Displaying items by tag: PMP

Pmp successfully starts green field tissue mill for universal paper manufacturers, South Africa - the gold eagle has spread its wings!

In December 2014, PMP (Paper Machinery Producer) signed a contract with Universal Paper Manufacturers (UPM), part of the Universal Paper group, for a turn-key green field tissue mill based on Intelli-Tissue® Advanced 1600 tissue making line. Thus it is our pleasure to announce that on the 19th of February 2017, 11:20 a.m. local time, TM#5 successfully started-up at UPM’s Ga-Rankuwa mill in South Africa!

In 2014 UPM made a decision regarding a significant expansion plan to shift its family-owned business to the next level by creating a green field tissue mill. Universal Paper’s biggest goal has been to become the preferred tissue supplier in the Southern Africa region, offering a wide span of ultra-premium, 100% virgin fibre tissue paper products. Its mission is to develop innovative products for the most demanding consumers adding flavors of creativity and education. Universal Paper branded products (FSC-certified) have already gained a significant number of enthusiasts who are fascinated with their uniqueness on a worldwide scale. Universal Paper is the proud manufacturer of Dinu, one of South Africa's leading household tissue brands.

The project was named “Gold Eagle”. Its goals were to double the annual capacity of UPM and to widen its product portfolio adding ultra-premium tissue products. PMP’s Intelli-Tissue® Advanced 1600 Crescent Former tissue making line was the best response for UPM’s defined needs.

PMP’s scope of delivery covered: collaboration with the building design engineers, a tissue making line (starting from stock preparation, a broke line, stock approach, baseplates, a tissue machine itself and a shaft puller), all auxiliary systems (a lubrication system, a steam & condensate system, a dust removal system, DCS, QCS, mechanical drives), field installations (pre-piping and pre-conduit) as well as a rich scope of engineering services (pre-erection, erection and start-up supervision). UPM’s Intelli-Tissue® Advanced 1600 has a total capacity of 28 000 tpa (operating speed 1600 m/min, reel trim 2670 mm), depending on the tissue grade (basis weight at reel from 13 to 40 gsm). An applied technology (PMP Intelli-Jet V® single layer hydraulic headbox, a Crescent Former Intelli-Former®, Intelli-Press® with a single press configuration, equipped with a 16’ steel Yankee Dryer - Intelli-YD® a steam heated hood and PMP Intelli-Reel® is focused to ensure the best quality of the final product - softness at a premium level and excellent hand feel to open the door to new market niches. In addition applied state-of-the art PMP Intelli-Tissue technology ensures ultra-low media consumption. Thanks to a unique partnership, TM#5 today has a bright future, ensuring high flexibility and world-class performance.

It is worth mentioning that the “Gold Eagle” project was implemented based on a philosophy of Premium Quality & Reliability. The investment has been the biggest in UPM’s entire history taking its value and scope into account. Also it is the 1st new high speed tissue line installed in South Africa within last 20.

After a successful and smooth start-up, both companies are ready to say that “Gold Eagle” has spread its wings empowering the future of UPM and bringing all involved pride and satisfaction.

About UPM:

Universal Paper Manufacturers (UPM) – is one of Universal Paper’s business units and is the sister company to Universal paper & Plastics (UPP). Both companies are still family owned. UPP was established by the Sher family in 1950 and has operated successfully for over 67 years. The company started as a manufacturer of various paper and plastic products, and has grown significantly since inception. However, during this time, its direction has changed – with the discontinuation of product lines in the plastics industry, while continuing to supply the tissue paper industry. The company has vertically integrated, by manufacturing raw materials within the inks and paper industry. Today, the focus is on high quality printed serviettes and napkins, bathroom tissue, household towels and hankies. (learn more: www.upap.co.za)

About PMP:

PMP – a global provider of tissue, paper & board technology, has been supporting pulp and paper industry for over 160 years, executing projects on 6 continents, in 34 countries. Company with headquarters in Jelenia Góra, Poland, owns 6 facilities in 4 countries (Poland, USA, China, Italy). PMP is a recognized international player in both paper & tissue industry. At the end of December 2015, PMP introduced new branding initiative including launching a new logo & visual identity. (learn more: www.pmpgroup.com)

PMP to supply key technological units for zhe jiang huachuan’s pm8 in china including the delivery of 1st pmp’s intelli-shaker®!

