Displaying items by tag: metso

Metso’s Board of Directors withdraws the proposal for an extra dividend

Metso Corporation’s Board of Directors has decided to withdraw its proposal for an extra dividend of EUR 0.50 per share for the financial year ended December 31, 2011. The Extraordinary General Meeting planned for October 12, 2012 has consequently been cancelled.

After the Board decision of September 6, 2012 on proposal on extra dividend, Metso made a decision of the restructuring of its paper machine business. Metso has successfully implemented a number of major reorganizations and improved the efficiency of its operations together with its personnel in recent years that have helped make the Group one of the leading technology companies in its field.

Taking this into consideration and in order to support and secure the process to successfully plan and implement the essential restructuring required in the Group's paper machine business and to secure the Group’s long term sustainable performance, the Board has concluded that it no longer believes that an extra dividend is warranted at this time. Withdrawing the proposal is in the Board’s view in the best interests of the company, its shareholders, the personnel and thereby Metso’s overall position and future development.

Metso to adjust its Finnish operations

Metso is to begin statutory employer-employee negotiations on personnel reductions and layoffs in several of its units serving the paper industry and in its paper production service business. Negotiations will cover approximately 4,100 employees at Metso’s Finnish units serving the paper industry. It is estimated that reductions will affect a maximum of around 630 employees, with around 150 positions likely to be outsourced.

“It’s very unfortunate that we are forced to resort to such drastic measures affecting our employees. They are essential to maintain our competitiveness and leading position in a rapidly changing business environment, however,” says Pasi Laine, President of Metso’s Pulp, Paper and Power business. “The negotiations that we are now initiating are aimed at finding solutions to this situation, together with our employees.”

Personnel reductions are necessary because of the need to adjust the manufacturing capacity of Metso’s paper business unit to the permanent structural changes that have impacted the business and weakened its competitiveness and profitability. The main factors here have been the ongoing reduction in in the demand for paper machinery, increasing demand for cheaper solutions, growing competition, and the downturn in demand for foundry products. The general climate of uncertainty in the global economy has also affected the paper industry’s appetite for new investments.

“The gains made by new communications technologies have weakened growth in the consumption of printing and writing paper. As a result, the market for new printing paper machines has slowed, while the demand for more economical medium-sized board machines has continued. This global change in demand means that we must adjust our capacity not only in Finland, but also abroad, including China. The medium-sized machine segment is also of interest to smaller suppliers, which makes competition here particularly tough. We have to be able to produce cheaper, quicker, and more flexible solutions to survive in this market,” says Laine.

The aim of the personnel reductions is to bring production capabilities in line with current and expected demand, and secure Metso’s global competitiveness over the longer term. A lighter operational cost structure and greater flexibility is essential. Outsourcing some operations will also improve Metso’s ability to adapt to changing workloads and focus on its core business.

“The paper industry will continue to be of great interest and importance to us as a business area, despite the slowdown in the printing paper machinery market. Board and tissue consumption is continuing to grow moderately, and Metso’s vast installed base will offer us opportunities to further develop our service business. A lighter cost structure will enable us to compete more effectively in the marketplace,” continues Pasi Laine.

Personnel reductions

The estimated need for reductions at Jyväskylä, Järvenpää, Tampere, Raisio, Juankoski, and Valkeakoski covers approximately 630 people in maximum, with around 150 positions likely to be outsourced. Negotiations will commence immediately and will affect all personnel groups. Reductions are expected to be implemented during the first half of 2013.

Temporary layoffs

The need for temporary layoffs will affect all personnel serving the paper industry at Metso’s locations in Jyväskylä, Järvenpää, Tampere, Raisio, Juankoski, and Valkeakoski, approximately 3,500 employees in all. Negotiations will commence immediately. The exact number of reductions will be determined on the basis of the 2013 production situation and order book.

Targeted savings

The target is to achieve savings of approximately EUR 30 million in annual operational costs as a result of the negotiations. It is estimated that the cost reductions will be implemented in full as of the third quarter of 2013.

Metso Process and Quality Vision system’s new features bring papermakers further improved performance

Metso’s high-selling machine vision system, Metso Process and Quality Vision (Metso PQV) is now available with several new features to further improve runnability and ensure flawless quality for paper makers. These include:

- New Full HD digital matrix cameras allowing more accurate image quality

- Boosted performance in image analysis for the most demanding web inspection

- New superbright flashing LED lights for optimum image quality in all solutions

- Flexible improved user interface to support your operations everywhere

(The latest machine vision technology has been utilized in making improvements and special attention is given to image analysis performance. There is no point in seeing all the defects, but the defects that are important to the user.

(The latest machine vision technology has been utilized in making improvements and special attention is given to image analysis performance. There is no point in seeing all the defects, but the defects that are important to the user.

