Displaying items by tag: lenzing

Lenzing Group: Persistently Difficult Market Environment, Cost Savings Measures Positively Impact Results

The Lenzing Group is working to counteract the ongoing difficult market environment prevailing in the fiber industry. Sales and earnings declined in the first nine months of 2014 compared to the prior-year performance, but cost savings are having a positive impact. This led to a slight earnings improvement in the third quarter of 2014, the first time in about two years. Further cost reductions are planned in light of the fact that no significant impetus is expected from the market.

The Lenzing Group is working to counteract the ongoing difficult market environment prevailing in the fiber industry. Sales and earnings declined in the first nine months of 2014 compared to the prior-year performance, but cost savings are having a positive impact. This led to a slight earnings improvement in the third quarter of 2014, the first time in about two years. Further cost reductions are planned in light of the fact that no significant impetus is expected from the market.

- Q1-3 EBITDA of EUR 159.8 mn (down 16% from the previous year)

Ongoing weak fiber prices burden Q1-3 sales and earnings

The decline in the average fiber selling prices and the high volatility on the fiber market continue to negatively impact the company’s business operations. Consolidated sales decreased by 6.2% to EUR 1,357.7 mn in the first three quarters of 2014, down from EUR 1,447.0 mn in the previous year. More than half of the sales drop is due to the non-recurring effects relating to the disposal of the Business Unit Plastics in 2013. Consolidated sales were down by 2.8% in a like-for-like comparison. Average fiber selling prices of the Lenzing Group fell to 1.55 EUR/kg compared to 1.73 EUR/kg in the first three quarters of 2013. The price decline could not be fully offset by increasing fiber production and sales volumes, in part as a result of the successful start-up of the new TENCEL® fiber manufacturing facility at the Lenzing site. Fiber sales volumes rose by 7% year-on-year to 706,900 tons in the first nine months of 2014.

In a like-for-like comparison of continuing operations, consolidated EBITDA1 in the first nine months of the year amounted to EUR 159.8 mn, a 16.0% decrease compared to EUR 190.2 mn for Q1-3 2013. This corresponded to an EBITDA margin of 11.8% (Q1-3 2013: 13.6%). Consolidated nine-month earnings before interest and taxes (EBIT) amounted to EUR 69.5 mn, a drop of 34.8% from EUR 106.6 mn in the previous year. This comprised an EBIT margin of 5.1% (Q1-3 2013: 7.6%). As a consequence of the excelLENZ program, the number of employees working for the Lenzing Group fell to 6,352 people as at September 30, 2014 (December 31, 2013: 6,675) despite the full operation of the new TENCEL® fiber production plant in Lenzing.

1 Earnings before interest, taxes, depreciation on property, plant and equipment and amortization of intangible assets and before income from the release of investment grants.

Third-quarter earnings reflect cost reductions

The third-quarter 2014 performance of the Lenzing Group was marked by a slight year-on-year earnings improvement as well as in comparison to the second quarter of 2014. “The measures are succeeding. The earnings improvement is mainly attributable to the excelLENZ cost-cutting drive but also from the first fiber sales volumes produced by the new TENCEL® fiber plant in Lenzing”, says Lenzing CEO Peter Untersperger.

In spite of higher sales volumes, consolidated sales in the third quarter of 2014 stagnated at EUR 457.7 mn compared to the prior-year level of EUR 457.1 mn, which is due to the lower average fiber selling prices. Nevertheless, third-quarter EBITDA rose to EUR 68.0 mn (Q3 2013: EUR 61.8 mn), and EBIT in the third quarter of 2014 totaled EUR 37.1 mn (Q3 2013: EUR 33.4 mn), whereas EBT improved to EUR 33.3 mn from the figure of EUR 28.2 mn in the prior-year quarter.

