Displaying items by tag: valmet

Valmet hires nearly 400 young people as summer trainees in Finland

This summer, nearly 400 students will work as summer trainees in Valmet's locations in Finland. Additionally, young people from elementary and high schools will work at the company through a Finnish summer job program aimed at getting to know working life.

Valmet will employ summer trainees in 16 locations, with the largest number of trainees located in Tampere and Jyväskylä. Most of the summer employees, over 220, will work in engineering, customer service, sales, marketing, product development and financial administration. Around 40 percent of the summer trainees will be employed in the production facilities.

Valmet will employ summer trainees in 16 locations, with the largest number of trainees located in Tampere and Jyväskylä. Most of the summer employees, over 220, will work in engineering, customer service, sales, marketing, product development and financial administration. Around 40 percent of the summer trainees will be employed in the production facilities.

"We are excited to welcome so many young people to join us as trainees for the summer. We can offer them a great opportunity to learn new skills and gain working experience in a global, rapidly developing company. In return, the trainees provide us with new approaches and fresh ideas. We hope that this experience will inspire and motivate our trainees to become future professionals in the pulp, paper and power industry as well as automation," says Julia Macharey, Senior Vice President, Human Resources at Valmet.

Valmet supports the Responsible Summer Job 2018 campaign

For the fourth consecutive year, Valmet is participating in the Responsible Summer Job campaign organized by T-Media and the Economic Information Office (TAT) in cooperation with corporate partners. The target of the campaign is to challenge companies to increase the amount and quality of summer jobs offered in Finland. Valmet wants to promote responsible practices to ensure the trainee periods are safe and fair, and to give meaningful opportunities and experience to the trainees.

Valmet iRoll technology reaches the milestone of 500 customer deliveries

The 500th case to utilize Valmet iRoll technology took place at SsangYong C&B, one of the biggest tissue producers in South Korea. Valmet analyzed the nip loading and performance of their press equipment under dynamic conditions using its portable iRoll technology.

Valmet iRoll technology and a Valmet press roll cover upgrade enabled SsangYong C&B to improve tissue dryness and felt profiles on their TM 4 machine, as well as to save energy and increase the machine's speed.

"The results of our co-operation with Valmet have been satisfying in terms of energy savings and increased machine speed. We are looking forward to continuing the development to improve our energy and production efficiency even further and achieve more cost savings," says Jong-Dae Byun, Director & Mill Manager at SsangYong C&B.

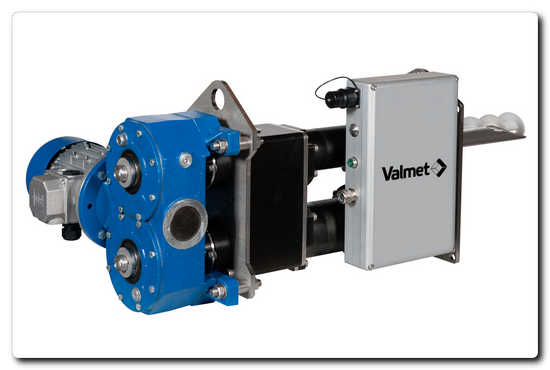

Valmet iRoll

Valmet iRoll

The dry content and profiles improved, leading to energy savings through 5 percent less steam consumption. More energy savings came from a 5 percent decrease in roll drive loads. The machine speed increased by up to 30 meters a minute.

Improvements in customers' process performance globally

In addition to the case at SsangYong C&B's TM 4, Valmet iRoll technology has reached several global achievements and led to process improvements, such as an 80 percent reduction in reeling and winding broke, an increase of 30 meters a minute in the paper machine's running speed, 40% reduction in coat weight profile variation, and a 60 percent longer press felt lifetime.

Due to the strong results and positive customer feedback, Valmet is continuously increasing the utilization of its iRoll technology globally with the aim of improving its customers' production efficiency, quality and runnability even further.

