Displaying items by tag: Kelheim Fibres GmbH

Kelheim Fibres welcomes EU agreement on deforestation-free supply chains

The renowned viscose fibre manufacturer Kelheim Fibres welcomes the preliminary political agreement reached between the European Parliament and the Council on an EU regulation on deforestation-free supply chains, which was adopted at the end of 2022. The new rules are intended to prevent goods that cause forest degradation or deforestation from being placed on the EU market.

As one of the largest economies worldwide, the EU is a major consumer of wood-based raw materials. Therefore, the new law can significantly contribute to reducing global deforestation and forest degradation as well as protecting threatened forest areas.

As one of the largest economies worldwide, the EU is a major consumer of wood-based raw materials. Therefore, the new law can significantly contribute to reducing global deforestation and forest degradation as well as protecting threatened forest areas.

“Wood is an incredibly versatile and valuable renewable resource and the basis for countless products. Our viscose fibres are just one example – they offer an environmentally friendly alternative to synthetic materials in various applications and are thus a promising material for the future. Of course, this only applies if the production of our raw materials does not take place at the expense of our earth's natural forest resources. These forests are a bastion of biodiversity and climate protection for our entire planet and must be protected at all costs. No one can escape this responsibility," says Craig Barker, CEO at Kelheim Fibres.

Therefore, Kelheim Fibres has been exclusively using FSC® or PEFCTM certified pulps exclusively from sustainably managed sources for many years and has received a top spot in the HotButton ranking three times in a row. This ranking is compiled annually by the Canadian NGO Canopy that campaigns for the preservation of ancient and endangered forests.

About Kelheim Fibres Kelheim Fibres GmbH is the world’s leading manufacturer of viscose speciality fibres.

Innovative products, flexible technologies and an exceptional focus on sustainability form the foundation of the company’s success.

Our speciality fibres are used in most diverse applications from fashion, hygiene and medical products to nonwovens and speciality papers.

All our fibres are made from 100% wood pulp from PEFCTM or FSC© certified sources. They are fully biodegradable and offer an environmentally sound alternative to petroleum-based materials in a broad range of different end products – while maintaining or even enhancing the functional performance of the product.

The production takes place exclusively in Germany and complies with the strict German environmental legislation. Our closed-loop philosophy and an energy-efficient way to operate our plants help to save valuable resources. Kelheim Fibres is the first viscose manufacturer worldwide with an EMAS-validated environmental management system.

www.kelheim-fibres.com

Responsible Care: Kelheim Fibres scores high points with Flushable Moist Toilet Tissue and Integrated Product Policy

Kelheim Fibres was pleased to claim the Recognition Award in the Responsible-Care-Competition 2017 of the Bavarian branch of VCI (Association of the Chemical Industry e.V.) for its integrated product policy.

The topic of the competition was "The Closed Circle Econom" relating to the areas of environmental protection, product responsibility and dialogue in respect of Responsible Care.

Kelheim Fibres, world-leading manufacturer of viscose speciality fibres, scored high points with their viscose short cut fibres VILOFT®, specifically developed for the production of increasingly popular moist toilet tissue; worldwide, the demand in this segment is increasing significantly. In contrast to traditional (spunlace) wipes, wet wipes made of Kelheim’s VILOFT® short cut fibres disintegrate rapidly and prevent the blockage of pumps in the waste water system.

Again, in contrast to commercially available standard products, these wipes are completely biodegradable.

Kelheim’s short cut viscose fibres therefore offer an enormous potential for savings with regard to energy and maintenance costs for regional waste water operations. At the same time, they offer a solution for the growing issue of increased pollution of water by micro plastics - a huge benefit for the environment

This fact convinced the independent jury of experts, who judged the projects submitted by their quality, creativity, impact and exemplary character. The citation for VILOFT® states: „This project impresses with the integrated product policy outlined: Even at the product design stage the focus is on the complete system. A bio-persistent material is being replaced. This prevention of waste and residual materials results in a Germany-wide saving potential in municipal infrastructures.“

Kelheim Fibres‘ Business Manager Horst Wörner is pleased: We have been pursuing the topic Flushability for years. With our VILOFT® fibre we offer the solution that has been sought by waste water authorities for years. Unfortunately, the dimensions of the problem and the corresponding saving potential is not universally known yet.