Implementation of further cost savings

“We expect cost savings exceeding EUR 90 mn for the entire year 2014, of which about one quarter involves personnel expenses. The remaining cost decreases equally relate to reduction in material costs and savings derived from efficiency projects to cut general and administrative expenses”, adds CEO Untersperger. “Planning work has begun to enable a further improvement of the Lenzing Group’s cost structure to be achieved in 2015. Starting in 2016 we will achieve sustainable cost reductions of over EUR 160 mn p.a. These measures are designed to safeguard the long-term competitive strength of the company and its self-financing capacity for future investments.”

Outlook Lenzing Group

The global market for man-made cellulose fibers will continue to be impacted in the upcoming months by low pulp prices and surplus fiber production capacities against the backdrop of good volume demand.

The successful ramp-up of the TENCEL® fiber plant in Lenzing, the initiated improvements in the product mix, and the strong expansion of marketing and sales activities along the entire value chain will improve the company’s market position and its relative competitive strength. In addition to an intensification of the excelLENZ cost reduction program, the realignment initiative in the fields of Lenzing Technik, site maintenance and repair services will make an important contribution towards achieving operational improvements at Lenzing.

The Lenzing Group

The Lenzing Group is a world market leader with headquarters in Austria, production sites in all major markets as well as a worldwide network of sales and marketing offices. Lenzing supplies the global textile and nonwovens industry with high-quality man-made cellulose fibers. The portfolio ranges from dissolving pulp, standard and specialty cellulose fibers to engineering services.

Lenzing quality and innovative strength set global standards for man-made cellulose fibers. With 75 years of experience in fiber production, the Lenzing Group is the only company worldwide combining the manufacturing of all three man-made cellulose fiber generations on a large industrial scale under one roof – from the classic viscose to modal and lyocell (TENCEL®) fibers. The success of the Lenzing Group results from a unique combination of consistent customer orientation together with its leadership in innovation, technology and quality. Lenzing is committed to the principle of sustainable management and very high environmental standards.

Lenzing's core business fibers is complemented by our activities in the business field engineering.

The Interim Report 01-09/2014 is available for download via this link

Key Figures Lenzing Group 2013:

Sales: EUR 1.91 bn

Export share: 90,8%

Fiber sales volumes: 890,000 tons

Staff: 6,675

for more info please contact:

Stephanie Kniep

Head of Investor Relations

Phone: +43 (0) 7672 701-4032

This email address is being protected from spambots. You need JavaScript enabled to view it.

Successful Start-up of World’s Largest TENCEL®¹ Production Plant in Lenzing

First sales volumes already successfully marketed

Technological milestone for TENCEL®, the fiber of the future

The TENCEL® production plant secures 140 jobs at the Lenzing site

Investment costs of EUR 150 mn and construction time of 24 months fully on schedule

The Lenzing Group has successfully initiated production at its new TENCEL® jumbo production facility, the largest in the world, at the Lenzing site in Upper Austria. The plant is in the midst of a stable ramp-up phase. The feedback on the part of the market is very positive.

The Lenzing Group has successfully initiated production at its new TENCEL® jumbo production facility, the largest in the world, at the Lenzing site in Upper Austria. The plant is in the midst of a stable ramp-up phase. The feedback on the part of the market is very positive.

“We are more than satisfied with the progression of the start-up curve. Based on the production process in the past days and weeks, we have reasonable grounds to believe that this latest generation of TENCEL® technology will completely fulfill our expectations”, says a confident Lenzing Chief Executive Officer (CEO) Peter Untersperger. “The successful start-up of production operations is a technological milestone for TENCEL®, the fiber of the future, and for the entire Lenzing Group. We are optimistic that we will be able to achieve the planned production target of 30,000 tons by the end of 2014. This new TENCEL® facility is decisive to ensure the long-term viability of fiber production at the Lenzing site and the basis for future investments in all markets”, adds Lenzing’s Chief Operating Officer (COO) Friedrich Weninger.

