Displaying items by tag: tappi

GridBeyond Joins TAPPI to Support Wood, Pulp & Paper Businesses in Navigating Energy Markets

GridBeyond, the global leader in intelligent energy technology for C&I and Distributed Energy Resource Management (DERM), has joined TAPPI as a Sustaining Corporate Member.

TAPPI is the leading association for the worldwide pulp, paper, tissue, packaging and converting industries. GridBeyond supports large energy users, including wood, pulp and paper businesses, in improving their bottom line through new revenue streams, savings and operational efficiencies.

GridBeyond harnesses the power of AI technology to connect large energy consumers and their assets; including on-site demand, energy storage, generation and EV charging, to the award-winning Point platform. The platform enables participation in energy services including demand response, smart tariffs, energy trading and peak cost avoidance, and provides access to a range of monitoring tools to enhance business resilience and operational integrity.

GridBeyond harnesses the power of AI technology to connect large energy consumers and their assets; including on-site demand, energy storage, generation and EV charging, to the award-winning Point platform. The platform enables participation in energy services including demand response, smart tariffs, energy trading and peak cost avoidance, and provides access to a range of monitoring tools to enhance business resilience and operational integrity.

Wayne Muncaster, Vice-President for North America, commented:

“Energy is one of the largest costs for wood, pulp and paper mill operators and as such it needs to be carefully managed, especially during times of economic uncertainty. This is why we are excited to have joined TAPPI to support members with our expertise and energy market insights. As businesses look for ways to improve their bottom line and recover from the impact of the pandemic, energy markets provide opportunities to create new streams of income, enhanced savings and increased environmental credentials.

“Assets used by wood, pulp and paper businesses are typically highly flexible in their energy consumption, and therefore perfectly positioned to participate in energy services. By connecting debarkers, chippers, grinders, refiners, paper machines, on-site generation and storage, to our intelligent energy technology platform, businesses can access new revenue streams, cheaper power and increase their operational resilience. All without any impact on production or capital expenditure budget.”

Larry Montague, TAPPI President & CEO, commented:

“TAPPI’s Sustaining Members represent a wide range of exceptional companies, both from within and without our diversified industries.

“Visionary companies like GridBeyond understand the value of relationship building, as well as the types of scientific, technical and educational resources TAPPI offers their employees as they strive to dig deeper and share more about how energy creates opportunities for the industries we serve. We welcome them as a valued addition to the TAPPI family of Sustaining Members.”

Pete Augustine, President Fabio Perini North America, Chair of the Board for TAPPI

Peter R. Augustine, President, Fabio Perini North America, has been named as Chair of the Board for the Technical Association of Pulp and Paper Industry (TAPPI).

His wide-ranging professional and personal experience naturally aligns with TAPPI’s focus on driving innovation for the paper and packaging industry which, according to TAPPI CEO and President Larry Montague, made Augustine a standout choice for the role.

His wide-ranging professional and personal experience naturally aligns with TAPPI’s focus on driving innovation for the paper and packaging industry which, according to TAPPI CEO and President Larry Montague, made Augustine a standout choice for the role.

“TAPPI’s Board Chair represents a person of knowledge and discernment,” Montague explained. “Pete has consistently demonstrated these traits as a TAPPI Fellow. As the Board Chair, his vision is sure to shape the future of TAPPI and make it better for the industries that we serve.”

“I am excited and honored by the opportunity to continue serving on the TAPPI board – explained Pete Augustine - I’m grateful to work with such an experienced group of directors whose professional and personal backgrounds mirror the diversity of the pulp and paper industry. Together we will guide the TAPPI leadership and staff as they chart the course for the future of the association.”

Augustine joined Fabio Perini S.p.A. in 2011 as General Manager for North America and was promoted to his current position as President in 2013. He oversees the entire operation for Fabio Perini in North America, including strategic planning, sales, and production. Augustine holds a Bachelor of Science from the University of Wisconsin and an MBA from Purdue. He also served as a Captain in the United States Army.

About Fabio Perini S.p.A.

