Displaying items by tag: valmet

Valmet to supply advanced process controls and analyzers for Nippon Paper in Japan

Valmet has received repeat orders of advanced process control (APC) systems and analyzers from Nippon Paper in Japan. The solutions will be delivered to three of the Nippon Paper mills and consist of Valmet Advanced Process Control (APC) systems and Valmet Kappa Analyzers for the mills bleaching and lime kiln processes. The solutions will provide Nippon Paper with savings in chemicals and in energy consumption, as well as reduce end product quality variability. The new, latest technology kappa analyzers replace Nippon Paper's existing analyzers. The new advanced process controls and kappa analyzers will be in operation in 2016.

Valmet has received repeat orders of advanced process control (APC) systems and analyzers from Nippon Paper in Japan. The solutions will be delivered to three of the Nippon Paper mills and consist of Valmet Advanced Process Control (APC) systems and Valmet Kappa Analyzers for the mills bleaching and lime kiln processes. The solutions will provide Nippon Paper with savings in chemicals and in energy consumption, as well as reduce end product quality variability. The new, latest technology kappa analyzers replace Nippon Paper's existing analyzers. The new advanced process controls and kappa analyzers will be in operation in 2016.

Additionally, Valmet will provide Nippon Paper with performance services which will sustain the results and savings long term. The services contain expert support and consultation, and the processes will be improved further in in close cooperation with the customer as part of the services.

The order was included in Valmet's first quarter 2016 orders received.

Excellent results from an earlier delivery

The order is based on excellent results from an earlier delivery to Nippon Paper's Akita mill. In 2015, a performance improvement project was successfully delivered for Nippon Paper Akita mill.

"The highlight of the project is the speed in which Akita mill was able to achieve significant savings," comments Mr. Kameda, Senior technical manager of automation department, Akita Mill, Nippon Paper. This was achieved by delivering a holistic solution consisting of APC, analyzers as well as process consultation. The savings were delivered on schedule and clearly exceeded all targets.

The Akita mill now enjoys bleaching chemical savings of 7 %, 28% decrease in final brightness standard deviation, 5.5% saving in specific energy at the lime kiln, and has entered into Performance Sustainability agreement with Valmet to maintain and improve those savings long term.

"Through our proven automation and analyzer technology, and with our global and local professionals, we deliver concrete benefits and move the customers operations to a whole new level," says Atsushi Yamamoto, Sales Manager, Japan, Automation, Valmet.

Record high kappa analyzer deliveries in the past 12 months

In the past 12 months, Valmet has received a record number of orders for kappa analyzers. This has further strengthened Valmet's leading position on the global kappa analyzer market and increased its market share.

All greenfield pulp mills started up in the 2000s are equipped with Valmet's kappa analyzers. Since its introduction in 1992, Valmet has installed over 430 Valmet Kappa Analyzers in pulp mills around the world. Today, all leading chemical pulp producers worldwide use this technology in their processes.

Read more about the kappa analyzer market trends on valmet.com: Valmet's kappa analyzer deliveries hit record high in the past 12 months

Proven performance solutions through advanced process control and optimization

Valmet's performance solutions are part of comprehensive services offering and are designed to provide sustained performance improvement to pulp and paper producers. Valmet is a market leader of advanced process control (APC) with its 320 installations globally. The solutions combine advanced process control and optimization technology and expertise, and utilize Valmet's process measurements and analyzers. The solutions are scalable from one department to a line or mill level optimization.

Read more about Valmet Process optimization services and solutions at valmet.com.

Information about the customer Nippon Paper

Nippon Paper Group is one of the leading producers of paper and cardboard in the world. Nippon Paper Akita is the leading Japanese producer of paper, cardboard and pulp.

Valmet inaugurates new logistics center in Brazil

On July 7, 2016 Valmet inaugurated its logistics center in the city of Araucária, in Paraná state in Brazil. The center is Valmet's fifth logistics center globally and serves the pulp, paper, fiber board and other industries across South America with spare parts and components produced by Valmet and its local suppliers.

The inauguration ceremony was attended by local authorities, customers and Valmet's management. From left Marcos Ozório, Vice-Director of Codar, Celso Tacla South America Area President, Valmet, Marcelo Lupparia Vice President, Abimaq, Rui Souza Araucária Vice Mayor, and Elio Krummenauer Services Director, Valmet.

The inauguration ceremony was attended by local authorities, customers and Valmet's management. "This is an important milestone for Valmet in South America and offers a concrete contribution to moving our customers' performance forward," stated Celso Tacla, Area President for South America at Valmet in his inauguration speech.