This factory comprises the first time in which a single production line with an annual nominal capacity of 67,000 tons was installed. Previous TENCEL® production lines were usually only one-quarter as large. The new plant design incorporates lessons learned from the longstanding experience of three existing Lenzing Group TENCEL® production plants located in Austria, USA and Great Britain. As a consequence, the new TENCEL® plant in Lenzing represents the world’s leading generation of TENCEL® technology. The new design of the jumbo production line also enables investment costs to be maintained at a very competitive level of approximately EUR 150 mn (about EUR 2,200 per ton of capacity). This comprises the decisive approach to the further competitive scaling of TENCEL® fibers as a universally deployable textile and nonwoven fiber. The new, broader product portfolio on the basis of the TENCEL® technology successfully complements Lenzing’s specialty strategy.

With a construction time of 24 months, Lenzing completely adhered to both the budgeted investment costs as well as all timetables. The TENCEL® production in Lenzing secures 140 jobs at the Lenzing site.

Thanks to the new plant, annual nominal TENCEL® production capacity of the Lenzing Group will rise from 155,000 tons p.a. to about 220,000 tons. In this way Lenzing will further expand upon its global market leadership for TENCEL® fibers and offer its global customers new expansion opportunities in both the textile and nonwovens segments as well as new and innovative applications. “The related market development activities have already been in full swing for quite a few months”, states Robert van de Kerkhof, the Chief Commercial Officer (CCO) of Lenzing responsible for the fiber business. Moreover, new technical applications will be opened up and massively expanded in the years to come.

TENCEL® - the fiber of the future

TENCEL® is the latest generation of man-made cellulose fibers, and is manufactured in a particularly environmentally-compatible production process awarded the “European Award for the Environment” by the European Union. Lenzing is the only industrial-scale supplier of TENCEL® in the world. TENCEL® fibers are used by the textile industry as well as for nonwovens. Typical applications of the high-tech fiber TENCEL® include sportswear, soft denim applications, home textiles as well as baby wipes and cosmetic wipes. However, TENCEL® is also being increasingly deployed for technical applications. For example, as a powder added to construction materials, TENCEL® ensures a pleasant indoor climate.

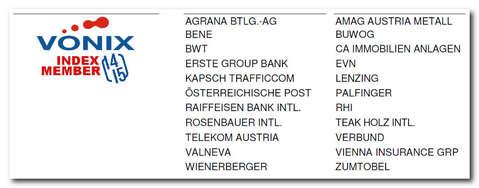

Lenzing Listed in the VÖNIX Sustainability Index for the 9th Straight Year

Since 2005, about 60 publicly traded Austrian companies are analyzed each year on the basis of about 100 environmental and social criteria. The best companies are accepted for listing in the VÖNIX index (VBV Austrian Sustainability Index) for a period one year.

Lenzing belongs to this group of companies for the 9th straight time, and was also given a very good rating again this year.

In the 2013/14 index year, the performance of the VÖNIX index was reflected in a 10.6% gain in value, thus 3.6 percentage points lower than the ATX Prime. A total of 22 stocks (alphabetically listed) will be included in the VÖNIX 2014/15 index.

Lenzing Fibers Sold in Ja! Natürlich Products

Innovation with Lenzing fibers: vegetable nets of 100% natural origin for Ja! Natürlich – the organic brand of REWE International AG

Innovation with Lenzing fibers: vegetable nets of 100% natural origin for Ja! Natürlich – the organic brand of REWE International AG

Recently Lenzing fibers made of the renewable raw material wood also began to be used in the retail food sector. The organic food supplier Ja! Natürlich took a further step to avoid plastics within the context of its Green Packaging Initiative launched in the year 2011. Accordingly, onions, potatoes and beetroots are now being packaged in 100% biodegradable nets.

An regional solution

100% Lenzing Modal® Color is used for the production of the nets, which was developed in a joint project involving the Packaging Center Graz, Lenzing AG and Borckenstein, a long-standing partner company of Lenzing AG. These nets keep the vegetables fresh even longer thanks to their moisture- regulating and breathable properties. In addition, they can be conveniently disposed of in the home compost because the nets are biodegradable. The fine nets which are soft to the touch also protect the contents more effectively than the previously used plastic nets.