About Valmet iRoll technology

The iRoll product family is an advanced toolset for optimizing the efficiency and nip profiles of papermaking lines. Valmet's iRoll technology provides accurate online profile measurement and process control opportunities in press, sizer, coater, reel, and winder applications.

"It is the fastest and most sensitive online profile measurement tool in the industry. In addition to nips, iRoll also measures parameters affecting paper quality, and it can be connected to a machine automation system for closed-loop process control," says Tatu Pitkänen, Global Technology Manager at Valmet.

iRoll is part of Valmet Intelligent Roll Solutions, which offer a unique combination of Valmet's proven roll products and expert services. These technologies provide paper-, board- and tissue-makers with fast, sensitive online measurements, condition monitoring, data analysis, remote analytics and profile control applications - combined with Valmet's expertise and process know-how.

Read more:

http://www.valmet.com/campaign/iRoll/

http://www.valmet.com/board-and-paper/services-for-board-and-paper/roll-services/iroll-technology/

Valmet to supply a tissue machine restart-up package for Xiamen Sin Yang Paper Co., Ltd

Valmet will supply a tissue machine restart-up package to Xiamen Sin Yang Paper TM1 in China. The delivery will include necessary project management, maintenance, spare parts and start-up of a tissue machine idled in 2014 and originally delivered by Valmet. The start-up is scheduled for July 2018.

Valmet will supply a tissue machine restart-up package to Xiamen Sin Yang Paper TM1 in China. The delivery will include necessary project management, maintenance, spare parts and start-up of a tissue machine idled in 2014 and originally delivered by Valmet. The start-up is scheduled for July 2018.

This order is first of the kind for Valmet in China area. Zihou Song, Senior Manager, Mill Improvements from Valmet says: "This is a very challenging project due to tight time schedule, but at the same time very exciting new kind of a project for us that strengthens our services to tissue customers in China."

Valmet AB, Fabio Perini S.p.A., Elettric80 S.p.A.: Smart Factory launch

Smart Solutions for integrating the processes of the tissue value chain presented at Valmet Tissue Making Days 2018

During Valmet Tissue Making Days 2018, Valmet, Fabio Perini and Elettric80 disclosed new digital solutions to implement the “ideal smart factory” resulting from the cooperation of three market leading companies.

The conference has been hosted since 1983 by Valmet, the leading global developer and supplier of process technologies, automation and services for the pulp & paper industries. This year Valmet has involved Fabio Perini, leading company in the converting & packaging industry, and Elettric80, specialized in creating automated solutions for FMCG (Fast Moving Consumer Goods) as partners for the event.

It has been three days of sharing ideas, technologies and market trends with the key tissue players and producers from all over the world.

From left: Jenny Lahti-Samuelsson, Manager Global Tissue Technology, Valmet - William Nelson, President of Elettric80 Inc & Elettric80 S de RL – Kent Nika, Valmet and Oswaldo Cruz, Fabio Perini CEO

From left: Jenny Lahti-Samuelsson, Manager Global Tissue Technology, Valmet - William Nelson, President of Elettric80 Inc & Elettric80 S de RL – Kent Nika, Valmet and Oswaldo Cruz, Fabio Perini CEO

The event theme, T-Evolution – Transforming Tissue Together, focused on the transformation of the business environment and how Industrial Internet and digitization are leveraging new strategies and solutions to satisfy the Customers.

Valmet, Fabio Perini and Elettric80 are three individual companies, part of a unique value chain. They work as separate entities but can at the same time be integrated into one System. They are individually strong, worldwide established companies, but can make the difference within a tissue factory meeting the customers’ needs.

“To continue to develop this industry we have identified and created new solutions with a more holistic approach. This is a proof that working together with our partners and utilizing the data from end to end can bring greater value for both the tissue industry and the development of new sustainable solutions” says Jenny Lahti-Samuelsson, Manager Global Tissue Technology at Valmet.