This Responsible-Care-Award confirms that we are on the right path and I hope it helps to create more awareness at the consumer level.“

Kelheim Fibres further strengthens its speciality fibre business

Forward-looking investment despite a difficult market environment: Kelheim Fibres further strengthens its speciality fibre business

Kelheim Fibres, Bavarian manufacturer of viscose speciality fibres, steadily continues to implement their innovation strategy. This is further confirmed by the expansion of production line 1 for the production of wet tow and wet short cut fibres in addition to the current capability of dry tow and therefore dry short cut fibres.

Kelheim Fibres, Bavarian manufacturer of viscose speciality fibres, steadily continues to implement their innovation strategy. This is further confirmed by the expansion of production line 1 for the production of wet tow and wet short cut fibres in addition to the current capability of dry tow and therefore dry short cut fibres.

With this investment, Kelheim Fibres is extending its short cut capacity by further 2000 tons per year and will be in a position to deliver even more flexibility when it comes to a rapid reaction to specific customer demands.

“In the currently difficult market environment, this investment in our plant is a clear statement”, so says Sebastian Basel, Kelheim Fibres’ Business Manager for short cut fibres. “Today, we are the only European manufacturer of short-cut viscose fibres for paper applications, of dry tow for stretch- breaking and of wet tow – and in the future, the name Kelheim Fibres will stand even more for innovative speciality fibres. The conversion of our line 1 is a major step towards our goal of increasing the share of speciality fibres in our portfolio to more than 80%. And we remain fully focused on that goal.”

With this investment and the expanded capacity for the production of short cut fibres, Kelheim Fibres intends to meet the rapidly growing demand for modern, tailor-made filtration products, and score points in the hygiene Industry, particularly when it comes to flushability. Here, Kelheim Fibres further benefits from its long-standing position as world market leader for hygiene fibres for tampons.

Kelheim Fibres GmbH is the world’s leading producer of viscose speciality fibres and the most important supplier of viscose fibres for the tampon industry.

Approximately 90,000 tons of viscose fibres are produced and tested every year at Kelheim in South Germany. These are used in most diverse applications – from fashion, hygiene and medical products to nonwovens and speciality papers.

Innovative products, flexible technologies and a strong customer orientation form the foundations of the company’s success.

For further information, please contact:

Matthew North Commercial Director Kelheim Fibres GmbH Tel: +49 (0)9441 99-368

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Kelheim Fibres GmbH Acquires FR Fibre Technology from Bankrupt Avilon

In line with its strategy of continued specialisation, Kelheim Fibres GmbH, the world's leading producer of speciality viscose fibres, has reached an agreement with the bankrupt Finnish fibre company Avilon for the acquisition of knowhow and technology for the production of flame retardant viscose staple fibres, previously marketed under the Visil name.

In the late 1990s, operating as Saeteri, Avilon pioneered the production of such fibres designed to meet the requirements in place for furnishings in the American market. Matthew North, Commercial Director of Kelheim Fibres GmbH, comments: "The US market has become dependent on supply of FR viscose fibres from China. The agreement we have reached will allow us to finalise development of FR fibres based on the knowledge and experience of the historical market leader and offer a reliable, high-quality alternative to Asian sources".

Initial production trials at Kelheim with the support of Avilon technicians were completed successfully in April 2013 and the fibres are currently undergoing testing. It is expected that

samples of the new fibre will be available for customer tests by early May 2013.

Kelheim Fibres GmbH will be showing its full range of speciality viscose fibres at the IDEA International Engineered Fabrics Exhibition in Miami, USA from 23. to 25. April 2013.

Global Specialty Cellulose Market: Trends & Opportunities (2012-2017)

Researchandmarkets.com has announced the addition of the "Global Specialty Cellulose Market: Trends & Opportunities (2012-2017)" report to their offering. (link below)

The unique physical and chemical properties of specialty cellulose make it a catalyst to enhance the performance of product in various applications. Produced from the naturally occurring cellulose in plants, specialty cellulose is used in wide variety of end applications such as production of textile, pharmaceuticals, LCD films, coating and various other FMCG products. It is mainly used in its derived form of ether, acetate, high strength viscose and nitrocellulose.

While the specialty cellulose industry is characterized by huge capital investment and technological advancements, potential opportunities in the market makes it a highly lucrative proposition. As a result, companies operating in this market opt for huge investments in innovation as well as expansion.