“The time is ripe for ecological innovations such as this one. For Lenzing this project means entering a completely new market, from which we expect a lot in the future”, says Friedrich Weninger, COO of Lenzing AG with responsibility for research and development.

“Lenzing and Borckenstein have been trusted partners for decades, cooperating at a high technical level”, Manfred Kern, Managing Director of Borckenstein adds. “This was a decisive reason for the incredible speed with which this idea could be implemented”.

Lenzing Modal® Color is produced from European beech wood and is thus 100% natural. More than one-third of the wood is derived from Austrian forests. Pulp and fiber production are carried out in line with the principle of sustainability. Lenzing manufactures the pulp it uses itself, and thus exerts control over the entire production process, which is considered to be a worldwide best practice. This is unique in the global fiber industry.

“We are proud that Lenzing fibers can make such an important contribution to a better life”, comments Peter Untersperger, Chief Executive Officer of the Lenzing Group. “Lenzing fibers have become a small but often indispensable part of our modern industrial society. We are doing everything we can to produce these consumer goods with the least possible environmental impact. This Austrian innovation in the field of food packaging is clearly a step in the right direction”, Peter Untersperger adds.

“I am very happy that we have taken a further step forward in green packaging. In the light of the fact that plastics have dominated the field of packaging materials over the last 40 years, we are now offering a sustainable alternative based on the use of natural materials”, says Martina Hörmer, Managing Director of Ja! Natürlich.

Lenzing Partners with NanoCarbons LLC to Develop New Activated Carbons for Energy Storage Systems

Lenzing AG and NanoCarbons LLC, Fort Lauderdale (Florida, USA), will cooperate in the future to develop and explore the use of new activated carbons in electrode technology. This technology is based on a combination of Lenzing’s TENCEL® fibers and the technology provided by NanoCarbons LLC. After extensive research Lenzing constructed a new pilot production facility to take the technology forward.

Lenzing AG and NanoCarbons LLC, Fort Lauderdale (Florida, USA), will cooperate in the future to develop and explore the use of new activated carbons in electrode technology. This technology is based on a combination of Lenzing’s TENCEL® fibers and the technology provided by NanoCarbons LLC. After extensive research Lenzing constructed a new pilot production facility to take the technology forward.

The jointly developed carbons should deliver optimal performance in the area of energy storage. It is believed that these new carbons will accelerate the development of the already rapid growth in uses of electrical devices such as double layer capacitors (also known as ultra capacitors or super capacitors). These high performance capacitors are being increasingly used in hybrid vehicles as well as with stop-start systems, uninterruptable power supplies and wind turbine blade orientation.

“For Lenzing, the development of new, special applications in the technical segment comprises an important extension of the use of our fibers”, says Peter Untersperger, Chief Executive Officer of the Lenzing Group in commenting on the new partnership. “The strongly growing market for energy storage devices is a promising market niche for us. With our TENCEL® fibers we will certainly witness the development of a series of additional, highly interesting technical applications in the coming years.”

Friedrich Weninger, COO of the Lenzing Group with management responsibility for research and development, adds: “We are continuing to invest in new areas of research to increase the range and reach of our product portfolio, both in-house and through external cooperation. The new carbons optimally complement our existing business with separator materials for the energy storage devices. We strongly believe in the future growth of this market. We are offering our customers a sustainable product with consistent quality to allow the industry to develop further.”

Rud Istvan, CEO of NanoCarbons LLC, comments: “I strongly believe that this development will allow the double layer capacitor market to make a significant advancement. With the combination of Lenzing’s technical understanding and infrastructure and Nanocarbons’ technology, we can expect an acceleration in the market uses and exploitation of double layer capacitors, from new automotive stop-start systems to uninterruptable power supplies. This could be a breakthrough for electrode technology that will reap dividends for the designers of electrical components and the drivers of vehicles alike.”

