Displaying items by tag: sappi

Sappi is investing in Gratkorn Mill’s future paper production with two large-scale projects

Global paper producer Sappi is ensuring its mill in Gratkorn is fit for the future with two technology upgrades: In November 2014, its PM11 paper machine has been upgraded. Furthermore the possible grammage range for coated paper has been increased. In March 2015 a general rebuild of critical parts of the liquor boiler and recovery plant will start. These are essential parts of the pulp production. Key to this upgrade is the positive environmental impact with a decrease in noise pollution and in NOX/SO2 emissions.

Global paper producer Sappi is ensuring its mill in Gratkorn is fit for the future with two technology upgrades: In November 2014, its PM11 paper machine has been upgraded. Furthermore the possible grammage range for coated paper has been increased. In March 2015 a general rebuild of critical parts of the liquor boiler and recovery plant will start. These are essential parts of the pulp production. Key to this upgrade is the positive environmental impact with a decrease in noise pollution and in NOX/SO2 emissions.

Max Oberhumer, Mill Director of Sappi Gratkorn, is very happy with the conclusion of the technology upgrade,“ We successfully finished the first of the two large-scale projects. With the upgraded PM11 we will remain an important Sappi Europe production facility for our global customers. With this new technological concept we have generated key success factors for our future.“

Mat Quaedvlieg, Manufacturing Director of Sappi Europe, points out the importance of the project: “ The only way for european production facilities to survive, is to use innovative technologies. The committed team assembled all of its experience to overcome the challenges faced in realizing the project. This is an important element in Sappi Europe’s future developement.“

Upgrade of the paper machine PM11

Project aims were to enhance paper quality and to increase the operating windows of Gratkorn’s biggest paper machine. To achieve these aims, extensive rebuilding was required. More than 400 mechanics and engineers worked day and night for over three weeks. This was the only way that the complex and ambitious rebuilding of the 230 meter long paper machine could be managed. More than 100 truckloads of machine parts from Finland, Austria and other european countries were necessary to finish the project. The achieved quality enhancement completely meets expectations. The production of paper meeting all quality standards began almost immediately after the startup of the rebuilt machine.

General rebuild of liquor boiler and recovery plant

In spring 2015 the second large-scale project will commence. The general rebuild of the liquor boiler and recovery plant will take approximately three months. Within this project, essential parts of the liquor boiler and the flue gas cleaning will be replaced. Results of these actions will be a decrease in noise and NOX/SO2 pollutions, as well as assured continued pulp production for the longterm.

These two projects are two of the three large-scale projects that Sappi Europe is undertaking in the 2015 business year. A total investment of 120 million € will be realised.

About Sappi’s Gratkorn Mill:

Sappi Gratkorn mill is part of Sappi Europe. Annually it produces 990,000 tons of high quality double and triple coated papers which are used for premium quality publications all over the world. Gratkorn mill also produces 250,000 tons of totally chlorine free (TCF) chemical pulp. The mill employs 1240 paper industry professionals from production to R&D. About 95 % of the mill’s production is exported.

The mill operates under management systems consisting of certified Environmental Management System (ISO 14001), Energy Management System (ISO 50001), Occupational Health and Safety Management System (OHSAS 18001), Quality Management System (ISO

9001) and Chain Of Custody Verification from the Programme for the Endorsement of Forest

Certification (PEFC™) scheme and Forest Stewardship Council (FSC®).

About Sappi

Sappi Europe SA is the leading European producer of coated fine paper used in premium magazines, catalogues, books and high-end print advertising. Headquartered in Brussels, Belgium, Sappi Europe is recognised for innovation and quality. Its graphic paper brands include Magno™, Quatro™, Vantage™, Royal™, Galerie™, GalerieArt™ and Jaz™ ranges. Algro®, Fusion®, Leine® and Parade® are the brands for speciality labelling, topliner, packaging papers and boards. Sappi papers are produced in mills accredited with ISO 9001, ISO 14001 and OHSAS 18001 certification and EMAS registration for all our mills in the EU. Sappi European mills hold chain-of-custody certification under the Forest Stewardship Council (FSC®) and the Programme for the Endorsement of Forest Certification (PEFC™) schemes.

Sappi Europe SA is a division of Sappi Limited (JSE), a global company headquartered in Johannesburg, South Africa, with over 13,500 employees and manufacturing operations on three continents in seven countries, sales offices in 50 countries, and customers in over 100 countries around the world.