“Demand for process and quality management solutions is increasing. We are focused to continuously set the technology benchmark on the field and currently over 200 most demanding processes are enjoying the benefits of our process and quality inspection technology. In terms of units, our volume in web break monitoring systems has exceeded 500 camera units annually.” says Sami Riekkola, Director, Machine Vision, Metso Automation.

‘’Since the new camera and image processing standards have now been set, we are already hard at work developing and preparing for new features to our systems. Through our service coverage we are simultaneously ensuring consistent maintenance and development of the installed base.’’ he continues.)

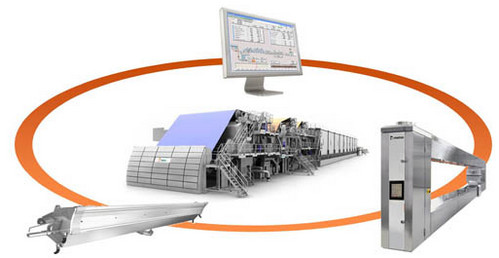

Metso Process and Quality Vision

Metso Process and Quality Vision (Metso PQV) combines web break analysis and web inspection system functions into one comprehensive solution that utilizes the same digital image capture and processing technology for both.

It integrates web break analysis capabilities and web quality inspection using high-frequency camera images to produce a continuous view of the moving web. Three different geometries are typically used in web inspection system installations. Transmission geometry is used to detect flaws in the sheet, high angle geometry is used for surface defects and low angle geometry is used to detect coating imperfections.

The web break analysis camera images and web inspection information are combined into a common operator interface. This allows the operators to detect key quality faults at well-defined CD and MD locations in the paper web and to track their origins in the process. (www.metso.com/machinevision)

Improved Metso IQ takes end product quality to a new level

Global market leader in quality control solutions introduces a number of new features

Metso is now bringing a new Metso IQ quality control system with a number of new features to improve the paper making process and guarantee optimal end product quality.

New surface and structure measurements provide on-line information from porosity and fiber orientation to printability prediction.

The system also features a new optical caliper measurements based on blue-ray technology and color measurements for tissue to complete Metso´s unique nuclear-free tissue concept with Metso IQ Fiber measurement.

To offer wider scalability to various needs Metso also introduces the new Metso IQ Fixed Point C-frame and stand-alone Metso IQ Scanner. New measurements together with new multivariable quality controls and Metso IQ Profilers form the industry’s most complete portfolio of quality management solutions.

Metso IQ goes far beyond the traditional Quality Control System. As recognition of its capabilities Metso’s solution has been selected to replace a number of competing solutions during the last years, making Metso the global market leader in quality control solutions in 2012.

Metso IQ

Metso IQ is a combination of intelligent scanning, high-speed quality measurements, robust multivariable controls and the analysis toolbox unleashes a set of diagnostic capabilities that alert the operators to potential sources of problems and provides them with the necessary information online so they can run the machine better.

Jari Almi, Director of QCS, explains: ‘’ The Metso IQ solution provides value down the line, from raw material to finished product, allowing our customers to accurately optimize and ensure the optimal end product quality. This attention to detail helps paper makers reduce broke and provides raw material savings, resulting in considerable added value and a rapid return on investment across the entire lifecycle of the Metso IQ solution. At the same time, when the production process is truly optimized, the plant’s energy consumption will also be reduced creating additional savings in both monetary and environmental terms.’’

Metso’s state of the art transmitter technology contributes to the efficiency and profitability of Chinese paper mills

Recently, Metso has won several measurement orders from Chinese paper mills, like Jiangsu Jinhuang Paper Co., Ltd, Hebei Changtai Paper Industry Co., Ltd, Anhui Huatai Forest Pulp & Paper Co., Ltd, Guangdong Huatai Paper Co., Ltd, and Wuhan Jin Feng Huang Paper Industry Co., Ltd.

Metso has contracted with the Anhui Huatai Forest Pulp & Paper Co., Ltd. on the delivery of a dozen consistency transmitters, one of them being a Metso OC, an optical consistency transmitter. The upcoming delivery for the rebuilding of a pulp factory also includes several Metso SP (blade) and Metso Rotary transmitters, as well as equipment for cooking liquor measurement, among other things.

The Jiangsu Jinhuang Paper Co., Ltd. has ordered several Metso SP (blade) transmitters for a greenfield factory. A further customer for another greenfield project is the Hebei Changtai Paper Industry Co., Ltd. for whom a linerboard project as well as a plasterboard paper machine will be delivered. The Wuhan Jin Feng Huang Paper Industry Co., Ltd. is also among the recent major customers, making an order for two new board machines PM3 and PM5, as well as 16 Metso SP consistency transmitters. All the orders from the Chinese papermaking industry companies are due to be delivered in the autumn of 2012.