Lenzing Group: TENCEL® Celebrates 20th Anniversary

TENCEL® has turned 20. The first large production facility for lyocell fibers was put into operation in Mobile/Alabama (USA) in 1992. Today the Lenzing Group manufactures TENCEL® fibers at three sites located in Austria, Great Britain and the USA. Lenzing celebrated this anniversary by holding a commemorative ceremony and a customer symposium.

TENCEL® has turned 20. The first large production facility for lyocell fibers was put into operation in Mobile/Alabama (USA) in 1992. Today the Lenzing Group manufactures TENCEL® fibers at three sites located in Austria, Great Britain and the USA. Lenzing celebrated this anniversary by holding a commemorative ceremony and a customer symposium.

20 years ago the TENCEL® plant in Mobile was the first large-scale industrial production site in the world for the new lyocell fibers. The factory was originally built by the British company Courtaulds plc., a former Lenzing competitor. Lenzing also took over this facility within the context of the acquisition of the Tencel Group in the year 2004. In recent years it has been technologically upgraded, and annual production capacity was increased to the current level of about 50,000 tons of TENCEL® fibers. Today Lenzing manufactures TENCEL® fibers at three sites: Heiligenkreuz (Austria) with an annual capacity of 60,000 tons, Grimsby (Great Britain), featuring a capacity of approx. 40,000 tons each year, and the Mobile, Alabama plant. A fourth production plant is currently being constructed in Lenzing (Upper Austria). Total annual capacity will amount to 60,000 tons, and the facility will be the first second-generation TENCEL® plant from a technological perspective.

On the occasion of the special commemorative ceremony, Lenzing CEO Peter Untersperger emphasized the tremendous importance of the TENCEL® technology. “TENCEL® has been the biggest technological step forward in the man-made cellulose fiber industry since the invention of viscose fibers about 100 years ago. The development of the fiber over the last 20 years only marks the beginning of a success story which will continue for many decades to come. TENCEL® ideally combines the need for competitive production costs compared to other fibers with the requirement of ensuring sustainable, environmentally compatible production. TENCEL® is a breakthrough technology, and I am proud that the Lenzing Group is by far the world’s number one provider of TENCEL® fibers.“

On the occasion of the special commemorative ceremony, Lenzing CEO Peter Untersperger emphasized the tremendous importance of the TENCEL® technology. “TENCEL® has been the biggest technological step forward in the man-made cellulose fiber industry since the invention of viscose fibers about 100 years ago. The development of the fiber over the last 20 years only marks the beginning of a success story which will continue for many decades to come. TENCEL® ideally combines the need for competitive production costs compared to other fibers with the requirement of ensuring sustainable, environmentally compatible production. TENCEL® is a breakthrough technology, and I am proud that the Lenzing Group is by far the world’s number one provider of TENCEL® fibers.“

The beginnings: a competitive race between giants

The initial phase in the development of lyocell fibers (marketed by Lenzing today exclusively under the brand name TENCEL®) was characterized by a bitter rivalry between the Lenzing Group and Courtaulds. Both companies conducted research in competition with each other to become the first of the two firms to launch promising new fibers on the marketplace. At the production start in Mobile in 1992, Courtaulds had a competitive edge, but Lenzing’s first large-scale lyocell factory in Heiligenkreuz (Burgenland) was already in the pipeline. It was successfully put into operation in 1996. In 2004, Lenzing finally acquired the Tencel Group and all its production sites.

The initial phase in the development of lyocell fibers (marketed by Lenzing today exclusively under the brand name TENCEL®) was characterized by a bitter rivalry between the Lenzing Group and Courtaulds. Both companies conducted research in competition with each other to become the first of the two firms to launch promising new fibers on the marketplace. At the production start in Mobile in 1992, Courtaulds had a competitive edge, but Lenzing’s first large-scale lyocell factory in Heiligenkreuz (Burgenland) was already in the pipeline. It was successfully put into operation in 1996. In 2004, Lenzing finally acquired the Tencel Group and all its production sites.

