Ianadmin

Metso Process and Quality Vision system’s new features bring papermakers further improved performance

Metso’s high-selling machine vision system, Metso Process and Quality Vision (Metso PQV) is now available with several new features to further improve runnability and ensure flawless quality for paper makers. These include:

- New Full HD digital matrix cameras allowing more accurate image quality

- Boosted performance in image analysis for the most demanding web inspection

- New superbright flashing LED lights for optimum image quality in all solutions

- Flexible improved user interface to support your operations everywhere

(The latest machine vision technology has been utilized in making improvements and special attention is given to image analysis performance. There is no point in seeing all the defects, but the defects that are important to the user.

(The latest machine vision technology has been utilized in making improvements and special attention is given to image analysis performance. There is no point in seeing all the defects, but the defects that are important to the user.

“Demand for process and quality management solutions is increasing. We are focused to continuously set the technology benchmark on the field and currently over 200 most demanding processes are enjoying the benefits of our process and quality inspection technology. In terms of units, our volume in web break monitoring systems has exceeded 500 camera units annually.” says Sami Riekkola, Director, Machine Vision, Metso Automation.

‘’Since the new camera and image processing standards have now been set, we are already hard at work developing and preparing for new features to our systems. Through our service coverage we are simultaneously ensuring consistent maintenance and development of the installed base.’’ he continues.)

Metso Process and Quality Vision

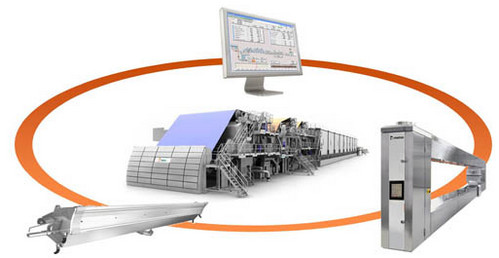

Metso Process and Quality Vision (Metso PQV) combines web break analysis and web inspection system functions into one comprehensive solution that utilizes the same digital image capture and processing technology for both.

It integrates web break analysis capabilities and web quality inspection using high-frequency camera images to produce a continuous view of the moving web. Three different geometries are typically used in web inspection system installations. Transmission geometry is used to detect flaws in the sheet, high angle geometry is used for surface defects and low angle geometry is used to detect coating imperfections.

The web break analysis camera images and web inspection information are combined into a common operator interface. This allows the operators to detect key quality faults at well-defined CD and MD locations in the paper web and to track their origins in the process. (www.metso.com/machinevision)

Improved Metso IQ takes end product quality to a new level

Global market leader in quality control solutions introduces a number of new features

Metso is now bringing a new Metso IQ quality control system with a number of new features to improve the paper making process and guarantee optimal end product quality.

New surface and structure measurements provide on-line information from porosity and fiber orientation to printability prediction.

The system also features a new optical caliper measurements based on blue-ray technology and color measurements for tissue to complete Metso´s unique nuclear-free tissue concept with Metso IQ Fiber measurement.

To offer wider scalability to various needs Metso also introduces the new Metso IQ Fixed Point C-frame and stand-alone Metso IQ Scanner. New measurements together with new multivariable quality controls and Metso IQ Profilers form the industry’s most complete portfolio of quality management solutions.

Metso IQ goes far beyond the traditional Quality Control System. As recognition of its capabilities Metso’s solution has been selected to replace a number of competing solutions during the last years, making Metso the global market leader in quality control solutions in 2012.

Metso IQ

Metso IQ is a combination of intelligent scanning, high-speed quality measurements, robust multivariable controls and the analysis toolbox unleashes a set of diagnostic capabilities that alert the operators to potential sources of problems and provides them with the necessary information online so they can run the machine better.

Jari Almi, Director of QCS, explains: ‘’ The Metso IQ solution provides value down the line, from raw material to finished product, allowing our customers to accurately optimize and ensure the optimal end product quality. This attention to detail helps paper makers reduce broke and provides raw material savings, resulting in considerable added value and a rapid return on investment across the entire lifecycle of the Metso IQ solution. At the same time, when the production process is truly optimized, the plant’s energy consumption will also be reduced creating additional savings in both monetary and environmental terms.’’

Metso’s state of the art transmitter technology contributes to the efficiency and profitability of Chinese paper mills

Recently, Metso has won several measurement orders from Chinese paper mills, like Jiangsu Jinhuang Paper Co., Ltd, Hebei Changtai Paper Industry Co., Ltd, Anhui Huatai Forest Pulp & Paper Co., Ltd, Guangdong Huatai Paper Co., Ltd, and Wuhan Jin Feng Huang Paper Industry Co., Ltd.

Metso has contracted with the Anhui Huatai Forest Pulp & Paper Co., Ltd. on the delivery of a dozen consistency transmitters, one of them being a Metso OC, an optical consistency transmitter. The upcoming delivery for the rebuilding of a pulp factory also includes several Metso SP (blade) and Metso Rotary transmitters, as well as equipment for cooking liquor measurement, among other things.

