Displaying items by tag: voith paper

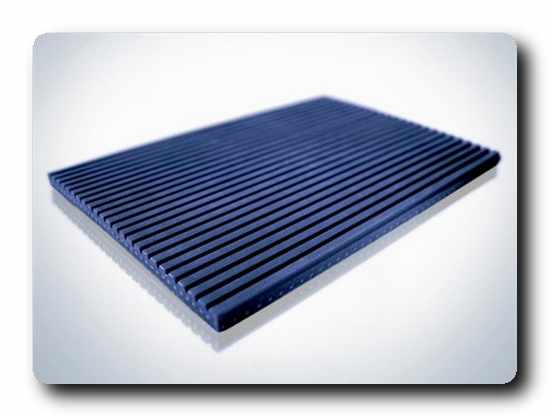

UpElement: Unique felt technology to quickly reach full production speed

Voith introduces UpElement to its expanding portfolio of tissue press fabrics. The modular treatment increases efficiency by achieving significantly faster startup times. Through an optimized surface enhancement UpElement improves dewatering properties during startup. As a result, manufacturers benefit from a higher production yield over the run of one felt cycle.

Smooth performance during startup is crucial for maximum efficiency in tissue production. With UpElement Voith offers an innovative solution that is specially tailored to meet these production challenges. As part of the Voith’s Element-Series of add-on solutions, the modular treatment complements the manufacturer’s existing press fabrics portfolio for tissue, and thus fits in well with the PressMax AdvancedPRODUCTS.

The modular treatment UpElement enables faster startup times and higher production gains.

The modular treatment UpElement enables faster startup times and higher production gains.

Faster startup time, stable operating conditions

Due to their unique technology, the felts have a higher saturation capability during startup which ensures optimal dewatering of the paper web. UpElement makes startup up to 50 percent faster compared to standard press fabrics, without compromising operational stability or long-term performance.

Higher production yield with each Voith felt

By reaching full machine speed significantly faster, UpElement not only keeps energy consumption to a minimum, but also delivers notably higher production output per felt: Depending on the operating setup, UpElement can increase output by an additional 100,000 € worth of saleable product per year. In this way, a quick return on investment can be expected.

“UpElement has proven itself in several trial runs resulting in immediate repeat orders from international tissue manufacturers,“ says Susanne Klaschka, Global Product Manager Press Section, Voith Paper. “We are proud to provide customers with yet another innovative solution to make tissue production even more efficient, more profitable and more sustainable.”

For more information about UpElement please visit: www.voith.com/fabrics

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, components and products on the market and offers paper manufacturers solutions from one single source. The company’s continuous stream of innovations takes papermaking to the next level and facilitates resource-conserving production. With its Servolution concept, Voith offers its customers tailored service solutions for all sections of the production process. Voith Papermaking 4.0 ensures that equipment is optimally connected, while the secure use of generated data enables paper manufacturers to improve plant availability and efficiency.

Voith sets World Record with QualiFlex CrownT at Hayat Kimya Alabuga TM 4

Hayat Kimya Alabuga TM 4 sets a new world record by using Voith’s QualiFlex CrownT sleeve on the ViscoNip application in Russia. The paper mill produces virgin fiber-based toilet paper, paper napkins and kitchen towels.

- New sleeve world record with a running time of 661 days

- Voith’s QualiFlex extends its leading position for shoe press applications

In December 2017, a QualiFlex CrownT sleeve was installed at Hayat Kimya TM 4 maintaining stable machine production during the entire sleeve lifetime. Voith’s QualiFlex CrownT sleeve reached a world record life of 661 days and 473,810,000 nip cycles. The former world record sleeve on such an application was set in China, achieving 585 days.

Voith’s QualiFlex CrownT sleeve.

Voith’s QualiFlex CrownT sleeve.

The customer was very satisfied with the result. “My congratulations to the whole Voith team for this excellent result and belt quality. My personal thanks to Voith for the support and proper service during the runtime of this belt,” says Mr. Lenar Safin, Tissue Production Chief at Hayat Kimya.

Press sleeves for every requirement

With QualiFlex CrownT, Voith offers a superior press sleeve for tissue shoe press applications which enables stable machine operating conditions and optimum efficiency. Selected polyurethane materials ensure the highest possible abrasion resistance under challenging high temperature conditions.