Combining forces

The merger of Tencel and Lenzing led to a bundling of their collective strengths. The two-way know- how exchange and the decision to consolidate research and development on TENCEL® fibers at one site finally led to the sought-after breakthrough on the marketplace for the new generation of fibers. The range of applications was expanded, and the TENCEL® business subsequently developed very dynamically, spreading from the USA to Europe and Asia.

Diverse applications

At the present time TENCEL® fibers are used by the textile industry as well as for nonwovens. The production process is particularly environmentally compatible, and is characterized by the nearly complete recovery of the deployed solvent.

At the present time TENCEL® fibers are used by the textile industry as well as for nonwovens. The production process is particularly environmentally compatible, and is characterized by the nearly complete recovery of the deployed solvent.

Lenzing is continuously developing new applications in cooperation with customers and partners. The optimal moisture management of TENCEL® fibers makes them attractive for use in home textiles such as mattresses, quilts and bed linen as well sportswear and women’s outerwear. TENCEL® is also integrated into sensitive segments such as cosmetics, hygiene, and medicine, for example in wound dressings and baby wipes. In the technical segment, TENCEL® is used, for example, to strengthen plastics or to manufacture electrotechnical components.

The Lenzing Group

The Lenzing Group is a world market leader with headquarters in Austria, production sites in all major markets as well as a worldwide network of sales and marketing offices. Lenzing supplies the global textile and nonwovens industry with high-quality man-made cellulose fibers and is the leading supplier in many business-to-business markets. The portfolio ranges from dissolving pulp, standard and specialty cellulose fibers to high-quality plastic polymer products and engineering services.

Lenzing quality and innovative strength set global standards for man-made cellulose fibers. With more than 70 years of experience in fiber production, the Lenzing Group is the only company worldwide combining the manufacturing of all three man-made cellulose fiber generations on a large industrial scale under one roof – from the classic viscose to modal and lyocell (TENCEL®) fibers. The success of the Lenzing Group is based on a unique combination of consistent customer orientation together with its leadership in innovation, technology and quality. Our successful specialization strategy and an outstanding cost position are the basis for our economic strength.

Lenzing is committed to the principle of sustainable management and very high environmental standards. Lenzing's core business fibers is complemented by our activities in the business fields plastics and engineering.

Key Figures Lenzing Group 2011:

Sales: EUR 2.14 bn

Export share: 91.5%

Fiber production: 705,100 tons

Staff: 6,593

For more info please contact:

Angelika Guldt

Head of Corporate Communications

Phone: +43 (0) 7672 701-2713

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Lenzing Group: Second Best Nine-Month Results Despite Headwinds

In spite of economic headwinds, the Lenzing Group succeeded in achieving the second best business results in its history. However, as expected, the company could not match the record performance of the previous year. Fiber shipment volumes rose by 12% year-on-year, whereas average selling prices for Lenzing fibers fell by about 11%, as anticipated.