The Jiangsu Jinhuang Paper Co., Ltd. has ordered several Metso SP (blade) transmitters for a greenfield factory. A further customer for another greenfield project is the Hebei Changtai Paper Industry Co., Ltd. for whom a linerboard project as well as a plasterboard paper machine will be delivered. The Wuhan Jin Feng Huang Paper Industry Co., Ltd. is also among the recent major customers, making an order for two new board machines PM3 and PM5, as well as 16 Metso SP consistency transmitters. All the orders from the Chinese papermaking industry companies are due to be delivered in the autumn of 2012.

Inline consistency measurement has never been easier

The Metso optical consistency transmitter is a new member in the family that uses state of the art technology with a new design, offering reliable measurement at all times. In mechanical pulping (e.g. TMP, GW and CTMP) typical applications are grinders, cyclone cleaners, latency removal, screening, and low consistency refining. In chemical pulping, the new transmitter can be used for screening, washing, refining, and drying machine applications.

Inline consistency measurement has never been easier – the Metso OC employs the latest electronics technology with multiple optical fiber channels, using a single light source and optimal probe design for reliable measurement. Installation is simple and safe. Inserting and retracting the measurement probe is safe and easy, even in high process pressure. The Metso OC can be calibrated with just one laboratory sample. No regular maintenance is needed – the entire transmitter-related cost remains low.

Follow link to Metso Optical Consistency Transmitter pages on Automation's web

Metso's breakthrough in optical caliper measurement

The new Metso IQ Optical Caliper sensor offers improved accuracy on low opacity papers

All papermakers can now benefit from improved runnability with confidence in quality provided by the sub-micron profile accuracy of the new Metso IQ Optical Caliper measurement.

The new sensor has been operating for several months at a leading Scandinavian mill with no problems on low opacity papers. Janne Sällilä of Metso, says, “The  conventional laser penetrates deeply into the siliconized paper. The customer wanted to measure the total caliper of both fibers and silicon together. This new sensor provided the answer and the mill reports much smoother profiles. Its self cleaning head has also provided a maintenance advantage over the previous sensor which had to be cleaned regularly. ”Mills producing low opacity grades such as greaseproof paper can now take advantage of a new development in optical caliper measurements by Metso.

conventional laser penetrates deeply into the siliconized paper. The customer wanted to measure the total caliper of both fibers and silicon together. This new sensor provided the answer and the mill reports much smoother profiles. Its self cleaning head has also provided a maintenance advantage over the previous sensor which had to be cleaned regularly. ”Mills producing low opacity grades such as greaseproof paper can now take advantage of a new development in optical caliper measurements by Metso.

Optical measurements have become accepted technology to avoid the sheet pinching effect experienced with contacting caliper measurements; but due to the conventional measurement technology, light penetration of the sheet can undermine accuracy with low opacity or porosity grades.

Metso has been quick to take advantage of the latest developments in new technology that through the improved light scattering of the shorter wavelength light, and new detection technology, eliminates errors due to light penetration. As there are no pinching parts that could cause holes or sheet breaks.

IQ Optical Caliper combines two accurate measurement techniques. The magnetic principle is used to measure the distance of the optical measurement to a reference plate while the non-contacting optical principle measures the distance to the paper surface. Paper thickness is reached by subtracting these individual measurements from each other. As well as the use of the blue light source (patent pending) to solve light penetration problem, the new self cleaning construction of the sensor head (patent pending) eliminates one further difficulty experienced with conventional laser sensors.

Metso IQ is a combination of intelligent scanning, high-speed quality measurements, robust multivariable controls and the analysis toolbox unleashes a set of diagnostic capabilities that alert the operators to potential sources of problems and provides them with the necessary information online so they can run the machine better.

Swedish company Svan Data introduces tailor-made import & export statistics for the Chinese paper industry

Svan Data has since the start in 1980 provided the European paper industry with import and export statistics for a large number of countries. The Chinese paper industry’s export success has resulted in Svan Data seeing great potential in the Chinese market. Their aim is to provide data for a better understanding of the flow of paper from a global perspective.

Svan Data has since the start in 1980 provided the European paper industry with import and export statistics for a large number of countries. The Chinese paper industry’s export success has resulted in Svan Data seeing great potential in the Chinese market. Their aim is to provide data for a better understanding of the flow of paper from a global perspective.

- We decided to exhibit at China Paper this year as we think it will facilitate getting in contact with the Chinese paper industry. We hope to meet those persons responsible for or those who have an interest in following the development of international paper trade, says Sven Andersson, CEO of Svan Data.

The philosophy of Svan Data is that their customers should have the possibility of influencing and designing the information after their specific requirements. Their latest service is the web distribution, meaning the user can log in and access the information on-line. The tailor-made statistics can therefore be accessible to several people within the same company. Two of Svan Data’s largest customers are Volvo Trucks and the European Association of Graphic Paper Producers (Euro-graph asbl).

