fiberline operations.

- A hardwood fiberline comprising a chip feed system, LoSolids continuous cooking, screen room and bleaching, and eight DD-Washers, which ensure low operating costs, low emissions, extremely high washing efficiency, and excellent fiber quality. The capacity (6,120 adt/d) is the highest in the world for a single fiberline.

- Two energy-efficient pulp drying lines (working width of 8,004 mm and capacity of 3,060 adt/d each) based on the high-capacity Twin Wire Former technology, air borne dryers, cutter-layboy, and five baling lines. The approach system includes a full cascade screening plant and ensures homogeneous pulp feed to the subsequent process stage. The pulp dewatering machine comprises a dilution-controlled headbox, Twin Wire Former, and press section with combi-press and shoe press. The drying plant is designed for a specific plant capacity of more than 380 tons per day and meter of working width, which has been very well proven for ANDRITZ pulp drying plants all over the world. The ANDRITZ airborne dryer is the most energy efficient of its kind. The reliable ANDRITZ cutter-layboy provides the pulp bales to be further processed in the high capacity baling lines, where the final pulp bales are produced.

- The largest black liquor evaporation plant in the western hemisphere (evaporation rate 1,950 t/h), which concentrates black liquor to a dry solids content of 80% for efficient combustion in the HERB recovery boiler. The plant is equipped with the latest of ANDRITZ’s innovations in secondary condensate quality enhancement for 100% reuse in other departments of the mill. Furthermore, the evaporation plant is integrated with the recovery boiler, which has an energy-efficient boiler feed water heating system.

- The largest recovery boiler in Latin America with a peak capacity of 8,250 tds/d. The ANDRITZ HERB recovery boiler is equipped with state-of-the-art combustion technology to minimize the emissions and maximize green energy production. It is capable of burning and destroying all the harmful non-condensable gases and the methanol produced in other process areas of the mill. The HERB recovery boiler supports and provides steam and power for the complete pulp mill and generates a large electricity surplus, which is to be distributed through the national grid.

- Energy-efficient and largest white liquor plant in the world (18,900 m3/d white liquor production), which meets the highest environmental standards and provides top performance and excellent availability under any process conditions. The white liquor plant consists of the single-line recausticizing plant and two lime kilns (840 t/d each), designed to burn oil, natural gas, and syngas.

- In addition, ANDRITZ has delivered a chloride and potassium removal system to enhance the chemical recovery process and a liquid methanol plant for production of biofuel.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors as well as for animal feed and biomass pelleting. Other important business segments include automation and service business. In addition, the international Group is also active in the power generating sector (steam boiler plants, biomass boilers, recovery boilers, and gasification plants) and in environmental technology (flue gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard as well as recycling plants. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 25,400 employees. ANDRITZ operates more than 250 sites in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as the treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboard (MDF), as well as recycling plants are also part of this business area.

About Fibria

The world leader in eucalyptus pulp production, Fibria strives to meet – in a sustainable manner – the growing global demand for products from planted forests. With annual pulp production capacity of 7.25 million tons, the company has industrial units located in Aracruz (Espírito Santo state), Jacareí (São Paulo state) and Três Lagoas (Mato Grosso do Sul state), as well as in Eunápolis (Bahia state), where it operates Veracel in a joint operation with Stora Enso. Fibria has 1,056,000 hectares of forests, which include 633,000 hectares of planted forests, 364,000 hectares earmarked for environmental preservation and conservation, and 59,000 hectares allocated for other uses. The pulp produced by Fibria is exported to more than 35 countries and is the raw material for educational, health, hygiene and cleaning products. For more information please visit www.fibria.com

Mondi Neusiedler receives EN 15593 certification by SQS for its hygiene management system

Mondi Neusiedler recently completed the certification process for food safety management and has been awarded the EN 15593 certification by the renowned Swiss certifier SQS (Swiss Association for Quality and Management Systems).

Meeting customers’ hygiene requirements – every day

Food companies are using the speciality papers and professional printing papers produced at Mondi Neusiedler for their food packaging to combine the excellent print quality, an exceptional environmental profile and highest hygiene standards. The papers are for example converted into bread sleeves, bags, liners, folding boxes or secondary packaging. “For such converting purposes optimal technical paper grades are required and customers can rely on our knowledge and paper qualities,” explains Johannes Klumpp, Marketing & Sales Director Mondi Uncoated Fine Paper.

“Our customers are searching for a reliable partner and peace of mind when buying speciality papers for their food contact applications”, says Klumpp. “The certification fulfils exactly this need to ensure consumer safety as it independently proves Mondi Neusiedler complies with international standards in hygiene management. A quality our customers and end consumers can rely on every day”, he clarifies.