In August 2016, PMP (Paper Machinery Producer) signed a contract with Zhe Jiang Huachuan for a delivery of key technological units for PM8, located in Yiwu mill, Zhejiang Province, China.

A new PM8 (operating speed 700 m/min, reel trim 3460 mm) will be equipped with world class new technological items provided by PMP and will produce glassline papers. The project driving force is based on energy saving solutions & quality through application state-of-the-art technology.

PMP will deliver solutions from its Intelli-Paper® platform concept for papermakers. PMP will provide its first Intelli-Shaker® ever, which bring excellent formation and at the same time impressive paper quality. It enables PM capacity increase due to higher consistency in the headbox and it is proper to any paper grades.

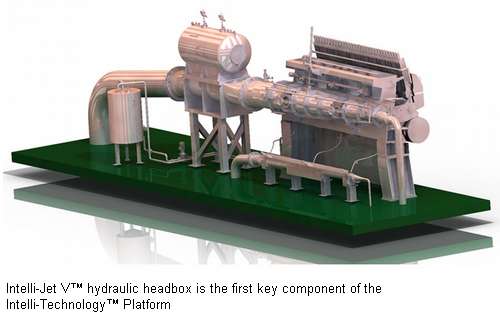

A scope of delivery includes also a state-of the-art, 3 channel Intelli-Jet V® hydraulic headbox which will also bring excellent formation and production flexibility for the mill (basis weight range from 28 to 90 g/m²). The headbox will include sophisticated Consistency Profiling System to ensure excellent basis weight control, resulting in uniform paper web structure and better CD basis weight profile. PMP Intelli-Jet V® Hydraulic Headbox Technology has become iconic – it is today a leading solution in the Pulp & Paper industry. It is a part of PMP Intelli-Paper® platform for papermakers. There are over 130 units working successfully on 6 continents.

In addition PMP will provide Intelli-Top® Former - a proved solution which assures the perfect formation and proper dewatering effectiveness as well as a new Intelli-Sizer® Metering Size Press, which will result with strong paper web & perfect printability.

The delivery, erection and start-up are scheduled for the second half of 2017.

About Zhe Jiang Huachuan:

Zhe Jiang Huachuan - Zhe Jiang Huachuan Industrial Group Co., Ltd. is located in Yiwu, Zhejiang Province, China. Company is working in several business areas such as: papermaking, printing and dyeing, chemical, technology, investment and more. Zhe Jiang Huachuan owns 6 wholly-owned and and holding companies in China. At present, the company covers an area of more than 20 million square meters and hires more than 1,600 employees. (learn more: www.huachuangroup.net)

About PMP:

PMP – a global provider of tissue, paper & board technology, has been supporting pulp and paper industry for over 160 years, executing projects on 6 continents, in 34 countries. Company with headquarters in Jelenia Góra, Poland, owns 6 facilities in 4 countries (Poland, USA, China, Italy). PMP is a recognized international player in both paper & tissue industry. At the end of December 2015, PMP introduced new branding initiative including launching a new logo & visual identity. (learn more: www.pmpgroup.com)

YFY’s & PMP’s COMMON PROJECT OF TM#7 REBUILD HAS RESULTED WITH A SUCCESSFULL START-UP!

In October 2015, Yuen Foong Yu has signed a contract with PMP for rebuild of TM#7 in Ching Shui Mill (Taiwan). The delivery included steel Intelli-YD®, Intelli-Hood® and Steam & Condensate system. Thus it is our pleasure to announce that in August 2016, TM#7 equipped with PMP’s state-of-the-art technology has been successfully started-up!