Compared to the conventional press sleeves, QualiFlex CrownT is especially designed for tissue applications. Conventional press sleeves show strong reactions to harsh conditions, and often suffer from hydrolysis, higher wear and reduced void volume.

Hayat Kimya Site in Tatarstan, Russia.

Hayat Kimya Site in Tatarstan, Russia.

With Voith’s QualiFlex CrownT, open area and void volume can be designed exactly to the customer’s needs. The special heat-resistant material formulation makes this press sleeve the perfect choice for very demanding applications.

Voith QualiFlex press sleeves extend the leading position for shoe press applications in the tissue sector.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, components and products on the market and offers paper manufacturers solutions from one single source. The company’s continuous stream of innovations takes papermaking to the next level and facilitates resource-conserving production. With its Servolution concept, Voith offers its customers tailored service solutions for all sections of the production process. Voith Papermaking 4.0 ensures that equipment is optimally connected, while the secure use of generated data enables paper manufacturers to improve plant availability and efficiency.

Acquisition of BTG successfully closed

After all required regulatory approvals were received, Voith successfully closed on the acquisition of BTG on December 1, 2019. The Swiss-based company offers a high-value portfolio of optimized and customized solutions for a range of applications, primarily for paper manufacturers.

“The acquisition of BTG is an important strategic step for Voith. With BTG and its portfolio that is highly complementary to our own products and services, we strengthen our position as a full-line supplier,” states Andreas Endters, CEO of Voith Paper.

“The acquisition of BTG is an important strategic step for Voith. With BTG and its portfolio that is highly complementary to our own products and services, we strengthen our position as a full-line supplier,” states Andreas Endters, CEO of Voith Paper.

The agreement for the acquisition was signed on September 19 between Voith and Spectris plc, the former parent company of BTG, for a total gross cash consideration of €319 million. BTG will remain entrepreneurial in nature and will operate under the established BTG brand. Therefore, Voith and BTG customers will be able to purchase via their existing sales channels as usual.

BTG supplies companies mainly in the areas of packaging, graphic papers and tissue. Its portfolio includes beds and rods for film-metering size presses, high-performance ceramic and cermet coating blades, and pulp and paper process control sensors and laboratory instruments. Moreover, BTG is a decisive partner in the digital transformation of the pulp and paper industry with its offerings in the areas of data analytics, automation and software.

“We are very excited with the acquisition of BTG by Voith. Together, we will have some tremendous opportunities to deliver more value to our customers, including integrated technologies, as well as Papermaking 4.0 and IIoT solutions. We are looking forward to joining forces with Voith. This will also present more opportunities for our employees going forward,” says Rob Crossman, BTG President.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, components and products on the market and offers paper manufacturers solutions from one single source. The company’s continuous stream of innovations takes papermaking to the next level and facilitates resource-conserving production. With its Servolution concept, Voith offers its customers tailored service solutions for all sections of the production process. Voith Papermaking 4.0 ensures that equipment is optimally connected, while the secure use of generated data enables paper manufacturers to improve plant availability and efficiency.

Papierfabrik August Koehler SE trusts Voith with the upgrade of its PM 5

Papierfabrik August Koehler SE has engaged Voith to comprehensively modernize the PM 5 paper machine at its main paper mill in Oberkirch. This vote of confidence in Voith is further evidence of the long-standing successful business relationship between the two companies.

- SpeedSizer AT improves competitiveness and increases flexibility

- Fewer downtimes and web breaks

- Contactless high-performance qDryPro Compact dryer increases efficiency

- Upgrade to pave the way for future speed increase and second expansion phase

Voith worked with Koehler to develop a customized concept for the PM 5 that improves competitiveness and increases flexibility. Downtimes and web breaks will be reduced and efficiency increased. The upgrade with high-tech components will allow paper coated on both sides to be produced in a larger operating window in future. The paper machine is also being prepared for a speed increase in a possible second expansion phase.

To achieve these ambitious project goals and improve the customer’s competitiveness, Voith’s upgrade incorporates the applicator unit SpeedSizer AT, which is ideal for fast running paper machines, the energy efficient, contactless high-performance dryer qDryPro Compact, and the PrevoSystem for short and reliable threading. For the pulpers in the press and reeling section, new pulping units are to be installed for even more effective pulping of the broke.

Voith PM 5 August Koehler SE Oberkirch, Germany.

Voith PM 5 August Koehler SE Oberkirch, Germany.