- New record fiber shipment volumes

- Lower average fiber selling prices as expected

- Guidance confirmed for the entire year 2012

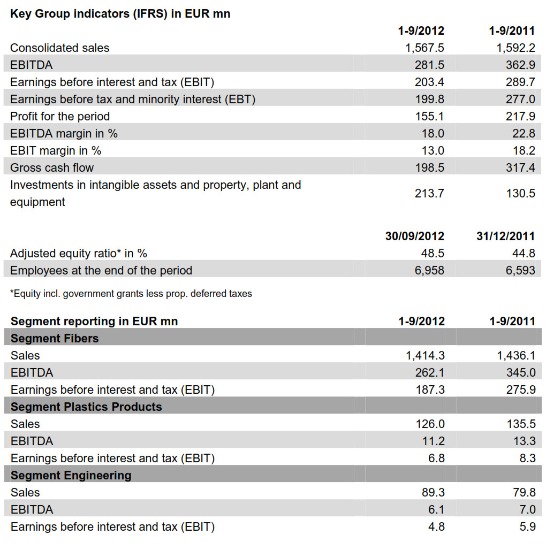

Consolidated sales of the Lenzing Group in the first nine months of 2012 amounted to EUR 1,567.5 mn, a drop of 1.5% from the prior-year level of EUR 1,592.2 mn. Consolidated EBITDA (earnings before interest, tax, depreciation and amortization) in the first three quarters was the second highest in the company’s history, totaling EUR 281.5 mn, down 22.4% from EUR 362.9 mn in Q1-3 2011. The EBITDA margin remained at an attractive double-digit level of 18.0% (Q1-3 2011: 22.8%). Earnings before interest and tax (EBIT) were also at a gratifying level of EUR 203.4 mn (Q13 2011: EUR 289.7 mn). This corresponded to an EBIT margin of 13.0% for the Lenzing Group in the first nine months of 2012, compared to 18.2% in the prior-year period.

“In spite of the difficult market conditions, we were able to achieve record sales of 590,000 tons of fibers in the first three quarters of 2012 against the backdrop of the full utilization of our production capacities. This underlines the world market leadership of the Lenzing Group based on quality, innovation, a global presence and optimal service“, says Lenzing’s Chief Executive Officer Peter Untersperger.

Adjusted Group equity totaled EUR 1,152.0 mn as at the end of September 2012, a rise of 9.9% from the comparable figure of EUR 1,048.1 mn at the end of 2011. The adjusted equity ratio was 48.5% as at September 30, 2012 (December 31, 2011: 44.8%). As a result of the lively investment activity within the Group, net financial debt increased to EUR 295.3 mn at the end of the third quarter (December 31, 2011: EUR 159.1 mn). Accordingly, net gearing continued to be a very low level of 25.6% (December 31, 2011: 15.2%).

(click picture to enlarge)

Outlook

Lenzing confirms its guidance for the entire year 2012, which was published as part of the half-year results. As a consequence, Lenzing is well on track to achieve the second best business results in the company’s history in 2012 as a whole. However, due to the current market developments, a decline of average fiber selling prices to about EUR 1.85 per kilogram is expected. Accordingly, Lenzing now expects that it will likely reach the lower end of the targeted range with respect to its performance indicators for the entire year 2012. This means consolidated sales are anticipated to be within a range of EUR 2.1-2.15 bn, whereas EBITDA will amount to EUR 350-400 mn and EBIT will total somewhere between EUR 240-290 mn. Capital expenditure for 2012 is budgeted to be about EUR 325 mn.

Long-term megatrends such as population growth, increasing per capita fiber consumption in the emerging markets and growing demand for resource-saving, environmentally compatible fibers remain intact, and are good arguments in favor of man-made cellulose fibers. However, this longterm growth trend does not exclude the possibility of repeated phases of delayed or accelerated economic growth. Lenzing remains committed to its long-term growth strategy.

Lenzing Group: Successful start of the fifth line at Indonesian subsidiary SPV

PT. South Pacific Viscose (SPV) is now the world’s largest viscose fiber plant

In late October, trial operations of the fifth production line started successfully at Lenzing’s Indonesian subsidiary PT. South Pacific Viscose. With an additional nominal capacity of 80,000 tons of viscose fibers p.a., the annual total capacity of SPV will increase to 320,000 tons once Line 5 has been launched. SPV will thus exceed the capacity of the parent plant in Lenzing/Upper Austria (250,000 tons p.a.) for the first time and become the world’s largest viscose fiber plant.

In late October, trial operations of the fifth production line started successfully at Lenzing’s Indonesian subsidiary PT. South Pacific Viscose. With an additional nominal capacity of 80,000 tons of viscose fibers p.a., the annual total capacity of SPV will increase to 320,000 tons once Line 5 has been launched. SPV will thus exceed the capacity of the parent plant in Lenzing/Upper Austria (250,000 tons p.a.) for the first time and become the world’s largest viscose fiber plant.

“Asia is the most important market for the Lenzing Group. It’s where we generate more than half of our fiber revenues. Therefore it is only logical that our largest plant is located in Indonesia”, Peter Untersperger, Chief Executive Officer of Lenzing, explains the general thrust of the expansion. “More than half of our fiber production capacity is now located in Asia.”