This time, the scope of supply covered 12’ steel YD designed and manufactured by PMP (2420 mm sheet width on Yankee), a high efficiency Yankee hood supplied with an air fan – Intelli-Hood® – and a Steam & Condensate equipment. Designed Yankee is a steel welded construction with bolted on journals. In order to increase Yankee’s efficiency, PMP offered optimized and tailor-made solutions. Intelli-YDTM designed for YFY is capable to operate up to 9.5 bar(g) of steam pressure and a maximum design speed of 1200 mpm. Additionally PMP exchanged existing steam Yankee Hood with Yankee Cap to reduce steam consumption. Changes in the Steam & Condensate system were implemented to fit new system conditions.

YFY decided to choose PMP Intelli-YD® due to great running references representing very high performance and ultra-low media consumption. This project is an example where PMP’s technological knowledge combined with high-tech equipment can become a key factor to achieve common success.

About YFY:

Yuen Foong Yu – one of the leading Asian Corporations with a turnover of 1.8 billion US dollars, ranked in the top 5 among tissue producers in China, was founded in 1925. At present, YFY is active in three business areas: fine paper & board, packaging and consumer products. It owns 23 facilities in China, Taiwan and Vietnam. YFY’s activity within the tissue sector is focused on delivering value for consumers through Mayflower, Tender and Delight brands mainly in China and Taiwan. (learn more: www.yfy.com)

About PMP:

PMP – a global provider of tissue, paper & board technology, has been supporting pulp and paper industry for over 160 years, executing projects on 6 continents, in 33 countries. Company with headquarters in Jelenia Góra, Poland, owns 6 facilities in 4 countries (Poland, USA, China, Italy). PMP is a recognized international player in both paper & tissue industry. At the end of December 2015, PMP introduced new branding initiative including launching a new logo & visual identity. (learn more: www.pmpgroup.com)

PMP SUCCESSFULLY IMPLEMENTS ANOTHER INTELLI-NIP® SHOE PRESS

NEW PRESS SECTION INTELLI-PRESS® FOR PM#1 APIS SZCZECIN- SKOLWIN, POLAND

Read more:

In February 2016, PMP (Paper Machinery Producer) launched another Intelli-Nip® Shoe Press as a core technological item of a new press section Intelli-Press® for Apis Sp. z o.o., Szczecin-Skolwin, Poland.

Intelli-Nip® Shoe Press technology is great hybrid of energy saving solution & impressive paper properties and is recently a desired solution worldwide. At present, PMP is executing 4 projects that include its shoe press solution: in USA, Mexico, Columbia and China.

The customer decided to re-start an existing PM#1 (reel trim 5425 mm), originally built by Fampa (a predecessor of PMP), and change its production profile from newsprint into fluting and liner grades.

Beside a production’s philosophy change, it was important to reach an annual production capacity goal at the level of 100 000 tpa of premium quality fluting and liner grades (basis weight range : 80-140 g/m2 ) at operating speed of 500 mpm.

To meet budget expectations, a scope of delivery was divided between parties. Apis team took care of a significant number of changes in the area of a stock preparation system and a PM’s wet end (a headbox and a wire) and in addition a refurbished size press was added. Whereas a new press section was fully designed and built by PMP (based on deliveries and services provided by PMP’s Polish divisions: PMPoland S.A. and PMP Rolls & Services).

PMP was also responsible for: pre-assembly services of the press section, movement tests before shipment, logistics, on site services including: erection, commissioning, start-up, training and optimization.

To achieve technological project goals within a press section area, PMP designed a modern Intelli-Press®, including 3 nips: a plain roll – on the 1st position (nip load 90 kN/m), a suction roll – on the 2nd position (nip load 30-40 kN/m) and the Intelli-Nip® Shoe Press on the 3rd position (design nip load 750 kN/m, module type: 1300).

A sophisticated press section configuration helps to achieve a dryness after press at the level of 50% following low steam consumption figures, supports reaching PM targeted annual capacity significantly and, in a visible way, reduces open draws increasing production effectiveness (higher PM effectiveness, stable PM operation, less paper breaks). In addition, shoe press technology helps to achieve expected paper properties especially much better bulk and stiffness.