Fabio Perini S.p.A. was founded in 1966 in Lucca, Italy, the hub of world tissue production and converting technology. Today, with five production facilities in Italy, the United States, Brazil, and China, Fabio Perini helps its customers stay competitive and grow thanks to complete production solutions for converting and packaging. An ongoing commitment to technology, globalization, and research make the company the internationally recognized standard of excellence in the tissue industry. Learn more at www.fabioperini.com

Ametek surface vision engineer recognized for outstanding contribution at tappi awards

TAPPI Presents Leonard Fiore with Process Control Division Technical Award 2018

An expert engineer from AMETEK Surface Vision, a world leader in automated online surface inspection solutions, was presented by TAPPI (Technical Association of the Pulp and Paper Industry), with a prestigious technical award at its recent PaperCon event in Charlotte, NC.

Senior Hardware Engineer Leonard (Lenny) Fiore received the 2018 Process Control Division Technical Award, which is presented annually by TAPPI in recognition of outstanding contributions to paper industry science and technology.

from left to right): Paul Durocher, Chair TAPPI Board of Directors, ; Leonard Fiore, Senior Hardware Engineer AMETEK Surface Vision; and Larry Montague, TAPPI President & CEO

from left to right): Paul Durocher, Chair TAPPI Board of Directors, ; Leonard Fiore, Senior Hardware Engineer AMETEK Surface Vision; and Larry Montague, TAPPI President & CEO

Mr. Fiore has spent more than 40 years in the pulp and paper industry, starting in 1977 with Foxboro, and been involved with web-based monitoring and inspection for the past 25 years. He is responsible for many important design and technical developments for the paper sector and is named as an inventor on six US patents.

In presenting the award, the TAPPI Awards Committee noted Mr. Fiore’s exceptional accomplishments throughout his long paper industry career and his involvement in the development of landmark products and systems. Those include Champion video capture view, rheometer automation design, Sartell quality information control system, roll diameter prediction and AMETEK Surface Vision’s SmartAdvisor® web monitoring and inspection system, with its incorporation of high-definition cameras and board redesign.

“This award is a thoroughly deserved recognition of Lenny’s technical skills and achievements. Those include his integral role on the team that designed and developed AMETEK Surface Vision’s innovative SmartNet® scalable quality control solution,” commented Marius Westermann, AMETEK Surface Vision Business Manager.

“It acknowledges the dedication and expertise of Lenny and many others at AMETEK Surface Vision, who have made us a world leader in our field.”

Taking Advantage of the US$400 Billion Dollar Industry

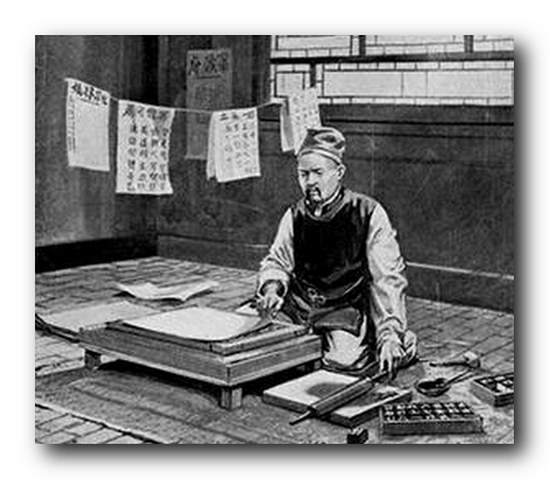

A government official in China, Ts'ai Lun was a figure who worked closely under Emperor Han of the Han Dynasty. In these ancient times, when inscriptions or writings were needed, they would be made on tablets of bamboo or on pieces of silk. With silk being costly, and bamboo heavy, written word was not common.

Ts'ai Lun was not happy with these options. One day as he watched outside his window, he noticed a swarm of wasps making their nests on a large Mulberry tree. With fibers from dead wood and plant stems, the small wasps would mix the fibers with saliva to construct their nests.

As he observed the wasps working, his mind hinted at an idea. The next morning he strolled over to the Mulberry tree. He collected bark from it and finely chopped it. Mixing it with hemp rags and water, he mashed it flat, pressed out the water and let it dry in the sun. Ts'ai Lun had invented paper.

Paper has come a long way since the Han Dynasty. In Australia, the industry is over 100 years old but certain sectors have been in a state of decline. Tim Woods is the Managing Director of IndustryEdge, which provides independent analysis for the Australian paper industry. He notes that "newsprint and some communication and advertising papers are experiencing decline, but office papers used in homes and offices remains very strong. It will be a long while before that changes dramatically."