You will meet Svan Data in the Swedish Pavilion, stand no. 1330. See further information on www.svandata.se

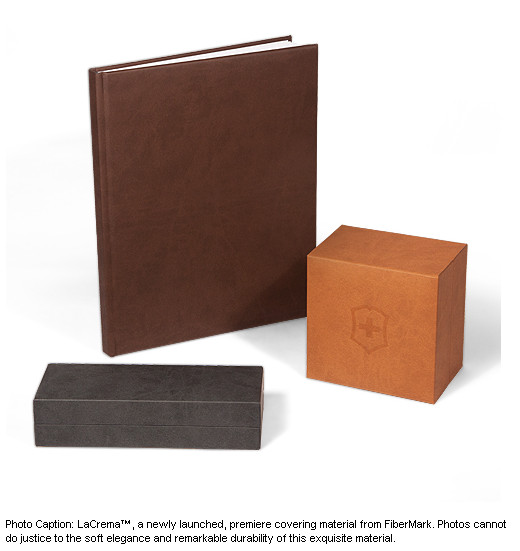

FiberMark Adds a New Dimension to its Line of Specialty Covering Materials with “LaCrema™”

FiberMark, (www.fibermark.com), a global leader in manufacturing innovative, fiber-based specialty covering materials for world-leading brands, has launched a new decorative product line that offers a remarkable array of unique benefits to designers, converters and manufacturers.

Called “LaCrema™,” the extremely unique new line of FSC®-certified, fiber-based material featuring a high loft coating was developed in response to customers’ desires for a more durable, resilient, yet exceptionally lush covering for premier applications. LaCrema also answered customer preferences for more environmentally friendly material with superior processing characteristics to its industry counterparts.

Developed with ground-breaking, patent-pending technology by a team of multi-disciplinary scientists and engineers at FiberMark’s impressive R&D lab in West Springfield, Mass., LaCrema is hitting the marketplace with some very promising results.

Dr. Jim Ding, FiberMark’s Executive Vice President of Research & Development and Marketing explains that the project to develop LaCrema began when a customer appealed to FiberMark for a covering material that was more forgiving and easier to work with. “Some of the competitive products were less than perfect. Traditionally, fabricators have had extreme difficulty where the competitive material didn’t fold or crease well around edges and corners, making it difficult to ‘process’; plus, they had durability issues.” He notes, “The customer had issues with what was standard in the industry for display boxes and other products that are typically covered in this manner. However, the efficiency LaCrema offers is just remarkable.”

One of LaCrema’s key benefits is to enable FiberMark’s customers to process the material much more successfully than they’re able to using competitive products. LaCrema can turn an edge or make a rounded corner, and is suitable for a wide range of applications including, but not limited to: high-end packaging, notebooks, diaries, book covers, presentation and literature covers, and restaurant menus.

In addition to its superior folding characteristics, LaCrema is also scuff- and stain-resistant. It can be successfully glued using conventional, water-based adhesives, requiring far less heat and potentially hazardous chemicals in the process.

With a cushioned feel combined with a decorative look, LaCrema is available in eight traditional colors, all with FiberMark’s unique soft-touch finish. Custom colors are also available. LaCrema is available direct from FiberMark and through its global distribution network.

Buckeye Technologies to present at UBS Global Paper Conference

RockTenn and DS Smith announce licensing agreement

I-Series forming fabrics from Voith enjoy worldwide success

The forming fabrics can be used for the production of fine papers to sophisticated packaging papers. The technology ensures very good runability at high speed, best performance, cost-efficient operation in respect of resources and energy consumed, as well as excellent quality.

Metso signs global agreement with Swedish Huhnseal for supplying Metso-branded mechanical seals

Introducing SealMax is in line with Metso’s ambition to expand its scope of supply. The two companies have initiated the development of tailor-made mechanical seals for Metso equipment, such as MC pumps, mixers, agitators, pulpers, screens and LC refiners. These sealing solutions will be available for new projects and also as upgrades for existing equipment. Huhnseal already have solutions for most standard applications in the pulp and paper industry. These solutions will now be sold and marketed globally through Metso.

Mechanical seals are critical components in many types of rotating equipment and are therefore often given a high priority in the maintenance strategy. “Adding SealMax seals to our offering gives us in Metso the opportunity to work even closer with our customers. By combining the product and application know-how of Metso and Huhnseal, we can offer solutions with improved overall performance and thus save money for our customers,” says Björn Kempe, Business Manager, Service Agreements, Metso.

“Huhnseal and Metso have cooperated for more than 10 years. Huhnseal has a vast experience of supplying Metso with standard and special sealing solutions for its heavy-duty applications,” says Per Hellman, CEO of Huhnseal. “This partnership is in line with our strategy to grow on a global scale. Huhnseal will provide product and service support to Metso via both our central as well as local resources around the world and continue with our ambition to supply the optimal sealing solution for each application.”

Huhnseal is a global supplier of mechanical seals for the process industry and is headquartered in Landskrona, Sweden. The company has R&D, product development, manufacturing and sales functions, all under one roof. Huhnseal is part of the Italian Meccanotecnica Umbra Group.