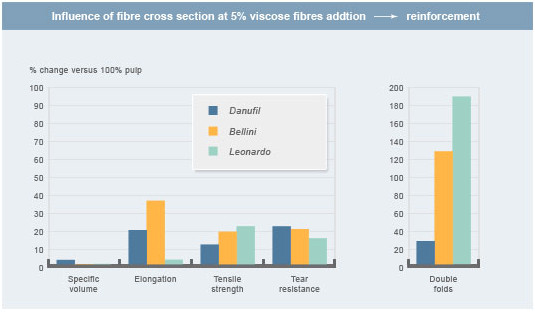

In wetlaid nonwovens or paper applications, good bonding properties of the fibres bring advantages for the strength of the web. Due to their large surface area and their high flexibility, fibres with flat cross-sections display very good bonding properties - our Bellini fibre is an excellent example.

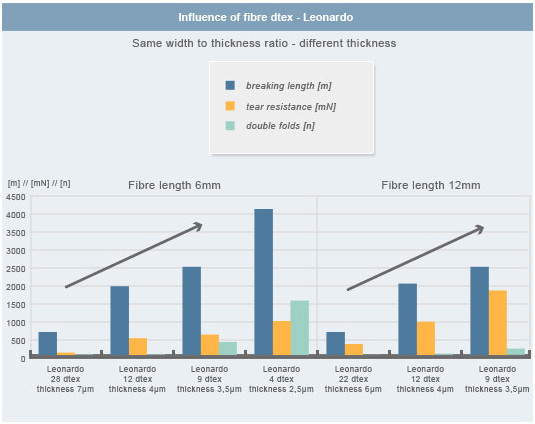

The extremely flat and smooth structure of our Leonardo fibre with its width to thickness ratio of 40:1 and its extremely regular and flat fibre surface not only facilitates good fibre-fibre bonding; it also makes the fibre highly transparent, allowing for the production of wetlaid nonwovens and papers with improved transparency.

The extremely flat and smooth structure of our Leonardo fibre with its width to thickness ratio of 40:1 and its extremely regular and flat fibre surface not only facilitates good fibre-fibre bonding; it also makes the fibre highly transparent, allowing for the production of wetlaid nonwovens and papers with improved transparency.

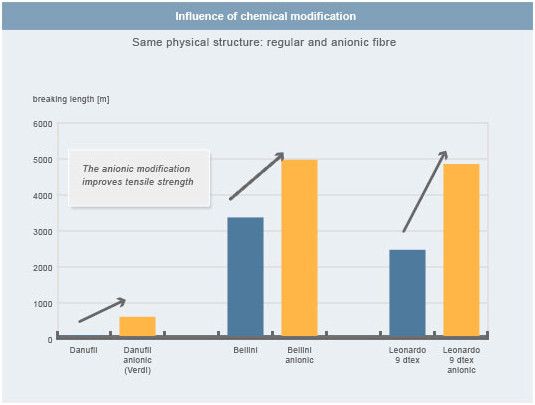

By the choice of the appropriate fibre cross-section, by chemical modification and by the selection of the right cut-length, our customers can achieve improvements in tensile strength, folding properties and other nonwoven parameters - and by adding Leonardo to our range of products we made the choice even wider for you. Don't forget: only small amounts of viscose fibres can improve your product significantly!