"Paper really is a part of everyday life and that will continue into the future. In Australia, consumption of packaging papers (boxes, cartons, bags and so on) is increasing, and the same is true for tissue products."

The industry's main focus is on packaging. "Globally paper and paper board accounts for approximately one third of all packaging. The growth is linked to GDP and as a result, if a country is doing well, then there will be growth in the industry." tells Tony Johnson, a Technical Director at Beca AMEC. The packaging market is worth over US$400 billion globally and Australia is poised to take a slice.

However the industry is negotiating the challenges posed by the increased use of digital communications and cheaper imports. By placing their focus on innovation, they hope to drive investment, sustainability and productivity. With the competitive advantages of relatively inexpensive resources, a highly skilled labour force and strong regulatory frameworks, industry leaders are confident in the future. Australia has one other advantage up its sleeve. "What we've got in Australia and New Zealand is Virgin Softwood Fibre and that's really positive because Asia is short Virgin Fibre" adds Tony. The fibre gives Australia a boost, providing certain characteristics (fibre length and coarseness to name two) that add excellent strength properties to packaging papers.

Foreign investors have seen this opportunity and capitalised on it in the last 25 years. "These investors are very switched on when it comes to making the best use of their assets and from an outsiders point of view it is a very strategic move getting access to the Virgin Softwood Fibre" says Tony. Tim remarks that "global owners from Europe, the US and especially Japan, has been profound and ultimately healthy for the industry. At the same time, the rise of the privately owned local businesses has been little short of remarkable. Visy are the stand-out in this regard, but in many respects, ABC Tissue is the next company to watch."

Foreign investors have seen this opportunity and capitalised on it in the last 25 years. "These investors are very switched on when it comes to making the best use of their assets and from an outsiders point of view it is a very strategic move getting access to the Virgin Softwood Fibre" says Tony. Tim remarks that "global owners from Europe, the US and especially Japan, has been profound and ultimately healthy for the industry. At the same time, the rise of the privately owned local businesses has been little short of remarkable. Visy are the stand-out in this regard, but in many respects, ABC Tissue is the next company to watch."

But with manufacturing competing in this cut-throat environment, industry leaders feel that they have been left without government support. "It always surprises me that Governments in home countries do not mandate local procurement of their paper supplies in Australia. It certainly happens elsewhere in the world and there is plenty of independent evidence that shows the net cost of local procurement is lower than when imported products are purchased, even at the same price. That's because local businesses pay wages and suppliers and taxes locally." says Tim.

. Jim Stanford of the Centre for Future Work at the Australia Institute agrees with this sentiment. "Australia’s manufacturing downturn is partly the result of major policy errors by government — which accepted too readily the idea that Australia doesn’t really need manufacturing. The costs of those errors will be long-lasting and broad (felt not just by displaced manufacturing workers, but by the whole national economy)." Many in the industry believe that if there is no support, " things will get worse, not better".

We've come a long way from Ts'ai Lun and the Mulberry tree. The Paper Industry is innovating, using its competitive advantages to capitalise on big markets like packaging. With a focus on innovation, investment, sustainability and productivity, Australia's paper industry is poised to grow in the future. But with subsidised competitors, it will be a difficult tree to climb.

About

Tony Johnson is Technical Director at Beca AMEC and was recently recognised as a TAPPI Fellow. TAPPI is the Technical Association of the pulp & paper industry, based in the USA. It has >7,000 members worldwide. He is the 3rd recipient for NZ in TAPPI ’s 100 year history. Australia and New Zealand have previously each only had 2 TAPPI fellows.

Tim Woods is the Managing Director of IndustryEdge, which provides independent analysis for the Australian paper industry.

Trent Torkar is the General Manager at Document King, which specialises in document scanning, destruction and process automation.

63rd annual 'Paper Days' set for April 3–4 at University of Maine

Maine - A ribbon cutting ceremony to mark the opening of the nation’s first cellulose nanofiber pilot plant and a keynote address by U.S. Sen. Angus King will highlight the 63rd annual "Paper Days" at the University of Maine, April 3–4.

