Ian Melin-Jones

Stora Enso CEO Jouko Karvinen comments on second quarter 2011 results announced today

“Stora Enso ended the second quarter with a solid operating profit. On the one side, the market environment and our own efforts allowed us to improve pricing on a broad scale year-on-year. On the other side, cost inflation offset a significant part of that result, so we could improve our operating profit only marginally. This is why we continue our never-ending effort to improve our cost base and flexibility, for example the plans announced within Fine Paper and Logistics.

“Some of our geographical markets, specifically coated fine paper in Europe, have in recent weeks shown signs of slowing down compared with the recovery in 2010. This, in addition to the European debt crisis, makes us and our customers see the short-term future as volatile and difficult to forecast. In this situation, it is crucial that we are prepared for more than one short-term demand scenario. All the capabilities and flexibility we have built up and are building up within Stora Enso – be it in maintenance support, administration outsourcing or logistics – are invaluable in the changing environment.

“Finally, we are also continuing to execute our strategic growth path, with the Montes Del Plata pulp mill, the Ostrołęka light-weight container board machine – both progressing as planned – and most recently the combined heat and power plant investment at Zdírec. New innovations, like the nanotechnology-based MFC pulp, are also an important part of our future – a future where we aim at having more and more of our earnings depending on us and less and less on external uncontrollable factors. We continue to rethink and question the old ways of doing things and always search for better solutions.”

Stora Enso invests in sustainable energy at Zdirec Sawmill in Czech Republic

Stora Enso is continuing to implement its Wood Products Business Area’s strategy to improve profitability by constructing a new combined heat and power (CHP) plant at Zdírec Sawmill in the Czech Republic. The EUR 21 million investment will optimise energy production and usage at the mill by boosting its heat supply.

“Zdírec is one of our core sawmills including value-added engineering wood products, such as solid construction timber (KVH). It is in a competitive location, and this investment is a logical step in further upgrading the mill with sustainable energy sourcing. The production and sale of renewable energy to local electricity suppliers will also improve the mill’s profitability,” says Hannu Kasurinen, EVP, Stora Enso Wood Products.

The project will commence in the third quarter of 2011 and is scheduled to be completed in the first quarter of 2013. The new CHP plant will utilise by-products from production as fuel, and when completed it will ensure 100% self-sufficiency for the mill in steam and electricity.

New Clariant innovation portal - Successful innovation with one click

Unlock the secrets to successful innovation at Clariant’s new Innovation web-pages launched today. Visitors to www.innovation.clariant.com are invited on a journey through the chemistry behind the challenges critical to society’s safety and advancement. They can also find out how they can work with Clariant to contribute to a sustainable and comfortable future.

For news on issues that impact daily life, visitors can sign-up to the new quarterly webmagazine “Innovation Spotlight – the chemistry behind your comfort”. Animations show how the products we use in our daily life are made eco-friendlier, more efficient, and saver through Clariant´s chemistry.

“With our new `Innovation Spotlight`, we aim to take the mystery out of the chemistry and put the secrets to successful innovation at the fingertips of our customers and the general public,” explains Martin Vollmer, Chief Technology Officer at Clariant International Ltd. The Summer-issue 2011 looks at how Clariant’s pioneering, environmentally-considerate solutions are helping to improve the leather tanning process.

Moreover, with its easy-to-follow explanations the new web-page provides an educational and inspirational insight into chemistry’s role in cutting-edge technology such as renewable energy and raw materials, water management, and advanced materials.

In addition, details of the innovation process at Clariant highlight the specialty chemical expert’s focus on ensuring its organization is best-equipped to support its customers. But this is just one half of Clariant´s philosophy regarding innovation: “Innovation to meet not only the needs of our direct customers but also those of wider society is at the heart of Clariant’s business. We needed a way to share this that would make it easier to grasp and therefore to inspire people to get involved,” comments Vollmer.

For more information visit www.innovation.clariant.com.

Clearwater Paper to Offer FSC Certified Premium and Ultra Tissue Products

Clearwater Paper Corporation has announced that the company will offer Forest Stewardship Council™ (FSC®) certified premium and ultra-premium bath tissue, and ultra-premium paper towel products to retail customers. The Rainforest Alliance's SmartWood Program performed all certification audits to ensure conformance to the FSC standards. The company shipped the first batch of these new FSC-certified ultra-premium tissue products in early June.

"We are delighted with Clearwater Paper's commitment to sustainability, which meets increasing consumer demand for tissue products from sustainable sources," said Tensie Whelan, president of the Rainforest Alliance. "Clearwater Paper has set an example through the certification of its own products; a forward thinking accomplishment that other innovative companies will follow."

In June 2010, Clearwater Paper began offering FSC-certified facial tissue to retail grocery private label customers. Since then, the company has applied the FSC logo and the Rainforest Alliance CertifiedTM seal to millions of customer facial cartons, and currently supplies the largest case volume of FSC-certified private label products to U.S. retail chains.

