Ian Melin-Jones

Amazon Papyrus to Increase Prices

“Amazon Papyrus Chemicals (APC), Hong Kong, announces a price increase of 5 - 15% depending on the products, with immediate effect or wherever contracts allow. This price increase is necessary due to a significant increase in raw material, manufacturing, packaging, transportation and regulatory costs. The APC team will continue to work proactively with our customers to further optimize applications related to process and functional chemicals, ensuring a favorable return on investments.”

“Amazon Papyrus Chemicals (APC), Hong Kong, announces a price increase of 5 - 15% depending on the products, with immediate effect or wherever contracts allow. This price increase is necessary due to a significant increase in raw material, manufacturing, packaging, transportation and regulatory costs. The APC team will continue to work proactively with our customers to further optimize applications related to process and functional chemicals, ensuring a favorable return on investments.”

About Amazon Papyrus

“Founded in 2000 and headquartered in Hong Kong, Amazon Papyrus is a specialty chemical company, which has established presence in 11 countries with more than 450 employees, serving over 350 pulp and paper, viscose and fiber cement manufacturers in Asia and Middle East. Learn more at Amazon Papyrus’ website “www.amazon-papyrus.com”.

Europac Viana PM4 vacuum system is fully installed

Europac Viana PM4 vacuum system is fully installed and fulfills all guarantees. This turn-key vacuum system rebuild project includes five (5) Ecopump Turbos, one low vacuum EP Blower, new Ecodrop water separators and full Ecoflow system. Turnkey delivery includes equipment, mechanical installation, piping, automation and installation supervision.

Old vacuum systems had 10 liquid ring pumps and 2 blowers. Total power consumption of the vacuum system was 3900 kW and SEC was 76 kWh/t. Now after short optimization period total energy consumption is 1800 kW / SEC 35 kWh/t. Total energy saving is over 17 GWh/year or 1,7 MEUR/a.

Europac Viana do Castelo mill is located in North parts of Portugal. Viana PM4 is one of the bigger virgin fiber krafliner machines in Europe. Machine is 6,4-meter-wide and produces almost 400 000 t kraft paper a year.

About Runtech

Runtech is your reliable partner, whenever you are looking for solutions to improve the runnability and efficiency of your tissue, board, paper and pulp machines.

With our patented solutions in vacuum system energy saving and system optimization, press section and forming section dewatering and doctoring optimization, as well as ropeless tail threading you can understand and control your paper machine operation conditions in the most cost-effective way.

The Runtech story started from a group of paper making professionals. It dates back to 1989, when Ecopump Oy started paper machine optimization services. In 1997, Runtech Systems Oy was established and later on in 2008 Ecopump Oy was merged to Runtech Systems. Selotek Oy was acquired in 2011.

Lucart has acquired the Spanish Group CEL Technologies

The Lucca-based Group continues its development in the markets of paper for hygienic and sanitary use in Europe

Lucart welcomes 2018 with a major investment aimed at strengthening its market position in the Iberian peninsula, through the acquisition of the assets of the Spanish Group CEL Technologies & System.

In the summer of 2017, the CEL Group had to initiate an extraordinary administration process during which a tender procedure was launched for the sale of its production assets. The acquisition by Lucart was finalised on 31 January through a newly established company, Lucart Tissue & Soap S.L.U.

Lucart’s project for restarting the business includes an investment plan of more than €20 million over the next 5 years.

With this operation, Lucart has acquired three production facilities in Spain, in the Basque Country near the city of Bilbao, designated for the production and conversion of tissue paper and the production of personal care soaps and detergents in the Away from Home industry. The acquisition also includes a substantial de-inking plant, which will allow Lucart to exploit its know-how in the sector of high-quality recycled ecological tissue paper, further consolidating its position as a leader in this field.

In terms of logistics, the geographical location of the plants is ideal for Lucart for serving both the Iberian and French markets.

In order to gradually resume production, Lucart has confirmed 146 jobs in the three plants acquired, with a business plan that envisages the following:

- restarting two continuous machines at the Aranguren plant, for an overall capacity of 50,000 tonnes per year;

- gradually restarting and implementing the converting activity in the Gunes plant;

- the development and strengthening of soap and detergent production activities in the Artziniega plant, which has never been discontinued.