Innovation, with a focus on biobased nanoparticles and biofuels, is the theme of this year’s Paper Days, coordinated by the University of Maine Pulp & Paper Foundation. According to a press release from UMaine, Paper Days is expected to draw more than 300 industry leaders, researchers and students from throughout the U.S. and Europe. An estimated 60 paper companies and engineering firms are expected to send representatives.

The event is designed to facilitate the connection between the university and industry by getting UMaine students and faculty, and industry representatives together to learn about the latest topics in the field and to network, said Jack Healy, executive director of the foundation.

Following a luncheon and address by Larry Montague, president and CEO of TAPPI, seminars on biobased nanoparticle opportunities will be led by Alan Rudie, Forest Products Laboratory; Robert Moon, Purdue University; and UMaine alumna Beth Cormier, Sappi Paper and Agenda 2020 Technology Alliance. All will occur in Wells Conference Center.

Tours of Jenness Hall will focus on the Process Development Center in Jenness Hall, which is observing its 25th anniversary, and the Cellulose Nanofiber Pilot Plant, funded by a $1.5 million grant from the U.S. Forest Service.

The ribbon-cutting ceremony for the pilot plant begins at 3:30 p.m. in D.P. Corbett Business Building. Expected to offer remarks will be UMaine President Paul Ferguson; Michael Rains, USDA Forest Service; Theodore Wegner, Forest Products Laboratory; and Sean Ireland, TAPPI and Verso Paper, Inc.

The pilot plant manufactures cellulose nanofibers (CNF), a wood-based reinforcing material that is increasingly of interest to researchers worldwide in the development of high-value materials. Last year, UMaine and the Forest Products Laboratory began a research collaboration on the conversion of wood components into novel nanomaterials; the incorporation of an array of nanomaterials into forest products to increase their functionality, durability and end-use performance; and development of new generations of high-performance wood-based materials.

UMaine is in a consortium with the Forest Products Lab, six other universities and numerous industrial partners pursuing research using CNF. Nanomaterial has applications in automobile components, paint and coating additives, composites and filtration media.

The Paper Days honors banquet begins at 6 p.m. in Wells Conference Center featuring a keynote address by Sen. King, and award and scholarship presentations.

Also being announced is a gift by Sappi Fine Paper North America to help launch the UMaine Pulp and Paper Foundation’s $2 million fundraising campaign for scholarships.

The following day, Paper Days participants will tour the Forest Bioproducts Research Institute’s Technology Research Center in Old Town, followed by an industry panel discussion, “Biofuels in the Face of Changing U.S. Energy Availability.” At the luncheon that day, Frederick Clark of EKA Chemicals will speak on “The Business Case for Sustainability.”

The 2013 TAPPI Introduction to Wet End Chemistry course

The 2013 TAPPI Introduction to Wet End Chemistry course equips you with the latest technology and terminology for optimum papermaking performance.

Instructors for this course know that cost savings is ultimately your mark for a strong finish, so they focus the 3-day interactive training on innovative wet end chemistry principals and the use of additives to change or create new paper products.

This is the only training program that offers an in-depth focus on additives and what they can and can't do for your process.

Through case studies, break-out sessions and networking with others in the course, you’ll learn how to:

- Implement new wet end technology to reach higher efficiency and consistent, quality products

- Use additives to improve or create new products

- Reduce downtime and off-spec production

- Make better judgments on selection and use of chemicals

- Better troubleshoot problems

- Respond quickly to changing fiber qualities, regulations and competitive pressures

This course is ideal for engineers involved in training, particularly within mills that have brought in newer employees or lost valuable experience through retirement. Many chemical engineers entering paper mills today don’t have a specific background in pulp and paper manufacturing and may not understand how to apply what they’ve learned to the papermaking wet end process. In this course, you will learn the importance of better communication of correct terminology in context to the chemicals and additives used in making better paper products that can rev up production.

Learning Outcomes

You could pour over all the how-to manuals available and still not retain this level and quality of working knowledge. Completing this workshop will enable you, among other skills, to:

- Identify the properties of papermaking furnish and the process components and discuss how they interact to affect wet-end chemistry phenomena.

- Discuss possible solutions to paper machine process and paper quality problems associated with wet end additives and arising from chemical deposits.

