Displaying items by tag: Metso Group

Metso to perform replacement of chemical recovery boiler for UBE Chemicals in Thailand

Metso will perform replacement of a chemical recovery boiler for UBE Chemicals in Thailand. With Metso’s solution, recovered chemicals can be combusted more efficiently, creating energy extraction benefits with minimal burden on environment. The total value of the order is above EUR 10 million and will be included in Energy and Environmental Technology’s Q2/2011 orders received.

UBE Chemicals operation in Rayong, south of Bangkok in Thailand, is engaged in the production of nylon from raw materials. In the production process chemicals are released and can be combusted. The Metso delivery provides for an efficient combustion process solution of chemicals, and is based on Metso’s recovery boiler concept used in the pulp- and paper industry. Metso’s delivery brings value and efficiency to the innovative products and solutions UBE Group is offering to customers around the world.

”Our choice in Metso for this project is due to their innovative and efficient skills proven during earlier cooperation”, says Watchara Pattananijnirudorn, Executive Vice President of UBE Chemicals in Thailand. ”Metso has previously performed a similar replacement for UBE Chemicals in Spain when a new combustion plant for chemicals was installed with exceptional results.”

In Thailand Metso is to replace the entire pressure vessel with a new designed incinerator to be situated within the existing structure. The current combustion process will be replaced with a complete and more efficient solution in terms of recovery and end combustion of chemicals. Commercial start-up and take over is scheduled for summer 2012.

UBE Group is a diversified manufacturer with a core focus on the chemical sector. With global presence, UBE’s chemicals can be found in everything from digital electronics and consumer goods to automotive parts and pharmaceuticals. UBE also produces a wide range of products beyond the chemicals sector, supplying useful materials and goods such as cement, building materials and aluminum wheels.

Technical information

The new pressure vessel concept will utilize burners at two levels, were fuels are sprayed into the burning chamber section of the boiler. Combustion air is then added in a three level air system and the air ports are equipped with automatic rodding devices for remote operation. The firing technique is significantly reducing the amount of sodium carbonate carry over in flue gases and heat is recovered in the heat absorbing surfaces consisting of water screens, convection, and economizer. The various heat absorption areas are cleaned by soot blowers. The smelt is discharged to the dissolving tank through the water cooled smelt spout and the spout is designed for automatic rodding by Metso’s DeckHand, an industrial type robot.

Metso to supply off-machine coater main parts for Ilim Group’s Koryazhma Branch mill in Russia

Metso will supply the main components for the coated woodfree paper line’s off-machine coater at the Koryazhma Branch mill of Ilim Group in Koryazhma, Russia. The start-up of the PM 7 off-machine coater is scheduled for the fourth quarter of 2013. The value of the order is approximately EUR 20 million.

Metso’s off-machine coater will be 4-stage, 2-sides, and the delivery will include a ValSizer coating station, an OptiSoft Gloss calender, two energy efficient high-drying-capacity PowerDry Plus gas dryers and a WinDrum winder. The Metso DNA automation system will comprise quality controls, process controls and machine condition monitoring, as well as electric drive and machine controls for the coater and the winder. Metso’s supply will also include a coating color kitchen with ultrafiltration and a StreamLine C roll handling and wrapping machine, serving both the PM 7 paper machine and the coater. The PM 7 will produce uncoated and coated woodfree paper in the basis weight range of 60 to 170 g/m2.

Ilim Group is a leading Russian pulp and paper producer, headquartered in St. Petersburg. The strategic partner of Ilim Group is International Paper, a global leader in the paper and packaging industry. The total annual pulp and paper production volume of Ilim Group is more than 2.3 million tonnes. Ilim Group employs over 20,000 people.

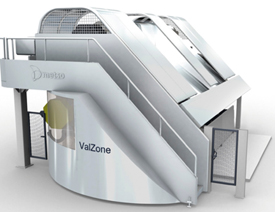

First ValZone metal belt calender for fine paper starts up at Sun Paper Group mill in China.