The new logistics center will help to secure the reliability and efficiency of customers' processes in South America by supplying the required spare parts and components from the same continent, saving on freight costs and cutting delivery times.

"We'll be delivering just-in-time services to our customers, and we will reduce their dependency on spare parts imports. In addition, our customers will not have to invest in inventories, as Valmet is prepared to take care of their inventory management," says Jukka Tiitinen, Business Line President of Services at Valmet.

By securing a presence close to its customers' operations, Valmet's new logistics center in Araucária takes Valmet closer to its vision of becoming the global champion in serving its customers. Valmet's other logistics centers are located in Beloit (USA), Wuzi (China), Sundsvall (Sweden), and Helsinki (Finland).

"We want to deliver the best service experience to our customers worldwide. One part of that is being close and available whenever needed," states Elio Krummenauer, Valmet's Services Director in South America.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to supply a biomass-fired boiler plant to Segezha Pulp and Paper Mill in Russia

Valmet will deliver a biomass-fired boiler plant and related automation and environmental systems to Segezha Pulp and Paper Mill (Segezha PPM) in the Republic of Karelia, Russia. The boiler will produce steam for the mill's production processes and enables the mill to use wood residues and sludge as fuel and thus reduce the use of heavy fuel oil and lower its emissions and environmental impact. Valmet's delivery is scheduled for 2017.

The order is included in Valmet's second quarter 2016 orders received. The value of the order is not disclosed.

The order is included in Valmet's second quarter 2016 orders received. The value of the order is not disclosed.

"We selected Valmet's multi-fuel boiler after comparing a number of supplier offers. We took into account the reliability of the equipment and its operation, and the price/quality ratio. The decisive criteria that determined our decision were the technological factors and successful boiler references in numbers of industry enterprises. We see that a modern multi-fuel boiler can efficiently burn waste from wood processing with high and variable humidity, as well as sludge from our effluent treatment," comments Sergei Pondar, Vice President of Production for Segezha Group.

The new order strengthens Valmet's position as the leading supplier of bubbling fluidized bed (BFB) boilers with electrostatic precipitator based flue gas cleaning on the Russian market. This is the third boiler delivery featuring Valmet's bubbling fluidized bed (BFB) technology to Russia in the past three years.

"Over decades Valmet has delivered numerous biomass-fired boilers as well as chemical recovery boilers to Russia. We have an established supplier network in Russia and significant part of the delivery for Segezha will be manufactured in Russia. We look forward to delivering our competitive technology to Russia's market also in the future," remarks Nikolay Doroshenko, Director of Energy Sales and Services Operations, Russia and CIS, Valmet.

Technical information about Valmet's delivery

Valmet's delivery includes a 90 MW HYBEX boiler utilizing BFB combustion technology, Valmet electrostatic precipitator based flue gas cleaning equipment, electrification and a Valmet DNA automation system to control and operate the plant.

The HYBEX boiler developed by Valmet features wide fuel flexibility, high combustion efficiency, high reliability, excellent controllability and low emissions. Its main advantage is the possibility to use fuels with high moisture content and a low thermal value.

Information about the customer Segezha Pulp and Paper Mill

Segezha Pulp and Paper Mill is part of Segezha Group, a vertically integrated international forest industry holding company that comprises Russian and European enterprises in the forest, wood processing and pulp and paper industries as well as paper packaging manufacturing enterprises. Segezha Group has assets in 13 countries and employs around 13,000 people.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet selected to replace automation system at Papeterie du Bourray in France

Arjowiggins' Papeteries du Bourray graphic papers mill in France has ordered a Valmet DNA distributed control system (DCS) for PM1 to replace an earlier control system that is reaching end-of-life. The new Valmet DNA system will replace an old system from another supplier.

The order is included in Valmet's second quarter 2016 orders received. The value of the order is not disclosed. Typically the order value of this kind of automation system deliveries is below EUR one million.

The order is included in Valmet's second quarter 2016 orders received. The value of the order is not disclosed. Typically the order value of this kind of automation system deliveries is below EUR one million.

"Our Valmet DNA is based on more than 30 years of developing distributed control systems ranging from micro-sized systems to mill- and plant-wide systems that support global organizations. In this project we are replacing an old distributed control system from another supplier. The limited space in the mill's cross connection room meant that a major requirement for the mill was our ability to install the new system in the existing cabinets. Meeting both the ergonomic and performance expectations of the mill were keys to winning the replacement," says Boris Hosteins, Valmet Sales Manager in Bordeaux.