Learn more about Sappi at www.sappi.com

Sappi Q4 and year end result 2014

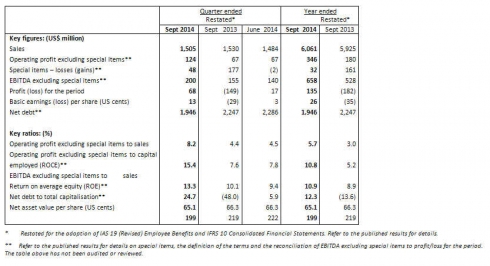

Sappi Limited results for the year and fourth quarter ended September 2014. Debt below US$2 billion; full year EBITDA excluding special items increase by 25% on strong fourth quarter

Sappi Limited results for the year and fourth quarter ended September 2014. Debt below US$2 billion; full year EBITDA excluding special items increase by 25% on strong fourth quarter

Highlights for the Year

- Strategy delivers strong earnings growth

- EBITDA excluding special items US$658 million (up 25% year-on-year)

- EPS excluding special items 22 US cents (restated 2013 loss per share 4 US cents)

- Net debt US$1,946 million, down US$300 million year-on-year

Highlights for the Quarter

- EBITDA excluding special items US$200 million (up 29% year-on-year)

- EPS excluding special items 12 US cents (restated Q4 2013 1 US cent)

- US$288 million cash generation in the quarter (restated Q4 2013 US$111 million)

Commenting on the key financial highlights of the quarterly and year-end results, Sappi Chief Executive Officer Steve Binnie said:

“We made significant strides in the execution of our strategy this past year. Notable achievements were reduction of net debt, improved performance of our European and Southern African paper businesses and delivery of substantially increased dissolving wood pulp volumes into a growing and high margin market. Additionally, we disposed of Nijmegen Mill in order to reduce costs, and sold our Usutu forests which were surplus to requirements, to assist with reducing net debt. The North American business had a challenging year; however, we can already see advancement in that business and expect further improvement in the year ahead.

The first full year of operation for our expanded Specialised Cellulose operations as well as reduced capex expenditure following the completion of the dissolving wood pulp projects, allowed for a focus on cash generation and debt reduction. The group’s EBITDA excluding special items for the full year increased by 25% over the prior year.

The group continued the strong progress made throughout 2014 and delivered a 29% rise in EBITDA excluding special items compared with the equivalent quarter last year. It is pleasing to note that all three regions improved from the prior quarter. Cost reductions across the group and higher selling prices in some markets contributed to the growth. Volumes continued to decline in the graphic paper markets, but at a slower rate than experienced in recent years.

“The European business saw an encouraging improvement in margin in this seasonally better quarter, achieving an EBITDA excluding special items margin of more than 10% for the first time since 2012.

“In North America, market conditions were extremely competitive throughout the year and we experienced significant downward pressure on pricing. During this seasonally stronger quarter, operating profit excluding special items recovered compared with the prior quarter, which included the impact of outages. The result was slightly below that of the equivalent quarter last year due to lower paper prices and higher input costs, particularly for wood. Prices for coated woodfree web increased during the quarter, but have yet to match prior year price levels. The release paper business was once again impacted by weak Chinese demand, only partially offset by stronger sales to the rest of the world.

“Overall, this has been a good year for the Southern African business, with an expanded Specialised Cellulose business and the restructured paper business consistently delivering enhanced margins. The performance of the Southern African business improved compared to the equivalent quarter last year due to increased sales volumes for dissolving wood pulp, as well as higher average prices for paper and paper packaging.

“The Specialised Cellulose business had another solid quarter, with increased sales volumes and a weaker Rand/Dollar exchange rate offsetting the lower average dollar dissolving wood pulp prices compared to both the prior quarter and prior year. Strong shipment volumes contributed towards an EBITDA excluding special items of US$77 million.

“Based on current market conditions, we believe that EBITDA excluding special items in the 2015 financial year will be broadly similar to that of 2014. The expected improvement in the underlying operational performance of the paper businesses will be offset by lower US Dollar dissolving wood pulp pricing and the impact of the projects at Gratkorn and Somerset.

“The first quarter result will be negatively impacted by the Gratkorn PM11 upgrade project, resulting in three weeks of downtime for the paper machine. The results will be further impacted by the extended annual maintenance outage and the finalisation of the natural gas conversion project at Somerset Mill in the US.