This particular project is an example where PMP’s technological knowledge combined with high-tech equipment can become a key factor to achieve common success. Intelli-Nip® Shoe Press technology, supported by patented solutions, ensures reliable PM performance and top sheet dryness level resulting in significant steam consumption savings and user-friendliness.

About APIS:

APIS - Apis Sp. z o.o. was established in 2002. Thanks to the commitment and expertise of its founders Apis Sp. z o.o. started the production of corrugating board already in its first year. Company has increased the volume of production from year to year and won a significant market share in a short time. APIS offers high quality products and timely delivery while keeping prices on a competitive level. Company’s mission is the continuous increase of competiveness and volume of sales of corrugated board and packaging. learn more: www.pwapis.eu

About PMP:

PMP – Paper Machinery Producer - a global provider of tissue, paper & board technology, has been supporting pulp and paper industry for over 160 years, executing projects on 6 continents. Company owns 6 facilities in 4 countries (Poland, USA, China, Italy). PMP – the only paper machinery manufacturer in Poland - is a recognized international player in both paper & tissue industry. At the end of December 2015, PMP introduced new branding initiative including launching new logo & visual identity. learn more: www.pmpgroup.com

PMP successfully completed PM#4 wet end rebuild for Smurfit Kappa, Saillat, France

In April 2015, PMP (Paper Machinery Producer) was awarded by Smurfit Kappa Saillat (France) a PM#4 wet end rebuild. Thus it is our pleasure to announce that on January 8th 2016 at 7:00 p.m. local time, PM#4 was successfully brought on stream at the Saillat mill in France. At the same time, saleable paper parameters has been achieved just 1.5 hour later.

In April 2015, PMP (Paper Machinery Producer) was awarded by Smurfit Kappa Saillat (France) a PM#4 wet end rebuild. Thus it is our pleasure to announce that on January 8th 2016 at 7:00 p.m. local time, PM#4 was successfully brought on stream at the Saillat mill in France. At the same time, saleable paper parameters has been achieved just 1.5 hour later.

The main goals of the project were: paper quality improvement (Basis Weight CD profile, TSO profile and 2 sigma COV), as well as PM capacity increase.

PMP’s scope of delivery included a 4 channel Intelli-Jet V® (hydraulic head-box) for a top ply, a pressure pulsation attenuator system, a temperature control system and a wire rebuild (top ply mini-Fourdinier). The new hydraulic head-box assures significant improvement of basis weight profile, uniform paper web structure and significantly better formation. The temperature control system minimizes CD slice open deviations due to thermal, pressure and gravity forces, but also minimizes production loses. PMP was responsible also for a Vacuum System, on site erection and start-up supervision.

The delivery was divided into two stages:

1st stage – during August 2015: erection of a Top Mini-Fourdrinier including a Vacuum System installation and a Save-all System.

2nd stage – during January 2016: erection of a Top Ply Intelli-Jet V® Hydraulic Head-box with Consistency Profiling and a new turning roll, followed by commissioning and start-up supervision.

Main project achievements are: The TSO profile of top ply range increased significantly. The dry basis weight profile 2 sigma in cross machine direction (CD) was also improved. Top layer formation have been also improved.

Formation improvement can be seen in a much better top side smoothness. Final product formation has been improved as well. As a result of a better tuning allowed, operating machine speed increased as well.

About PMP Intelli-Jet V® Technology:

PMP Intelli-Jet V® Hydraulic Headbox Technology has become iconic – it is today a leading solution in the Pulp & Paper industry. It is a part of PMP Intelli-Paper® platform for papermakers. There are over 130 units working successfully on 6 continents.