‘This acquisition will allow us to continue to strengthen our presence in the tissue paper market, in line with the company’s strategic growth plan in European markets, serving all of our Group’s Business Units,’ Massimo Pasquini, CEO of Lucart, explained.

Lucart

Lucart, a leading company in Europe in the production of MG paper, tissue products (paper items for daily use such as toilet paper, kitchen paper, napkins, tablecloths, handkerchiefs etc.) and airlaid products, was founded in 1953 by the Pasquini Family. The company's production activities are distributed over 3 Business Units (Business to Business, Away from Home and Consumer) operating in the development and sales of products with brands such as Tenderly, Tutto, Grazie Natural and Smile (Consumer area), Lucart Professional, Tenderly Professional, Fato and Velo (Away from Home area). With this new acquisition, Lucart’s production capacity exceeds 350,000 tonnes/year of paper on 12 continuous machines and 62 converting lines. Its consolidated turnover will amount to more than €450 million, with more than 1,500 employees in 10 production plants (five in Italy, one in France, one in Hungary and three in Spain).

Södra strengthens offer for pulpwood and pine logs

Södra is raising its purchase price for pulpwood and pine logs. Demand for both softwood and hardwood pulp is high, while the market for sawn timber remains strong. To ensure continued high levels of supply, Södra is raising its purchase price for pine logs by SEK 30/cubic metre of solid volume underbark (m ᶾ sub) and introducing a contracting premium of SEK 25/m ᶾ sub for softwood and hardwood pulp. The price changes will apply from 1 February 2018.

“The strategic investments in Södra’s pulp mills in recent years have led to a steady increase in softwood pulpwood consumption and demand for softwood pulp. This market situation presents ideal conditions for increased forest thinning which, in the long term, will further strengthen both the value and quality of Swedish forests,” said Olof Hansson, President of the Södra Skog business area.

For questions, please contact:

Olof Hansson, President of the Södra Skog business area,

Tel: +46 (0)470-857 67

Sofia Petersson, Wood Supply Manager Södra Skog,

Tel: +46 (0)470-859 86

Södra was founded in 1938 and is the largest forest-owner association in Sweden, with a membership of more than 50,000 forest owners. We engage in modern and responsible forestry, and operate state-of-the-art mills in which we process our raw material. Through value-generating relationships and a long-term approach, Södra is leading the way for the next generation of forestry.

Toscotec will provide four new AHEAD-2.0M tissue machines to Vinda Hubei Xiaogan mill.

Vinda International Group purchased four new Toscotec AHEAD-2.0M tissue machines, to be installed in its new production base in Xiaonan district, Xiaogan, Hubei. Toscotec will deliver the first two lines in mid-March and the second two in mid-May 2018.

PM1, PM2, PM3 and PM4 will have similar configurations, including second generation large diameter TT SYD and Toscotec’s most recent technological developments in dryness efficiency, taking its widely acknowledged energy saving results to the next level.

The four AHEAD-2.0M are scheduled to come online by the end of 2018, leading to a total production increase of over 120,000 t/y for Vinda. This year the Italian supplier is also delivering two AHEAD-2.0M tissue machines to Vinda’s new Yangjiang mill in Guangdong. Overall, these six Toscotec-supplied lines will add a total of over 180,000 tons to Vinda International’s annual production output.

Toscotec Chief Executive Officer Mr. Alessandro Mennucci stated, “We know that this large project at the heart of China’s central region is of strategic importance to Vinda, and we are proud to be part of it. Toscotec will be there with today’s best available tissue technology, including our latest advancements. I am confident that Vinda will appreciate the benefits of the AHEAD-2.0M in terms of both tissue quality and consumptions.”

Located in the high-demand central China tissue market region, Vinda’s new Hubei mill will become another important strategic production base for Vinda Group.