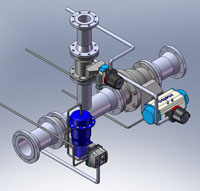

Inline consistency measurement has never been easier

The Metso optical consistency transmitter is a new member in the family that uses state of the art technology with a new design, offering reliable measurement at all times. In mechanical pulping (e.g. TMP, GW and CTMP) typical applications are grinders, cyclone cleaners, latency removal, screening, and low consistency refining. In chemical pulping, the new transmitter can be used for screening, washing, refining, and drying machine applications.

Inline consistency measurement has never been easier – the Metso OC employs the latest electronics technology with multiple optical fiber channels, using a single light source and optimal probe design for reliable measurement. Installation is simple and safe. Inserting and retracting the measurement probe is safe and easy, even in high process pressure. The Metso OC can be calibrated with just one laboratory sample. No regular maintenance is needed – the entire transmitter-related cost remains low.

Follow link to Metso Optical Consistency Transmitter pages on Automation's web

Metso's breakthrough in optical caliper measurement

The new Metso IQ Optical Caliper sensor offers improved accuracy on low opacity papers

All papermakers can now benefit from improved runnability with confidence in quality provided by the sub-micron profile accuracy of the new Metso IQ Optical Caliper measurement.

The new sensor has been operating for several months at a leading Scandinavian mill with no problems on low opacity papers. Janne Sällilä of Metso, says, “The  conventional laser penetrates deeply into the siliconized paper. The customer wanted to measure the total caliper of both fibers and silicon together. This new sensor provided the answer and the mill reports much smoother profiles. Its self cleaning head has also provided a maintenance advantage over the previous sensor which had to be cleaned regularly. ”Mills producing low opacity grades such as greaseproof paper can now take advantage of a new development in optical caliper measurements by Metso.

conventional laser penetrates deeply into the siliconized paper. The customer wanted to measure the total caliper of both fibers and silicon together. This new sensor provided the answer and the mill reports much smoother profiles. Its self cleaning head has also provided a maintenance advantage over the previous sensor which had to be cleaned regularly. ”Mills producing low opacity grades such as greaseproof paper can now take advantage of a new development in optical caliper measurements by Metso.

Optical measurements have become accepted technology to avoid the sheet pinching effect experienced with contacting caliper measurements; but due to the conventional measurement technology, light penetration of the sheet can undermine accuracy with low opacity or porosity grades.

Metso has been quick to take advantage of the latest developments in new technology that through the improved light scattering of the shorter wavelength light, and new detection technology, eliminates errors due to light penetration. As there are no pinching parts that could cause holes or sheet breaks.

IQ Optical Caliper combines two accurate measurement techniques. The magnetic principle is used to measure the distance of the optical measurement to a reference plate while the non-contacting optical principle measures the distance to the paper surface. Paper thickness is reached by subtracting these individual measurements from each other. As well as the use of the blue light source (patent pending) to solve light penetration problem, the new self cleaning construction of the sensor head (patent pending) eliminates one further difficulty experienced with conventional laser sensors.

Metso IQ is a combination of intelligent scanning, high-speed quality measurements, robust multivariable controls and the analysis toolbox unleashes a set of diagnostic capabilities that alert the operators to potential sources of problems and provides them with the necessary information online so they can run the machine better.

Metso signs global agreement with Swedish Huhnseal for supplying Metso-branded mechanical seals

Introducing SealMax is in line with Metso’s ambition to expand its scope of supply. The two companies have initiated the development of tailor-made mechanical seals for Metso equipment, such as MC pumps, mixers, agitators, pulpers, screens and LC refiners. These sealing solutions will be available for new projects and also as upgrades for existing equipment. Huhnseal already have solutions for most standard applications in the pulp and paper industry. These solutions will now be sold and marketed globally through Metso.

Mechanical seals are critical components in many types of rotating equipment and are therefore often given a high priority in the maintenance strategy. “Adding SealMax seals to our offering gives us in Metso the opportunity to work even closer with our customers. By combining the product and application know-how of Metso and Huhnseal, we can offer solutions with improved overall performance and thus save money for our customers,” says Björn Kempe, Business Manager, Service Agreements, Metso.

“Huhnseal and Metso have cooperated for more than 10 years. Huhnseal has a vast experience of supplying Metso with standard and special sealing solutions for its heavy-duty applications,” says Per Hellman, CEO of Huhnseal. “This partnership is in line with our strategy to grow on a global scale. Huhnseal will provide product and service support to Metso via both our central as well as local resources around the world and continue with our ambition to supply the optimal sealing solution for each application.”