The report titled Global Specialty Cellulose Market: Trends & Opportunities (2012-2017) analyzes the worldwide growth of specialty cellulose. The report also analyzes the three major segments of the specialty cellulose market - Cellulose Acetate, Cellulose Ethers and High Strength Viscose. The end-market application of Cellulose Acetate, Cellulose Ethers and High Strength Viscose has been presented in the report.

Further, the report also assesses the key growth drivers and challenges faced by the global specialty cellulose market and the future growth of the industry. Michael Porter's Five Forces Analysis has been done to highlight the various internal and external factors influencing the Specialty cellulose industry. The report also profiles the key players - Rayoneir, Buckeye, Tembec, Sappi, and Borregaard and provides an insight to the business strategies followed by them.

Key Topics Covered:

1. Executive Summary

2. Understanding Specialty Cellulose Market

3. Global Specialty Cellulose Market - Sizing and Segmentation

4. Global Cellulose Acetate Market - Sizing and Growth

5. Cellulose Ether Market - Sizing and Growth

6. High Strength Viscose Market (By Capacity, Actual and Forecast)

7. Global Specialty Cellulose Market: Drivers & Challenges

8. Global Specialty Cellulose Market - Michael Porter's Five forces Analysis

9. Company Analysis

Companies Mentioned

- Borregaard

- Buckeye

- Rayoneir

- Sappi

- Sateri

- Tembec

For more information visit http://www.researchandmarkets.com/research/km7pkx/global_specialty

source: Fort Mill Times

The perfect design of viscose fibres for wetlaid nonwovens

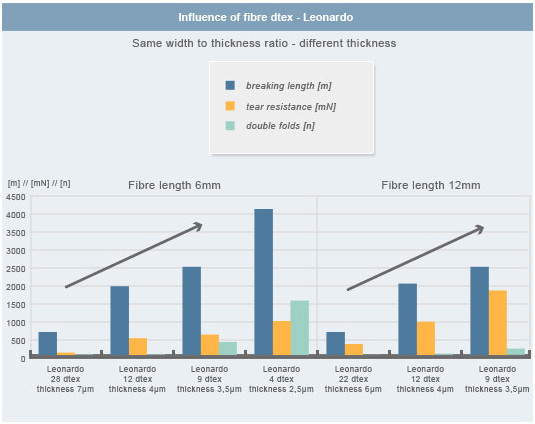

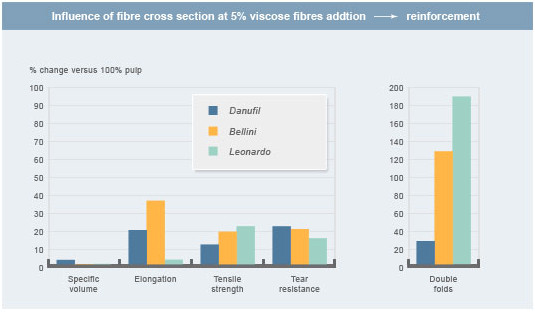

In wetlaid nonwovens or paper applications, good bonding properties of the fibres bring advantages for the strength of the web. Due to their large surface area and their high flexibility, fibres with flat cross-sections display very good bonding properties - our Bellini fibre is an excellent example.

The extremely flat and smooth structure of our Leonardo fibre with its width to thickness ratio of 40:1 and its extremely regular and flat fibre surface not only facilitates good fibre-fibre bonding; it also makes the fibre highly transparent, allowing for the production of wetlaid nonwovens and papers with improved transparency.

The extremely flat and smooth structure of our Leonardo fibre with its width to thickness ratio of 40:1 and its extremely regular and flat fibre surface not only facilitates good fibre-fibre bonding; it also makes the fibre highly transparent, allowing for the production of wetlaid nonwovens and papers with improved transparency.

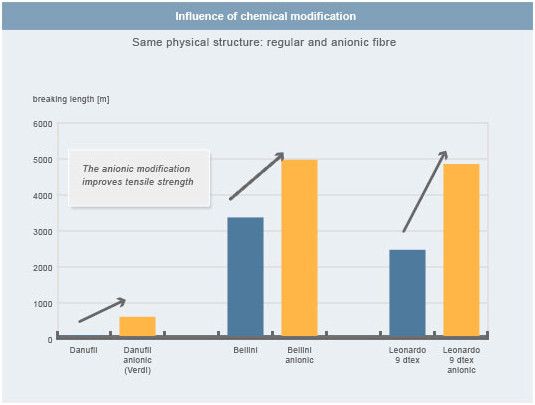

By the choice of the appropriate fibre cross-section, by chemical modification and by the selection of the right cut-length, our customers can achieve improvements in tensile strength, folding properties and other nonwoven parameters - and by adding Leonardo to our range of products we made the choice even wider for you. Don't forget: only small amounts of viscose fibres can improve your product significantly!