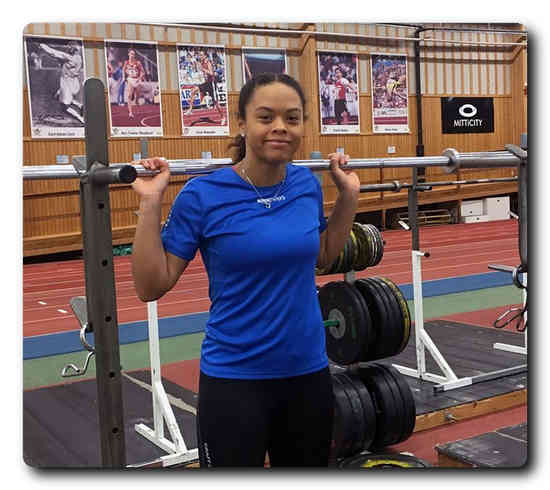

Nordic Paper in cooperation with Swedish sprint athletics

We are proud to announce that we recently initiated a cooperation with the local sprint athletics Claudia Payton from Värmland county in Sweden.

Claudia is 19 years old and already has multiple athletics merits.

She is aiming at the Olympic Games 2020.

The cooperation is a natural step for Nordic Paper, since the sport that is associated with Claudia also is associated with power and strength. Something that our paper and pulp company really knows!

We manufacturer kraft paper globally and our kraft paper is among the strongest in the world.

Supporting this local future athletic hope in her career is also a part of taking social responsibility, we believe.

- Claudia will be our face outwards and it feels really good to be supporting a young, local and of course promising athlete and we hope that we can give her good support in her striving for her dream goal, says Marie Stenquist, Head of Corporate Communications/PR.

Also Claudia is glad to make this announcement.

- Nordic Paper will be a great support for me when it comes to my commitment within the athletics. I´m very pleased with this cooperation and I think that it will be a great deal of fun to work together with Nordic Paper, Claudia says.

Nordic Paper is a leading producer of Greaseproof paper and Kraft Paper.We are located in Scandinavia and operates in Sweden and Norway. Our four paper mills and two pulp mills are all within 250 kilometers of one another.We have been manufacturing special paper for a range of applications since the late 19th century. Our expert knowledge of paper manufacturing has been passed down through generations.We use only renewable forestry resources in our manufacturing processes. Everything we do, we do with the greatest possible consideration for the environment, which is witnessed by the many certification processes we have satisfied.Our motto is that we always are near, natural and premium!For more information, please visit: www.nordic-paper.com

Considering efficiency: electric motor repairs or replacements

Electric motor failure can strike even with the best preventative measures in place, and it can be difficult to know just what to do. As business downtime and losses mount, it’s very easy to make a panicked decision over whether to invest in an electric motor rewind and repair or replace your motor.

The challenge faced is a difficult one. With new high-efficiency motors available, should owners invest in a whole new motor altogether that promises higher efficiency levels but with significantly greater costs? Or, do they commit to a motor repair or rewind? While the cost is often lower, many are concerned about the potential inefficiencies that an electric motor rewind can bring — yet are these worries grounded in fiction?

This now widespread misconception originates from a study that was carried out around smaller motors. It found that carrying out a rewind can drop efficiency by between 1% and 5% each time it is rewound. Considering the associated expense and sheer volume of energy these motors use, this is naturally concerning. However, more recent research has countered these findings.

In a study carried out by EASA and AEMT alongside Nottingham University, it was found that when rewound using good practice, the efficiency of the motors was not significantly altered. However, in some instances, efficiency actually increased. This clearly dispels the belief that a rewind is actually detrimental to a motor’s performance.

What should you consider?

With the myths dispelled, perhaps you don’t need to shell out on an expensive replacement motor after all. Of course, in cases of catastrophic failure, this may be your only option. However, it’s very important to fully evaluate your options to make sure you make the right choice in terms of operation, cost and efficiency. This can be done by asking a number of key questions, as explained by Houghton International.

How suitable is your electric motor for purpose?

As your needs shift, you may find that your existing electric motor is now unsuitable. Review the scale of the damage alongside the requirements for the motor’s processes and duty cycles. If the motor is no longer suitable or too damaged, your option is to replace the motor.

How about stator core and rotor condition?

Checking your stator core and rotor is essential. If significant damage is present, it may be more beneficial to purchase a new motor, as depending on the extent of the damage, repairs can be costly.