Huhnseal is a global supplier of mechanical seals for the process industry and is headquartered in Landskrona, Sweden. The company has R&D, product development, manufacturing and sales functions, all under one roof. Huhnseal is part of the Italian Meccanotecnica Umbra Group.

Metso introduces new energy-saving roll cover for boardmaking

Metso has launched PressPolar, a new polyurethane roll cover for press rolls. The cover is suitable for large and highly loaded press rolls, mainly used in boardmaking. The PressPolar cover is designed to significantly reduce the energy consumption of roll drives in the press section.

Metso has launched PressPolar, a new polyurethane roll cover for press rolls. The cover is suitable for large and highly loaded press rolls, mainly used in boardmaking. The PressPolar cover is designed to significantly reduce the energy consumption of roll drives in the press section.

New polyurethane material offers low rolling resistance

The roll drives in press sections consume remarkable amounts of energy, and also the soft roll covers on roll bodies greatly influence energy consumption. The rolling resistance of a roll cover is what affects the drive power consumption. In the PressPolar roll cover, due to the new polyurethane material, the rolling resistance is remarkably lower than that in conventional rubber and polyurethane roll covers. In addition, a roll with a PressPolar cover needs no internal water cooling. These features provide significantly reduced energy consumption.

Development of durable and long-lasting cover materials continues

Polyurethane roll covers have been well-known for their good wear resistance properties for decades. Metso continues the development in this field and the PressPolar cover offers the best durability ensuring extended service intervals and longer total roll cover lifetimes.Metso-supplied spray sizing unit successfully started up at Papierfabrik Schoellershammer in Germany

Metso and Papierfabrik Schoellershammer have together succesfully started up Europe’s first spray sizing unit for the mill’s swing testliner and recycled fluting machine, PM 5, located in Düren, Germany. The new two-sided spraying unit was installed in an existing pond size press, originally delivered by Metso in 2005. After the start-up on May 12, 2012, the production line has produced sellable paper from day one and has since been able to successfully produce its full product range with the new equipment.

“This is a big step forward in terms of runnability. Thanks to higher solids we can now also use increased starch amounts without compromising production capacity. We foresee considerable savings in steam consumption as well,” says Konrad Franken, Production Manager at Papierfabrik Schoellershammer.

The 5-m-wide PM 5 produces testliner and fluting grades in the basis weight range of 90-170 g/m2 at the maximum production speed of 1,100 m/min.

Metso has been developing the spray sizing technology for several years, and the work has its foundations in Metso’s long tradition with film sizing, water sprays and earlier spray coating developments. The technology is protected by several international patents and applications. In 2008 Metso started up the first one-sided prototype unit of spray sizing for fluting in Korea. Since then the company has delivered five spray sizing projects in total in Asia, three of them with two-sided spray. “We see that spray sizing is clearly the future method for surface sizing of containerboards and it has potential benefits in other applications as well,” says Topi Tynkkynen, RTD Project Manager at Metso. Spray sizing has a major role in Metso’s new OptiSizer family, to be launched to the market in 2012.

Papierfabrik Schoellershammer, located in Düren, Germany, produces testliner and fluting board grades from 100 % recycled paper 220,000 tonnes a year and high-quality specialty papers 6,000 tonnes a year. The company has a good market position in their main market area in Europe. The family-owned company employs a total of 230 persons.New RapidDraw3D™ Valve Model Generator from Metso

Metso's new RapidDraw3D Valve Model Generator is a free automated valve assembly model generator that allows users to quickly create realistic, to-scale, 3D valve assemblies and export them to any CAD program for use in plant piping diagrams.

Metso's new RapidDraw3D Valve Model Generator is a free automated valve assembly model generator that allows users to quickly create realistic, to-scale, 3D valve assemblies and export them to any CAD program for use in plant piping diagrams.

According to Bruce Weetherbee, Metso's Sr. Engineering Manager, "Drawing simple boxes to represent sophisticated valve assemblies in the CAD program leaves a lot of unanswered questions, such as: Which components? What's the scale? Where are the electric, air, or pneumatic connections? RapidDraw3D is a better solution that assures that these important questions are clearly answered."

RapidDraw3D is easy to use- simply choose the desired Metso valve and actuator. RapidDraw3D automatically displays the linkage available for that combination, allowing the user to then specify the orientation of the actuator and pick accessories such as positioners, solenoids, etc.

The final step is selecting the appropriate file output based on the user's CAD program (PDF, AutoCAD, SolidWorks 2D, SolidWorks 3D, DXF, STEP, IGES, Parasolids, etc..) A realistic 3D rendering can then be downloaded from the Internet for import into the chosen CAD program. These 3D files stay on the RapidDraw3D server for 90 days so they can be modified and retrieved easily.

For free access to RapidDraw3D: http://www.RapidDraw3D.com to register, and start using the program right away.