Technical details of the delivery

Valmet's delivery includes engineering, installation supervision, training and commissioning. The start-up of the new system scheduled for September 2016.

Valmet DNAis a single automation system for all applications - process, machine, drive and quality controls. It can also cover information management functions along with mechanical and field device condition monitoring. Guaranteed compatibility between different generation Valmet products helps to future-proof investments and maximizes the effectiveness of existing equipment.

About the customer Papeterie du Bourray

Arjowiggins manufactures a range of high quality natural white 100% recycled papers at the Papeteries du Bourray Mill in Le Mans, France. Printing paper production at the site started in 1951 and the present capacity is 80,000 tons per year.

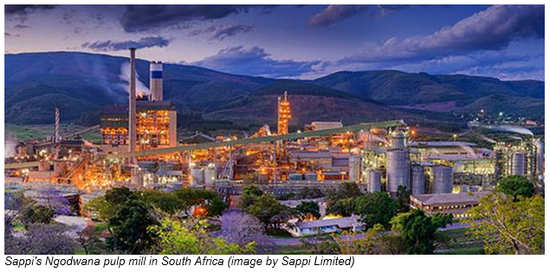

Valmet to supply a demonstration scale plant for next generation dissolving pulp cooking to Sappi in South Africa

Valmet will supply a dissolving pulp cooking demonstration plant to Sappi in South Africa to explore and optimize the extraction of biorenewable chemicals. The plant will be close to industrial size and is located at Sappi's Ngodwana mill. The demonstration plant will make it possible to study the next generation dissolving cooking process and test new ideas in mill scale. Start-up of the new plant is scheduled for the beginning of 2017.

The order is included in Valmet's second quarter 2016 orders received. The value of the order will not be disclosed.

In this project Sappi and Valmet will together take the next step in dissolving pulping and explore new revenue possibilities in the dissolving pulp production. These new revenues include possibilities to extract bio-based materials from the cooking plant pre-hydrolysate stream such as sugars and lignin to beneficiate to higher value bio-chemicals.

"This investment in new technology continues to support Sappi's strategic direction of seeking new bio-based opportunities and at the same time will generate a platform with associated benefits for further increased volumes and quality of dissolving wood pulp," noted Andrea Rossi, Sappi's Group Head Technology.

"We are very pleased that Sappi has selected Valmet as the supplier of the Ngodwana mill dissolving cooking demo plant. Our common target is to create the next generation dissolving pulp cooking concept which has the potential to be a game changer for our industry the coming years. The main features with the new concept are higher dissolving pulp quality, lower operating cost and a new optimized hydrolysate revenue stream. This project is in line with our R&D targets to provide advanced technologies and promote the use of renewable material. This will also further strengthen our market leadership position within dissolving pulp technology," says Lars Sjödin, Director at Valmet's Fiber Processing business.

Information about the customer Sappi

Sappi Specialised Cellulose is a division of Sappi Limited and sells dissolving wood pulp (specialised cellulose) to converters for a wide range of consumer products, but in particular for the manufacture of viscose staple fiber (VSF) for clothing and textiles. They are the world's largest manufacturer of dissolving wood pulp (from two mills in Southern Africa and the Cloquet Mill in North America) and export almost all of the production from their mills.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to deliver Valmet IQ to new extrusion coating line at Metsä Board Husum

Metsä Board has ordered Valmet IQ quality control systems(QCS) for the new extrusion coating line to start in the first half of 2017 at its Husum mill. This order follows the recent startup of Valmet IQ QCS on Husum's new BM1 board machine and off-line coater.

The order is included in Valmet's second quarter 2016 orders received. The value of the order is not disclosed. Typically the order value of similar automation system deliveries is below EUR one million.

"The new quality control system, supplied by Valmet, will support our work at different production stages. In their daily work, the machine operators can monitor products using one single system and combine different views to guarantee efficient and consistent production," says Kai Vikman, Vice President for Technology in Metsä Board.

"The delivery of the third quality control system to Husum is a significant opportunity to show again that Valmet can deliver a complete quality measurement and control system for both coated or uncoated qualities," says Mikael Jonzon, Sales Manager for Valmet's on-line quality management solution.

Technical details of the delivery

The delivery includes two scanners, the first measuring basis weight, moisture and caliper before coating with the second to measure and control the extrusion coating-thickness on both sides of the board. Additionally machine and cross direction controls are included in the delivery.