“We therefore expect the group EBITDA excluding special items in the first quarter to be similar to that achieved in the equivalent quarter last year, despite the improved underlying performance of the overall business.”

click image to resize

The year and quarter under review

Operating profit excluding special items for the year was US$346 million compared to US$180 million in the prior year. Special items amounted to a charge of US$32 million, comprised mainly of net restructuring charges and loss on disposal of assets across our businesses. This was partially offset by plantation fair value pricing gains of US$18 million.

Special items for the quarter were a net charge of US$48 million. Included in the special items was a provision for retrenchments and restructuring costs in our European paper business. These charges were offset by a deferred tax asset of US$53 million in North America which was recognised due to the non-taxability of bio-fuel tax credits received in fiscal 2009 and 2010.

Earnings per share for the quarter were 13 US cents (including a gain of 1 US cent in respect of special items), compared with a loss of 29 US cents (including a charge of 30 US cents in respect of special items) in the restated equivalent quarter last year.

Net cash generated for the full financial year was US$243 million compared to utilisation of US$247 million last year. This significant turnaround was due to the improved operating cash generation, excellent working capital management, reduced capital expenditure and the receipt of proceeds of ZAR1 billion from the sale of the Usutu forests.

Net debt at financial year-end decreased to US$1,946 million as a result of the increased cash generated, and was within our target to end the year below US$2 billion. At the end of September 2014, we had liquidity comprising US$528 million of cash in addition to undrawn committed revolving credit facilities of €350 million and ZAR1 billion in Europe and South Africa respectively. In October 2014, we utilised cash resources to redeem US$27 million (ZAR300 million) of our US$67 million (ZAR750 million) public bonds due April 2015.

Outlook

Markets will remain challenging, both for graphic paper, where demand is expected to continue to decline, and for dissolving wood pulp due to current pricing pressures. In the dissolving wood pulp market, demand remains robust. US Dollar prices have weakened post the financial year due to pressure from lower cotton prices and the continued oversupply of dissolving wood pulp and viscose staple fibre production capacity. Cloquet Mill will likely take advantage of its ability to swing between dissolving pulp and hardwood paper pulp production to optimise margins for the US business. Volumes with key dissolving wood pulp customers will not be impacted by any such optimisation. We will continue to focus on cost management in order to maintain our current margins for the overall Specialised Cellulose business.

Currency movements affect margins in our European and Southern African businesses, having both transactional and translational impacts. A weaker Rand and Euro in relation to the US dollar both support local and export pricing for these businesses, historically offsetting any input cost impact of the weaker currency.

Capital expenditure in 2015 is expected to be in line with that of 2014, and focussed largely on the investments at our Kirkniemi and Gratkorn Mills.

We are considering utilising our increased cash reserves to repay and refinance a portion of our debt in order to lower future costs. We typically experience a cash outflow in our first fiscal quarter and this will lead to an increase in net debt as at the end of December 2014. Nevertheless, we expect to reduce our net debt further over the course of the year and reduce our financial leverage towards our target of two times net debt to EBITDA.

Sappi and Innovia show compostable packaging concept

Sappi Fine Paper Europe and Innovia Films have completed a joint project to produce compostable flexible packaging manufactured from renewable resources.

The aim of the project is to show brands and converters what is possible to help them prepare for forthcoming packaging regulations that limit the amount of materials that can be landfilled.

"The results are not only compostable they are also renewable as they are both derived from trees," said Innovia Films product manager Paul Barker. "There isn’t much recycling of plastic laminates, and this (composting) is a nice simple solution. Polyolefins are non-compostable and this really will divert waste away from landfill.

In the pilot study a range of different flexible packaging products including drink sachets, food wrapping and roast coffee packets were produced from a combination of Sappi’s Algro Nature paper and Innovia’s NatureFlex cellulose films.

Products were produced using a range of processes including extruded lamination and with solvent, water-based and solvent-less adhesives to show the range of applications and production methods possible.

Barker added that Innovia could tailor the water and gas permeability of its films to suit a range of applications from breathable bakery bags to water tight pouches.

"We can control the permeability of biopolymers depending on the application," he said. "We can achieve results as good as OPP for liquids."

