Again and again, coating units are affected by damaged hoses, resulting in hose changes and rather long unplanned downtimes of the paper machine due to inaccessible clamping areas for the metering unit. With the new SpeedRod M metering-rod bed generation, damaged hoses can be avoided to a large extent thanks to simple, preventive checks. In addition, the time needed for an unplanned hose change is reduced by more than 90%.

Again and again, coating units are affected by damaged hoses, resulting in hose changes and rather long unplanned downtimes of the paper machine due to inaccessible clamping areas for the metering unit. With the new SpeedRod M metering-rod bed generation, damaged hoses can be avoided to a large extent thanks to simple, preventive checks. In addition, the time needed for an unplanned hose change is reduced by more than 90%.

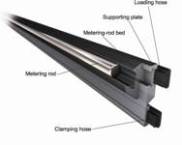

The supporting plate is the integrated holder for metering rod, clamping and loading hoses and can be used repeatedly. Clamping and loading hoses are identical: ready-to-use and pressuretested hoses with end areas additionally secured against overload by shrink hoses. The new metering-rod bed design provides the following advantages for the papermaker: The individual components can be checked preventively and replaced outside the coating unit, if required. Production losses in case of damaged hoses are reduced to a minimum, since a hose change only takes five minutes (instead of e.g. 60 minutes with the previous system). Only one hose type is used both for clamping and loading. Thanks to ready-to-use, pressure-tested hoses, downtimes are reduced. The metering-rod bed is a wear part and can be exchanged independently of the supporting plate.

Conclusion: SpeedRod M reduces the time needed for changing a hose to five minutes. In addition, unplanned changes can be avoided to a large extent by easy, preventive checks of the hoses.

Published in

Featured Products

Tagged under