Extrusion coating thickness will be measured by a variant of the successful Valmet IR Coat Weight sensor with the patented technology offering a direct correlation to extrusion coat weight. The same sensor also makes a direct measurement of moisture.

Information about the customer Metsä Board

Metsä Board is a leading European producer of folding boxboards and white linerboards made from fresh forest fibres. Its lightweight paperboards are developed as the perfect fit for consumer goods, retail-ready and food service packaging. The pure fresh forest fibres Metsä Board uses are a renewable resource, traceable to origin in northern forests.

The global sales network of Metsä Board supports customers worldwide, including brand owners, converters and merchants. In 2015, the company's sales totalled EUR 2.0 billion, and it has approximately 2,600 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply two spray moisturizer systems to SAICA's corrugated board converting plants in Spain and France

Valmet will supply two Valmet IQ Moisturizer systems to SAICA's corrugated board converting plants in El Prat, Spain, and Beaulac, France. By installing Valmet's advanced moisturizing technology in their corrugators, SAICA's plants will be able to reduce corrugated board warping and consequently reduce waste and improve productivity in their converting processes.

The order was included in Valmet's first quarter 2016 orders received. The value of the order will not be disclosed. A moisturizer is usually valued below EUR 1 million. The deliveries will take place during the third quarter of 2016.

The order was included in Valmet's first quarter 2016 orders received. The value of the order will not be disclosed. A moisturizer is usually valued below EUR 1 million. The deliveries will take place during the third quarter of 2016.

"After many years of successful experiences working together with Valmet's automation solutions on paper production, Saica Group celebrates Valmet movement towards the introduction of automation technology on corrugators to ensure board quality as well as line production efficiency. The collaboration of the two companies' innovation technology teams is resulting on reliable control systems working on line and this order is a proof of our satisfaction," says Federico Asensio, Saica Group, Director, R&D and innovation.

"Entering paper and board converting with the Valmet IQ quality control solutions is one of Valmet's growth initiatives. We have earlier supplied a moisturizer system to SAICA's converting plant in Viana, Spain. A repeat order from SAICA is now proof that we are on the right track for delivering proven, value-adding quality control solutions also for the converting industry," states Jari Almi, Director, Quality Management Solutions, Automation, Valmet.

Technical information about Valmet IQ Moisturizer

Valmet's delivery includes two Valmet IQ Moisturizers that are part of the Valmet IQ product family for monitoring and optimizing process performance and end product quality.

Valmet IQ Moisturizer is a moisturizing system with applications for moisture cross-direction profiling, warp (curl) control and smooth moisture level increase. It features an air atomized micro droplet spray nozzle, a linear water control valve and excessive spray mist removal system.

Information about the customer SAICA

SAICA Group has three business areas: paper mills (Paper), collection of recyclable materials (Natur) and corrugated paper pack containers (Pack). The consolidated sales figures of the Spanish company for year 2015 were EUR 2,378 million. SAICA Group is a leading company in Europe in the manufacturing of containerboard paper, corrugating board with a capacity of almost 2.5 million tons of paper and more than 2.400 million square meters of corrugated board. The company has more than 8,800 employees at present in Spain, France, Italy, Portugal, United Kingdom, Ireland and Turkey.

Valmet receives repeat order for a new Advantage DCT tissue production line from Papel San Francisco in Mexico

Valmet will supply an Advantage DCT 100TS tissue production machine to Papel San Francisco in Mexico. The new machine will be installed at the company's mill in Mexicali and start-up is planned for the second half of 2017.

The order is included in Valmet's second quarter 2016 orders received. The value of the order is not disclosed

Continuation of good cooperation

The new tissue line will fulfill Papel San Francisco's need of new capacity for standard tissue products. Valmet has previously delivered three tissue machines to the company. Two Advantage DCT machines started up in 2006 and 2009 and one Advantage NTT started up in 2013 which fulfills the company's demand of textured tissue.

"Our previous installations are running very well. The Advantage DCT machines are operating at high speed and made the world speed record of 2160 m/min already in 2009. The Advantage NTT machine has reached record high production capacity in conventional mode and the textured products are well received on the market. Due to the need to increase our capacity of standard tissue we decided to go for the cost and energy efficient Advantage DCT technology equipped with the Advantage ViscoNip press," says Dario Palma y Meza Espinoza, Operational Director, Papel San Francisco.