A Metso-supplied ValZone metal belt calender was started up on the PM 23 fine paper machine of Yanzhou Huamao Paper Industry Co. Ltd., member of Sun Paper Group, in Yanzhou city, Shandong Province, China at the end of April. Earlier the line was operated with a soft calender. The Metso-supplied paper machine has a wire width of 7.85 m and a design speed of 1,600 m/min, and it produces approximately 350,000 tonnes of uncoated fine papers annually.

With the metal belt calender, the line is able to produce top quality printing paper grades with superior feel and visual appearance. The ValZone metal belt calender allows raw material optimization, for instance by allowing an increase in the filler content of the sheet. Also, as a result of increased bulk, the same printing qualities can be reached with a lower grammage.

With the metal belt calender, the line is able to produce top quality printing paper grades with superior feel and visual appearance. The ValZone metal belt calender allows raw material optimization, for instance by allowing an increase in the filler content of the sheet. Also, as a result of increased bulk, the same printing qualities can be reached with a lower grammage.

The delivery is a repeat order of the ValZone technology as Sun Paper Group’s coated board line PM 22 also is equipped with metal belt calendering. The ValZone metal belt calender of PM 23 is the first installation for fine paper grades.

“This start-up is a milestone that brings the metal belt calendering technology into a whole new area of application. It is now for the first time used for printing papers and for the first time in a wide and fast paper machine thus demonstrating that the metal belt calendering technology has a lot of potential with regard to future development,” says Timo Valkama, Senior Paper Technology Manager, Metso’s Paper business line.

Yanzhou Huamao Paper Industry Co. Ltd. belongs to Sun Paper Group, which is one of the foremost paper and board producers in China. Altogether the group runs 22 paper machines mostly producing printing and writing grades with a combined capacity well exceeding 2,200,000 t/y. Sun Paper Group employs more than 7,000 persons.

Metso continues to strengthen its service network - New Metso Service Center at Gainneville, France

Metso has opened a new Metso Service Center in France, at Gainneville in the Normandy area. The new center, which covers 500 square meters of workshop, storage, training and office space, will further enhance  Metso’s service support for local valve customers.

Metso’s service support for local valve customers.

Besides traditional valve maintenance services, Metso Service Centers offer value-added services, such as Criticality Analysis, Valve HealthChecks and Valve Management Solutions. Customer-specific predictive and preventive maintenance programs are also part of the offering at the Gainneville service center.

As in all Metso Service Centers, all repair and overhaul work is carried out according to Metso-defined service procedures, and products leave with certification and a standard warranty.

The Metso Service Centers follow quality and environmental procedures according to ISO9001 and ISO14000- All service personnel at the French service center are ATEX certified. The Metso Service Center at Gainneville will be MASE certified during 2012.

31 service centers globally for valve maintenance

Metso’s strategy is to offer knowledge-based services close to customers’ premises, so its global service network is continuously growing. Today, Metso has 31 service centers globally to safeguard customers’ valve maintenance. Globally, Metso has signed more than 70 Valve Management Agreements with its customers.

Metso to supply containerboard line to Greenpac Mill in the United States

Metso will supply a containerboard production line to Greenpac Mill LLC to their new mill site in Niagara Falls, NY, in the United States. The start-up of the production line is scheduled for the second quarter of 2013. The value of the order is approximately EUR 65 million.

Metso’s delivery will include a complete linerboard machine from headbox to roll handling, including air systems, machine pulpers, a broke collection system and a quality control system. The delivery will also comprise board machine clothing under a long-term agreement. The production speed of the 9.05-m-wide (356.3 in wire) board machine, PM 1, will be 915 m/min (3,000 ft/min). The annual production capacity will be approximately 430,000 tonnes (540,000 short tons) of linerboard in the basis weight range of 97.6–170.9 g/m2 (20–35 lb/ft2), out of 100 % recycled fiber.

Greenpac Mill LLC is a Cascades affiliate. Created in 1997, Norampac, a Division of Cascades, is the largest containerboard producer in Canada and the 6th largest in North America, with nearly 5,000 employees. Today, Norampac operates several containerboard and boxboard mills, corrugated product plants, folding carton plants and a graphic center in Canada and the United States.

Metso advanced process and quality vision system improves quality control at Canfor Pulp Limited Partnership pulp mills

Metso will supply advanced process and quality vision system, Metso PQV, to three Canfor Pulp Limited Partnership’s pulp mills (CPLP) in British Columbia, Canada. Metso PQV is using the most advanced high-resolution, high-speed digital imaging technology available on the market, and will target improvements to the mills’ efficiency and quality control.