Always fully consider the bigger picture when deciding whether to invest in a new motor. For example, if the lead times for the motor you need are long, you may to decide to repair rather than replace to minimise downtime.

How damaged are other mechanical parts?

It is common for the shaft, frame, bearing housing and other mechanical parts to damage as a result of motor failure. Examine the extent of the damage; you may be able to replace the affected parts at a lower cost than replacing the entire motor.

What type of motor do you have?

It is possible that motor failure will provide the reason to upgrade you have been looking for. If you are considering making the investment, make sure you fully understand the return you’ll receive from doing so. Consider the energy savings you’ll make alongside the expected life of the motor and its hours of operation. Always consider your overall budget too, to make sure the replacement aligns with your current financial position.

Remember that if you are happy with your motor and the efficiency it delivers, a motor rewind — when carried out by a qualified service centre — will not lead to a significant efficiency drop.

To make the right decision between repairing, rewinding and replacing your electric motor, make sure that you fully consider all of your options in depth.

Valmet to supply a waste-fired boiler to Shanying Huazhong Paper in China

Valmet and Shanying International Holdings Co., Ltd. have signed a contract regarding a delivery of a mill waste-fired boiler plant to Shanying Huazhong Paper's paper mill, in the city of Jingzhou in Hubei province, China. The new waste-to-energy boiler plant will supply electricity for the paper mill and enables the mill to utilize all of its mill waste in energy production.

The order was included in Valmet's fourth quarter 2017 orders received. The value of the order will not be disclosed.

Shanying International Holdings' investment in waste-to-energy solution enables high overall efficiency with very effective heat and power generation and supports circular economy. Installation is scheduled to begin in June 2018. Heat and power production will start early 2019.

Shanying International Holdings' investment in waste-to-energy solution enables high overall efficiency with very effective heat and power generation and supports circular economy. Installation is scheduled to begin in June 2018. Heat and power production will start early 2019.

"Valmet's boiler technology offers the highest steam parameters and overall plant efficiency. We expect to achieve high economic efficiency with reduced need for maintenance and production shut-downs," says Yi Shuai, Plant Director at power plant of Shanying Huazhong Paper. "The tailor-made boiler design meets our expectations of steam parameters which allows us to utilize standard turbine, and we believe it will help to optimize the entire plant," he continues.

"This boiler delivery will be the first paper mill waste-to-energy boiler which has the highest steam parameters. We have developed our waste-to-energy concept especially for this type of power plants. The solution will enable excellent efficiency through high steam parameters even when combusting demanding waste fuels. Utilizing waste in energy production will enable a significant reduction of CO2 emissions compared to fossil fuel powered plants," says Kai Janhunen, Vice President, Energy business unit, Valmet.

Valmet announced in December 2017, that it will supply an OptiConcept M containerboard making line for Shanying International Holdings.

Technical information about the delivery

Valmet's delivery includes major parts of a CYMIC boiler island from fuel silo to boiler outlet. The boiler uses circulating fluidized bed (CFB) technology.

The green field boiler plant will use mill waste (paper rejects, pulp rejects and pulp sludge) as its fuel totaling to 260,000 tons of waste annually. Light fuel oil is used only for start-ups. The chlorine and alkaline content in the waste derived fuel is relatively high, but using Valmet's circulating fluidized bed technology the emissions are controlled efficiently.

Information about Shanying International Holdings Co., Ltd.

Shanying International Holdings Co., Ltd., formerly Anhui Shanying Paper Industry Co., Ltd., is a China-based company, principally engaged in the manufacture and distribution of paper products. The Company's main products consist of various packaging paper boards, corrugated cardboard boxes, culture paper and other paper products, which are marketed under the brand name of Shanying. The Company distributes its products within domestic markets, with eastern China as its main market.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

For further information, please contact:

Xin Bo, Sales Manager, Energy, Pulp and Energy business line, China

tel. +86 13910107348, This email address is being protected from spambots. You need JavaScript enabled to view it.

Sanna Röyskö, Director, Boiler and Gasification Plants, Energy, Pulp & Energy business line

tel. +358 40 821 1268, This email address is being protected from spambots. You need JavaScript enabled to view it.