Both products are independently certified as compostable to OK Compost Home by Vincotte and DIN E13432 by DIN Certco. Compostable inks and adhesives are also available.

However, both firms emphasised that it was impossible to extrapolate too much from one test due to other variables aside from the paper and cellophane including the adhesives and inks used as well as the production processes.

"All the individual components have been tested," said Barker. "Now it is over to brand owners and converters to experiment."

Sappi uses low SA rates to revise debt

SAPPI, the world’s largest maker of glossy paper, plans to sell bonds to refinance debt even as yields on existing securities rise as the company retools mills from South Africa to the US to produce pulp used in clothing.

The company will raise at least R1bn, CEO Ralph Boettger said on March 26. Yields on Sappi’s euro debt due in April 2018 climbed by 87 basis points from a record low on January 14, reaching 5.4% on Thursday.

Rates on similarly dated euro bonds of competitor Stora Enso advanced by 45 basis points to 4.3%. South African firms’ dollar-bond yields have added 10 basis points in the period, JPMorgan Chase indices show.

"Sappi is hoping to achieve a more competitive interest rate in the bond market," Mohamed Kharva, a Cape Town-based analyst at Nedbank Group, says.

The Johannesburg-based company, which is also the world’s biggest maker of dissolving wood pulp, is selling debt to take advantage of the lowest South African interest rates in more than 30 years, which have spurred an increase in issuance by companies.

Sappi has to repay R1bn of bonds on June 27. Yields on the debt have climbed to 6.32% since reaching a record low of 5.66% on July 19.

Rates on the South African rand bonds due on August 1 have gained 66 basis points, or 0.66 of a percentage point, to 5.02%.

The company is spending $540m converting parts of its paper mills into plants that make the pulp, used to produce goods from sports clothing to pills and cellphone screens.

Sappi is betting on the product to increase profit and allow it to resume dividend payments, which it stopped in 2008 as it struggled with a high debt burden amid weakening paper sales in Europe.

Debt sales by companies in the continent’s biggest economy, excluding financial institutions, increased to $1.4bn in the first quarter from $1.06bn a year earlier, according to data compiled by Bloomberg.

"We can confirm that we are busy finalising the refinancing," Sappi head of corporate affairs Andre Oberholzer says. "We already use banks for other lines of finance. The bond market provides an additional avenue."

The wood-pulp conversion projects at the Ngodwana mill in Mpumalanga province and the Cloquet facility in Minnesota should be completed by the end of the third quarter, in June, raising Sappi’s output of the pulp by about 40% to more than 1.3-million tons a year, Mr Oberholzer says. "The overall dissolving wood-pulp market is growing at 6% a year while the viscose staple-fibre market grows at 8% a year."

The viscose variety, which is made from dissolving wood pulp, is used in sports clothing.

"Our global share of the overall dissolving wood-pulp market for 2012 was 14% and of the viscose staple-fibre market was 20%. These are set to increase once additional capacity comes online," Mr Oberholzer says.

Sappi, which returned to profitability in the year through to last September, said on February 6 that profit fell 62% in the first quarter because of lower paper and pulp prices.

The company derived 25% of its sales from southern Africa in the year to September.

The rand has depreciated 8.6% against the dollar this year, the worst performance among 16 major currencies tracked by Bloomberg after Japan’s yen, which has lost 9%.

The rand slipped 0.5% to R9.2725/$ in Johannesburg on Thursday morning.

Sappi’s stock dropped 7.1% in the first quarter, making it the worst performer in the 25-member Standard & Poor’s global timber and forestry US dollar index, behind Golden Agri-Resources, the world’s second-biggest palm-oil producer.

South Africa’s Mondi was the best performer, rising 34%.

As consumers turn from magazines and newspapers to computers and cellphones to consume media, Sappi’s move away from paper makes sense, Mr Kharva says.

"For them to increase exposure to dissolving wood pulp is a good diversification strategy due to it being a growth market, unlike graphic paper, which is in structural decline."

63rd annual 'Paper Days' set for April 3–4 at University of Maine

Maine - A ribbon cutting ceremony to mark the opening of the nation’s first cellulose nanofiber pilot plant and a keynote address by U.S. Sen. Angus King will highlight the 63rd annual "Paper Days" at the University of Maine, April 3–4.