“The main reasons for upgrading our PM 5 are to increase efficiency, improve flexibility to allow a wider range of paper grades, and reduce costs.”, says Hartmut Felsch, Mill and Division Director Oberkirch at August Koehler SE.

SpeedSizer AT: Optimum film application at all times

SpeedSizer AT enables uniform, flawless application of sizing and coating films and improves paper qualities, penetration and surface coverage. The carbon fiber support beam is dimensionally stable regardless of external temperature fluctuations. It maintains maximum straightness and allows uniform film application over the entire operating period. The doctor rod holder used will be the patented modular system SpeedRod M, in which doctor rod, doctor bed, pressure hose and clamp hose are integrated in one component. Any type and diameter of doctor rod can be selected without necessitating laborious machine adjustments. Because individual components can be replaced, malfunctions can be fixed quickly and easily, downtimes reduced and production losses minimized. The SpeedSizer AT has already proven effective in more than 300 customer installations.

qDryPro Compact: Energy efficient, contactless high-performance drying

The qDryPro Compact is a high-performance dryer for paper and board grades with single or double-sided coating. There is usually very little space available for paper machine upgrades. This is why the air system of the qDryPro Compact was designed to be especially space-saving. The air circulation fan is integrated into the dryer. The combination of infrared and hot air drying is extremely energy efficient, because it uses only the waste heat from the infrared heaters to heat the air hood.

PrevoSystem: Reliable and short threading processes

Voith’s scope of supply also features the Prevo threading and cutting system including the PrevoThread C vacuum threading belt and a PrevoCut DTC double tail cutter. Because an inefficient threading process can stop production for up to an hour for every web break and restart, Voith developed the fully automated PrevoSystem, which ensures reliable threading processes and short threading times. It reduces production losses after every web break and increases productivity. 1,000 Prevo solutions installed worldwide testify to its benefits.

About the Koehler Paper Group

With a history that goes back some 210 years and a turnover of around EUR 900 million, the Koehler Paper Group is one of the few independent family-owned German companies in the paper industry.

At its headquarters in Oberkirch and paper mills in Kehl, Greiz and Weisenbach, its workforce of 1,850 people uses cutting-edge technology to produce more than 500,000 metric tons a year of specialty papers and board for the worldwide market.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the large family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, components and products on the market and offers paper manufacturers solutions from one single source. The company’s continuous stream of innovations takes papermaking to the next level and facilitates resource-conserving production. With its Servolution concept, Voith offers its customers tailored service solutions for all sections of the production process. Voith Papermaking 4.0 ensures that equipment is optimally connected, while the secure use of generated data enables paper manufacturers to improve plant availability and efficiency.

Voith builds world’s largest and fastest kraftliner machine for Ilim Group

Ilim Group, Russia's largest pulp and paper producer with an annual production volume of more than three million tons, will significantly expand its production capacity in a project now underway. As part of an extensive investment program, the company plans to produce up to 600,000 tons of kraftliner per year at its new plant in Ust-Ilimsk, Eastern Siberia, starting in 2021. The key partner in this project is the technology group Voith, which is working with Ilim Group on this scale for the first time.

- Production of up to 600,000 tons of kraftliner per year

- Project scope includes two BlueLine refining lines, one XcelLine system, drive components, comprehensive training measures and the Process Line Package (PLP)

- Integrated Papermaking 4.0 components increase efficiency, product quality and machine availability

As part of the Process Line Package (PLP), Voith assumes full responsibility for the project. The experts for the entire papermaking process ensure that the plant in Siberia starts up safely, on schedule and with precisely coordinated components. The PLP reduces the number of required interfaces and contact persons and simplifies the entire project handling, which ultimately also reduces costs.

As a full-line supplier, Voith is able to provide all system components including screens for each section, as well as comprehensive Papermaking 4.0 digitizing technologies. In addition, the globally positioned group is responsible for the electrical equipment and the entire drive system of the plant. A comprehensive training program on the new machine is also part of the project scope.

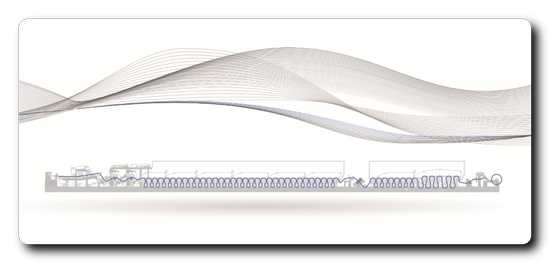

With XcelLine paper machines, Voith offers efficient paper production of every paper grade on a new level.