Indonesia has a significant textile industry, which represents one of the largest industrial sectors of the Southeast Asian island state. SPV has been an important supplier and reliable partner of the local industry for nearly 30 years. Moreover, customers are supplied with high-quality fibers for textile and nonwovens use from the Purwakarta plant not only in the Asian region, but in nearly all continents as part of the global market presence of the Lenzing Group.

Lenzing Issues EUR 200 Mn German Private Placement

Lenzing AG, global market leader in the production of man-made cellulose fibers, has successfully issued and placed a German Private Placement (Schuldschein) to the amount of EUR 200 mn (senior debt, unsecured) on the debt capital market. Lenzing AG was able to attain an extremely favorable interest rate of 2.55%, with an average term to maturity of six years. Moreover, the transaction was multiple times oversubscribed compared to the original offering. The German Private Placement (Schuldschein) was offered with a term to maturity of four and seven years respectively, in each case at fixed and variable interest rates, as well as with a term to maturity of ten years but only at a fixed interest rate.

Lenzing AG, global market leader in the production of man-made cellulose fibers, has successfully issued and placed a German Private Placement (Schuldschein) to the amount of EUR 200 mn (senior debt, unsecured) on the debt capital market. Lenzing AG was able to attain an extremely favorable interest rate of 2.55%, with an average term to maturity of six years. Moreover, the transaction was multiple times oversubscribed compared to the original offering. The German Private Placement (Schuldschein) was offered with a term to maturity of four and seven years respectively, in each case at fixed and variable interest rates, as well as with a term to maturity of ten years but only at a fixed interest rate.

“Following the issuance of a corporate bond in 2010 and the capital increase within the context of the Re-IPO 2011, we want to take advantage of a further asset class for financing purposes on behalf of the Lenzing Group. Thus we are implementing the diversification of Group financing, especially as it is possible to optimally add further tranches in the future to the existing German Private Placement”, says Lenzing Chief Financial Officer Thomas G. Winkler.

The Lenzing Group currently has a strategic liquidity reserve of about EUR 353 mn at its disposal (cash and cash equivalents as well as short term securities). In addition, Lenzing can draw upon unused lines of credit to the amount of over EUR 200 mn. The issued German Private Placement (Schuldschein), which increases the level of liquidity by EUR 200 mn, takes advantage of the favorable market situation at present, with a historically low EURIBOR interest rate, in order to safeguard the financing of Lenzing’s dynamic expansion drive over a period of up to ten years.

Lenzing Repeats Last Year’s Success and Wins Austrian Ranking in the Category “Big Player“

For the 14th time, the business daily WirtschaftsBlatt set out to identify the most successful companies in Austria together with the credit reference agency KSV1870 and PwC. Lenzing AG once again convinced the jury and won the Austrian ranking in the category “Big Player” for the second time. A firm’s good performance over a period of years and not short-term business results is what counts for the Austrian Leading Companies Award. The current analysis took account of the company’s performance in the years 2009-2011. The issue of sustainability also plays a major role in this competition.

For the 14th time, the business daily WirtschaftsBlatt set out to identify the most successful companies in Austria together with the credit reference agency KSV1870 and PwC. Lenzing AG once again convinced the jury and won the Austrian ranking in the category “Big Player” for the second time. A firm’s good performance over a period of years and not short-term business results is what counts for the Austrian Leading Companies Award. The current analysis took account of the company’s performance in the years 2009-2011. The issue of sustainability also plays a major role in this competition.

Lenzing CEO Peter Untersperger is pleased with this award. “This victory again in the overall Austrian rankings impressively underlines the fact that Lenzing belongs to the premier league of Austrian companies”, he says.

For years the Lenzing Group has achieved good results and also operates extremely successfully. Viscose fibers are in vogue around the world, and demand is steadily rising. For this reason, the global market leader Lenzing is in the midst of a Group-wide expansion program which aims to almost double current fiber production capacity to 1.2 mn tons by 2015.