Innovation, with a focus on biobased nanoparticles and biofuels, is the theme of this year’s Paper Days, coordinated by the University of Maine Pulp & Paper Foundation. According to a press release from UMaine, Paper Days is expected to draw more than 300 industry leaders, researchers and students from throughout the U.S. and Europe. An estimated 60 paper companies and engineering firms are expected to send representatives.

The event is designed to facilitate the connection between the university and industry by getting UMaine students and faculty, and industry representatives together to learn about the latest topics in the field and to network, said Jack Healy, executive director of the foundation.

Following a luncheon and address by Larry Montague, president and CEO of TAPPI, seminars on biobased nanoparticle opportunities will be led by Alan Rudie, Forest Products Laboratory; Robert Moon, Purdue University; and UMaine alumna Beth Cormier, Sappi Paper and Agenda 2020 Technology Alliance. All will occur in Wells Conference Center.

Tours of Jenness Hall will focus on the Process Development Center in Jenness Hall, which is observing its 25th anniversary, and the Cellulose Nanofiber Pilot Plant, funded by a $1.5 million grant from the U.S. Forest Service.

The ribbon-cutting ceremony for the pilot plant begins at 3:30 p.m. in D.P. Corbett Business Building. Expected to offer remarks will be UMaine President Paul Ferguson; Michael Rains, USDA Forest Service; Theodore Wegner, Forest Products Laboratory; and Sean Ireland, TAPPI and Verso Paper, Inc.

The pilot plant manufactures cellulose nanofibers (CNF), a wood-based reinforcing material that is increasingly of interest to researchers worldwide in the development of high-value materials. Last year, UMaine and the Forest Products Laboratory began a research collaboration on the conversion of wood components into novel nanomaterials; the incorporation of an array of nanomaterials into forest products to increase their functionality, durability and end-use performance; and development of new generations of high-performance wood-based materials.

UMaine is in a consortium with the Forest Products Lab, six other universities and numerous industrial partners pursuing research using CNF. Nanomaterial has applications in automobile components, paint and coating additives, composites and filtration media.

The Paper Days honors banquet begins at 6 p.m. in Wells Conference Center featuring a keynote address by Sen. King, and award and scholarship presentations.

Also being announced is a gift by Sappi Fine Paper North America to help launch the UMaine Pulp and Paper Foundation’s $2 million fundraising campaign for scholarships.

The following day, Paper Days participants will tour the Forest Bioproducts Research Institute’s Technology Research Center in Old Town, followed by an industry panel discussion, “Biofuels in the Face of Changing U.S. Energy Availability.” At the luncheon that day, Frederick Clark of EKA Chemicals will speak on “The Business Case for Sustainability.”

Sappi Fine Paper North America Publishes eQ Journal 005: Rethinking Recycling

Sappi Fine Paper North America today announced the release of eQ Journal 005:Rethinking Recycling, distinguishing between the facts and general misconceptions surrounding recycling and the paper life cycle. In this fifth edition of the company's eQ series, theJournal sheds light on the benefits of recycling while challenging the common assumption that paper produced with a high percentage of recycled fiber is always better for the environment.

"The use of recycled fiber is not a one size fits all solution. We should examine not just what's in our paper, but take into consideration the sourcing of materials, the environmental impact of manufacturing, and understand what happens to paper as it moves through the life cycle," said Laura Thompson, Ph.D., director of sustainable development and technical marketing, Sappi Fine Paper North America. "With this latest eQ Journal, we invite our community to look at the bigger picture of recycling – the way we do at Sappi – to ensure our industry is putting recycled fiber to its best use, finding the most appropriate options that produce lower emissions and higher yield."

In fact, a study of our Somerset Mill included in the Journal revealed that adding 10 percent recycled content increases the product's carbon footprint by 16 percent, compared to the same product made with 100 percent virgin fiber. More details on the study findings, as well as other industry statistics comparing the carbon footprints of different pulp sources using a comprehensive Life Cycle Analysis (LCA) can be found in the Journal.

In addition to revealing the trade-offs associated with recycled fiber, this fact-based publication also promotes best practices of recycling, raising awareness of practical ways consumers can reduce their environmental impact of using printed materials. As part of this edition, Sappi provides a series of custom-designed recycling logos available for download on our eQ microsite, inviting everyone–especially corporate marketers and graphic designers–to get creative about promoting the initiative to reduce, reuse, and recycle.