With XcelLine paper machines, Voith offers efficient paper production of every paper grade on a new level.

“Voith is partnering with Ilim Group in this historical and outstanding project. It will become a milestone for the Russian pulp and paper industry, and we are proud to contribute with our deep experience and latest innovations,” says Christoph Müller-Mederer, President Projects EMEA at Voith Paper.

The centerpiece of PM 1 in Ust-Ilimsk is a XcelLine of the latest generation. With a wire width of 10,300 millimeters, the Ilim Group plans to produce up to 2,150 tons of kraftliner per day with basis weights between 80 and 175 grams per square meter. This will make the new machine the most powerful of its kind in the world. The production speed of 1,200 meters per minute also represents a top performance.

OnCare.Health and OnCare.Asset as well as OnEfficiency.Strength are among Voith’s Papermaking 4.0 digitalization technologies that ensure consistently high product quality and reliably efficient manufacturing. In Ust-Ilimsk, OnCare.Health monitors the current status of the system at all times, registers even the smallest malfunctions and their causes, alerts the papermaker and independently works out optimization measures. In combination with the intelligent maintenance management system OnCare.Asset, this enables a significant increase in machine availability.

In addition to the record-breaking XcelLine machine, two BlueLine stock preparation systems are also included – one for hardwood pulp, the other for softwood pulp. They ensure exact compliance with the composition of the pulp. Voith's technology thus sets the course for maximum product quality right from the start of the process.

The preassembled equipment will be erected directly at the construction site in Ust-Ilimsk. In addition to the XcelLine and the BlueLine, components supplied by Voith will include a FlowJec dosing system for additives, the former section with two Fourdrinier machines equipped with MasterJet Pro F, a ModuleJet II and DuoShake, EcoCal hard calender, the drying section with CombiDuoRun dryers and a Sirius reel with EcoChange and VariFlex Performance winder. The delivery of the 79-ton Nipco-P roll represents a particular challenge for the project.

“Ilim sees its leadership role not only as the largest pulp and paper product manufacturer, but also as an investor into state-of-the-art innovative technologies. This investment decision was based on impressive results demonstrated by Ilim Group in the Asian market”, said Xenia Sosnina, General Director of Ilim Group. “We know this market well and see its opportunities. The contract we have signed is one of the largest contracts in the history of the Russian pulp and paper industry. Voith Paper, a leading manufacturer of paper and board machines with the highest level of automation and digitalization, has become our partner under this project. Our project will be one of the most advanced high-tech projects in the global pulp and paper industry, and will provide the Asian market with the volumes of high quality products it demands.”

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide, and is thus one of the large family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, components and products on the market, and offers paper manufacturers solutions from a single source. The company’s continuous stream of innovations takes papermaking to the next level and facilitates resource-conserving production. With its Servolution concept, Voith offers its customers tailored service solutions for all sections of the production process. Voith Papermaking 4.0 ensures that equipment is optimally connected, while the secure use of generated data enables paper manufacturers to improve plant availability and efficiency.

More efficient, safer and with lower emissions: Voith launches new infrared emitter HelioX on the market

With its new gas-fired HelioX infrared emitter, Voith is offering a particularly efficient solution for contactless drying along with impressively low emissions. Not only can the new emitter be used to increase productivity, the reduced fire risk also improves safety in paper production.

- Productivity increase thanks to output of up to 14 kW

- Gas consumption and emission values considerably reduced

- Reduced fire risk in the event of web breaks for improved safety

The new infrared emitter HelioX promises to deliver higher productivity with lower emissions and a reduced fire risk.

The new infrared emitter HelioX promises to deliver higher productivity with lower emissions and a reduced fire risk.

The key component of the new HelioX infrared emitter is its incandescent body, which has a highly efficient ceramic structure with a notably large surface area. The special geometry ensures improved combustion, resulting in both higher drying efficiency and a 50 percent reduction in nitrogen oxide (NOx) and carbon monoxide (CO) emissions. These low emission values are becoming increasingly important in view of the German air pollution control regulations (TA Luft) and more stringent emission limits in various countries, so as to obtain long-term operating approvals.