"We are excited to further expand our customers' choices - giving them more options to use quality tissue products from FSC-certified forests," said Gordon Jones, chairman, president and CEO of Clearwater Paper. "The addition of these high-quality tissue products reinforces our position as the leading U.S. tissue manufacturer to offer FSC certified tissue products for retail sales."

Retailers now have a unique opportunity to feature this globally recognized certification on their premium private label tissue products. Certification allows retailers the ability to display the FSC logo and the well-known Rainforest Alliance Certified frog seal on their premium tissue products signifying strong environmental awareness for manufacturers, retailers and consumers.

"The combination of certified premium and ultra-premium facial products since June of last year, coupled with increases planned this year, means that products certified by the Rainforest Alliance to FSC standards represent more than 50 percent of Clearwater Paper's total retail product case volume nationwide," stated Bob DeVleming, president of Clearwater Paper's consumer products division. "That amount of product, carrying both the FSC logo and the Rainforest Alliance Certified seal, offers both organizations significant exposure to the end consumer — a win-win situation for everyone involved."

FSC-certification indicates to consumers that the products they are purchasing come from responsible, well-managed forests where forest ecosystems are conserved and the rights of workers and their communities are protected.

"Clearwater Paper has paved new roads for FSC in the retail grocery private label arena," said Corey Brinkema, president of the Forest Stewardship Council-U.S. "Thanks to Clearwater Paper, we now have expanded impact and visibility in a market that is trending toward environmentally and socially responsible products."

OnV FeltView is now even more compact and maintenance friendly

In the course of revising OnV FeltView, an analysis system for press felts, improvements were made to both the design and software. The new version thus requires less installation space and can be used in paper machines with even the tightest available space. Along with the noticeably more compact shape of the cross member and the measuring head, the dimensions of the supply cabinets were also reduced to less than half of the original space requirement. Moreover, the new cross member is more accessible and thus easier to service. Another benefit is the modular design of the system with up to four cross members.

In the course of revising OnV FeltView, an analysis system for press felts, improvements were made to both the design and software. The new version thus requires less installation space and can be used in paper machines with even the tightest available space. Along with the noticeably more compact shape of the cross member and the measuring head, the dimensions of the supply cabinets were also reduced to less than half of the original space requirement. Moreover, the new cross member is more accessible and thus easier to service. Another benefit is the modular design of the system with up to four cross members.

The OnV FeltView control software is integrated into the latest Voith Paper Automation software architecture and is thus Web-based. It can also be operated directly via Internet Explorer 8 without additional software.

At the beginning of May 2011, the first press modules were equipped with the OnV FeltView system at the Paper Technology Center in Heidenheim. The tests in the press section were thus also more transparent for the customer. In addition, safety is increased for employees, since manual measurements are no longer necessary.

SynStron for high performance dryer fabrics

Contaminated roll surfaces, paper wads, heat and moisture – a real challenge for the polyester (PET) monofilaments of a fabric in the dryer section. SynStron is a new class of PET, developed by Voith for higher resistance to damage and abrasion under demanding running conditions.

Contaminated roll surfaces, paper wads, heat and moisture – a real challenge for the polyester (PET) monofilaments of a fabric in the dryer section. SynStron is a new class of PET, developed by Voith for higher resistance to damage and abrasion under demanding running conditions.

A record life of 446 days has been achieved with SynStron monofilaments in a PrintTech Q2 fabric on the Third Top DuoRun of a 1,300 m/min coating base machine. This is a 30% improvement over the standard PET fabrics that are normally removed after 12 months at a planned shut. Seam strength was still high at 72% of its original value. Effective sheet control throughout the fabric life has been helped by the contaminant release additive of SynStron achieving 76% fabric permeability retention.

SynStron monofilaments have higher strength and abrasion resistance; fibrillation resistance to reduce the effects of degradation and a contaminant release additive. These advantages give a better potential to improve dryer fabric performance.

Less damage due to SpeedRod M

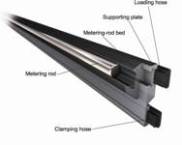

Again and again, coating units are affected by damaged hoses, resulting in hose changes and rather long unplanned downtimes of the paper machine due to inaccessible clamping areas for the metering unit. With the new SpeedRod M metering-rod bed generation, damaged hoses can be avoided to a large extent thanks to simple, preventive checks. In addition, the time needed for an unplanned hose change is reduced by more than 90%.

Again and again, coating units are affected by damaged hoses, resulting in hose changes and rather long unplanned downtimes of the paper machine due to inaccessible clamping areas for the metering unit. With the new SpeedRod M metering-rod bed generation, damaged hoses can be avoided to a large extent thanks to simple, preventive checks. In addition, the time needed for an unplanned hose change is reduced by more than 90%.

The supporting plate is the integrated holder for metering rod, clamping and loading hoses and can be used repeatedly. Clamping and loading hoses are identical: ready-to-use and pressuretested hoses with end areas additionally secured against overload by shrink hoses. The new metering-rod bed design provides the following advantages for the papermaker: The individual components can be checked preventively and replaced outside the coating unit, if required. Production losses in case of damaged hoses are reduced to a minimum, since a hose change only takes five minutes (instead of e.g. 60 minutes with the previous system). Only one hose type is used both for clamping and loading. Thanks to ready-to-use, pressure-tested hoses, downtimes are reduced. The metering-rod bed is a wear part and can be exchanged independently of the supporting plate.