Viscose speciality fibres from Kelheim accepted into Material ConneXion’s library of innovative materials

Three of Kelheim Fibres’ new viscose fibre specialities have been assessed by a panel of creative professionals and have been accepted into Material ConneXion’s library of innovative materials – the world’s largest library of this type.

Three of Kelheim Fibres’ new viscose fibre specialities have been assessed by a panel of creative professionals and have been accepted into Material ConneXion’s library of innovative materials – the world’s largest library of this type.

The fibres Verdi, Danufil® Deep-Dye and Microfine as well as product samples made of these fibres are now displayed in Material ConneXion’s nine locations around the world.

In this library, which features more than 7,000 cutting-edge materials, including the largest selection of sustainable materials, designers and manufacturers from all disciplines and market segments, from industrial design to textile specialists, find solutions to their specific material challenges.

The fibres from Kelheim fit perfectly into Material ConneXion’s range of advanced materials:

each one delivers an additional benefit for the user:

Microfine, Kelheim’s finest viscose fibre, creates outstanding wearer comfort in high quality textiles and helps to enhance the physical properties of all types of speciality papers. Microfine is especially soft – an additional benefit for wipes.

Danufil® Deep-Dye is a chemically modified viscose speciality with a dye absorption capacity up to 40 times higher than standard viscose – ideal for optimising the dyeing process of textiles made out of viscose and PET, but also perfect for colour catcher fabrics which prevent colour staining in domestic wash cycles.

The the viscose fibre Verdi has been ionically activated in order to deliver a higher level of intrinsic absorbency and excellent dispersability in water – the fibre is ideally suited for paper applications where it improves the physical properties of speciality papers such as the paper’s strength.

Currently, Kelheim Fibres is preparing applications for further fibre innovations for the Material ConneXion Library.

Cellulose: from biogenic polymer to novel functions and innovative applications

This was the title of the paper given to approximately 280 attendees at the third Cooperation Forum Biopolymers in Straubing by Dr. Haio Harms, CEO of Kelheim Fibres GmbH. The paper illustrated impressively the versatility of viscose fibres made in Kelheim and presented future-oriented applications possibilities for their use.

This was the title of the paper given to approximately 280 attendees at the third Cooperation Forum Biopolymers in Straubing by Dr. Haio Harms, CEO of Kelheim Fibres GmbH. The paper illustrated impressively the versatility of viscose fibres made in Kelheim and presented future-oriented applications possibilities for their use.

“Cellulose- and lignocellulose-based materials and composites” was one of the main topics of the Forum organized by Bayern Innovativ in collaboration with the Centre of Excellence for Renewable Resources in Straubing – and Kelheim’s viscose fibres are a prime example of such materials.

Speciality fibres from Kelheim are high-performance materials which can substitute oil based synthetic materials in certain applications and deliver equal or even better performance; filters and speciality papers are examples of end products which can benefit from Kelheim’s fibres – and even carbon fibres are made from viscose fibre precursors. In addition to this, viscose fibres are made from 100% renewable cellulose as a raw material and are therefore completely biodegradable.

As a result, the field trip to the speciality fibre manufacturer’s headquarters at Kelheim, which was offered as part of the additional programme of the cooperation forum, was met with great interest. Around 50 visitors were given the opportunity to see the production plant and Kelheim’s R&D pilot plants.

High-tech Biopolymer Viscose Fibres from Kelheim Fibres

Man-made Fibres Congress, Dornbirn: new studies & our latest developments

Every year, we present our latest research results and our new fibre developments at the Man-made Fibers Congress at Dornbirn. This year, Kelheim Fibres made four presentations - as you see, our R&D team has been very busy! Here is a short summary of two of the presentations - more next time!