Iggesund UK renews its finishing area with Pasaban machinery

The two KB2300 board sheeters will contribute to the British plant to continue offering a high-quality product alongside impeccable service.

Iggesund, an important Swedish group and a benchmark in the board mills on a global scale, produces two of the highest quality paperboard products in the market. In their Workington (UK) plant they make “Incada” folding box board. The brand is used for packaging in sectors with high quality requirements, such as the food, cosmetics, electronics and the pharmaceutical.

The factory’s finishing area is one of the fundamental areas of its production process. For 20 years, they have entrusted Pasaban with the supply and service of some of their paperboard cutting machines, this way offering them a total solution.

In the Workington Mill, Iggesund already has a KDD-2600 board sheeter which, together with an old Jagenberg and a Pasaban board winder, they have been some of the key machines in the paperboard finishing area. However, they are currently immersed in a machinery renewal process for which they have once again trusted in Pasaban. We will substitute the old equipment for two KB-2300 sheeters with highly automated rotary unwind stands able to process 170 to 400 gsm folding box board (FBB).

We are proud to be able to continue to satisfy our customer needs and to continue being a benchmark in the market. In this case being a part of the manufacturing process of 'Incada' and 'Ivercote' FBB.

VIDEO: The Making of Incada here

Once again, the quality of Pasaban machines, services and customised solutions make it a reliable brand for the world's leading paper and board manufacturers.

Metsä Board’s Better with Less – Design Challenge collaborates with Pro Carton’s Young Designers award

Metsä Board, the leading producer of premium fresh fibre paperboards launched the Better with Less – Design Challenge last November. This international packaging design competition aims to find new more environmentally-friendly and functional packaging solutions for some of the world’s most frequently used and fastest growing types of consumer packages, including takeaway meals, e-commerce, wellness, cosmetics and dry food.

We are happy to announce that the competition has now joined forces with the Pro Carton Young Designers Award, which will provide the benefit that all student participants will have two chances to win with one great idea.

Pro Carton is the European Association of Carton and Cartonboard Manufacturers who through their competition wants to encourage innovative design with cartonboard and reduce, or replace plastic.

Therefore, the two competitions perfectly complement each other, and recognise the global emphasis needed on promoting young packaging design talent and developing sustainable packaging designs using renewable materials.

Since its launch in November, the Better with Less – Design Challenge has aroused a lot of positive attention globally and a number of exciting entries have already been received. The competition is being supported by an international jury consisting of renowned brand and packaging experts including Lars G. Wallentin, Terri Goldstein, Marianne Rosner Klimchuk, Peter Désilets, John B. Mahaffie, and Cyril Drouet.

Competition chairman Cyril Drouet, Design & Innovation Director, Metsä Board comments: “We are very excited by this development with Pro Carton as participants now have two chances to win with their design proposal. To create a true impact in the world we need to join forces and take action across the whole packaging chain. As consumption of packaging grows, we need to think about the packaging lifecycle from start to finish, and inspire discussion and innovation on more sustainable and experimental packaging. The Better with Less – Design Challenge is one forum to do this and the great response received so far shows there’s lots of new ideas emerging.”

Registration for the Better with Less – Design Challenge is open for designers and design students until 31 March 2018 at: www.betterwithless.org. The main prize is EUR 10,000, and for students there is an additional prize of an internship opportunity for one student with Metsä Board’s packaging services team in Shanghai. The finalists and the winners for the Better with Less – Design Challenge will be announced during Spring 2018 and the Pro Carton Young Designers Award will be announced in September.

The competition can be followed on social media with the hashtag #betterwithless

Metsä Board

www.metsaboard.com

Metsä Board is a leading European producer of premium fresh fibre paperboards including folding boxboards, food service boards and white kraftliners. Our lightweight paperboards are developed to provide better, safer and more sustainable solutions for consumer goods as well as retail-ready and food service applications. We work together with our customers on a global scale to innovate solutions for better consumer experiences with less environmental impact. The pure fresh fibres Metsä Board uses are a renewable resource, traceable to origin in sustainably managed northern forests.

The global sales network of Metsä Board supports customers worldwide, including brand owners, retailers, converters and merchants. In 2016, the company’s sales totalled EUR 1.7 billion, and it has approximately 2,500 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.