“The complexity of the market - Oswaldo Cruz, Fabio Perini CEO, comments – calls for cooperation between companies like ours in supplying customers with solutions enabling them to go beyond their business objectives: improve overall equipment efficiency, maximize production output, look after environment sustainability, focus on safety and optimize overall cost, as well as a general and transversal efficiency, attainable only through integration”.

"Elettric80 has totally changed the way of designing tissue factories, offering one of the most efficient and safe solutions available around the world that is able to respond quickly to customers’ needs and to changes in the market - says William Nelson, President of Elettric80 Inc & Elettric80 S de RL-. The solutions by Elettric80 cover the entire value chain because they enhance the reliability and safety of the entire plant as well as of the entire business life cycle. The results are a significant increase in factory efficiency, total traceability of handled products, significantly reducing spaces, maximum safety and cost-effectiveness. We work in close partnership with our customers around the world to solve the logistical challenges of the tissue industry; we do not offer our customers a single product, but solutions that are tailor-made, scalable, modular and efficient.

Valmet, Fabio Perini, Elettric80: how process integration happens

Product optimization, throughout machine digitization, starts right at the beginning of our ecosystem. The journey of the fibres from pulp to a dried tissue sheet is long and every step of the journey is important.

Through the Valmet Advantage NTT machine all the parameters used to transform the fibers into a tissue web and the characteristics of the dried paper, are collected and controlled for immediate corrective actions. The wet end system is measured and controlled by a variation of different Valmet Analysers. Every centimetre of produced tissue is monitored for quality, by the Valmet DNA system, carrying all information on the jumbo roll’s excellence and flaws: chemicals used, softness and eventual damages.

The Advanced Balance Control system (ABC) provides optimal and automatic balance control of hood and air system for any production range, boosts productivity while minimizing energy consumption, allows remote control of the parameters and enables a direct connection to Valmet experts for remote diagnostics on the drying process.

When Jumbo rolls are stored and ready to be transformed on the conversion lines, an Elettric80 LGV Elephant system machine collects the right reel from the warehouse and takes it towards the Fabio Perini converting line. Elettric80’s Smart Decision Maker - the “decision making” logic that oversees all the logistic operations and material movements inside the factory- reads and collects all the information transmitted by Valmet.

The main systems by Elettric80 and BEMA, the second company specialising in the manufacture of products that perfectly complete the Elettric80 value chain, designed according to the tissue customer’s needs are: a wide range of LASER GUIDED VEHICLES (LGVs); WOODPECKER pallet control system; DRAGON palletizer; SILKWORM stretch wrapper; ROBOTIC LABELLER and SMART STORE warehouses. SMART BOX is a unique, sturdy, modular and extremely efficient solution. Within a 12m x 7.5m space, it combines palletizing, stretch wrapping and labelling in a flexible and compact layout. SMART BOX offers multiple advantages such as high efficiency, reduced accumulations, low maintenance costs constant over time.

The reel is automatically loaded on the new Fabio Perini Smart Unwinder (chuckless and crankless) with intelligent features, that allow to optimize manpower and prevent injuries.

The next step is embossing: the Fabio Perini CATALYST smart embosser can change both steel rolls in just 10 minutes, without an overhead crane, thanks to its exclusive technology. Saving time helps to improve production and optimize cost, confirming that “Less is more”. The Active Exchange System allows adding or removing the steel rolls from the warehouse while the machine is running, granting flexibility and versatility.

The Fabio Perini 179AX LOG SAW is able to change the Log Saw blade automatically, with no operator access inside the machine, thanks to its 5-slot warehouse feeding an automatic system that is able to change the worn blade in less than 3 minutes.

More than 80% of machine downtime saving and 100% Reduction of Operator Intervention, during changeover procedures, can be attained thanks to the Fabio Perini A6T Wrapper with the Trolley One Touch.

Throughout the whole production cycle, a factory is an assembly of complementary processes performed by different machines, each performing very unique activities. We may say that a factory, in many ways, is like an orchestra, each machine being like a musician creating its own sound, and all the coordinated sounds resulting in music.