Metso will supply advanced process and quality vision system, Metso PQV, to three Canfor Pulp Limited Partnership’s pulp mills (CPLP) in British Columbia, Canada. Metso PQV is using the most advanced high-resolution, high-speed digital imaging technology available on the market, and will target improvements to the mills’ efficiency and quality control.

The new Metso PQV will replace an existing off-line dirt count analysis system. Through faster, more accurate and more efficient detection of defects in the produced pulp, the mills will improve quality control.

“Implementation of the Metso PQV across all four of our fibre lines confirms our commitment to constantly improve our quality to CPLP’s global customers,” stated Joe Nemeth, President and CEO of CPLP.

Metso PQV integrates web quality inspection and web break analysis capabilities. The delivery scope to Canfor Pulp LP includes a dirt count application for full web-length pulp quality analysis.

Metso PQV incorporates high intensity LED-illumination and transmission imaging to analyze the on-line dirt count of the pulp according to TAPPI’s statistical dirt count index significantly improving the dirt count measurement accuracy.

The new systems were delivered in March 2011 and will be fully operational during this Autumn. Total value of the delivery is EUR 1,3 million.

Metso supplies its 300th RM3 retention analyzer to the paper and board industry

Metso, the pioneer in measuring and controlling retention, has reached an important milestone with the delivery of its 300th Metso RM3 retention analyzer to the paper and board industry. It was installed on BM 2 at Stora Enso Imatra Mills’ Kaukopää production unit in Imatra, Finland, in May. The wet end of the machine that produces packaging and graphic grades was equipped with a total of three analyzers for measuring white water consistency of all layers online. The delivery also included two Metso MCA microwave consistency sensors for measuring total consistency after the machine chest.

Metso, the pioneer in measuring and controlling retention, has reached an important milestone with the delivery of its 300th Metso RM3 retention analyzer to the paper and board industry. It was installed on BM 2 at Stora Enso Imatra Mills’ Kaukopää production unit in Imatra, Finland, in May. The wet end of the machine that produces packaging and graphic grades was equipped with a total of three analyzers for measuring white water consistency of all layers online. The delivery also included two Metso MCA microwave consistency sensors for measuring total consistency after the machine chest.

Earlier the white water analyses on BM 2 were carried out in the mill laboratory with water samples taken manually from the production line. Now the RM3 analyzers measure white water consistency online.

“With the help of the new white water consistency measurements, we are able to stabilize retention better than before. This decreases machine fouling, in addition to improving runnability and product cleanliness,” says BM 2 Supervisor Riku Suurnäkki.

Reliable and accurate RM3 is suitable for all monitoring and closed loop control applications. It is the only optical measurement on the market able to measure both true ash consistency and total consistency from a continuous sample flow. It can also be used to measure stock flocculation. Retention and ash controls based on reliable measurements provide excellent tools for enhancing production efficiency, improving quality and lowering production costs in a paper or board production process.

RM3 represents the third generation in Metso’s retention measurement technology, which has become an industry standard. The analyzer’s success is based on over 20 years’ experience in optical consistency measurements as well as on continual, fruitful cooperation with paper and board makers. The analyzers are widely used at paper and board mills and DIP plants around the world.

The Kaukopää production unit is part of Stora Enso’s Imatra Mills with an annual capacity of over a million metric tons of board and paper. Specialized in packaging, paper and wood products, Stora Enso has about 26,000 employees globally. Its net sales in 2010 reached 10.3 billion euros.

Metso’s new cost-efficient valve design

Metso has strengthened its product offering with the addition of a new valve design derived from our traditional V-port segment valve series. The new two-way-tight, single-seat design is suitable for a wide range of applications and is available for R-series valves. The optional two-way-tight feature covers the size range from DN25 up to DN700 (1” up to 28”) in all available pressure classes.

Metso has strengthened its product offering with the addition of a new valve design derived from our traditional V-port segment valve series. The new two-way-tight, single-seat design is suitable for a wide range of applications and is available for R-series valves. The optional two-way-tight feature covers the size range from DN25 up to DN700 (1” up to 28”) in all available pressure classes.