The HelioX infrared emitter is designed for an output of 14 kW. Consequently, it achieves a better drying efficiency, which enables higher machine speeds and more flexibility to produce different paper grades, and as a result, increases the productivity of the plant. With up to 10 percent better efficiency, the emitter also leads to lower gas consumption, lower running costs and a reduced CO2 footprint. Because of the low mass of the incandescent body, the HelioX infrared emitter offers a particularly fast heating up and cooling down time. This improves safety in production, as there is a much lower risk of fire in the event of web breaks. This means that the operating risk is also reduced, and shorter downtimes can be expected.

The design and highly efficient ceramic surface structure of the incandescent body ensure very homogeneous heat transfer, so that a maximum of energy is converted to infrared radiation.

The design and highly efficient ceramic surface structure of the incandescent body ensure very homogeneous heat transfer, so that a maximum of energy is converted to infrared radiation.

The gas-fired HelioX infrared emitter is now available. It can be used for contactless drying in any Voith paper machine and also in those of other manufacturers. It is also possible to use in other areas of application such as drying fiberglass mats or technical textiles.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the large family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, components and products on the market and offers paper manufacturers solutions from one single source. The company’s continuous stream of innovations takes papermaking to the next level and facilitates resource-conserving production. With its Servolution concept, Voith offers its customers tailored service solutions for all sections of the production process. Voith Papermaking 4.0 ensures that equipment is optimally connected, while the secure use of generated data enables paper manufacturers to improve plant availability and efficiency.

New shoe-blade gap former DuoFormer CBh with excellent first results at Smurfit Kappa

Voith expands its portfolio in the forming section with the DuoFormer CBh – a cost- and space-efficient shoe-blade gap former solution for the fabrication of packaging papers at high production rates, providing paper producers with the utmost flexibility and a fast return on investment.

- Compact design is ideally suited for rebuilds and new machines alike

- Features a unique, smart combination of well-known, reliable components from Voith’s DuoFormer product family

- Lower operating costs compared to other former concepts at reasonable investment

Papermakers who are either looking for a new former with a very good quality-performance ratio or are faced with the challenge of having to replace their existing former to gain productivity benefit from the DuoFormer CBh. Due to its compact design, it is ideal for rebuilds where space is at a premium.

Its dewatering elements are designed to achieve the best possible combination of dewatering capacity and paper strength with minimum effort. Using a full ceramic slotted impingement shoe cover design and a high vacuum suction box (HiVac) instead of a suction couch roll, the DuoFormer CBh ensures the highest dry content and lower maintenance costs compared to market standard solutions.

The compact design of the DuoFormer CBh is suited both for rebuilds and new machines.

The compact design of the DuoFormer CBh is suited both for rebuilds and new machines.

Voith’s DuoFormer CBh can be applied in a wide operation window, allowing for sustainable and reliable papermaking. It operates up to a maximum speed of 1,600 m/min. The drainage section’s capacity is exactly designed for desired production rates.

Well-devised design enables a steep ramp-up curve

After undergoing extensive testing at Voith pilot facilities in Heidenheim, the new former concept has already proven itself in actual use. “We chose Voith to supply this shoe-blade gap former for Roermond PM 1 because of the high quality and technology level of their equipment and their people. Based on our past experiences with Voith delivering successful projects, we felt good about investing in their technology, because it pays off in the long term,” says Wouter Lap, Managing Director of Netherlands-based manufacturer Smurfit Kappa Roermond Papier.

“Once again, the decision for Voith proved to be the right one. We had a great ramp-up curve from stock on wire to saleable quality within only one day after the rebuild that changed the entire forming section into an innovative DuoFormer CBh concept. We have seen a significant increase in the quality of our packaging papers and a production boost up 20% since the startup. Overall, we are very pleased with the results,” Lap concludes.

For more information about the DuoFormer CBh please visit

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the large family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, components and products on the market and offers paper manufacturers solutions from one single source. The company’s continuous stream of innovations takes papermaking to the next level and facilitates resource-conserving production. With its Servolution concept, Voith offers its customers tailored service solutions for all sections of the production process. Voith Papermaking 4.0 ensures that equipment is optimally connected, while the secure use of generated data enables paper manufacturers to improve plant availability and efficiency.

Improved paper quality and increased production capacity with Voith BlueLine products at Umka in Serbia

Increasing production capacity by over 90 percent and switching to more economic raw materials while increasing cleanliness of the end products – these were the two goals of the Serbian paper manufacturer Umka d.o.o. when upgrading its cardboard machine BM1. Part of the project was thereby an upgrade of the stock preparation with an InjectaCell Compact flotation unit and InfiltraDiscfilter disc filter from Voith’s BlueLine portfolio. Due to the excellent performance of the new products, the company has laid the groundwork to achieve these goals.