The whole process is managed centrally by a single software platform developed by Elettric80, named SM.I.LE80 (Smart Integrated Logistics), which ensures a "direct link" between systems and production processes, and the optimal and effective management of all internal and external plant operations: from incoming raw materials to complete warehousing and shipping management.

Valmet Tissue Technology Center upgraded to provide a wider range of opportunities

Valmet has upgraded its Tissue Technology Center in Karlstad, Sweden, to give the world's tissue producers a wider variety of technical solutions and configurations to support the demands of tissue making today and tomorrow. It will also provide new ways to utilize the Industrial Internet and advanced automation solutions to bring new insights about tissue production, as well as to give more detailed analysis, and information about the end-product quality.

The Tissue Technology Center is a unique resource for cultivation and realization of ideas, innovations and verifying new technology or machine configurations. It is used for both Valmet's own development and customer trials. Recently the center celebrated its 1,000th customer trial. The pilot center is also utilized by pulp, chemical and clothing companies supplying to the tissue industry.

"The upgraded pilot center can offer a renewed and even more flexible pilot machine to support our customers in their ambition to develop solutions that will take this industry to the next level. It can easily be adjusted to cover tissue making processes for conventional, textured and structured grades" says Karl-Johan Tolfsson, Manager, Tissue Technology Center, Valmet.

Tissue Pilot in Karlstad Sweden

Tissue Pilot in Karlstad Sweden

Tools to monitor and improve quality, runnability and efficiency

The current quality control systems on the pilot tissue machine have been replaced and complemented by the Valmet IQ quality management system. The new system contains online non-nuclear weight, moisture and softness measurements. It also includes two Valmet IQ Scanners and a dilution profiler with cross-direction control. Machine direction controls integrate fast responding wet end process and dry end feedback controls to achieve increased performance in tissue quality control. Valmet IQ Reporting provides users easy access to production and history data.

"With the renewed quality management system, we are able to get faster and more accurate information. The addition of the web monitoring and inspection system also enables the monitoring of the visual end product quality that was not possible before," says Marko Toskala, Director, Quality Management Systems, Automation, Valmet.

The Valmet IQ Web Monitoring System records video images of crucial events in the process, such as web breaks, tail feeding and defects triggered by the IQ Web Inspection System. Recorded images are available for playback, enabling operators to quickly find the origin of the event and correct the problem. This shortens downtime after breaks and improves runnability. Optimized machine efficiency delivers fast payback on investment.

The upgrade includes stock preparation and wet end measurement solutions providing tissue makers with new tools to improve quality, runnability and efficiency. The Valmet Wet End Analyzer (Valmet WEM) combines all relevant wet end variables for a total wet end management solution. Measured variables include charge, chemistry (pH, temperature, conductivity and redox), total and ash consistency, total and ash retention and ash content, all in one analyzer. A Valmet Fiber Image Analyzer (Valmet FS5), designed for routine paper mill laboratory and laboratory research, offers a comprehensive set of automated fiber measurements and the possibility to make the information easily available and useful.

Information about Tissue Technology Center

Tissue Technology Center provides access to a full sized, flexible pilot machine, a well-equipped and organized paper and fiber testing laboratory as well as wide technology and process expertise. The Center can also provide support from a wide network of know-how in the field of tissue making, such as pulp, chemistry, felts, wires, belts, creping etc. The pilot machine and auxiliary systems are designed and equipped for full flexibility to meet the tissue makers' every need.

The Tissue Technology Center is located in Karlstad, Sweden with Valmet's technology resources near at hand.

Valmet and Georgia-Pacific Enter Agreement on eTAD(TM) Technology

Valmet and Georgia-Pacific have entered into a licensing agreement covering the eTAD(TM) tissue making technology. Under the license agreement, Valmet will market, manufacture and install Advantage eTAD machines for tissue customers outside North America.