Cost-efficient shut-off

With our V-port segment valve series, we are able to improve process performance and reduce variability in control applications. However, there are a lot of applications where two-way-tight, on-off type performance is required. The customer benefit of the new V-port segment valve design is that it offers the possibility of combining control and on/off performance in a single valve assembly. The standard bi-directional shut-off classifications of the V-port segment valves are according to 10x ISO Rate D / FCI 70.2 Class IV; optional improved tightness classes are ISO Rate D / FCI 70.2 Class V @ dp 20 bar.

Economical solution provider

One of Metso’s paper mill customers installed a DN 600 RE flanged, V-port segment valve in a steam discharge application. In this particular case, low-pressure, superheated steam flows through the two-way-tight valve at 200 deg C. A traditional valve solution for this application would have been a two-way-tight ball valve. However, by selecting the new two-way-tight, V-port segment valve, the customer was able to save 50% on his capital costs.

In pulp mills there are many applications where two-way tightness is required. For example, there are many such valves next to batch– and continuous digesters. In the bleaching department, the on-off valve after the chemical mixer is typically quite large and can require the two-way tightness feature.

Availability of the new two-way-tight option

The two-way-tight option is available for both RA and RE valve series for all standard pressure classes and flange drillings. It is also available in all standard body materials. If there is a requirement for other materials, the local Metso sales office can help.

Metso to rebuild M-real’s board machines at Kyro and Äänekoski mills in Finland

Metso will rebuild two board machines for M-real in Finland: the BM 1 cartonboard machine at the Kyro mill and the BM 1 cartonboard machine at the Äänekoski mill. The start-up of the rebuilt Kyro BM 1 machine is scheduled for the fourth quarter of 2011 and that of the rebuilt Äänekoski BM 1 machine for the second quarter of 2012. The combined value of the orders is over EUR 15 million.

Metso's delivery to the Kyro mill will include a rebuild of the press, dryer and coating sections. In a coating drying rebuild, new energy-efficient high-drying-capacity PowerDry Plus air dryers will be added both to increase drying capacity and to replace old gas infrared dryers. The Kyro BM 1 produces folding boxboard in the basis weight range of 200 to 370 g/m2. After the rebuild, the annual board capacity of the Kyro mill will increase to approximately 190,000 tonnes.

Metso’s delivery to the Äänekoski mill will include a rebuild of the headbox, the coating section and the reel including an automatic parent roll transfer system to the new winder. A new ValFlo headbox and a new WinDrum two-drum winder will aim at capacity increase. The Äänekoski BM 1 produces folding boxboard in the basis weight range of 185 to 360 g/m2. After the rebuild, the annual board capacity of the Äänekoski mill will increase to approximately 240,000 tonnes.

M-real is Europe’s leading primary fiber paperboard producer and a major paper supplier. The company’s customers include brand owners, carton printers, converters, publishers, printing houses, merchants and office product suppliers. In 2010, the company’s sales totaled EUR 2.6 billion, and it has approximately 4,500 employees. M-real is part of the Metsäliitto Group.

Metso to rebuild Hamburger-Rieger’s paper machine in Germany

Metso will supply Hamburger-Rieger GmbH & Co. KG with a rebuild of their PM 1 paper machine at their Spremberg mill in Germany. The start-up of the rebuilt machine is scheduled for the fourth quarter of 2011. The value of the order will not be disclosed.

Metso’s delivery will include a rebuild of the existing pond size press into a film size press and supply of a TurnFloat air turn as well as a PowerDry Plus air dryer for coating drying.

The new film size press with two new applicator beams will enable the mill to produce both surface sized and pigment coated papers. The applicator rolls will be provided with a CoteFalcon cover, suitable for both film coating and surface sizing. Contactless drying with the high-capacity PowerDry Plus air dryer provides the most efficient solution with respect to paper quality and energy consumption. The maximum trim width of PM 1 is 5,300 mm at a production speed of up to 1,200 m/min.

The Spremberg mill of Hamburger-Rieger has been producing white top testliner grades from 100 % waste paper since 2005.

source: Metso Pulp and Paper