About Smurfit Kappa:

Smurfit Kappa - one of the leading providers of paper-based packaging solutions in the world with over 43,000 employees across 33 countries. Smurfit Kappa is located in 21 countries in Europe, and 12 in the Americas, and is the only large-scale pan-regional player in Latin America. Smurfit Kappa’s pro-active team relentlessly uses its extensive experience and expertise, supported by its scale, to open up opportunities for its customers. This is enhanced through the benefits of the integration, with optimal paper design, logistics, timeliness of service, and packaging plants sourcing most of their raw materials from own paper mills. Smurfit Kappa products, which are 100% renewable and produced sustainably, improve the environmental footprint of customers. (learn more: www.smurfitkappa.com)

Smurfit Kappa Saillat is a flag mill located in Saint-Junien, in central France, with nearly 130 employees.

About PMP:

PMP – a global provider of tissue, paper & board technology, has been supporting pulp and paper industry for over 160 years, executing projects on 6 continents, in 29 countries. Company owns 6 facilities in 4 countries (Poland, USA, China, Italy). PMP is a recognized international player in both paper & tissue industry. At the end of December 2015, PMP introduced new branding initiative including launching new logo & visual identity. (learn more: www.pmpgroup.com)

PMP is represented in France by Gérard Cottet Consulting (This email address is being protected from spambots. You need JavaScript enabled to view it.)

2nd PMP Intelli-Tissue® EcoEc tissue machine smothly launched in Hebei Xuesong Paper, China

Exactly a year ago (January 2015), Hebei Xuesong Paper Co., Ltd signed a contract with PMP (Paper Machinery Producer) for the delivery of 2nd Intelli-Tissue® EcoEc machine. That was a natural consequence of a successful start-up of the 1st machine six months before.

Efficient cooperation between two companies started from TM#1 project in 2013. First Intelli-Tissue® 1200 EcoEc was brought on stream in April 2014 and thanks to excellent cooperation between Hebei Xuesong Paper and PMP, just 5 days after start-up, the maximum production capacity and tissue quality guarantees were achieved. TM#1 is characterized by an ultra-low level of steam consumption (1.6-1.8 t/t) – the best in the industry in this level of technological solution. Optimized paramaters help to significantly minimize production costs and increase sales margins.

On January 16th this year, PMP successfully started up 2nd Intelli-Tissue® 1200 EcoEc at Hebei Xuesong mill. TM#2 (twin sister line to TM#1) is characterized by reel trim of 2850 mm, design speed of 1200 m/min and daily capacity 60 t/d (basis weight 12.5-20 gsm). After TM#2 installation, Hebei Xuesong Paper have two machines (right and left hand) in the same building based on an Integrated Tissue Mill concept. We are proud to announce that paper at reel appeared 3 hours after supplying the stock, at the same time paper reached saleable parameters on the 2nd jumbo roll.

TM#2 is a twin-sister machine of TM#1 and is also based on philosophy of Optimum Cost Solution including tissue machine fully designed in Europe, manufacturing of the key components such as a Intelli-Jet V® hydraulic headbox and a Intelli-YD™ steel Yankee in Europe, and the remaining manufacturing, tissue machine pre-assembly and tests completed at the Center of Excellence of PMP Group: PMP IB (Changzhou) Machinery & Technology, Changzhou (China). This combination has ensured to lower the cost investment for the customer, while maintaining excellent quality of the equipment supplied. PMP has provided a stock approach system, Intelli-Tissue® 1200 EcoEc machine, mechanical drives, electrical drives, a lubrication system, a steam & condensate system and PLC. The PMP team has also been responsible for an erection supervision and technological start-up.

The same model of right and left hand machines layout in one building is the most compact solution and the two machines can share a common spare parts base. As a result, both space and costs are saved as well as number of personnel required to run the installations. Finally, the valuable experience of PMP gained from TM#1 project has made TM#2 even more adapted to the customer’s requirements.