Conclusion: SpeedRod M reduces the time needed for changing a hose to five minutes. In addition, unplanned changes can be avoided to a large extent by easy, preventive checks of the hoses.

Ashland Inc. to launch new product portfolio at Labelexpo Europe

Ashland Performance Materials, a commercial unit of Ashland Inc. (NYSE: ASH), is launching new versatile products for narrow-web printing at this year's Labelexpo Europe exhibition in Brussels, Belgium, Sept. 28 - Oct. 1.

Technical sales and applications experts from Ashland Performance Materials will be available at the Brussels Exposition Center in Hall 11, stand 11s85, to illustrate the benefits of Ashland's comprehensive portfolio of varnishes, adhesives and coatings for narrow-web printing.

"We are excited to introduce a new portfolio of products with outstanding functionality in narrow-web printing applications," said Stuart May, director of sales, Ashland Performance Materials, Europe, Middle East and Africa. "Ashland's UV and water-based varnishes, adhesives and coatings are used in applications including food packaging, labels and tags, commercial printing, protective packaging and graphic arts. These unique technologies provide a number of process and end-product benefits to manufacturers to help improve their performance."

Ashland's Pureseal(TM) 23323E water-based synthetic cold-seal adhesive provides benefits for flexographic food packaging printing that include enabling shorter specialized runs, which are of particular importance in the confectionery bar market, and that it can be applied as an overall coat or pattern. It seals packages comprised of biaxially oriented polypropylene (OPP), white OPP metalized OPP, polyester and other substrates suitable for food packaging. It also releases from release-treated films or release lacquer-coated substrates and complies with U.S. Food and Drug Administration regulations for food packaging.

Ashland's other new adhesive technologies are UV curable low-migration varnishes and laminating adhesives. These products provide benefits to a broad range of food packaging applications. The instantaneous UV cure associated with these products is based on a stable, one-component system with near-zero volatile organic compounds. These technologies are designed specifically for flexographic printing but are also suitable for other application methods including gravure and multi-roll coating equipment. Ashland's UV curable low-migration varnishes and laminating adhesives are ideal for use with many different types of substrates such as packaging films, foils and papers.

In addition, Ashland offers an extensive range of liquid UV-curable, pressure-sensitive adhesives (PSAs) for narrow-web-flexo applications. These technologies cover a vast array of processes. They are suitable for in-line application as an alternative to conventional PSA label-stock and can also achieve pattern application for specialty label constructions such as expandable information labels, booklet and coupon constructions. Ashland's portfolio also includes specialty products, such as a cold-foil transfer adhesives and adhesive deadeners.

To learn more about Ashland's innovative varnishes, adhesives and coatings product lines, please contact a sales associate at This email address is being protected from spambots. You need JavaScript enabled to view it. or visit our website at www.ashland.com.

Ashland Performance Materials is the global leader in unsaturated polyester resins and epoxy vinyl ester resins. In addition, it provides customers with leading technologies in gelcoats, pressure-sensitive and structural adhesives.

Shandong Chenming starts up a Metso-supplied coated fine paper line in China

The Metso-supplied high quality art fine paper line PM 6 to Shouguang MeiLun Paper Co., Ltd. in Shouguang, Shandong province in China started up successfully on June 30, 2011.

PM 6 includes a complete OptiConcept paper making line from headbox to reel, as well as two winders. It produces doublecoated woodfree paper within the basis weight range of 70-128 g/m². The annual maximum production capacity of the 11.15-m-wide (wire) line is around 800,000 tonnes and the design speed 2,000 m/min. The paper making line has been equipped with latest Metso technology: OptiFormer SB forming section, OptiFlo Pro headbox and OptiDry Twin drying technology.

Shouguang MeiLun Paper is part of Shandong Chenming Paper Holdings Limited, one of the biggest paper producers in China. The group is made up of more than 10 subsidiaries with a production capacity of 4 million tonnes per year.

Kadant Acquisition of m-clean papertech: An open letter to our customers, suppliers, and partners

m-clean papertech AB was acquired by Kadant Inc. – a leading supplier of technology-based products and solutions to process industries around the globe.

Our name will become Kadant m-clean AB.

In addition to our name change, we will be expanding our sales coverage to include Kadant’s global selling team supporting nearly 200 countries around the globe.

For more than a century, Kadant has been delivering smart and efficient solutions to process industries worldwide. As a leader in fiber processing, fluid handling, water management, and doctoring systems, Kadant equipment plays a critical role in nearly every stage of paper making and paper recycling, enhancing process efficiency and product quality for its customers.

We are excited about this new chapter in our company's history and the prospects it holds for us and for you. M-clean products and solutions will be a key component of Kadant’s continued innovation and success. And with your on-going support, we are confident we can provide you with even better products, service, and support.