The eTAD(TM) technology was developed by Georgia-Pacific.The company has three eTAD(TM) machines operating in North America; the latest two re-built by Valmet in 2012. The machines are running in full eTAD(TM) configuration and producing structured tissue and towel with high quality and absorbency. The eTAD(TM) concept provides an ultra-premium product with high bulk to fiber ratio in combination with low energy and water consumption. The concept is also capital efficient.

Advantage-eTAD

Advantage-eTAD

"We are very excited about this agreement that will support our strategy to provide tissue making solutions that offer top quality tissue with sustainable production. Valmet and its customers will have the possibility to make trial runs on Georgia-Pacific's pilot eTAD(TM) machine, and also bring customers to reference visits at mills with operating eTAD(TM) machines. This agreement will further strengthen our product portfolio and ensure that we are able to provide tissue machine concepts covering the whole product range," says Jan Erikson, VP Sales, Tissue Mills Business Unit, Valmet.

"This technology meets consumer needs for premium qualities in tissue products, including softness and absorbency," says Kurt Adams, Vice President, R&D, Georgia-Pacific. "We are pleased to license eTAD(TM) technology to Valmet as we recognize the value-creating potential of offering this technology more broadly."

About Georgia-Pacific

Based in Atlanta, Georgia-Pacific and its subsidiaries are among the world's leading manufacturers and marketers of bath tissue, paper towels and napkins, tableware, paper-based packaging, office papers, cellulose, specialty fibers, nonwoven fabrics, building products and related chemicals. The company operates nearly 200 facilities and employs approximately 35,000 people directly, and creates nearly 92,000 jobs indirectly.

Valmet to supply a containerboard making line for a customer in China

Valmet will supply a high-speed containerboard making line for a customer in Zhejiang province, China. The board production line is designed to produce high-quality recycled fluting grades and the start-up is scheduled for the end of year 2019.

The order is included in Valmet's second quarter of 2018 orders received. The value of the order will not be disclosed. The total value of an order of this type and scope is typically around EUR 25-35 million.

The order is included in Valmet's second quarter of 2018 orders received. The value of the order will not be disclosed. The total value of an order of this type and scope is typically around EUR 25-35 million.

The customer's goal for the project is to increase its capacity and market share. "The customer is growing strongly and wants to achieve larger market share with more production capacity and a bigger production machinery. Valmet's strong references convinced the customer to choose our reliable and high-performing technology. One differentiating and decisive factor was Valmet's new type of a spray sizer," says Fan Ze, Vice President, Capital Sales, China, Valmet.

Technical details about the delivery

Valmet's delivery includes a complete containerboard making line with broke collection, approach flow system, an OptiFlo Foudrinier headbox, an OptiFormer Hybrid forming section with shoe and blade technology, an OptiPress Center press section, an OptiRun dryer section, OptiAir Hood high humidity hood, an OptiSizer Spray sizer with related supply system and surface size preparation system, ventilation equipment for board machine, and an OptiReel Pope reel. The delivery includes also Valmet IQ quality measurement system (QMS).

The 7,250-mm-wide (wire) board machine will produce recycled fluting grades with the basis weight range of 60-40 g/m2. The design speed of the machine will be 1,400 m/min.

Valmet to supply a containerboard making line for Hamburger Rieger in Germany

Valmet will supply a containerboard making line for Hamburger Rieger GmbH at its Spremberg Mill in Germany. The new production line (PM 2) including Valmet's automation solutions will be designed to produce high-quality testliner grades based on 100% recycled paper.

With the new high performance boardmaking machine producing products of a wide basis weight range, Hamburger aims to further strengthen its position in the growing European containerboard business. The start-up of the machine is scheduled for mid-2020.

The order is included in Valmet's second quarter of 2018 orders received. The value of the order will not be disclosed. The total value of an order of this type is typically around EUR 70-90 million.

"The ability to show good references is always an important factor when a customer chooses a supplier. This was also crucial for Hamburger when they decided to make an agreement with Valmet. Valmet's technology delivers high productivity, resource efficiency, excellent quality and low operating costs. We have built up a good and close relationship with Hamburger over the years. This forms an optimal foundation for an excellent project and a strong reference for Valmet in Europe," says Vesa Simola, EMEA Area President of Valmet.