- Compact flotation – minimum space requirement and excellent technological results

- Robust disc filters with wide operating window

The whole rebuild project was part of Umka’s initiative to expand its production from approximately 105,000 metric tons of cardboard per year to more than 200,000 metric tons. Until that time, Umka has supplied 30 European countries with cardboard in three quality grades. The increased capacity gives the company, founded in 1939, the opportunity to tap into other markets.

Voith BlueLine stock preparation with InjectaCell Compact

Voith BlueLine stock preparation with InjectaCell Compact

On the lookout for cost-effective raw materials

During the rebuild, not only was the capacity on the agenda, but so too was the quality of the raw materials. The demand for the bright white recovered paper used by Umka had increased significantly in recent years. Also, it was becoming more and more difficult to buy raw material, and prices were continuously rising. Plant operators were therefore setting their sights increasingly on more cost-effective raw materials such as newspaper and magazine paper, which were available on the market in sufficient quantities. However, the technology required to process such raw material grades is considerably more advanced compared to conventional approaches. Investing in a new stock preparation system was therefore an important first step toward implementing the corporate strategy. “Previously, we worked with one loop and without a flotation system, but the planned changes were inconceivable with this arrangement. Our long-term goals could only be realized by integrating a flotation unit into a second loop,” explains Dragoslav Nešković, Project Leader at Umka.

The Voith team’s first task was to extend the existing stock preparation to deal with the new challenges, like reliably removing contaminants such as inks, stickies and glue from the paper suspension. To increase storage capacity of the stock preparation and to separate water loops from paper machine for improved paper machine performance, a disc filter was installed.

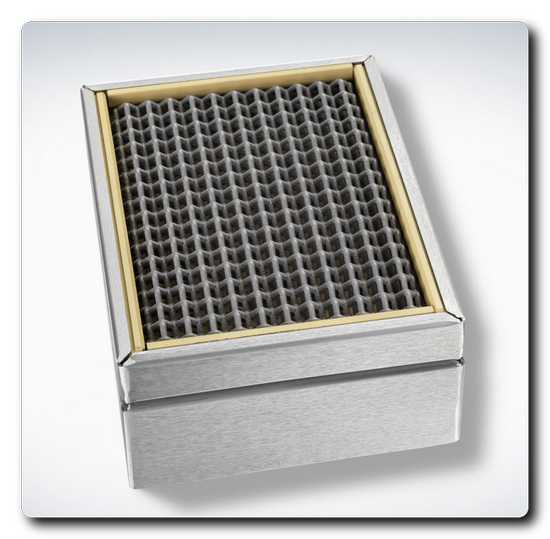

Compact flotation – minimum space requirement and excellent technological results

As a smart solution to effectively integrate the new machines into the existing building, Umka selected the InjectaCell Compact flotation unit ICC2/44 in combination with InfiltraDiscfilter IDF370. The new compact flotation system from Voith’s BlueLine range is based on InjectaCell (ICC) technology. It saves up to 50 percent energy compared to Voith’s famous EcoCell, which was the standard until 2012.

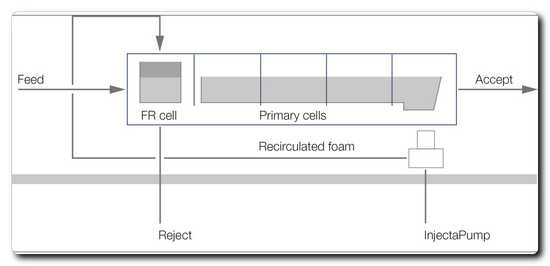

Schematic drawing of the InjectaCell Compact flotation system

Schematic drawing of the InjectaCell Compact flotation system

In InjectaCell Compact, secondary flotation cells are omitted. The first primary cells take over their task in addition to their normal duty. Due to this combined function, they are called fiber recovery (FR) cells. The foam from the consecutive primary cells is re-aerated by special injectors in these fiber recovery cells, thus maintaining the yield on an excellent level. A further important aspect of the InjectaCell Compact is the InjectaPump (ICP). InjectaPump is a combination of foam destroyer and pump that brings the foam from the primary cells to the fiber recovery injectors. As this is installed close to the flotation cells and no foam tank is needed any more, the whole InjectaCell Compact unit can be mounted on one floor.