To download a PDF version of Sappi's latest eQ Journal 005: Rethinking Recycling, or access Sappi's new library of recycling logos, please visit Sappi's eQ microsite, home to the latest and most trusted information regarding sustainability in our industry. To request a printed copy of eQ Journal 005, visit This email address is being protected from spambots. You need JavaScript enabled to view it.This email address is being protected from spambots. You need JavaScript enabled to view it. or call +1-800-882-4332.

SOURCE Sappi Fine Paper North America

Free download of Sappi’s complete 2012 End Use Analysis Report

Are you looking for insights into the future of our industry? Are you interested in knowing about the big megatrends shaping paper consumption trends?

Are you looking for insights into the future of our industry? Are you interested in knowing about the big megatrends shaping paper consumption trends?

From today, the complete 2012 End Use Analysis Report from Sappi is available to you, focusing on the industry's solutions to face an uncertain future. This study is based on interviews and conversations with industry leaders of the paper value chain.

Find out how industry changes will impact your business by downloading the full report now ![]()

Sappi Fine Paper Europe goes to the root of the matter with its 4th Employee-led Tree-Planting

On the 16th of November, employees from Sappi Fine Paper Europe’s Headquarters in Brussels headed out to the Forêt de Soignes, armed with 2750 saplings, ready to be planted. Sustainability is an everyday reality at Sappi, and this initiative is ‘real’ example of how Sappi people can, and do, embrace sustainability on a day to day basis.

Employee-led tree-planting started at Sappi in Spring 2010. Since then, over 8000 trees have been planted by employees in conjunction with the ANB (Agentschap voor Natuur en Bos), the equivalent of the Department of Forestry. This organisation is responsible for the planting of approximately 30,000 trees in the Forêt de Soignes every year as part of the National Forest Management Plan (Belgium). Over 50 people from the company volunteered to take part in the very physical team building exercise, and the result brought great satisfaction to the group.

Sophie de Guignard, responsible for coordinating the group said, “We‘re looking forward to next year when we will plant our 10,000th tree. It will be a significant milestone, and a great reason to inspire others to share the same experience, and understand how to make sustainability real.”

Sappi’s tree planting initiative belongs to a series of sustainability driven initiatives at Sappi all with the objective of demonstrating that sustainability is at the heart of everything that Sappi does. Sappi cares, and wants to engage with others to care together. In September, the Treehouse was launched (www.the-treehouse.be). The Treehouse partnership is both a physical and virtual platform, for like-minded individuals and companies to come together to find ways to embrace sustainability in their daily activities. Sappi’s new sustainability website - We Care (www.sappipositivity.com) - is similarly focused on sharing knowledge and inspiring others to join and build momentum.

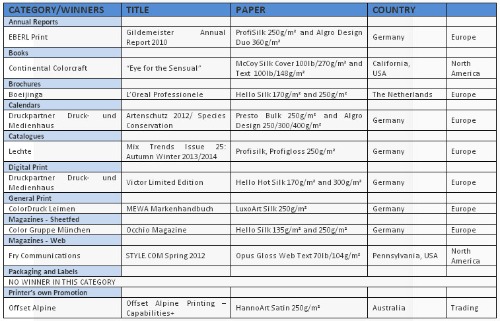

Sappi’s talent for innovation awarded during 2012 Pulp and Paper International (PPI) Awards

Sappi Fine Paper Europe is very proud to have won one award in the 2012 Pulp & Paper International Awards, during a ceremony hosted on 12 November in Brussels. The awards are dedicated to recognising the achievements of companies, mills and individuals in the pulp and paper sector and are truly global in scale.

Our 2012 award is in the following categories:

- Advances in Innovation in Speciality Papers (Mill) : Alfeld, White liner for corrugated board production [Fusion]

Sappi’s Alfeld mill in Germany was the innovation centre for a new type of white liner developed for corrugated board production, focused on the creation of a new reverse side barrier coating. The result was Fusion, a product which is much more than a simple white top liner; it is a premiumwhite liner. The innovation came about as a result of Sappi’s accumulated competence in paper coatings, and its vast knowledge and experience in packaging materials in the Alfeld mill. With this new innovation Fusion can offer customers a very special appearance and associated print performance that other top liners simply can’t beat. Sappi is very proud of this new innovation.