After signing the contract, from left: Werner Ofenböck, Jan Hagen (both from Hamburger), Harri Heikkilä (Valmet), Harald Ganster (Hamburger), Vesa Simola (Valmet), Cord Prinzhorn (Hamburger) and Marko Oinonen (Valmet)

After signing the contract, from left: Werner Ofenböck, Jan Hagen (both from Hamburger), Harri Heikkilä (Valmet), Harald Ganster (Hamburger), Vesa Simola (Valmet), Cord Prinzhorn (Hamburger) and Marko Oinonen (Valmet)

Technical details about the delivery

Valmet's delivery will include a new high-capacity containerboard machine from headbox to reel followed by an OptiWin Pro winder. The winder was selected because it gives high capacity due to its proactive winding geometry and faster sequences. The winder is equipped with Dual Unwind giving even higher capacity because the parent rolls can be changed in only one minute. The machine will be delivered with a fabrics package. The automation solution includes Valmet IQ quality measurement system and Valmet DNA process control system. The delivery will also include process support for six months after the start-up. The goal of the support period is production and quality development.

The 8,600-mm wide (wire) containerboard machine will produce uncoated white and brown testliner and white top testliner grades with a basis weight range of 90-180 g/m2. The design speed of the machine will be 1,500 m/min and the capacity 500,000 tonnes annually.

About the customer Hamburger Rieger

Hamburger Rieger is part of the Hamburger Containerboard Division within the Austrian Prinzhorn Group. Hamburger Rieger is the market leader in the segment of white coated corrugates base paper. With 2 million tonnes and seven plants, Hamburger Containerboard ranks among Europe's leading manufacturers of premium corrugated base paper. With its 6,600 employees in 15 countries, the Prinzhorn Group is a European market leader in the packaging, paper and recycling industry. The family owned and managed Prinzhorn Group has its headquarters in Vienna, Austria.

Valmet's new hard nip sizing technology started-up at Propapier in Germany

Valmet-delivered, a completely new type of a sizer, OptiSizer Hard, with related chemical systems were successfully started up at Propapier PM1 GmbH Burg mill in Germany a day ahead of schedule on April 19, 2018. The production line PM1 produces liner, fluting and kraft substitutes grades based on 100% waste paper. Thanks to a very good cooperation and a purposeful project work, all the produced containerboards have been saleable from the very start.

Good results from day one

A prototype product and a very tight shut-down schedule is a challenging combination. Despite the initial setup, most of the targets were achieved right after the start-up. The web passed through the nip smoothly and runnability was excellent. The new technology shows already a great potential to achieve the goals regarding strength properties and steam consumption.

"I was quite amazed to see the fast start-up of our new sizer. Earlier, high web tension levels were causing quite a bit of challenges to runnability. It looks like this obstacle no longer exists. We have achieved the targeted quality specification and now we can focus on the further benefits we are aiming at e.g. steam savings, higher strength levels or starch savings," says Phillipos Vrizas, Technology Manager at Propapier.

"The very first closing of the nip rolls is a moment telling a lot about any new sizer - especially a prototype sizer. It looked perfect. I couldn't see any web tension induced wrinkling in the web. The schedule was very tight with only a 11-day shutdown time. The fact that we were able to squeeze it into a 10-day break was quite amazing and a proof of an excellent cooperation and preplanning," says Jani Hakola, Development Manager at Valmet's Board and Paper Mills Business Unit.

The result of joint effort: First roll after the start-up of OptiSizer Hard at the Propapier's Burg Mill

The result of joint effort: First roll after the start-up of OptiSizer Hard at the Propapier's Burg Mill

Technical information about the delivery

Valmet's delivery included a new sizer called OptiSizer Hard. Compared to conventional sizer, OptiSizer Hard has a pair of hard cover nip rolls. Starch is sprayed on the rolls which transfer the starch into the nip where it is further transferred into paper web.