The essential components of the flotation unit date back to the late 1960s. Profound knowledge in the properties of deinking foam and customer needs led to the development of this unique concept of fiber recovery cells. “The compact flotation technology is quite new. However, the feedback from all customers which operate InjectaCell Compact has always been very positive,” Dr. Antje Voiron from Voith points out. Despite their compact design, the quality of the results is comparable to that of conventional two-stage flotation systems. Thanks to the innovative technology, Umka can produce a fiber suspension with precisely the properties that the company requires for its products.

Robust disc filters with wide operating window

The wide range of raw materials and the successive increase of the production by more than 40 percent were also special challenges in this project. Thanks to the robustness of InfiltraDiscfilter, it can accommodate broad production ranges and varying freeness of the used furnish. In conventional filters using polypropylene (PP) filter bags, such conditions need extremely close operator attention in order to avoid damage of the PP bags. The BaglessPlus discs take such variations easy. Its design is based on many years of experience with over 500 installed filter discs. Their unique bagless technology makes the InfiltraDiscfilters robust and reliable – two characteristics that are most wanted in the paper industry.

Voith BlueLine stock preparation with InfiltraDiscfilter

Voith BlueLine stock preparation with InfiltraDiscfilter

Both InfiltraDiscfilter and InjectaCell Compact have proven to be highly reliable, simple to operate and virtually maintenance-free. The operating costs, which are lower compared to conventional technologies, were a further argument for Umka to decide to work with Voith stock preparation equipment again after many years.

The board machine currently produces about 130,000 metric tons of paper, and Umka is already taking a positive view: “The performance of the InjectaCell Compact and the InfiltraDiscfilters has fully met our expectations. Our employees also appreciate the easy operation and reliability of Voith products,” says Dragoslav Nešković, Project Leader at Umka.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & au-tomotive. Founded in 1867, the company today has more than 19,000 em-ployees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the large family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, components and products on the market and offers paper manu-facturers solutions from one single source. The company’s continuous stream of innovations takes papermaking to the next level and facilitates resource-conserving production. With its Servolution concept, Voith offers its customers tailored service solutions for all sections of the production process. Voith Papermaking 4.0 ensures that equipment is optimally con-nected, while the secure use of generated data enables paper manufactur-ers to improve plant availability and efficiency.

Voith Group to acquire BTG, a Spectris Company

Voith has signed an agreement with Spectris plc to acquire BTG for a total gross cash consideration of €319 million. With BTG, a multinational provider of integrated, highly specialized process solutions for the global pulp and paper industry, Voith strengthens its position as full-line supplier.

The transaction is expected to close late in the fourth quarter of 2019. The closing is subject to the company obtaining all regulatory approvals as well as other customary closing conditions.

The transaction is expected to close late in the fourth quarter of 2019. The closing is subject to the company obtaining all regulatory approvals as well as other customary closing conditions.

“BTG and Voith together have 250 years of technological experience in the global paper industry. This strategic step will bring many advantages for the entire industry. With BTG, we found an ideal match to complement our portfolio and get the chance to add a high-performing company with widely recognized expertise in the pulp and paper market. This helps us to expand our competitive position as a full-line supplier for the paper industry in the areas of consumables, instruments, services and software,” states Toralf Haag, President & CEO of the Voith Group.

BTG offers a high-value portfolio of optimized and customized solutions for a range of applications, mainly in the areas of packaging, graphic papers and tissue. Among these are beds and rods for film-metering size presses, high-performance ceramic and cermet coating blades, and pulp and paper process control sensors and laboratory instruments. All of these technologies are supported with expert services and application support. Furthermore, BTG is a decisive partner in the digital transformation of the pulp and paper industry with its offerings in the areas of data analytics, automation and software. It will therefore add value to Voith’s Papermaking 4.0 portfolio. More information can be found at www.btg.com.

“We are excited about this opportunity. Voith is a well respected player in the paper industry and our offering is highly complementary to theirs. As part of the Voith Group, we will be able to offer our employees and our customers more opportunities, supporting BTG growth and allowing us to realise our full potential”, says Rob Crossman, BTG CEO.