About Intelli-Tissue® EcoEc Technology:

PMP Intelli-Tissue® EcoEc Technology – is a response to market demands and requirements of newcomers in the tissue business, however it may also be applied successfully to changing the technological concept of the mill. EcoEc means an Ecological and Economical machine with ultra low media consumption and low investment and operating costs. Intelli-Tissue® EcoEc can replace outdated and slow tissue machines, bringing costs savings and additional profits from a ready-made product. Reductions are directly connected to the limitation of space needed in the mill, less personel required to run the line and significantly smaller replacement parts base. Additional profits come from higher quality of the final product (soft tissue – higher margins) and entering new, unexplored market niches. Also note that working with state-of-art technology – such as the Cresent Former – is more efficient and easier for the operation personel.

About Hebei Xuesong Paper:

Hebei Xuesong Paper - a famous tissue-making enterprise in Hebei Province, China - was founded in 1987 and produces high-quality tissue products under "Xuesong” brand.

PMP – a global provider of tissue, paper & board technology, has been supporting pulp and paper industry for over 160 years, executing projects on 6 continents, in 29 countries. Company owns 6 facilities in 4 countries (Poland, USA, China, Italy). PMP is a recognized international player in both paper & tissue industry. At the end of December 2015, PMP introduced new branding initiative including launching new logo & visual identity. learn more: www.pmpgroup.com

PMP Group to supply another Intelli-Jet V® hydraulic headbox

In November 2012, PMP Group – a global provider of paper machinery, has signed a contract with Schumacher Packaging Werk Grudziądz, for the delivery of an Intelli-Jet V® hydraulic headbox.

The Schumacher Packaging Group, founded in 1948 and still owner‑managed, is now a leading manufacturer of tailor-made packaging solutions using corrugated and solid cardboard. Currently the company owns 10 facilities located in Poland and Germany, where it employs approximately 2200 people. It is one of the largest and most rapidly growing manufacturers of corrugated board and cardboard on the Polish market. In 2011, Schumacher Group reached a turnover of EUR 388 million. On its customer’s list, brands such as Bosch-Siemens, Lindt or Toshiba, can be found.

PMP Group’s scope of delivery will include an Intelli-Jet V® hydraulic headbox with Consistency Profiling System. The 5-channel unit, of pondside approximately 3100 mm and design speed 950 m/min, will be installed on PM#1 which is producing testliner. PMP Group will also be responsible for the unit’s assembly and supervision over the machine’s start-up which is scheduled for the second half of 2013.

PMP Intelli-Jet V® hydraulic headbox is the key component of the entire Intelli-Technology® platform - designed for paper and packaging production. A headbox is considered to be the heart of a paper machine, due to its high influence on the final product parameters. Thus PMP headboxes are high-tech products that are characterized by long product life-span.

The new unit, delivered to Schumacher Packaging, will make the 93rd headbox on PMP’s reference list so far.

PMP Successfully Starts Up Intelli-Tissue™ 1500 in Yuen Foong Yu in China

In July of 2011, PMP received an order for (2) new Intelli-TissueTM 1500 machines from Yuen Foong Yu located in Yangzhou, China. It is our pleasure to announce that the 1st of these machines, PM #5 was brought online on the 8th of August at 5:25pm. Mr. Ming-Fa Tang, the mill spokesman, commented “It was the fastest assembly and start-up in the history of the YFY Corporation”. The YFY and PMP team was very proud of this accomplishment and based on the overall satisfaction of their cooperation, look forward to potential future projects. Overall, this is the 2nd Intelli-Tissue™ 1500 machine installed by YFY with the 1st machine starting up in 2008 in Beijing, China.

YFY is a Corporation that is comprised of (3) Business Units. The Household Products Business Unit has (3) major brands of tissue paper: Mayflower, Tender and Delight. Their production lines cover paper products such as toilet paper, tissue paper, facial tissues, paper towels and napkins. The unit is also responsible for producing cosmetic products such as bio facial masks for leading brands in the country.