Strength is among the most important benefits with OptiSizer Hard. Starch is dosed in the roll nip with higher nip pressure, which increases the density of fibers. This leads into better strength properties. To mention a few other benefits of OptiSizer Hard, the life cycle costs are lower due spray application and runnability is better due to better nip profile control.

The existing and outdated starch preparation system was replaced with Valmet's starch preparation system specially designed for OptiSizer Hard and its spray application method. The properties of produced starch have substantially lower range of variation, which helps to produce liner boards within the targeted quality specifications. The delivered supply system is fully automated and equipped with pressure screens.

To further improve the properties of liner and fluting grades Propapier is producing, a cooperation agreement of 20 weeks was made. The target of the agreement is to find the best practices with the new sizer e.g. by reducing energy consumption, and by further improving liner and fluting properties, such as the lighter basis weight of containerboards without compromising other important properties.

Information about the customer Progroup

Progroup AG is questioning the existing, developing completely new approaches and bringing trend-setting concepts to market readiness. The successful development of the group is based on a consistent greenfield strategy, technological leadership, network management and an advanced supply chain strategy. With currently two paper factories (Propapier in Burg and Eisenhüttenstadt), a combined heat and power plant (Propower), ten corrugated board plants (Prowell) and several service companies (Prologistik, Proservice, Profund), Progroup's core business is the production of containerboard and corrugated board sheets. With 1100 employees, in 2017 the company generated sales of around 804 million euros and is one of the top 3 companies in the sector in Central Europe. The brands of the Next Generation Products are synonymous with the use of less raw material and less CO2 emissions coupled with an increase in performance, and have come to epitomise sustainable thinking and a sustainable way of doing business in the industry.

Under the Progroup umbrella, the production facilities of Propapier in Burg and Eisenhüttenstadt produce containerboard to become less dependent from the volatile paper market. At the Burg site in the German state of Saxony-Anhalt the heavier kraft liner substitutes and test liner products weighing from 110 to 230 g/m2 are made. The first-time installation of the OptiSizer Hard is again a great example for Progroup's "Power of Innovation" philosophy and is further strengthening Progroup's quality, reliability and cost leadership.

Valmet's new solution enables accurate high dry solids measurement for industrial applications

Valmet has launched a new Valmet High Solids Measurement (Valmet HS) that enables stable and accurate measurements for industrial wastewater treatment, pulp and paper production and a wide range of other industrial processes. Valmet HS measures for over 30% solids or 1-70% moisture.

Originally designed for municipal waste water plants, Valmet HS is based on microwave technology and features a patented sensor structure. It extracts a continuous sample flow from a downfall or drop leg section in the process and returns it back to the process after the solids content has been measured.

"We see high potential for this solution especially in the pulp and paper industry where an accurate high solids measurement provides many benefits, such as improved high consistency control, cost savings and higher quality," says Jarmo Havana, Product Manager, Automation, Valmet.

Cost and fuel savings lead to better sustainability

The new measurement brings numerous benefits to its users. It helps to minimize transport costs of sludge in waste water applications and reduce supplementary fuel use where sludge fuels a boiler, thus improving the sustainability of industrial processes. Additionally, Valmet HS makes it possible to optimize total solids levels and follow up, in real time, the performance of dewatering or drying processes.

Already in use after a high-consistency roll press, Valmet HS provides accurate pulp consistency control to refining and consequently more stable-quality pulp to the paper machine. Benefits include lower press energy consumption, reduced fiber crushing and the prevention of too high consistency causing damage to process equipment.

Other proven applications of Valmet HS include wastewater sludge solids measurement after dewatering in pulp and paper applications, measuring sawdust moisture before pelleting in the wood processing industry and sludge moisture monitoring before incineration.

"The solution has been so successful that new applications are coming up all the time. Ongoing development work in various industries includes the measurement of moisture with starch, sugar and gypsum as well control of a thermal drying processes," adds Havana