Sappi was nominated in a further three categories this year. This in itself is testament to the company’s continued strong performance in the market and dedication to investing in future growth opportunities, as well as its commitment to creating valuable tools and resources for Sappi customers and partners. The additional category nominations were as follows:

-

Innovative Products- Graphic Papers (Jaz Silk, digital paper)

-

Promotional Campaign (Houston, the digital universe of paper and printing knowledge)

-

Advances in Innovation in Sustainable Packaging (Mill) (Alfeld / Innovia – Laminate Structure for Compostable Packaging [Algro Nature])

The PPI Awards

First launched in 2009, the global PPI Awards (organized by RISI, the leading information provider to the global forest products industry ) are dedicated to recognising the achievements of companies, mills and individuals in the pulp and paper sector. The PPI Awards are global, and proudly provide a platform that honours leadership, vision, innovation and strategic accomplishments within the industry. http://www.risiinfo.com/events/ppi_awards/2012_finalists.html

Our Nominations Sappi Fine Paper Europe was nominated in 4 separate award categories as follows:

· Innovative Products- Graphic Papers (Jaz Silk, digital paper)

Jaz™ silk is a high-quality coated paper specifically made for high speed digital inkjet web printing. In an era where speed and customisation are key differentiators in highly competitive markets, print quality no longer has to suffer. Jaz™ silk digital coated paper has full high-speed inkjet functionality, yet manages to combine the reassuring look and feel of offset paper with full colour personalisation options and flexibility. Key characteristics for this paper include the fact that no bonding agent or other treatments are required, print efficiency leading to time saving, and lower consumption of ink compared to offset paper. Jaz™ silk is first achievement from a very successful partnership between HP, the world’s leading printer and PC manufacturer, and Sappi Fine Paper Europe.

· Promotional Campaign (Houston, the digital universe of paper and printing knowledge)

Houston is Sappi Fine Paper Europe’s brand new online knowledge platform specifically developed as a support tool for professionals working in the paper and graphic industries. As well as easily accessible information on paper, printing and converting-related topics, live experts work with professionals to find solutions to issues in real time. Anything you need to know about paper or print; Houston will have the answer! www.sappi.com/houston .

The idea for Houston came from the desire to share our wide expertise and accumulated knowledge with our customers. The knowledge platform includes all types of information from the latest printing techniques and paper types, to market trends and specific topics via Web Seminars. The platform also hosts polls, market feedback and opinions, and is regularly updated with news about, and from, the broader industry environment. One of the most exciting features is the live support service which is offered free of charge, enabling users to chat directly with Sappi technical staff to ask questions and share ideas.

· Advances in Innovation in Speciality Papers (Mill) (Alfeld, White liner for corrugated board production [Fusion]

Fusion is a premium white topliner designed for lamination onto corrugated board. Using 100% bleached virgin fibres, to ensure it is a spotless paper Fusion has been engineered to bring out the highest levels of quality - regardless of the printing process - offset, flexo and digital. But what makes the grade stand out is its flexibility and suitability for a range of markets, from corrugators, litho laminators, display manufacturers and folding box converters to direct mailers, pre-printers, designers, agencies and co-packers.

By coating and calendering the paper, the Fusion surface offers a special quality and gloss much closer to the quality of content and display packaging therefore carrying a perception of higher-value-for money. A cost effective high quality result is therefore achievable for brand owners, retailers, agencies and converters. Key to this is its ability to produce unrivalled results on a lower grammage sheet, mirroring the market trend towards lightweighting.

Fusion is especially attractive for brand owners requiring high shelf impact for applications from displays to packaging for consumer electronics, bag in box and pet food.

· Advances in Innovation in Sustainable Packaging (Mill) (Alfeld / Innovia – Laminate Structure for Compostable Packaging [Algro Nature])

Algro Nature is the first completely bio-based, renewable, recyclable and compostable paper and bioplastic packaging that can be used for a wide variety of foods, beverages and pharmaceuticals. It can be composted at home or even used in anaerobic digestion plants to produce heat and energy, meaning lower greenhouse gas emissions and less waste. As end users become more aware of the availability of environmentally sustainable paper, it has become increasingly important for mills to continue to improve the sustainability position of their products, and Sappi has dedicated significant resources to this effort. Sappi and its Algro Nature has teamed up with Innovia Films and its NatureFlex™ range to demonstrate the potential of laminate structures suitable for end users in the food, confectionery and beverage industries. The result of this effort is a product that is technically functional and utilizing renewable resources that enhance compostability.