- Identify additives that can be used to change the balance of charge for purposes of process control, trouble-shooting and optimization situations.

- Identify the most important factors affecting first-pass retention and the rate of drainage of water from the fiber mat during paper formation.

- Identify classes of wet-end chemical additives that can be used to achieve paper property objectives in various grades.

Download a printable copy of the 2013 Course Schedule here.

This course will sell out at 25 participants to encourage the most interactive discussions possible with ample question-and-answer opportunities.

Who’ll Be Attending

This course is designed for superintendents, product developers, process engineers, process and quality control technicians, as well as suppliers who need an introductory- to intermediate-level understanding of wet end chemistry.

- Chemical and Process Engineers

- Mill Superintendents and Department Managers

- Research and Development Engineers

- Technology and Chief Chemists

- VP Research and Development

- Technology Directors

- Process & Quality Control Technicians

- Account Representatives for Chemical, Machinery, Equipment Suppliers

Print a color Course Flyer that you can post at your workplace or give to your boss.

Participants should have one to five years of paper industry experience, and college-level chemistry and math courses are helpful.

IMERYS Minerals Ltd. Lead Scientist John Husband Named 2010 TAPPI Fellow

John C. Husband, Ph.D., has been designated as one of nine TAPPI Fellows for 2010. He currently serves as Lead Scientist for IMERYS Minerals Ltd., Cornwall, UK. Fellow is an honorary title bestowed upon less than one percent of TAPPI’s membership. It is given to individuals who have made extraordinary technical or service contributions to the industry and/or the Association.

John C. Husband, Ph.D., has been designated as one of nine TAPPI Fellows for 2010. He currently serves as Lead Scientist for IMERYS Minerals Ltd., Cornwall, UK. Fellow is an honorary title bestowed upon less than one percent of TAPPI’s membership. It is given to individuals who have made extraordinary technical or service contributions to the industry and/or the Association.

“Dr. Husband has been a prolific presenter at conferences in the United States and Europe, specializing in coatings,” said Larry N. Montague, President and CEO of TAPPI. “His knowledge has been instrumental in supporting the work of other scientists in the pulp and paper industry, both in North America and Europe.”

A native of Cornwall, he studied chemistry at Cornwall Technical College and later, Plymouth Polytechnic. He earned both his master of science and his Ph.D. in Paper Science from University of Manchester Institute of Science and Technology, now known as the University of Manchester.

His professional career began in 1969 when he joined the Chemistry Research Department of English China Clays. Initially focused on projects involving clay chemistry and rheology, he then worked on the development of paper fillers. In 1983, he began working on paper coating and in 2000, he transferred to the IMERYS Worldwide Paper Group. He now holds the title of Lead Scientist for the company’s Paper Research Group.

He has been granted eight patents and is extensively published in professional journals. On the basis of his research experience, he is a member of the Royal Society of Chemistry. He and colleague Janet Preston, Ph.D., have also been awarded the Silver Medal from the Institute of Printing for an article written about their work.

Dr. Husband is an active member of TAPPI, serving as a member of the Coating Fundamentals Common Interest Group (CIG) and the Technical Program Committee (TPC) for the Coating & Graphic Arts (C&GA) Division Coating Conference. He is also a member of PITA, the UK paper technical association. He lives in St. Austell, Cornwall, UK.

Dr. Husband and the other new TAPPI Fellows were honored at the TAPPI Fellows Luncheon, Sunday, May 2, 2010, at the Hyatt Regency, Atlanta, Ga., USA, in conjunction with the 2010 PaperCon meeting

Bob Kearney has joined Klass Associates Inc. as a Senior Associate.

Bob specializes in starch and starch applications for the paper industry. His strengths are problem solving, size press applications, starch in coating formulas and the use of starch at the wet end of the paper machine. Bob has 45 years of starch experience having worked for Penford, ADM, Cargill and Western Polymer.

He is active in the TAPPI Coating and Graphic Arts Division, has served as Division Chairman and received the Coating and Graphic Arts Division Leadership and Service Award in 2004.

For more info please contact:

Charles P. Klass

Klass Associates Inc.

16326 Gulf Boulevard - Suite 300

Redington Beach, FL 33708

Phone: 727-395-9435

Fax: 727-394-2540

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Web Site: www.klassassociates.com