PMP supplied (2) 2.8m wide crescent former Intelli-TissueTM 1500 machines with a maximum operating speed of 1,600 mpm and a capacity of 75 tpd for PM #5 and PM#6 in Yangzhou. The machines are designed as an Eco-Tissue machines which maximizes quality and minimizes media consumption. They are able to produce virgin fiber based tissue with a basis weight range of 13 – 31.3 gsm for conversion into facial tissue, bath tissue and kitchen towels. The scope of supply covered stock preparation, the tissue machine (Intelli-Jet VTM Headbox, Intelli-FormerTM Crescent Former, Intelli-PressTM, 16’ Yankee Dryer with a high efficiency steam hood and Intelli-ReelTM) and auxiliary systems such as mechanical drives, lubrication system, steam & condensate system and dust removal.

PMP brought another Intelli-Tissue™ 2100 on stream

PT Graha Cemerlang Paper Utama (GCPU), a subsidiary of Kompas Gramedia Group, has brought its second brand-new Intelli-Tissue™ 2100 machine on stream at its Cikampek mill in Indonesia. PMP tissue machine started-up smoothly and easily (plug & play philosophy) and as a result the first paper at reel appeared on 11th November at 15.15. Project team members were proud to celebrate both the great result of common efforts as well as the Polish Independence Day. According to the common tradition machine receive the name: “Natalia”.

GCPU is one of the market leaders in manufacturing and converting tissue in Indonesia. Recently the company was rewarded the Top Brand Award and the Indonesia Original Brands Award 2011 for innovations. Tessa brand by GCPU was recognized as a combination of premium quality and environmentally – friendly attitude.

PMPoland S.A. – member of PMP Group supplied a new 3650 mm crescent former Intelli-Tissue™ 2100 machine with a maximum capacity of 140 tpd and the maximum operating speed of 2000 mpm. It is important to underline that it is a repeated order of the machine supplied in 2005, however the Intelli-Tissue™ 2100 machine is of higher maximum operating speed and also approx 5% higher capacity. The new machine is be able to produce tissue in a basis weight range of 12-42 gsm for conversion into facial tissue, toilet rolls and towels from 100% virgin pulp both hardwood and softwood. The scope of supply covered stock approach, entire tissue machine (Intelli-Jet V™ headbox, Intelli-Former™ Crescent Former, Intelli-Press™, Intelli-Reel™ and 15’’ YD with high efficiency gas hood) including auxiliary systems like DCS for the entire technological line, lubrication system, steam & condensate and vacuum systems, dust & mist removal systems.

The project for GCPU is another significant step of partnership between GCPU and PMP. Mr. Bambang Dwi Setiawan, Project Director of GCPU says: “We were currently pursuing the greatest possible extent of the first paper at reel on 11th November 2011. Thanks to the efforts, team work and highly dedicated people; we completed the TM#2 project earlier than the target. We are grateful that Grace Paper is able to run the TM#2 and produce the high quality paper in a short period of time.”

PMP to Deliver a Reel Rebuild to Kimberly Clark - Aranguren, Spain

PMPoland S.A. – a member of the PMP Group will deliver a reel rebuild including extended reel rails and a safety package to the Kimberly-Clark - Aranguren mill. The scope of supply for the dry end rebuild covers Extended Reel Rails, Safety Guarding and Threading & Sheet Stabilization systems. The project is schedule to be installed in the third quarter of 2011.

Kimberly-Clark Corporation is a Fortune 100 company, and is a leading global manufacturer of personal care, consumer tissue and away-from-home products. The company’s global brands include HUGGIES®, KOTEX®, KLEENEX®, DEPEND®, SCOTT®, KIMWIPES® and WYPALL®. Other brands well known outside the US include ANDREX®, SCOTTEX®, PAGE®, POPEE®, and KIMBIES®. Kimberly-Clark is also a major producer of professional health care products and premium business correspondence and technical papers.

PMPoland S.A. will supply the reel rebuild for PM#5 in Aranguren, Spain. The machine has a reel trim of 2,760 mm and a design speed of 1,500 mpm. The main goals of the project are to improve tail threading and sheet stabilization. PMP’s technical solutions and high quality manufacturing techniques allow PMP to meet the requirements of this rebuild.