"Our relationship withPapel San Francisco is a showcase for how a supplier and customer cooperate to achieve continuous performance improvements with a win-win result. During the years Papel San Francisco has managed to break several records regarding speed and operation performance. Our relationship is built on respect, strong trust and cooperation with professional and technical focus," says Jan Larsson, Sales Director North America, Tissue Mills Business Unit, Valmet.

Technical information about the delivery

The new tissue machine will have a width of 2.8 m and a design speed of 2,200 m/min and will add 30,000 tons tissue paper per year to Papel San Francisco's current production of toilet tissue, kitchen towels and napkins.

Valmet's scope of delivery will comprise an Advantage DCT 100TS tissue machine. The machine will be equipped with OptiFlo headbox and cast alloy Yankee cylinder. The machine will also be featured with the well proven Advantage tissue technology including ViscoNip press, AirCap hood and WetDust dust system. Start-up and commissioning are also included in the delivery.

About the customer Papel San Francisco

Papel San Francisco started up their first tissue machine in 1980. In the past 35 years the company has grown steadily and are today operating five tissue machines with a yearly capacity of 150 000 tons of tissue products.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet invests in press felt production

Valmet develops its paper machine clothing production plant in Tampere, Finland by investing in press felt production. The investment is done in order to improve the product technology and production capacity of seamed press felts for the paper, board, tissue and pulp drying machines.

The investment includes a new wide weaving loom, updating of some existing weaving looms and a new fiber opening and blending machinery. The total value of the investment is several million euros and the investment project will be finalized during the first quarter of 2017.

Seamed felts improve safety and efficiency

The investment is done in order to meet the growing market needs as customers are willing to move away from endless felts in older machines. The seamed felt market is growing, especially in North America, where over 70% of the felts used in paper and board machines are endless. Also in Europe, the market of seamed felts is growing. The change from endless felts to seamed ones improves occupational safety and production efficiency at mills.The seamed felt installation is faster and takes much less manpower than installing an endless felt.

"This investment gives us the necessary assets to further develop our leading technology for the growing and demanding seamed felt market. It also ensures our capacity for the coming years to deliver felts that respond to customer needs for optimized production performance. This is also an investment in Valmet's renewed services approach," says Jari Stålhammar, Vice President, Fabrics, Services Business Line at Valmet.

For further information, please contact:

Jari Stålhammar, Vice President, Fabrics, Services Business Line, Valmet, tel. +358 40 5014239

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet renews its services approach

Valmet has renewed its services offering and unified its way to serve to enable better customer experience and growth in the services business.

"Our vision is to become the global champion in serving our customers. We constantly challenge ourselves to improve both our services offering and also the way we actually meet our targeted customer service level. After adding automation and related services to our offering in 2015, the natural next step was to start unifying our services offering and way to serve our customers. We see that our new approach, called "Shared Journey Forward", is a concrete step towards our vision," says Pasi Laine, President and CEO of Valmet.

After the renewal, Valmet's whole services offering is easy to understand and to choose from. The services are restructured under three categories: reliability services, performance services, and new technology upgrades. Furthermore, Valmet develops further its global expertise network and way to serve the customers both online and close by.

The core commitments Valmet is making to its customers are keeping safety as number one priority, being close to the customers, serving customers with solutions meeting their needs and having people to whom customers can trust.

"The commitments we give to our customers reflect also our priorities. We never compromise safety and continuously develop our safety culture and procedures. Being close to customers means both that we are globally present with over 100 service centers and we utilize industrial internet in helping our customers remotely. We listen to our customers in order to find the best solution for particular customer needs and we work hard every day to earn our customers' trust," says Jukka Tiitinen, President of Services Business Line.

Valmet's services offering is built to improve reliability and performance of customers' processes and also bring in new technology to keep the processes up-to-date in the changing business environment.

"In addition to strong individual services products our solutions are built to bring concrete benefits to our customers. Our reliability services keep the equipment and processes running smoothly. We can even take responsibility for maintenance and on-site services and inventory management. With performance services our customers can achieve reduced energy and raw material costs, reduced process variability, optimized quality and production, and enhanced environmental performance. Furthermore, adding new technology to the process at the right time keeps production competitive and helps to take the production to the next level," describes Jukka Tiitinen Valmet's renewed services offering.

For further information, please contact:

Jukka Tiitinen, Business Line President, Services, Valmet, tel. +1 404 433 0937

Petri Lakka, Vice President, Services Development, Valmet, tel. +358 40 521 1087

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.