- Dr. Roland Scholz, R&D Kelheim Fibres and

- Ina Sigmund, Saxony Textile Research Institute (STFI): Viscose Fibers for Improved Dispersibility of Wet Wipes

Wipes for personal hygiene applications are frequently flushed into toilets - and risk blocking the waste water system. In the course of the study nonwovens based on 100% viscose fibres were tested for flushability according the demands of EDANA/-INDA’s “Guidance Document for Assessing the Flushability of Nonwoven Consumer Products”.

Wipes for personal hygiene applications are frequently flushed into toilets - and risk blocking the waste water system. In the course of the study nonwovens based on 100% viscose fibres were tested for flushability according the demands of EDANA/-INDA’s “Guidance Document for Assessing the Flushability of Nonwoven Consumer Products”.

The results: the two crucial factors for dispersability and transportability through sewer pumps are the fibre-length and the strength of the nonwoven web. Both factors have to be sensitively balanced to achieve sufficient web strength, easy break-up of the nonwoven and a complete dispersion of the fibres.

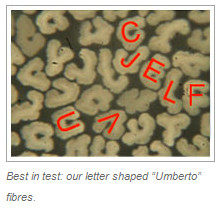

Nonwoven fabrics based on 20mm viscose fibres with round cross-sections and with the letter shaped cross section of our new “Umberto” fibres achieved the best test results for flushability.

Statement from : Matthew North, Commercial Director Kelheim Fibres

A Specialist specialises

We are proud to hold an excellent position in an increasingly competitive global market - what are the reasons for our success? First of all, we understand the challenges we face - and how to turn them into advantages.

As a medium-sized company in a high cost area we have skilled and reliable workforce and easy access to R&D resources. Our location on the banks of the Danube near a residential are means high environmental costs - yet at the same time it forces us to maintain the state-of-art technology of our plant. With eleven relatively small spinning lines our production capacity is limited - but we are highly flexible and can manufacture small lot sizes of speciality fibres competitively.

To guarantee our future success, our strategy focuses on four key elements: The effective and efficient use of available equipment and technology is the first important step. Based on that, we build leading positions in key markets and maintain them by continuous improvement of our products and production processes. To name just one example: We hold the number one position as supplier for short cut fibres for wet laid applications - 70% of viscose fibres used world wide in the manufacture of speciality papers are produced in Kelheim.

Forming strong partnerships with universities and research institutes and using the versatile viscose fibre process to our advantage, we adapt existing technologies for innovation. And last but not least, we establish new business in new applications, in the paper industry or filtration for example, where our speciality fibres offer benefits for an enhanced performance of the end product.

Our success is therefore not based on coincidence but solidy and strategically planned. With us, our customers have a reliable partner not just short-term, but also in the long run.

A Specialist specialises – Kelheim Fibres at Dornbirn’s Man-Made Fibers Congress

Commercial Director Matthew North will deliver a deep insight into the strategy of the Bavarian viscose fibre manufacturer Kelheim Fibres at this year’s Man-Made Fibers Congress in Dornbirn. In his speech with the title “A Specialist Specialises” he will reveals the secrets of success of Kelheim Fibres, who - as a medium-sized enterprise – has gained an excellent position in an increasingly competitive global market.

For those who want to know more about the newest products of the speciality fibre producer three more presentations will deliver more specific information..

Dr. Ingo Bernt from Kelheim Fibres’ R&D team will speak about the design of viscose fibres specially for wetlaid nonwovens. As current research shows, short fibres with a flat cross section prove particularly beneficial for the strength of a nonwoven web. The latest fibre invention from Kelheim, Leonardo, combines both properties perfectly and beyond that also scores with its extra smooth surface and transparency.

Dr. Philipp Wimmer, another member of Kelheim’s R&D team, will present viscose speciality fibres for enhanced fluid management. In his lecture he will speak both about speciality fibres with increased water absorbency and the completely new possibility to produce viscose fibres with reduced water absorbency or even water repellence.

Finally, Dr. Roland Scholz will present viscose fibres designed to improve dispersibility of wet wipes. The underlying research examined wet wipes for personal hygiene applications which frequently are flushed into toilets – and risk blocking the waste water system. In the course of the study important factors were discovered which facilitate the dispersibility of nonwovens based on 100% viscose fibres: In addition to water pressure in production and the properties of the nonwoven, the fibre geometry (titre, length and shape of cross-section) play a decisive role.

In addition to these lectures, Kelheim’s fibre experts are available for personal meetings at Kelheim Fibres’ information booth.