BTG, founded in 1921 in Sweden, is today headquartered in Éclépens, Switzerland, and employs around 600 professionals across the world. It operates four manufacturing sites, three research centers and several regional application centers. BTG has developed strong market positions, particularly in the pulp and paper industry, through a strong passion and commitment to delivering sustainable value to customers.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & au-tomotive. Founded in 1867, the company today has more than 19,000 em-ployees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

Voith supplies Papierfabrik Palm with complete BlueLine stock preparation line for new build project in Aalen

At the beginning of June 2019, the green light was given for the construction of the new Papierfabrik Palm paper mill for the production of testliner and corrugated baseboard. Voith will be supplying the stock preparation line for the project and has to this end designed one of the largest and most advanced BlueLine systems worldwide. As well as the entire stock preparation unit from feed-in of the recovered paper to the finished stock, the scope of supply also includes the complete design of the line and its measuring, control and instrumentation systems. Voith had already provided Papierfabrik Palm with support during the conceptual and approval phase for the new build project.

The stock preparation unit will produce 2,200 metric tons of stock per day. A precondition for the high quality of the product is an extremely clean furnish. At the same time, the company laid particular emphasis on achieving a sustainable, environmentally compatible paper production process. With its BlueLine concepts, Voith has already realized systems all around the world that achieve a maximum yield of high quality stock with low energy consumption and therefore meet the requirements imposed by Palm. The latest examples of these are the stock preparation lines for packaging papers at Leipa in Schwedt, at Hamburger Rieger Containerboard in Spremberg or at Propapier in Sandersdorf-Brehna. The expansion of the stock preparation line at the Aalen-Neukochen plant in 2018 has also been designed and installed by Voith.

Voith BlueLine stock preparation

Voith BlueLine stock preparation

Voith BlueLine EcoProcess

The design of the stock preparation line is based on the EcoProcess developed by Voith. The comprehensively tried and tested solution allows for an energy-optimized machine configuration. EcoProcess combines a strict counterflow principle with smart water cycle separation. In conjunction with water management across all systems, this results in a controlled discharge of dissolved and colloidal impurities with low water consumption. A cutting-edge, flexible long fiber screening concept, minimal solids content in the inlet to the waste water treatment facility and a special additional preparation line for largely clean recovered paper will result in high fiber yield and minimal waste volume. At the same time, the EcoProcess concept provides the basis for a stable paper manufacturing process and thus a consistently high product quality.

IntensaPulper and IntegraScreen components for efficiency and sustainability

For Palm and Voith, sustainability and efficiency were the key factors when choosing the individual components. For example, thanks to its optimized machine housing, the IntegraScreen ensures consistent flow and pressure conditions around the screen, which results in high contaminant separation efficiencies. An additional reject dilution step and the integration of an external reject recirculation to the machine reduces thickening of the reject and increases fiber yield.

The IntensaPulper ensures efficient yet energy-saving pulping. Thanks to the combination of a special vat geometry and the asymmetric arrangement of the rotor, the internal flow pattern of the IntensaPulper converts the flow energy into pulping performance. As a result, energy savings of up to 20 percent can be achieved. String-free disposal of contaminants from the pulper is ensured thanks to the IntensaMaXX, which was specially developed for this application.

The HiClean HCL5-I cleaner is another addition to the range of energy-efficient components in the stock preparation line. Smooth interior surfaces and a flow-optimized head piece enable maximum separation efficiencies in this technology developed by Voith. The patented EcoMizer reject dilution allows high reject concentrations at low overflow rates. As a result, the HiClean HCL5-I cleaner can work reliably and efficiently with high stock densities of up to three percent. The effect of this high intake stock consistency is a low energy consumption.

About Palm

Palm is one of the leading companies in the European paper industry. The Palm Group is divided into Papierfabrik Palm with its 5 paper mills for the manufacture of paper and Palm Packaging Group with 26 plants for the manufacture of corrugated board. The third pillar of our operations, which encompasses the purchasing of raw materials for all our papers and corru-gated boards made from 100% recycled paper are joined under the umbrel-la of Palm Recycling consisting of two recycling companies. www.palm.de

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the large family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, components and products on the market and offers paper manufacturers solutions from one single source. The company’s continuous stream of innovations takes papermaking to the next level and facilitates resource-conserving production. With its Servolution concept, Voith offers its customers tailored service solutions for all sections of the production process. Voith Papermaking 4.0 ensures that equipment is optimally connected, while the secure use of generated data enables paper manufacturers to improve plant availability and efficiency.