Mondi Group Food Safety Laboratory ensures consumer protection

In its own Food Safety Laboratory Mondi tests smart and customised packaging solutions that are optimised for food contact and support customers in meeting increasingly stringent regulatory requirements.

“We have a responsibility within the food packaging supply chain and are therefore taking part in processes to sustainably ensure consumer protection and guarantee product stewardship”, Klumpp says. “Our team of specialists develop optimised packaging solutions that meet the highest requirements for food contact and other sensitive packaging applications. We also support customers with know-how and solutions to meet increasing regulatory standards for food packaging.”

Combining process and product certifications for consumer safety

Mondi Neusiedler introduced process certification EN 15593 at both production sites and can produce the food contact paper grades according the requirements of the German Recommendation XXXVI (BfR).

Mondi Neusiedler now offers a comprehensive quality, safety and sustainability framework certified according to ISO 9001:2008 (quality management), ISO 14001:2004 (environmental management), OHSAS 18001:2007 (occupational health and safety management), EN 15593 (hygiene management), FSC® and PEFCTM chain-of-custody certifications.

Highest print quality and excellent runnability meet highest hygiene standards

Mondi’s portfolio of professional printing papers encompasses solutions for all modern printing technologies such as digital laser, high-speed inkjet or offset print. They are available in customised formats as reels and folio sheets and are produced under conditions meeting highest hygiene standards. “Food producers can now choose the paper with the shade and texture they like the most and which is ideally suited for their printing presses”, Klumpp adds. Professional printing brands such as Color Copy, PERGRAPHICA®, DNS® premium, DNS® for HP indigo, DNS® color print and DNS® high-speed inkjet, BIO TOP 3®, IQ PREMIUM, IQ SMOOTH, IQ BOARD white, MAESTRO® supreme, MAESTRO® extra, and YBBS® premium white board or even black IQ COLOR and black MAESTRO® color are certified to be used for food packaging.

Sustainable. Every day.

“Sustainability makes good business sense to us and to our customers. This is why we offer papers with impeccable environmental profiles”, states Johannes Klumpp. Mondi introduced the Green Range as an umbrella trademark for sustainable paper and packaging solutions. All Mondi uncoated fine papers belong to the Green Range. They are produced from FSC® or PEFC™ certified wood from sustainably managed forests or 100% recycled paper, or are produced totally chlorine free (TCF). This is how consumers can make a contribution – every day.

We are Mondi: IN TOUCH EVERY DAY

Mondi is an international packaging and paper Group, employing around 25,000 people across more than 30 countries. Our key operations are located in central Europe, Russia, North America and South Africa. In 2016, Mondi had revenues of €6.7 billion and a return on capital employed of 20.3%.

We are fully integrated across the packaging and paper value chain - from managing forests and producing pulp, paper and compound plastics, to developing effective and innovative industrial and consumer packaging solutions. With over 100 products customised into more than 100,000 solutions, we offer more than you may expect. Leading brands around the world rely on our innovative technologies and products across a variety of industries such as agriculture; automotive; building and construction; chemicals and dangerous goods; food and beverages; graphic and photographic; home and personal care; medical and pharmaceutical; office and professional printing; packaging and paper converting; pet care; retail and e-commerce; and shipping and transport.

We believe sustainable development makes good business sense. It's integral to our responsible and profitable growth, and embedded in everything we do, every day. We continue to look for ways to do more with less, promote the responsible management of ecosystems, develop and inspire our people, and enhance the value that our sustainable product solutions create.

Mondi has a dual listed company structure, with a primary listing on the JSE Limited for Mondi Limited under the ticker code MND and a premium listing on the London Stock Exchange for Mondi plc, under the ticker code MNDI. We have been included in the FTSE4Good Index Series since 2008 and the JSE's Socially Responsible Investment (SRI) Index since 2007.

About Mondi Uncoated Fine Paper

Mondi Uncoated Fine Paper is part of Mondi Group. In five paper mills in Austria, Slovakia, Russia, and South Africa Mondi Uncoated Fine Paper produces environmentally sound office and professional printing papers tailored to the latest professional digital print technology. The company complies with the strictest international certification standards to support sustainable production processes through the responsible management of forest, water and air resources. All Mondi uncoated fine papers belong to the Green Range of papers that are FSC® or PEFC™ certified, 100% recycled or bleached entirely without chlorine.

Its renowned brands such as Color Copy, DNS®, IQ, MAESTRO®, NAUTILUS®, BIO TOP 3®, PERGRAPHICA® or Snegurochka are used in office environments on laser or inkjet printers and by professional printers on digital or offset presses to create brochures, transactional material, folders, invitations, business cards, letterheads or other high-impact communication.